Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Hydrogen impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment methods for silicon nitride thin films

InactiveUS20190233940A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenChemical vapor deposition

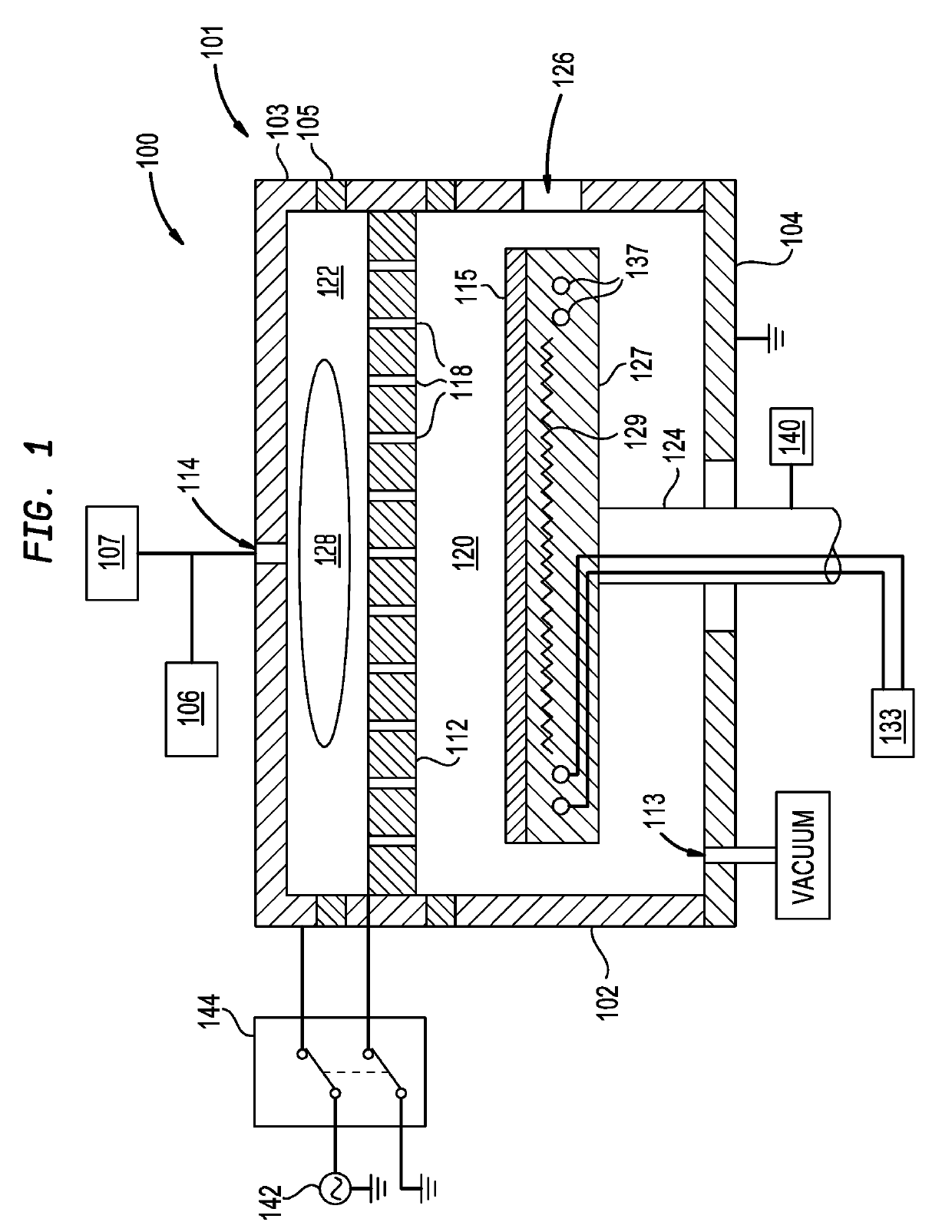

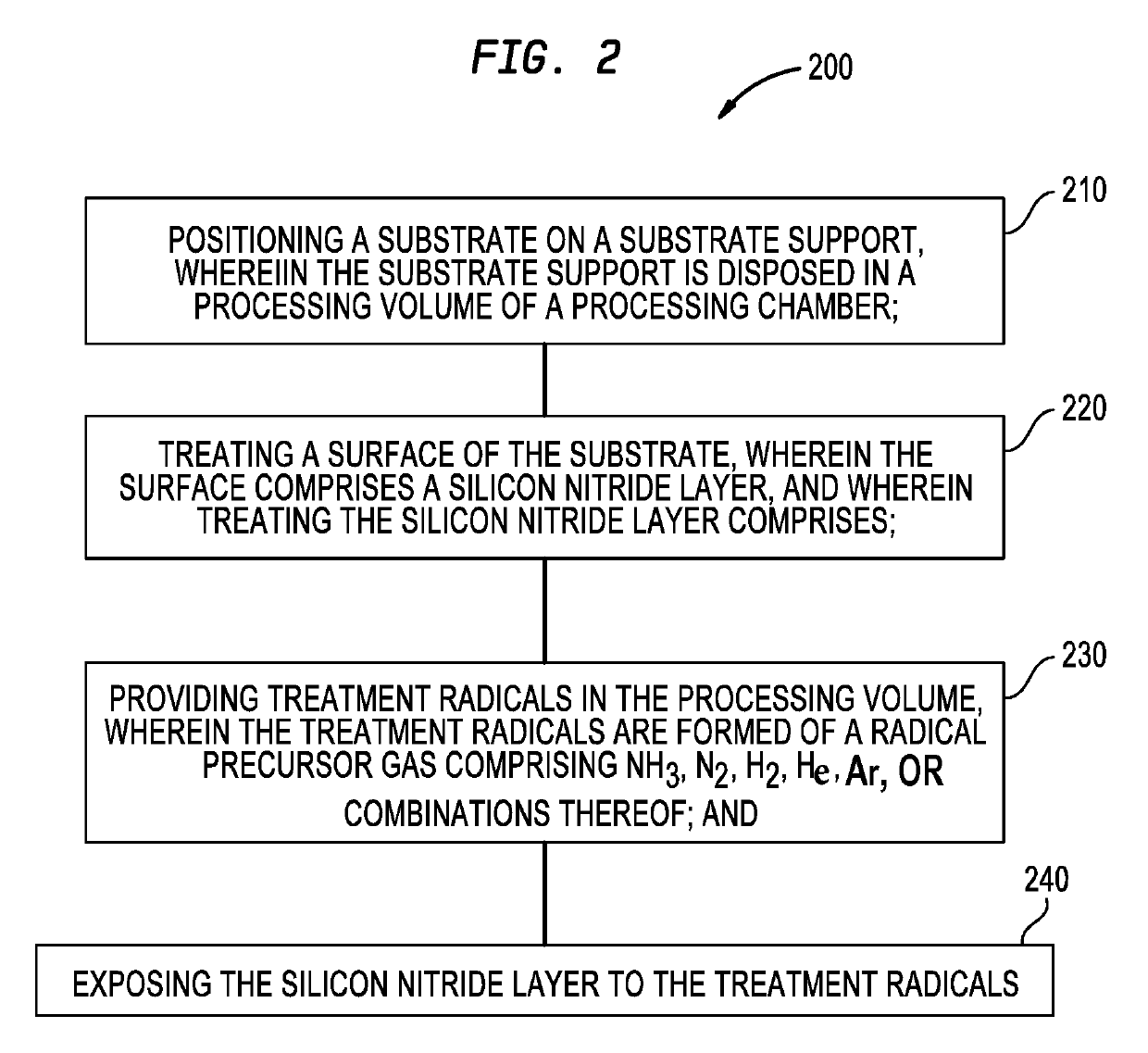

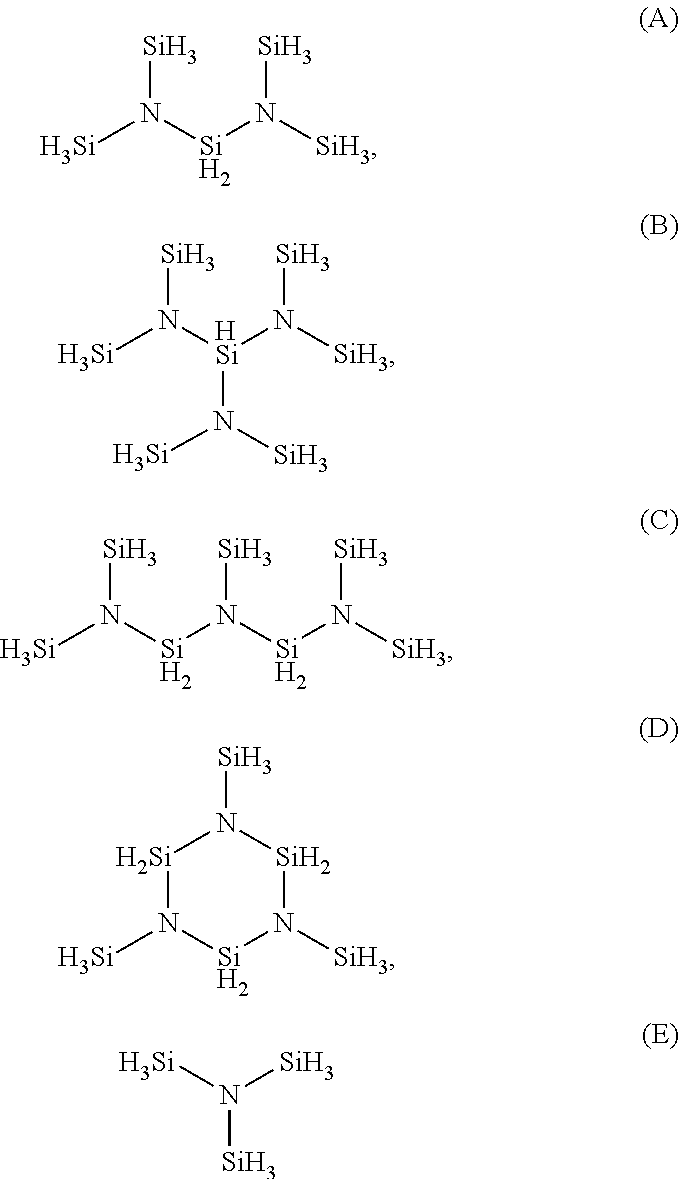

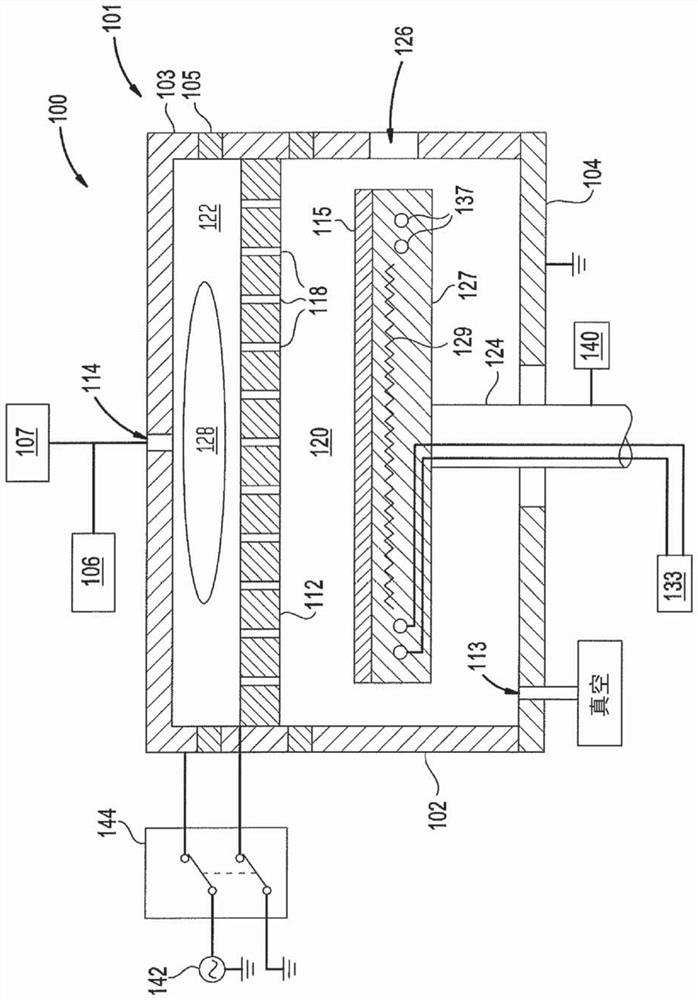

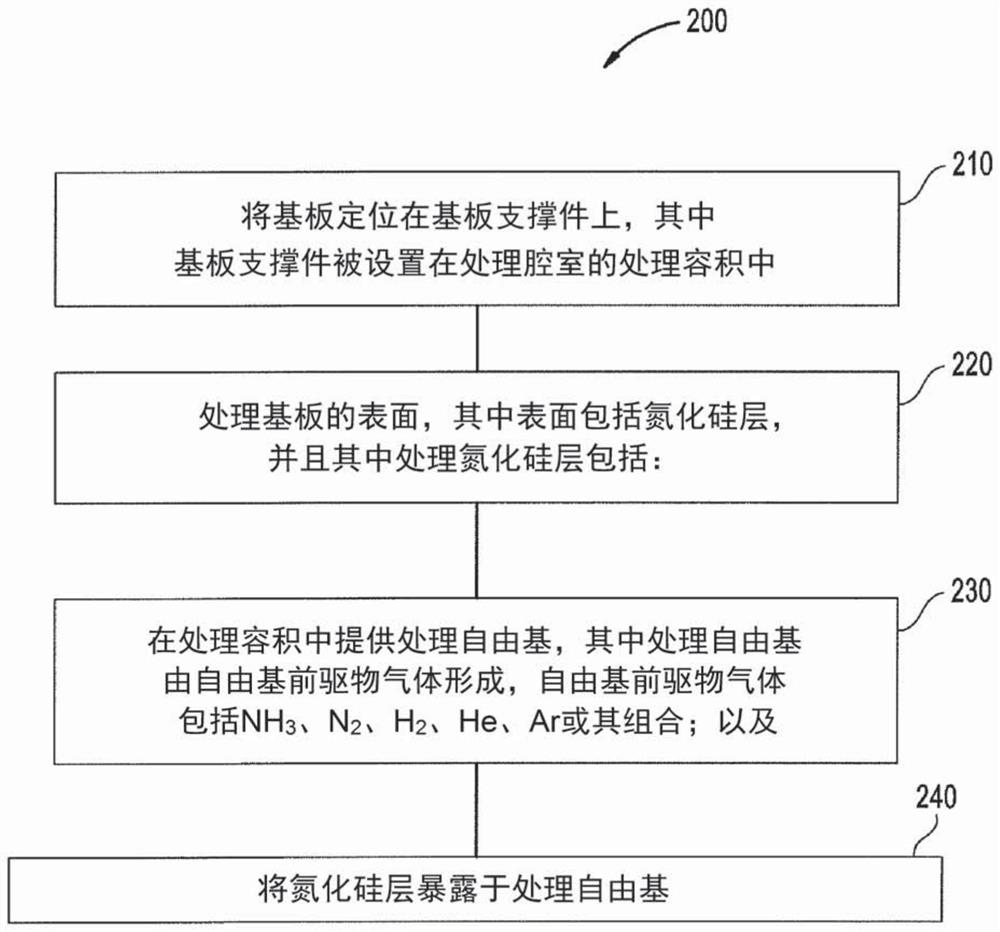

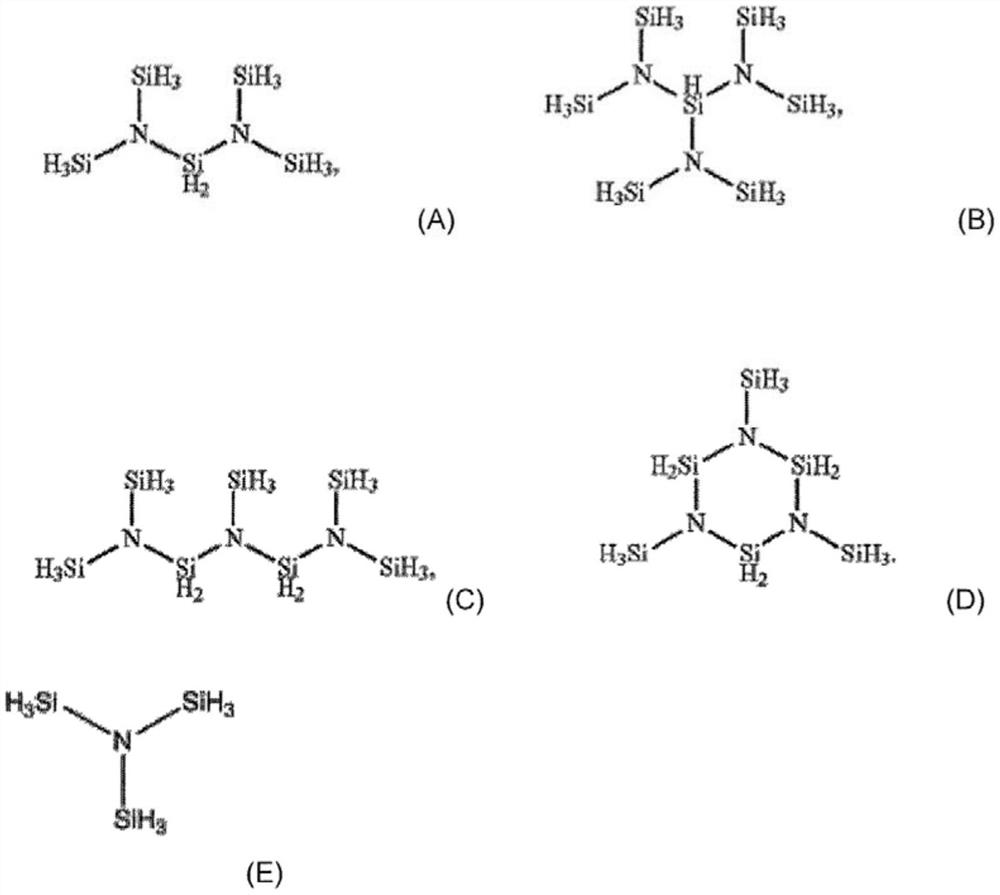

Embodiments herein provide for radical based treatment of silicon nitride layers deposited using a flowable chemical vapor deposition (FCVD) process. Radical based treatment of the FCVD deposited silicon nitride layers desirably increases the number of stable Si—N bonds therein, removes undesirably hydrogen impurities therefrom, and desirably provides for further crosslinking, densification, and nitridation (nitrogen incorporation) in the resulting silicon nitride layer. In one embodiment, a method of forming a silicon nitride layer includes positioning a substrate on a substrate support disposed in the processing volume of a processing chamber and treating a silicon nitride layer deposited on the substrate. Treating the silicon nitride layer includes flowing one or more radical species of a first gas comprising NH3, N2, H2, Ar, He, or combinations thereof and exposing a silicon nitride layer to the radical species.

Owner:APPLIED MATERIALS INC

Device and method of quickly and accurately detecting impurities in high-purity hydrogen for hydrogen fuel cell

ActiveCN110808203AExcellent qualitative analysis abilitySensitive highSamples introduction/extractionMaterial analysis by electric/magnetic meansResolution (mass spectrometry)Software system

The invention provides a device and a method of rapi`q dly and accurately detecting impurities in high-purity hydrogen for a hydrogen fuel cell. A direct sampling mode is adopted, complex sample pretreatment is omitted, and the cost and the system complexity are greatly reduced; high-purity hydrogen is taken as a carrier gas for quantitative sampling, and a standard gas is taken as reference, so that accurate quantification is realized; the special mass spectrum device for hydrogen detection greatly improves low-end mass number resolution, detection stability and sensitivity, and the system stability is remarkably superior to that of a general chromatographic mass spectrometry method; a special control software system comprises a mass axis automatic calibration software module, a high-purity carrier gas automatic measurement software module, a standard gas quantitative automatic measurement software module, a sample quantitative automatic measurement software module, a sample impuritygas automatic calculation software module, and due to a built-in algorithm, measurement and control automation are realized. The characteristics are beneficial to rapid and accurate determination of the high-purity hydrogen impurities of the hydrogen station of the hydrogen fuel cell.

