Method for detecting volatile organic compounds in cigarette tipping paper printing ink

A technology for volatile organic compounds and cigarette tipping paper, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problem of not having a more comprehensive test, and achieves good precision, high degree of operation automation, and recovery rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] 2. Preparation of samples to be tested

[0016] After shaking the ink sample evenly, use a 100 μL pipette gun to pipette 1 drop of the sample into a 20 mL headspace bottle, read the weight, accurate to 0.001 g, add 100 μL matrix corrector triacetin, and seal it for testing.

[0017] 3. Instruments and conditions

[0018] 1) Static headspace instrument conditions

[0019] Sample equilibration temperature 85°C; sample loop temperature 105°C; transfer line temperature 125°C. ; Sample equilibrium time 48min; sample bottle pressurization pressure 138kPa; pressurization time 0.2min; inflation time 0.2min; sample loop equilibrium time 0.05min;

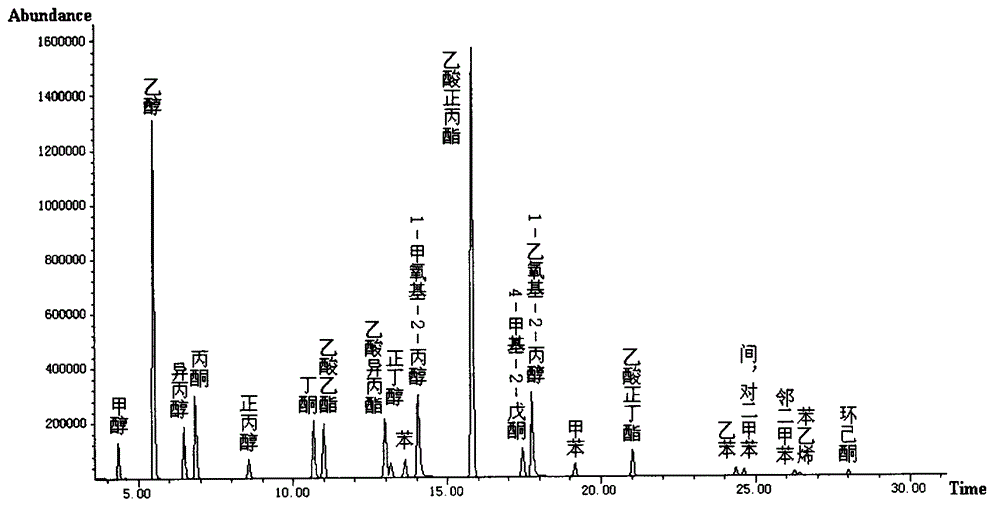

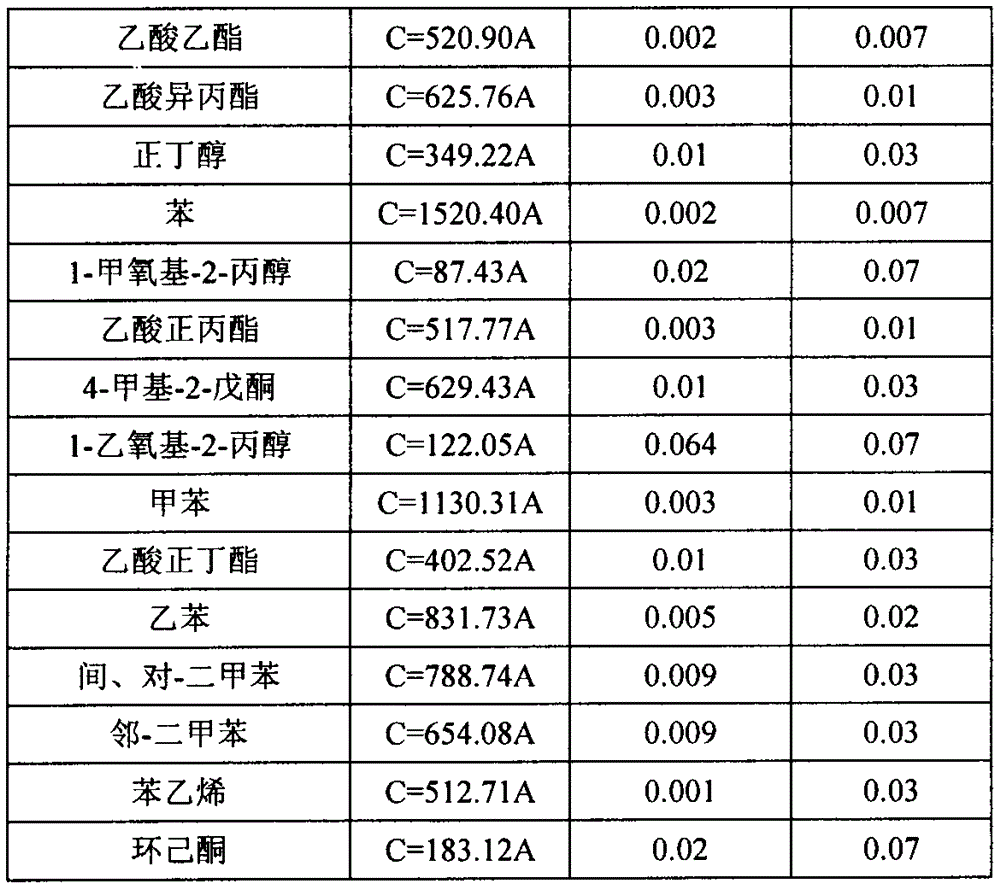

[0020] 2) Gas chromatography conditions

[0021] The chromatographic column is a VOC capillary column with a specification of 60m×0.32mm×1.8μm; the carrier gas is helium; the inlet temperature is 160°C; the split ratio is 20:1; the column flow rate is 2.0mL / min; ℃, keep for 2min, then increase to 180℃ at the rate of 4℃ / min, and the...

Embodiment 1

[0042] Select one ink sample for black, red and brown cigarette tipping paper respectively, shake the ink samples evenly, pipette 1 drop of the sample into a 20mL headspace bottle with a 100μL pipette gun, and read the weight. Accurate to 0.001g, add 100 μL matrix corrector glycerol triacetate, seal and perform headspace gas phase detection. The measurement conditions are as follows:

[0043] Static headspace instrument conditions: sample equilibrium temperature 85°C; sample loop temperature 105°C; transfer line temperature 125°C. ; Sample equilibrium time 48min; sample bottle pressurization pressure 138kPa; pressurization time 0.2min; inflation time 0.2min; sample loop equilibrium time 0.05min;

[0044] Gas chromatography conditions: the chromatographic column is a VOC capillary column, the specification is 60m×0.32mm×1.8μm; the carrier gas is helium; the inlet temperature is 160°C; the split ratio is 20:1; the column flow rate is 2.0mL / min; : The initial temperature is 40°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com