Modeling method for heterogeneous azeotropic rectification solvent dehydrating tower of industrial purified terephthalic acid (PTA) device

A technology of purified terephthalic acid and azeotropic distillation, which is applied in the separation/purification, fractionation, instruments and other directions of carboxylic acid compounds, can solve the problems of affecting the azeotropic separation effect, weakening the performance of the tower, etc., so as to avoid actual blind operation. , the effect of reducing optimization costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

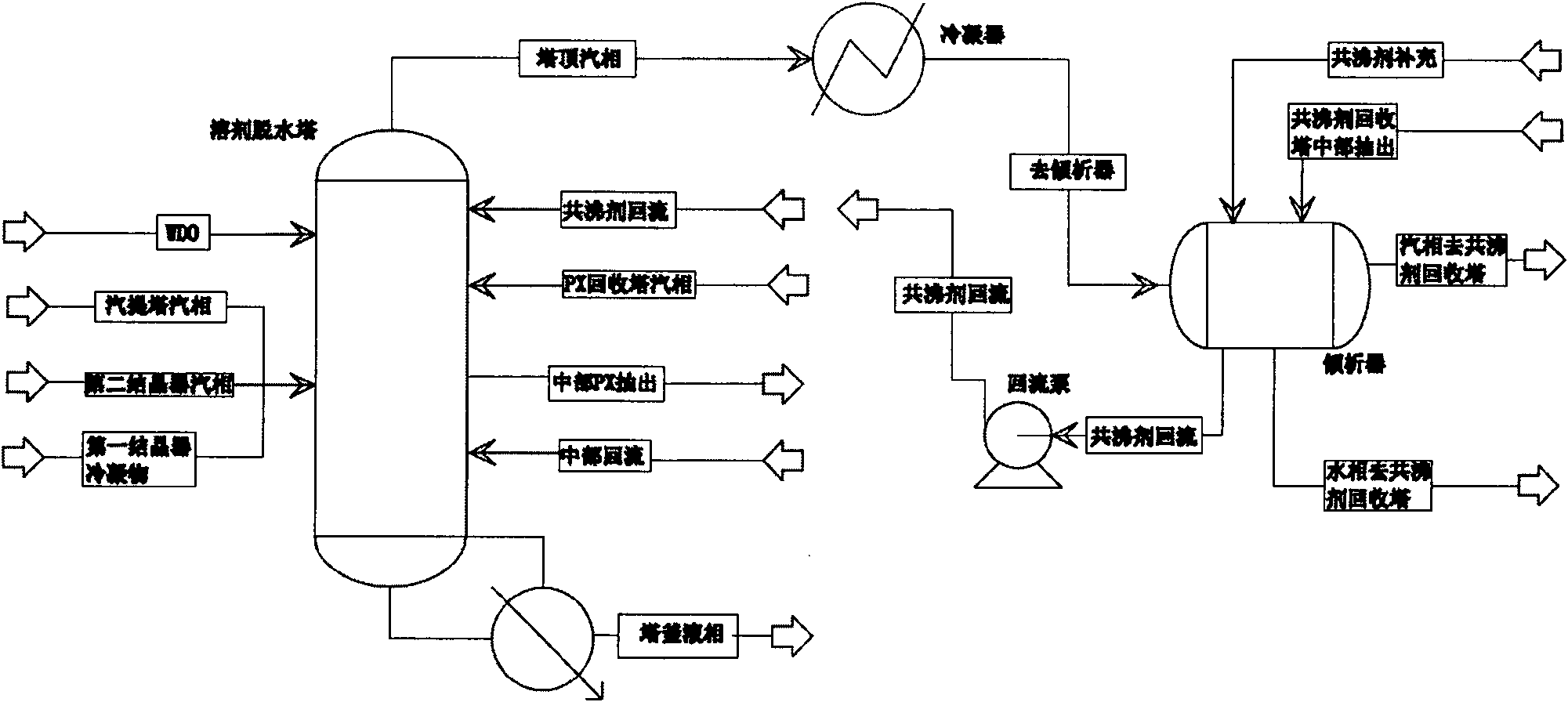

[0025] attached figure 1It is a process flow chart of the heterogeneous azeotropic distillation solvent dehydration tower of a domestic industrial purified terephthalic acid plant. The azeotropic distillation solvent dehydration tower is a three-stage packed tower, using n-propyl acetate (NPA) as an entrainer, wherein the feed includes WDO (from the water extracted from the oxidation reactor) that enters from the first and second stage packings. and the washing water of the high-pressure suction tower) and the overhead gas phase from the PX recovery tower, the gas phase from the stripping tower that enters from the second and third packings, the flash gas phase from the second crystallizer, and the gas phase from the first crystallizer Condensate from the vapor-liquid separator tank. A stream of liquid is extracted between the first and second packing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com