Owner:北京中计新科仪器有限公司 +1

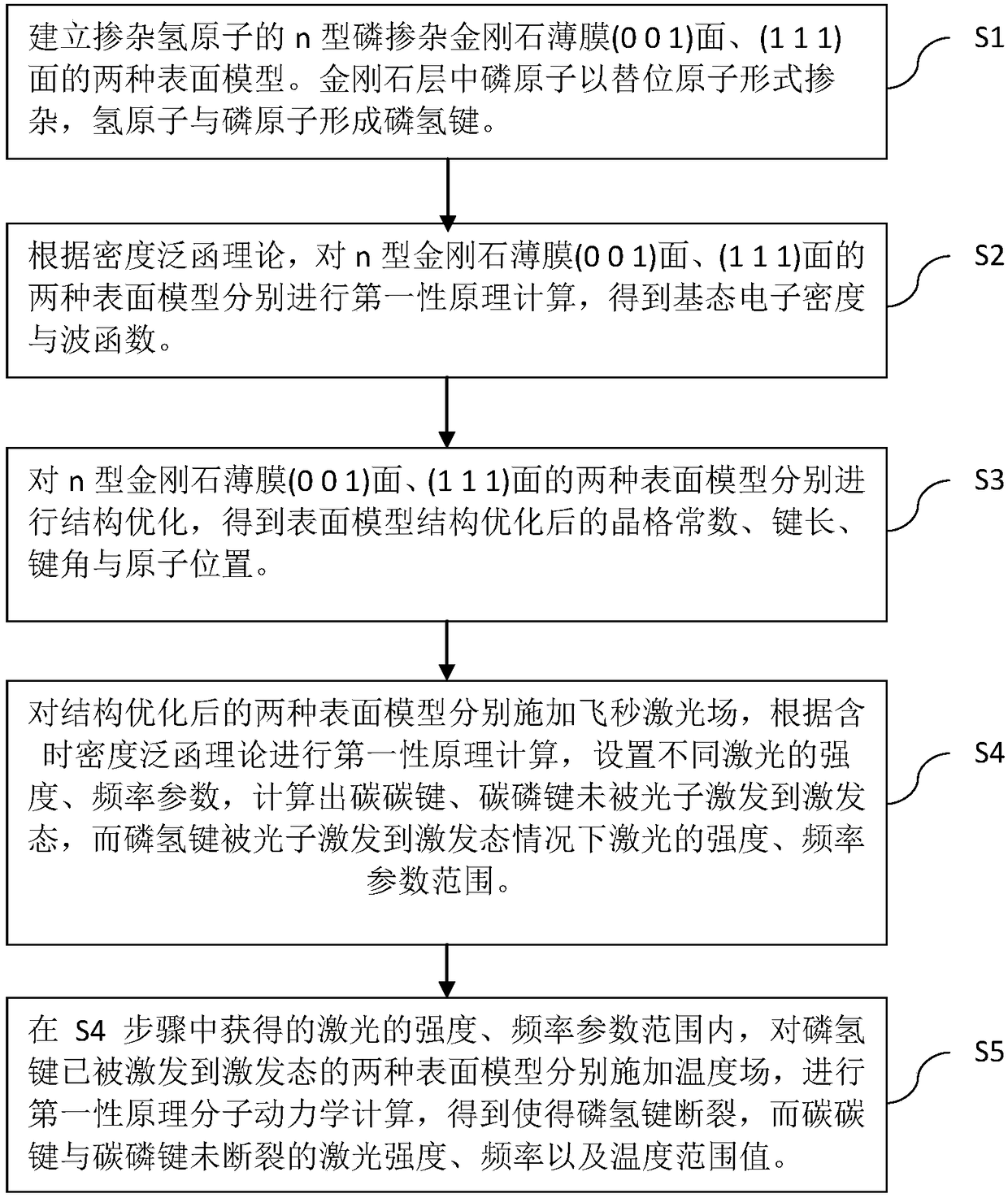

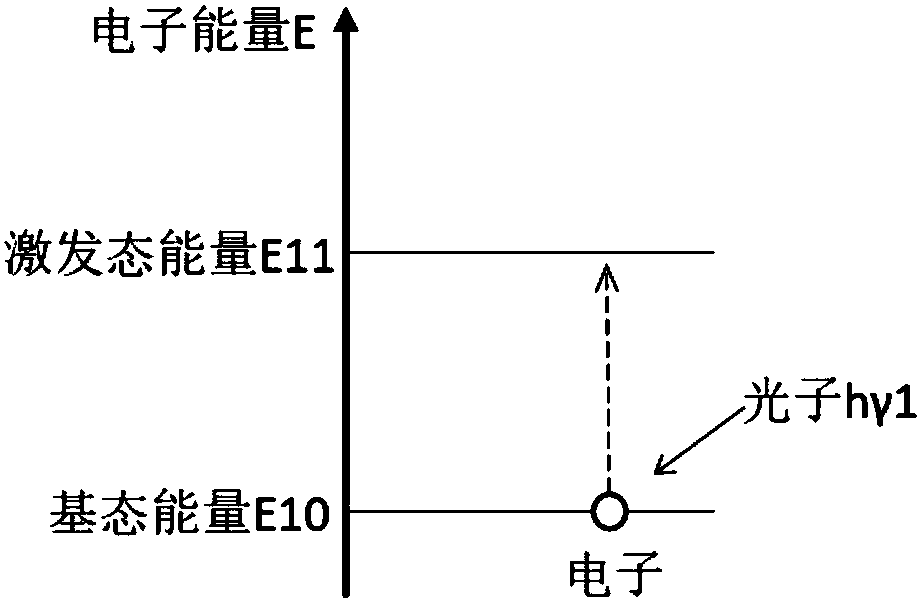

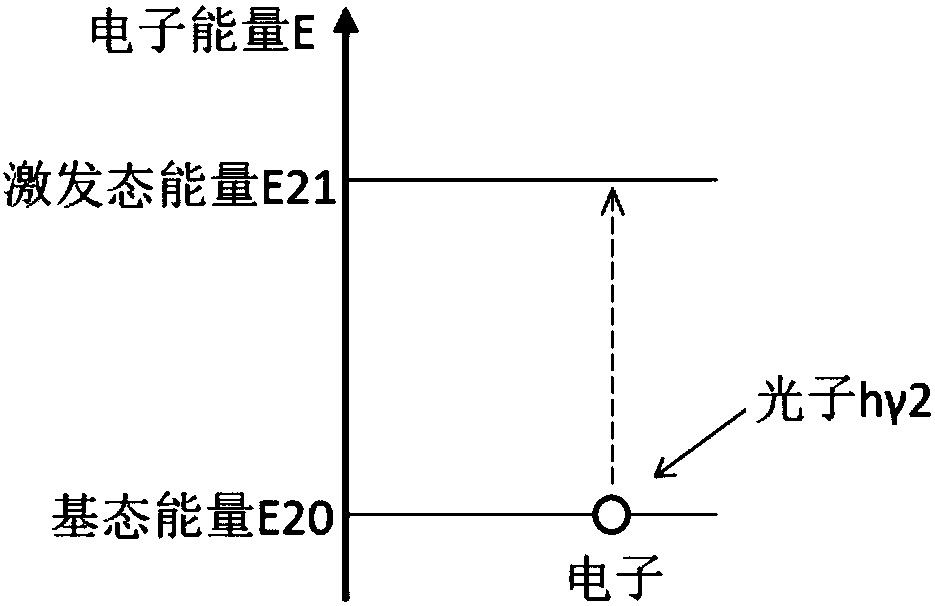

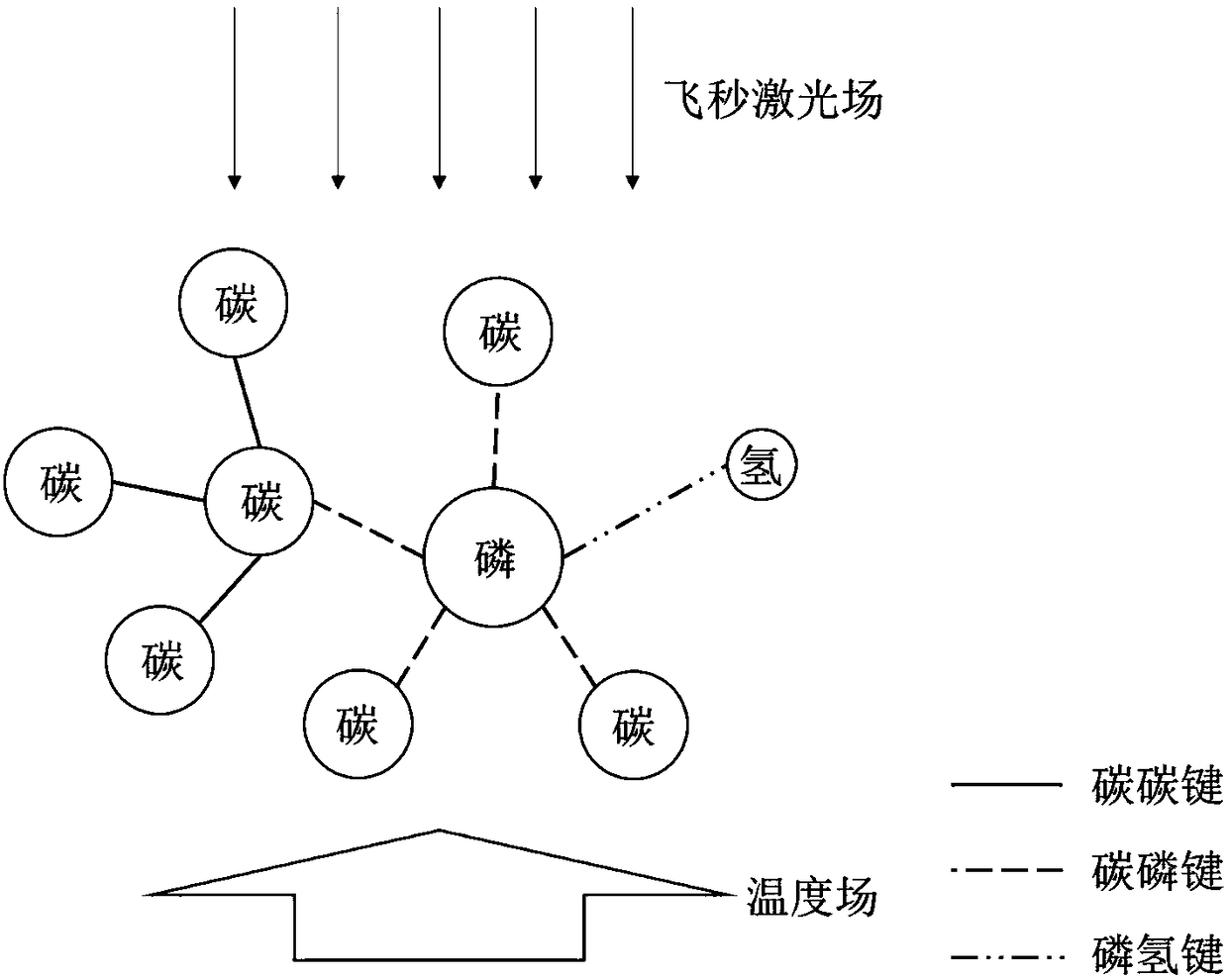

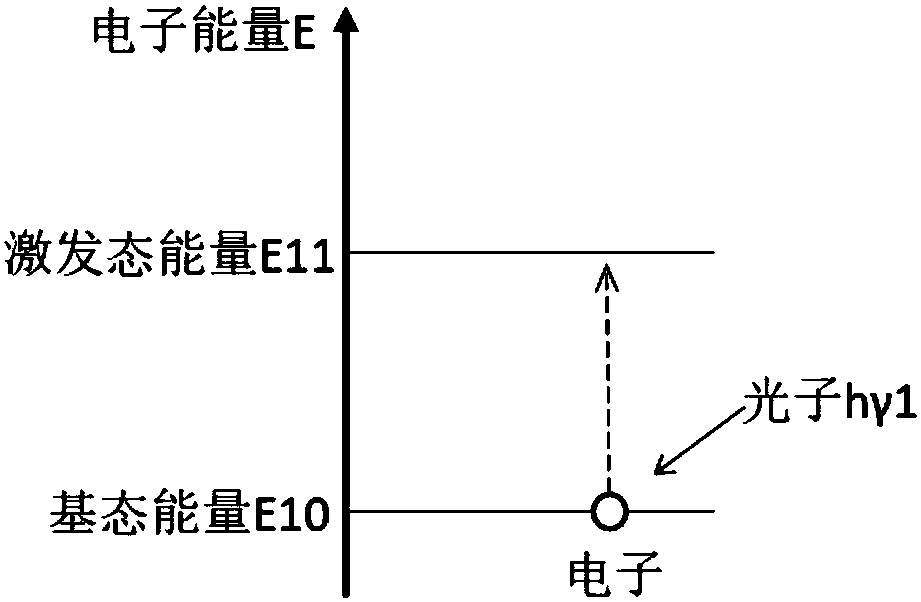

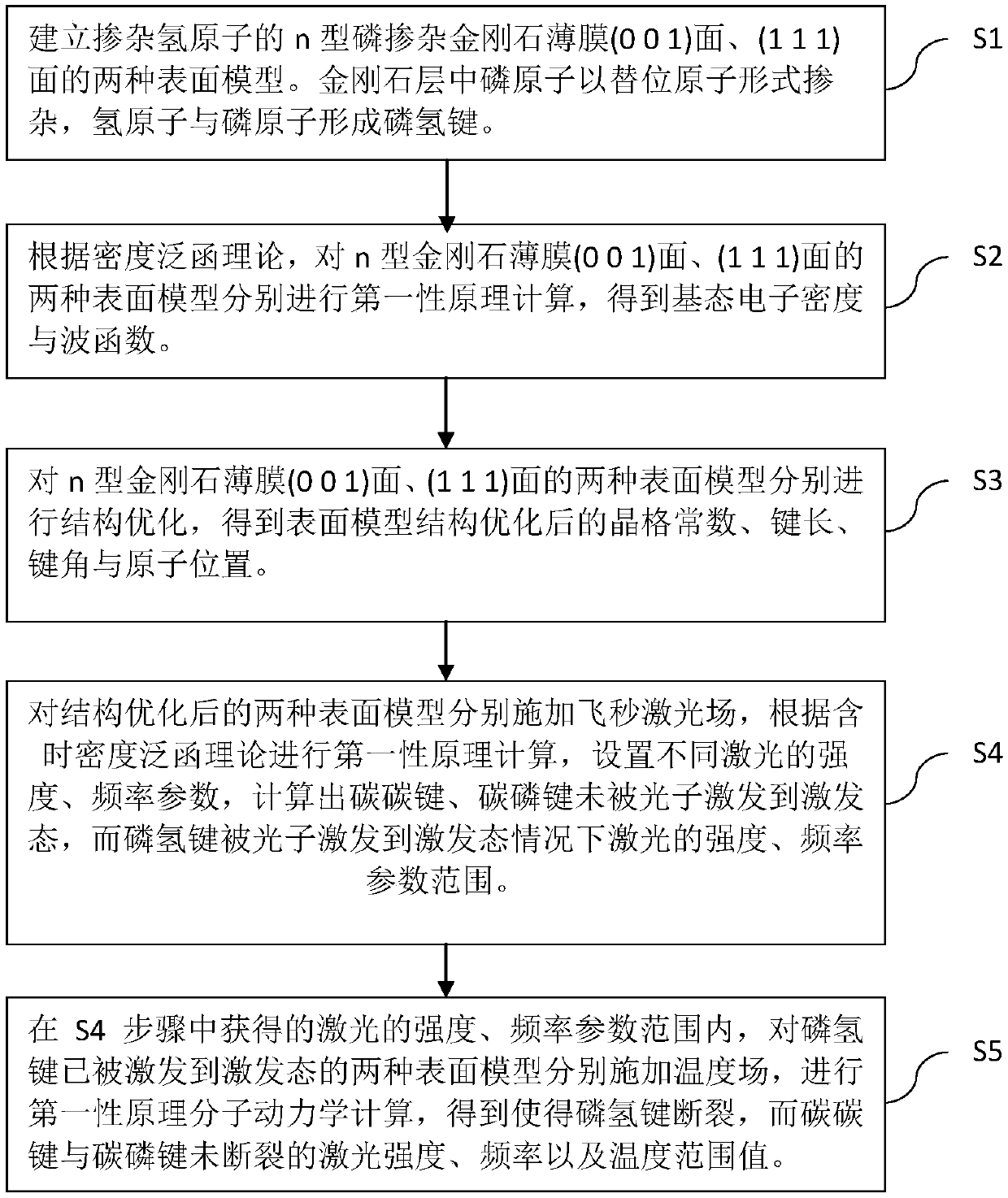

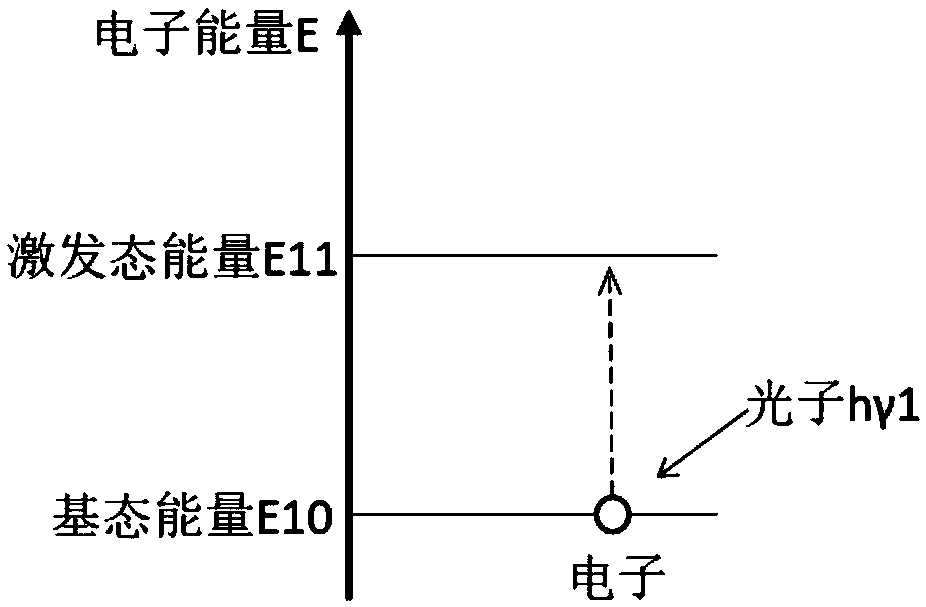

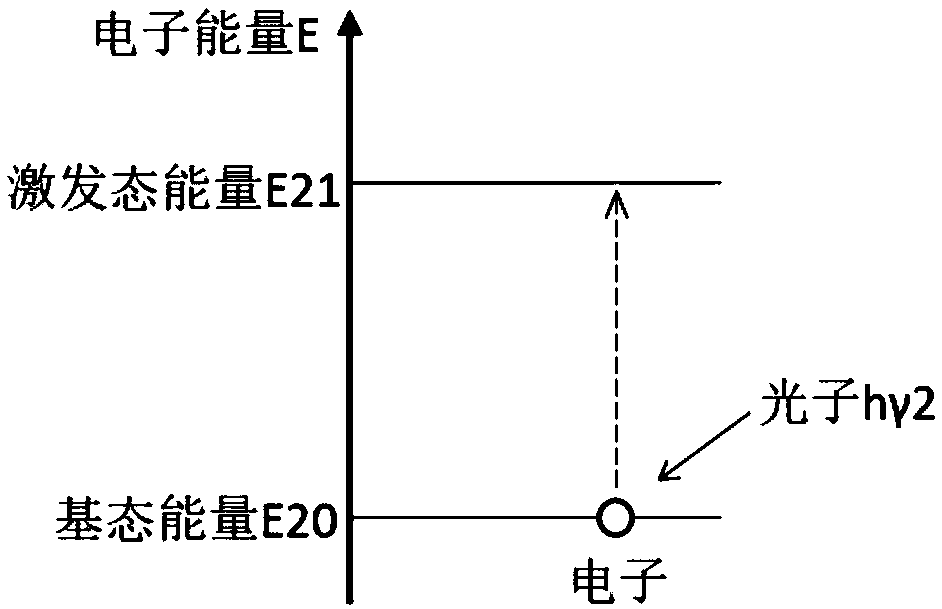

Simulation method for removing hydrogen impurity in n-type phosphorus doping diamond film

ActiveCN108425106AReduce hydrogen contentImprove electrical performanceAfter-treatment detailsChemical vapor deposition coatingValence electronFirst principle

The invention discloses a simulation method for removing the hydrogen impurity in an n-type phosphorus doping diamond film. According to time dependent density functional theory and the molecular dynamics theory, the first principle and molecular dynamics calculation is conducted on an n n-type phosphorus doping diamond film model, photon absorption, valence electron transition and chemical bond breakage in the model are simulated under a laser field and a temperature field, and the method for removing the hydrogen element impurity in the n-type phosphorus doping diamond film is further provided. The strength, the frequency and the range value of the temperature of femtosecond lasers which can break phosphorus and hydrogen bonds and remove the hydrogen impurity are calculated.

