Alcohol-soluble environment-friendly high-speed surface printing ink and preparation method thereof

An alcohol-soluble ink technology, applied in ink, household utensils, applications, etc., can solve the problems of poor light resistance and chemical resistance, easy to produce yellowing, etc., and achieve good environmental protection, strong controllability of production conditions, and chemical resistance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] White ink is composed of the following components by mass: 8-12 parts of polyamide resin, 0-5 parts of nitrocellulose resin, 30 parts of pigment, 12 parts of ethyl acetate, 12 parts of n-propyl acetate, and 15 parts of isopropanol , 15 parts of ethanol, 0.5 parts of adhesion promoter, 1 part of polyethylene wax powder and 0.5 parts of anti-sticking agent. The nitrocellulose resin is 1 / 8 second nitrocellulose resin, the anti-sticking agent is erucamide, and the pigment is titanium dioxide.

[0023] The present embodiment is formed by following preparation steps:

[0024] 1) Weigh the materials, weigh the required parts by weight according to the formula, and set aside;

[0025] 2) Configure nitrocellulose resin liquid, mix the whole weight of ethyl acetate, n-propyl acetate, isopropanol and ethanol evenly to obtain a mixed solvent, and then take the whole weight of nitrocellulose resin and 4 times the weight of nitrocellulose resin Mixed solvents, mixed and dissolved t...

Embodiment 2

[0031] Color ink, the pigment is selected from one of naphthol magenta, permanent yellow, phthalocyanine blue, carbon black, permanent orange, phthalocyanine green or permanent violet, and the mass parts of each component in the ink are as follows: polyamide 8 parts of resin, 5 parts of nitrocellulose resin, 15 parts of pigment, 15 parts of ethyl acetate, 12 parts of n-propyl acetate, 25 parts of isopropanol, 15 parts of ethanol, 0.5 parts of adhesion promoter, 1 part of polyethylene wax powder And 0.5 parts of anti-sticking agent. The nitrocellulose resin is 1 / 8 second nitrocellulose resin, and the anti-sticking agent is erucamide.

[0032] The ink with the above components was prepared into a finished ink according to the preparation process in Example 1, except that the speed of the disperser in step 3) was changed to 150r / min and 1200r / min in turn.

Embodiment 3

[0034] Color ink, the pigment is selected from one of naphthol magenta, permanent yellow, phthalocyanine blue, carbon black, permanent orange, phthalocyanine green or permanent violet, and the mass parts of each component in the ink are as follows: polyamide 12 parts of resin, 2 parts of nitrocellulose resin, 15 parts of pigment, 15 parts of ethyl acetate, 10 parts of n-propyl acetate, 20 parts of isopropanol, 25 parts of ethanol, 0.5 parts of adhesion promoter, 1 part of polyethylene wax powder And 0.5 parts of anti-sticking agent. The nitrocellulose resin is 1 / 8 second nitrocellulose resin, and the anti-sticking agent is erucamide.

[0035] The ink with the above components was prepared into a finished ink according to the preparation process in Example 1, except that the speed of the disperser in step 5) was changed to 1200r / min.

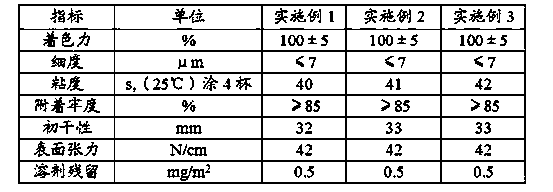

[0036] The quality indicators of alcohol-soluble high-speed surface printing environmental protection ink in the above-mentioned embodiment are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com