Owner:WUHAN UNIV

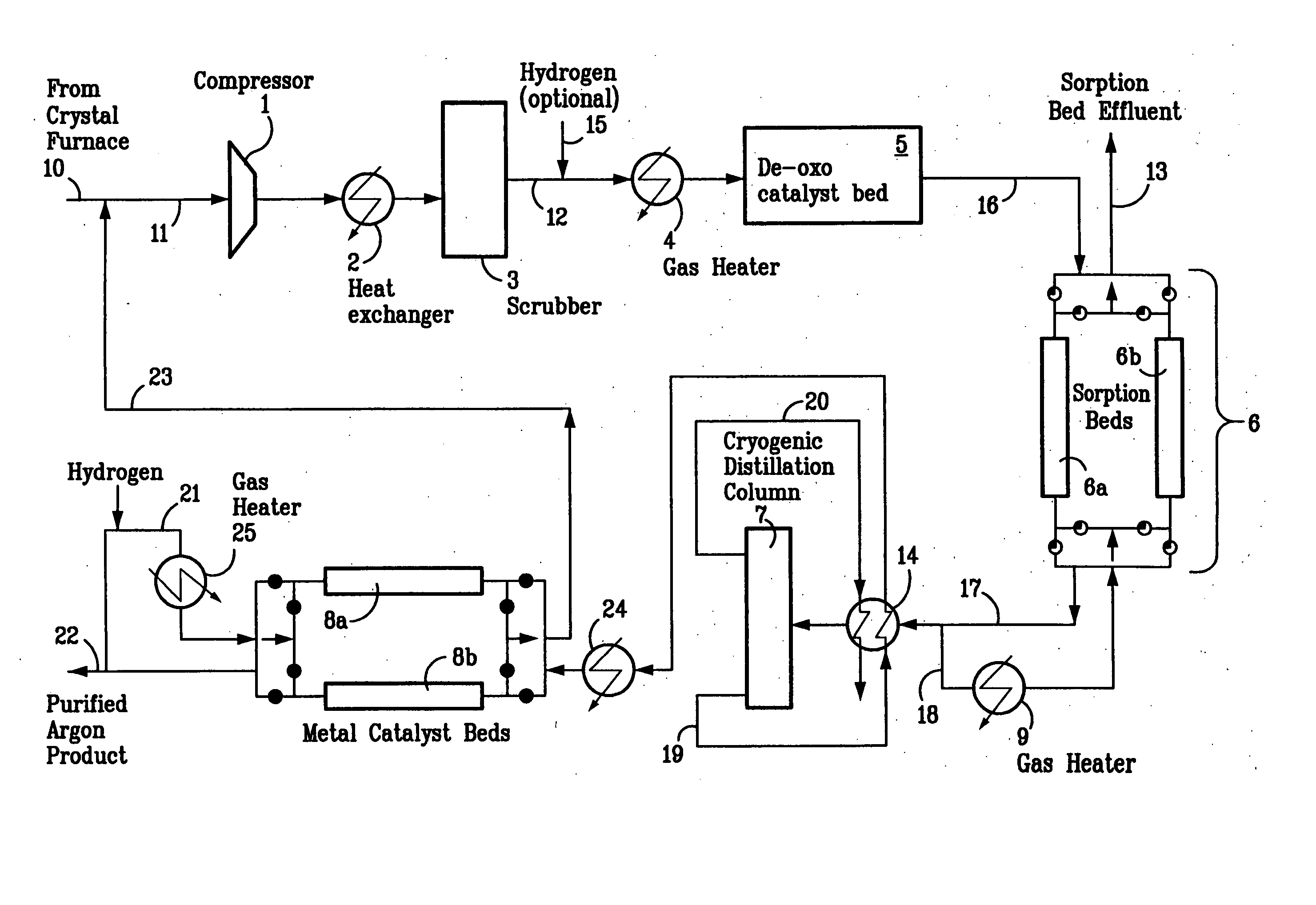

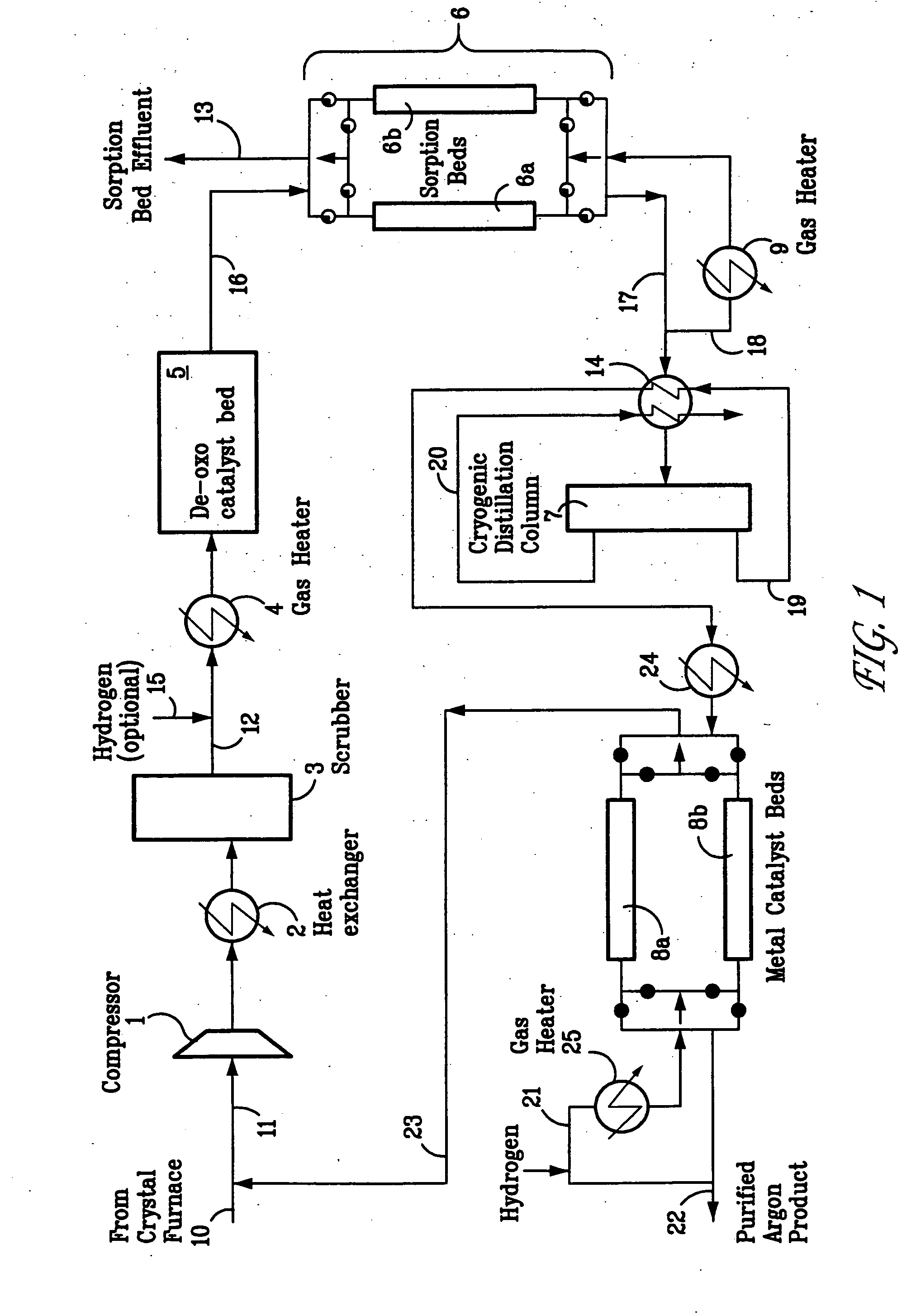

Process for recovery, purification, and recycle of argon

A system for the purification and recycle of impure argon is disclosed herein. The system of the present invention can produce very high purity argon, i.e., about 1 ppb or less of impurities. In one embodiment, a cryogenic separation apparatus is used to remove the nitrogen, hydrocarbon, and hydrogen impurities from the argon stream. A catalyst bed is then operated at ambient temperature to remove hydrogen, oxygen, and carbon monoxide impurities to provide the purified argon product.

Owner:VERSUM MATERIALS US LLC

Preparation method of high-purity hydrogen chloride

ActiveCN110697656AExtended service lifeEasy to useChlorine/hydrogen-chloride purificationOther chemical processesSorbentPhysical chemistry

The invention relates to the field of fine chemical industry, and in particular relates to a preparation method of high-purity hydrogen chloride. Compared with the prior art, the preparation method ofthe high-purity hydrogen chloride uses a styrene / ionic liquid high-crosslinking adsorbent which has a better effect of adsorbing hydrogen chloride impurities, and effectively reduces the impurity content of product gas; moreover, a deep separation type gas purifier is added, and tests show that the water content of the prepared high-purity hydrogen chloride can be reduced to 100 ppb or less and the gas impurities can be reduced to 50 ppb or less; moreover, compared with the prior separation type gas filter technology, the process is enlarged, the flow rate can reach 400 standard liters / minuteat the highest, and the production efficiency is greatly improved.

Owner:ZHEJIANG BRITECH CO LTD

Marine life-saving equipment

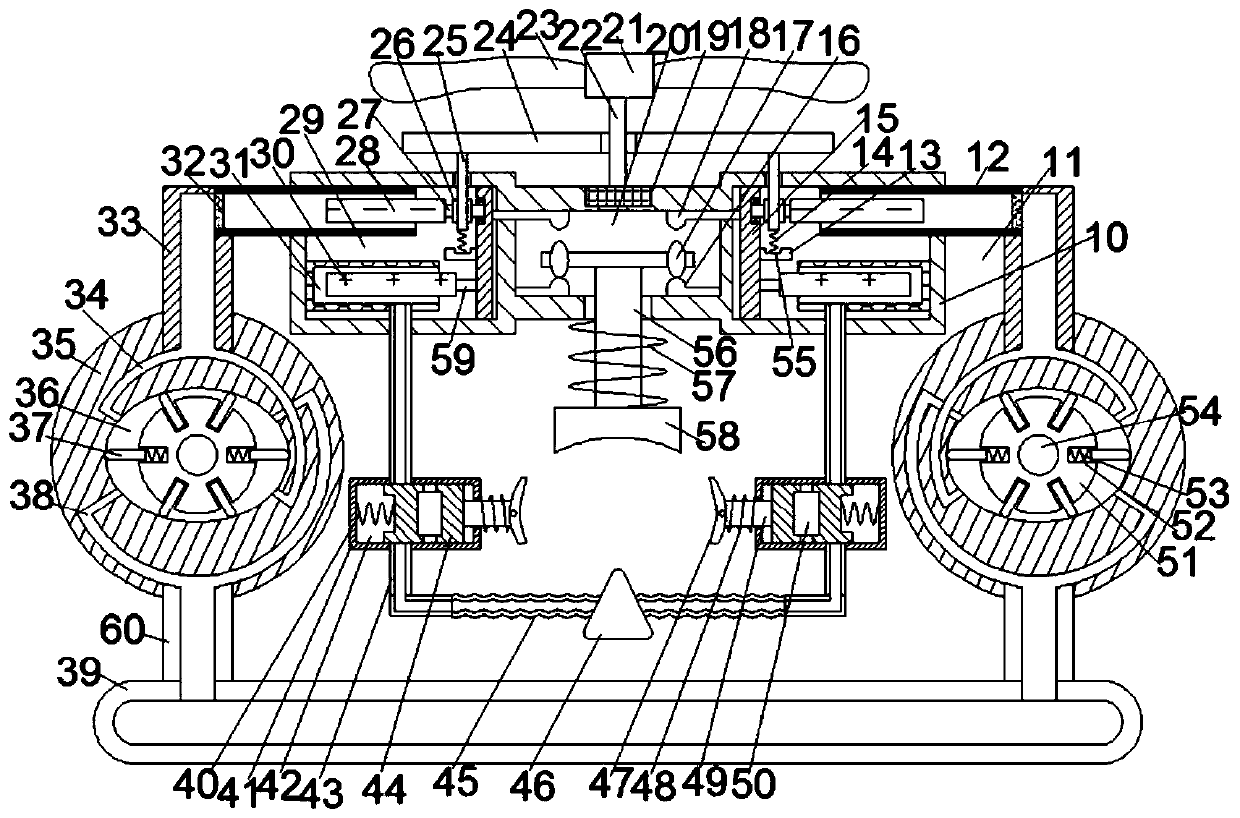

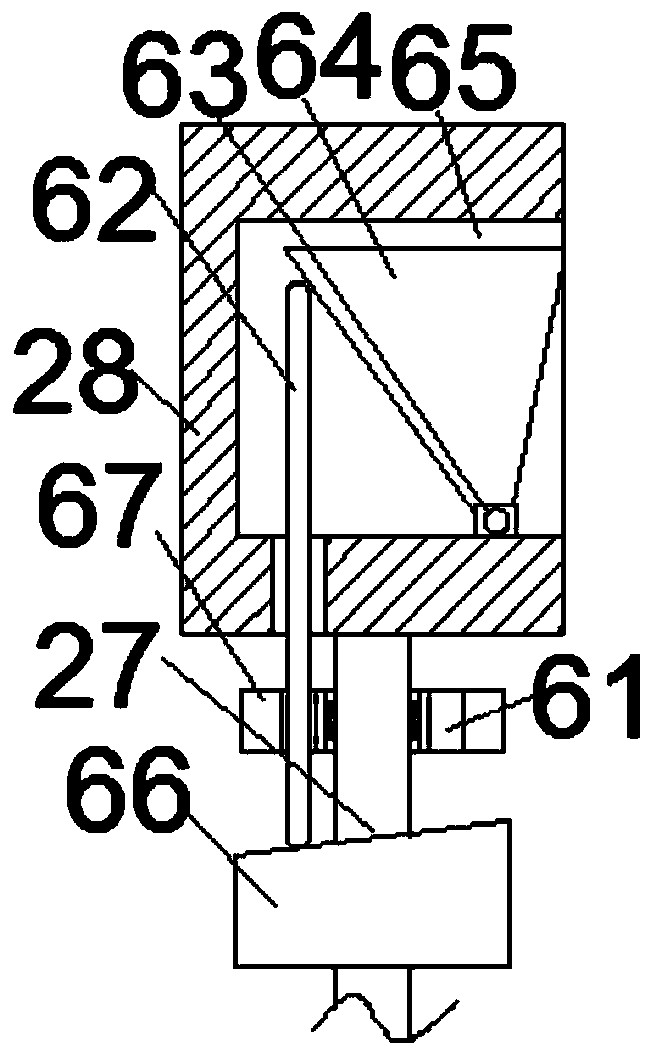

InactiveCN110294086AGuarantee the basic needs of lifeSaving of basic life needsLife-savingUnderwater equipmentRubber ringElectrolysed water

The invention discloses marine life-saving equipment. The marine life-saving equipment comprises an electrolytic box, wherein symmetrical hydrogen impurity removal devices are arranged on the left side and the right side of the electrolytic box, a rubber ring communicating with the hydrogen impurity removal devices is arranged at the lower ends of the hydrogen impurity removal devices, after hydrogen enters the rubber ring, the rubber ring is inflated to assist a user in floating upward, an accommodating cavity is arranged between the hydrogen impurity removal devices, a switch cavity is arranged in the electrolytic box, and a driving device is arranged outside the top of the switch cavity. The driving device drives the whole marine life-saving equipment to move through the electrolytic box, an abutting switch assembly is arranged in the switch cavity to control the circuit of the marine life-saving equipment, when the user puts the marine life-saving equipment on the head, a circuit start device can be automatically connected, and symmetrical electrolytic cavities located at the left end and the right end of the switch cavity are arranged in the electrolytic box. The marine life-saving equipment is simple in structure and convenient to operate, assisted buoyancy is provided by electrolysed water product hydrogen, oxygen supplies breathing, and the victim can breathe freely inthe water.

Owner:SUZHOU XINYAO HEALTH TECH CO LTD

Helium processing device of high yield neutron generator

InactiveCN104093261AHigh outputExtended service lifeDirect voltage acceleratorsNuclear targetsAlloyVacuum chamber

The invention discloses a helium processing device of a high yield neutron generator. The helium processing device is connected to a large-volume helium processing vacuum container through a vacuum pipeline outside a neutron generator main vacuum chamber. In the helium processing container, hydrogen absorption alloy which has large adsorbing capacity and high absorbing speed to deuterium and tritium gas, has low absorbing speed to non-hydrogen impurity gas, and does not have the absorbing effect on helium is used for absorbing the deuterium and tritium gas in a system, and remaining helium and non-hydrogen impurity gas are pumped by an ionic pump. Then, the hydrogen absorption alloy is appropriately heated, the absorbed deuterium and tritium gas is released to the inside of the vacuum container again, and the purposes that in the totally-sealed container, the deuterium and tritium gas is basically not consumed and meanwhile the helium and other impurity gas are dynamically eliminated are achieved. The helium processing device is particularly suitable for being used in totally-sealed deuterium and tritium neutron generators which has long service life and high yields.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

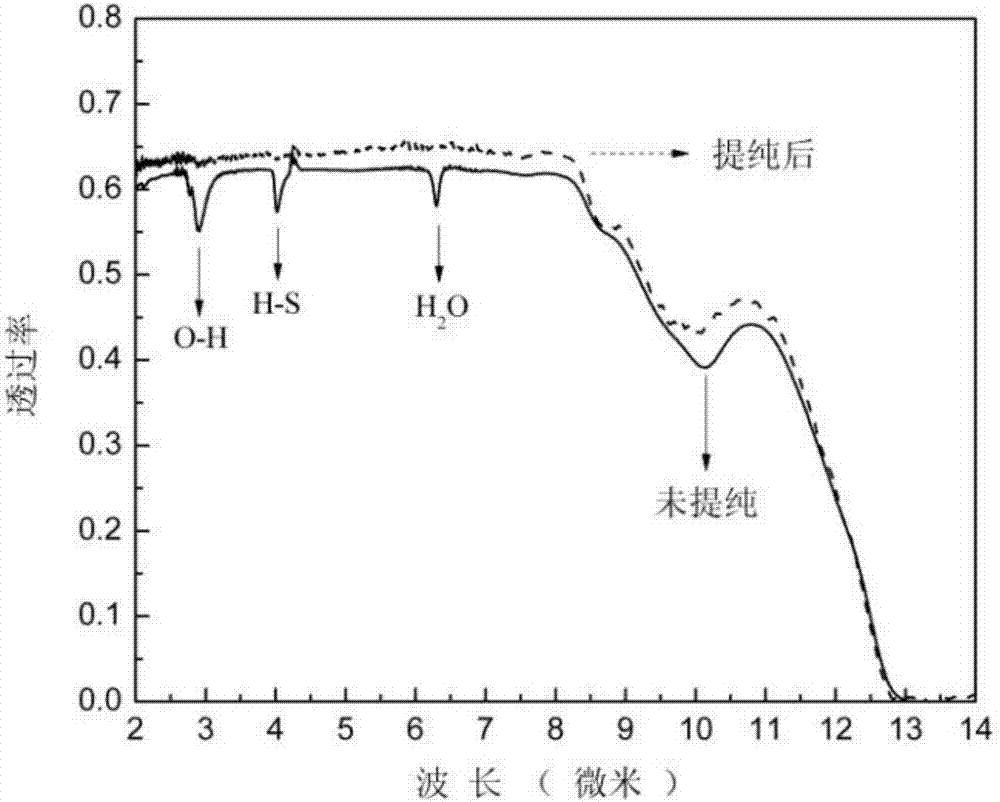

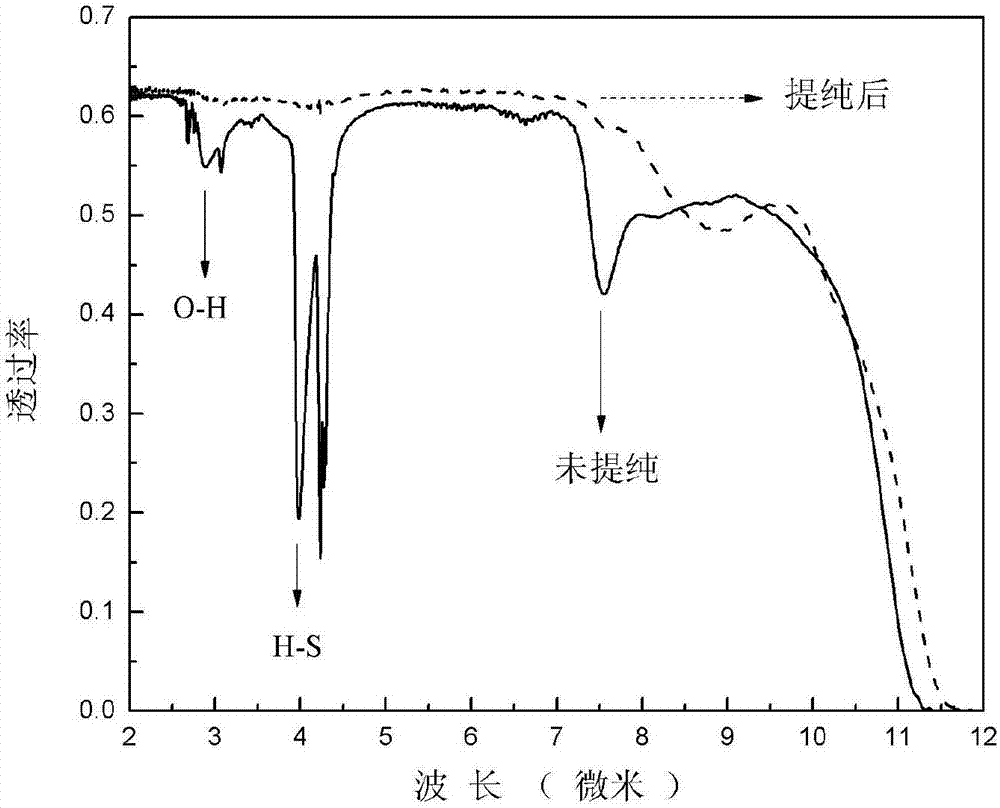

Infrared glass preparation method and water removing device thereof

The invention belongs to the field of infrared optical glass preparation, specifically relates to an infrared glass preparation method and a water removing device thereof and aims at solving the defect that impurities of hydrogen and oxygen in the infrared glass cannot be removed effectively in the prior art. The water removing device comprises an inert gas inlet pipe, a chlorine inlet pipe, a heating furnace, a raw material pipe and a gas outlet pipe, wherein the inert gas inlet pipe, the chlorine inlet pipe and the gas outlet pipe are each communicated with the raw material pipe, and the heating furnace is arranged outside the raw material pipe. Chlorine is utilized to remove water of infrared glass, the chlorine can effectively remove absorption peaks generated at 2.9 and 4.3 micrometer positions by O-H and H-S bonds, and practical foundation of the infrared glass is established. The technological principle is that a strong oxidant, namely of the chlorine, is mainly utilized to snatch the hydrogen impurity in the glass, hydrogen chloride gas is generated to be exhausted out glass melting liquid, and the hydrogen impurity is eliminated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

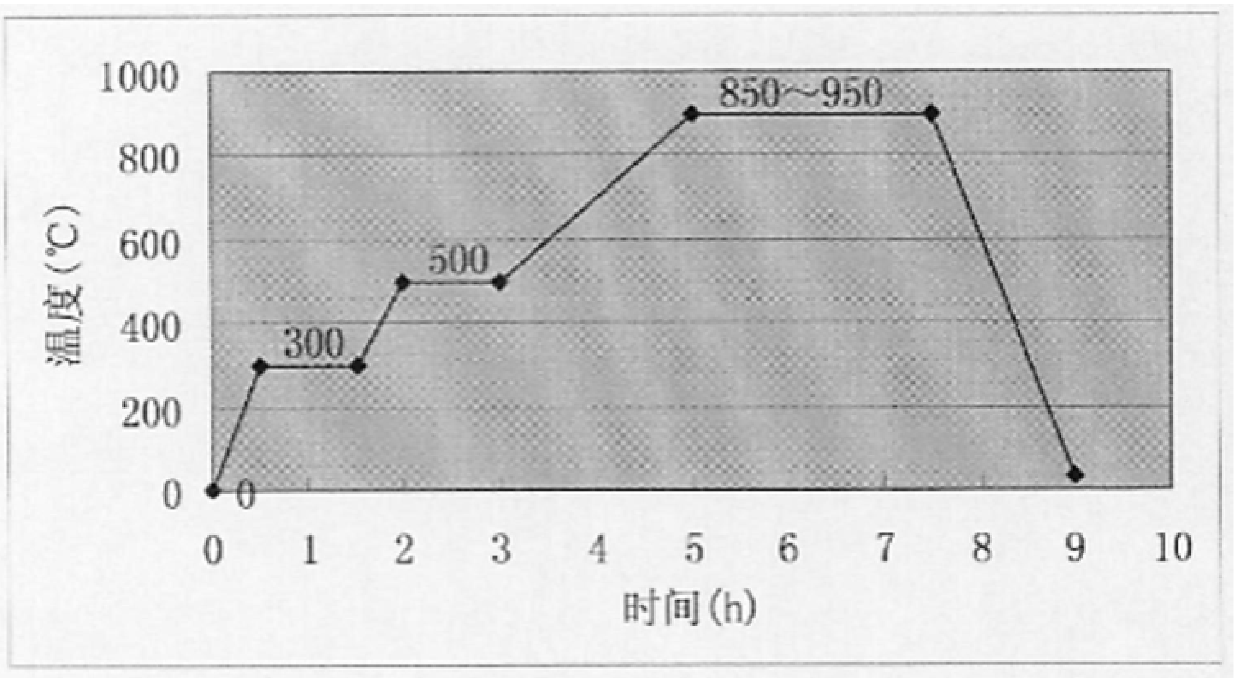

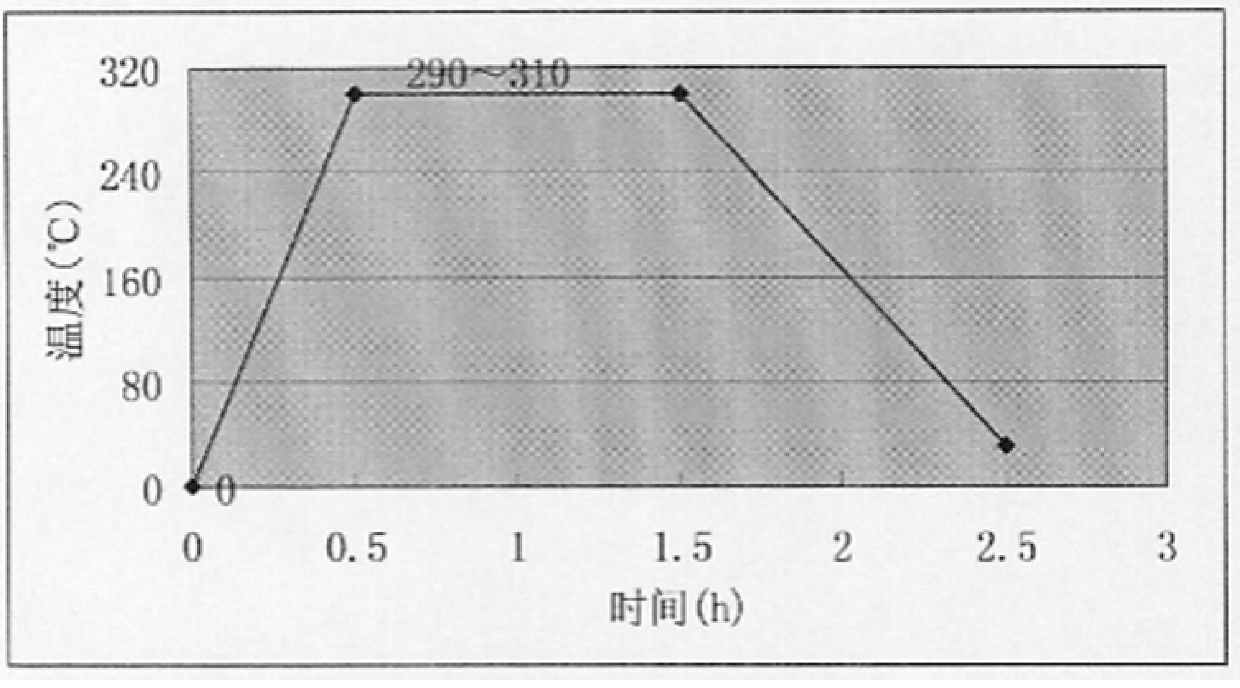

Preparation process of cobalt pellets in cobalt regulating rod assembly

ActiveCN106508058BImprove axial uniformityLower sintering temperatureFuel elementsNuclear energy generationHigh densityManufacturing technology

The invention relates to the manufacturing technology of nuclear fuel elements, in particular to a preparation process of pellets in cobalt regulating rod assemblies used in nuclear reactors. The process of the invention comprises the following steps: (1) powder granulation; (2) powder molding; (3) pellet sintering; (4) pellet degassing and sintering. The aspect ratio of the cobalt pellets produced by the process of the present invention is greater than 4, and the hydrogen impurity content is less than 1 μg / g, which meets the preparation requirements of high aspect ratio, high density, and defect-free cobalt pellets, and meets the requirements of the cobalt regulating rod assembly in the reactor. The technical requirements of the work are suitable for batch preparation.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

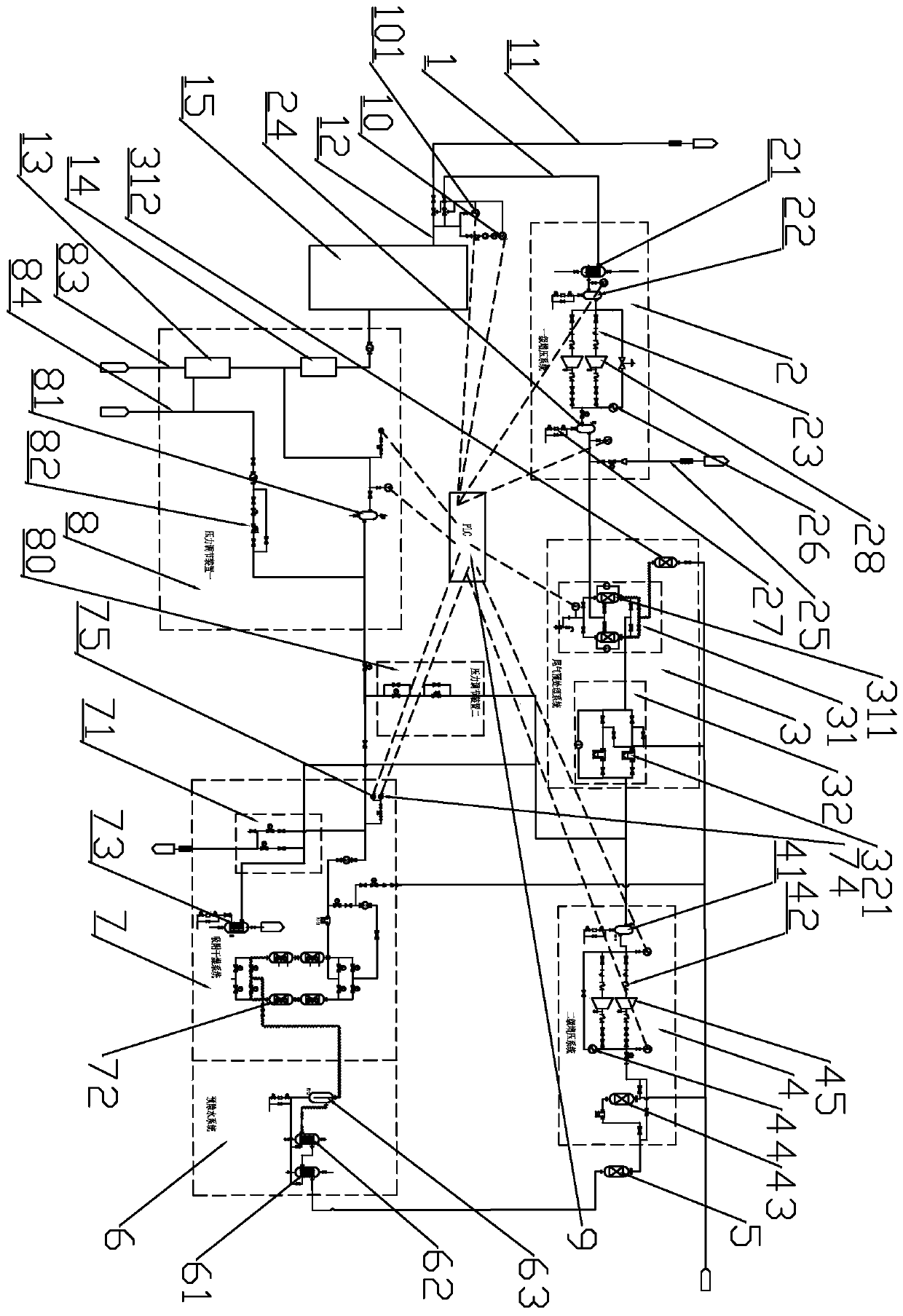

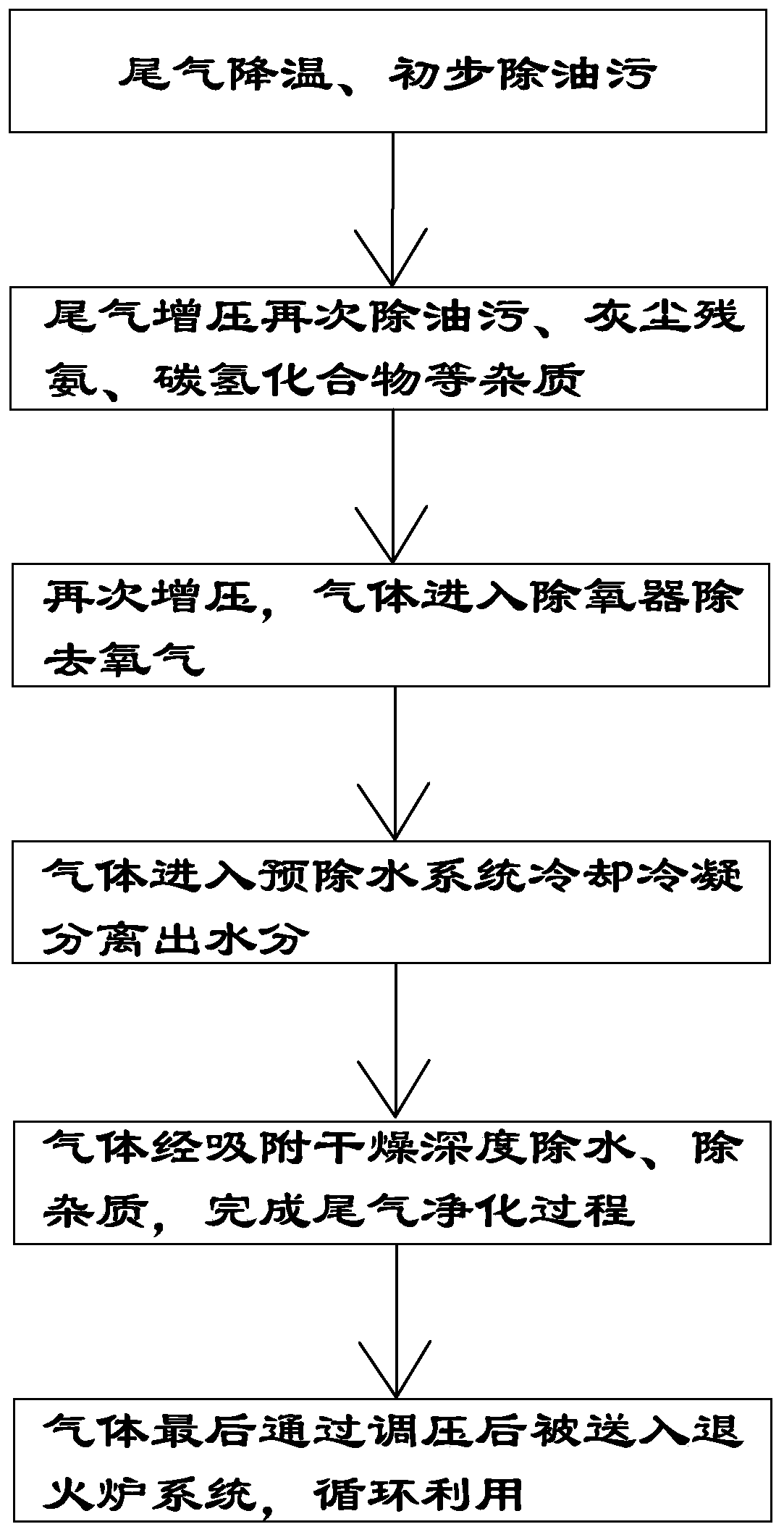

Tail gas recovery treatment and cyclic utilization device for zinc plating continuous annealing furnace and treatment technology thereof

PendingCN110595221AReduce shielding gas consumptionReduce consumptionFurnace typesIncreasing energy efficiencyProcess engineeringOxygen

The invention provides a tail gas recovery treatment and cyclic utilization device for an annealing furnace. The tail gas recovery treatment and cyclic utilization device comprises a tail gas recoverypipeline, a primary pressurizing system, a tail gas pretreatment system, a secondary pressurizing system, an oxygen removing device, a water pre-removing system, an adsorbing and drying system, a first pressure adjusting device and a PLC which are sequentially connected, wherein the PLC is in signal connection with the electric power. Tail gas is connected into an annealing furnace protecting gasinput main pipe after being connected with the first pressure adjusting device through the adsorbing and drying system. The treated tail gas is used by the zinc plating line annealing furnace in a cyclic manner. According to the treatment technology, after the tail gas generated by the furnace system passes through a cooler, most oil dirt is treated; then the tail gas enters the tail gas pretreatment system through the primary pressurizing system, so that oil dirt, dust, residual ammonia and carbureted hydrogen impurity in the tail gas are removed, and the tail gas enters the secondary pressurizing system, so that oxygen is removed; then the tail gas enters the water pre-removing system, so that water is separated out; the adsorbing and drying system carries out depth water removing and impurity gas removing, finally, the first pressure adjusting device adjusts pressure, the tail gas is fed into the zinc plating line continuous annealing furnace, cyclic utilization is achieved, and the device saves energy and is environmentally friendly.

Owner:江苏维麦气体科技有限公司

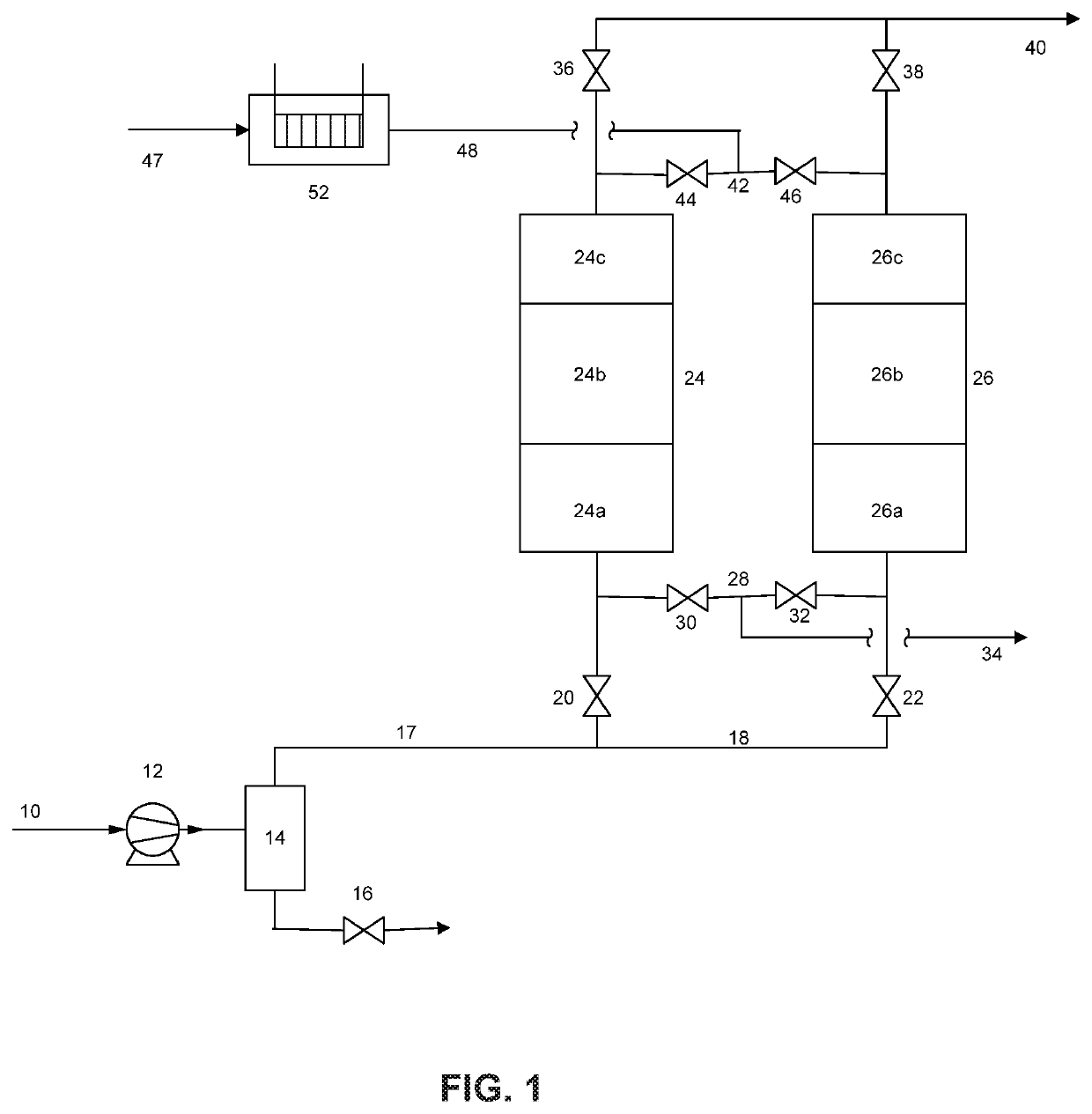

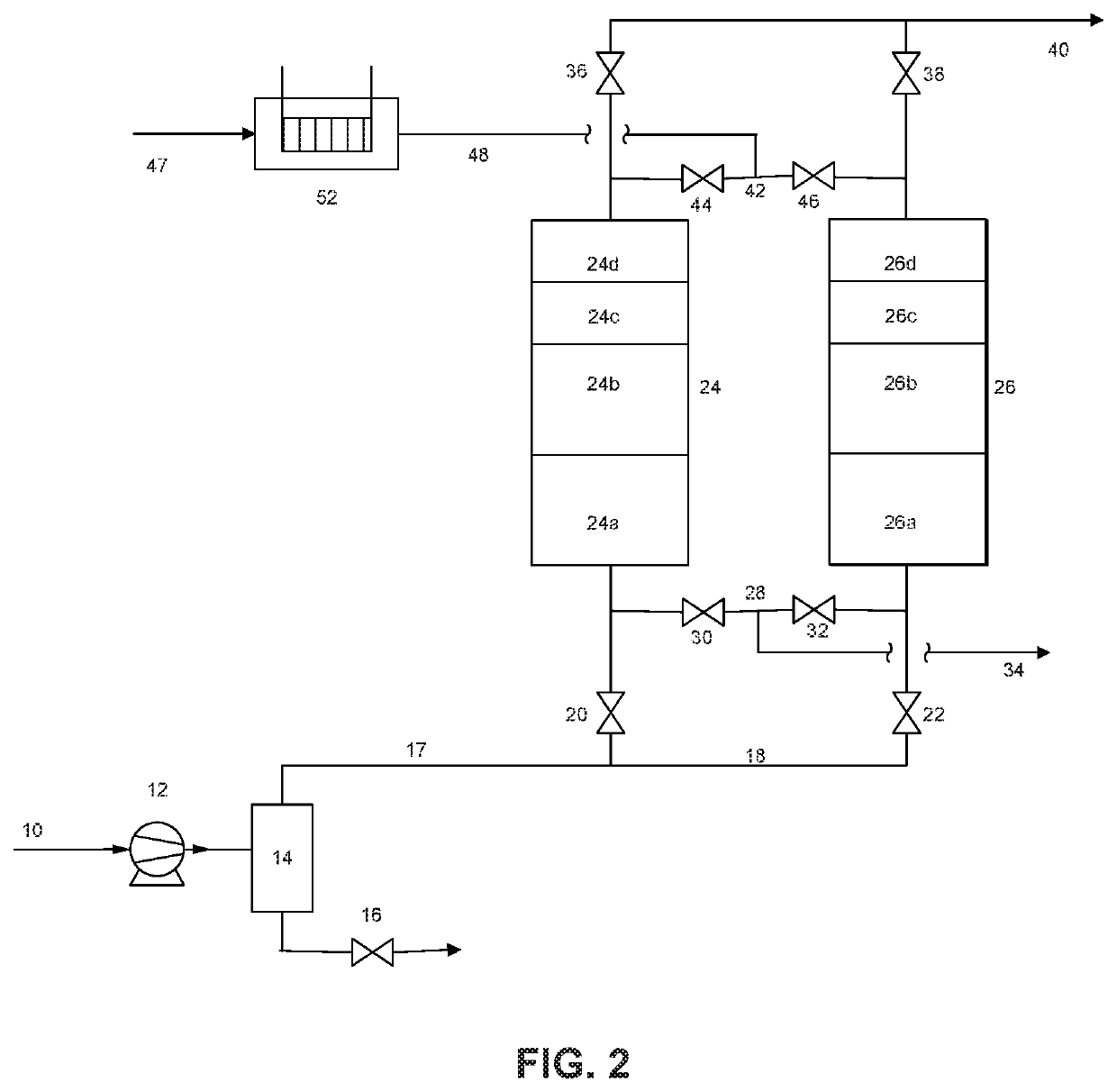

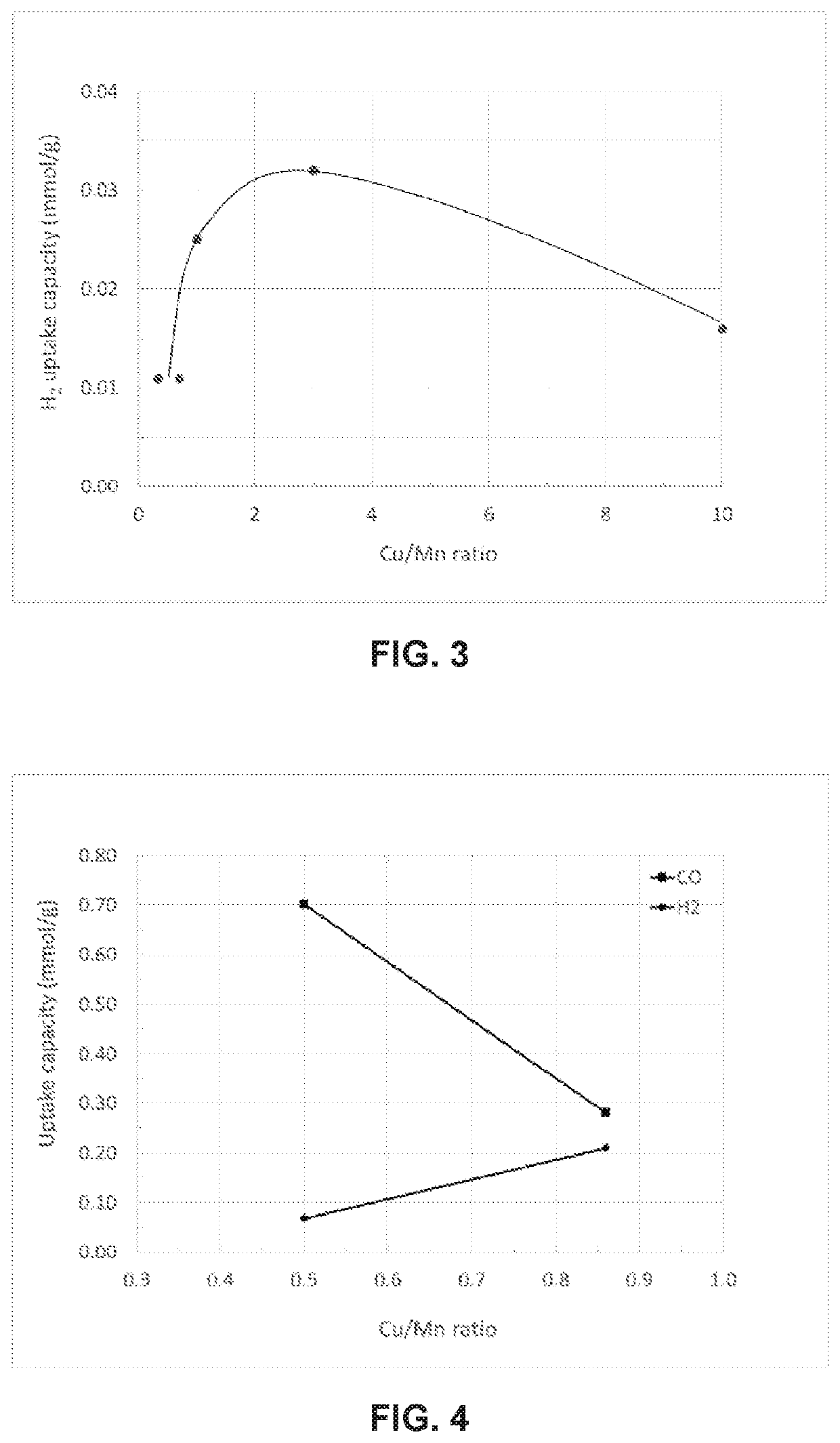

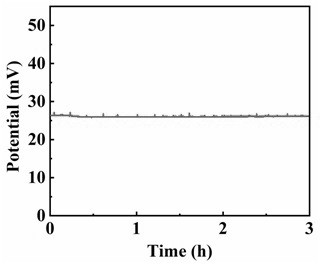

Removal of hydrogen impurity from gas streams

Trace hydrogen may be removed from a dry gas by passing the dry gas at a temperature from about 0° C. to about 60° C. through at least one layer of a first hopcalite catalyst to produce product gas that is at least substantially free of hydrogen, wherein the first hopcalite catalyst has a molar ratio of copper to manganese of more than 0.55. Advantages include increase hydrogen capacity, lower feed and regeneration temperatures and lower sensitivity to carbon dioxide than equivalent processes using standard hopcalite catalyst having a Cu / Mn molar ratio from 0.45 to 0.55.

Owner:AIR PROD & CHEM INC

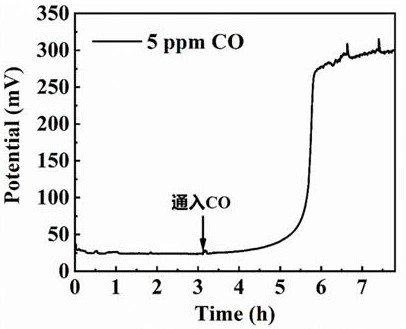

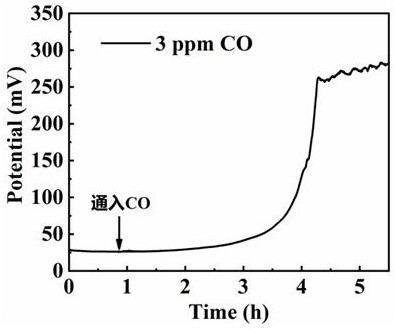

Method for accurately testing fuel cell anode overpotential caused by hydrogen impurities and application thereof

PendingCN113629278ATest accurateEliminate the effects of electrochemical polarizationCurrent/voltage measurementFuel cellsFuel cellsOverpotential

The invention provides a method for accurately testing fuel cell anode overpotential caused by hydrogen impurities and application thereof,. A hydrogen pump principle is utilized, that is, an anode is subjected to a hydrogen oxidation reaction, a cathode is subjected to a hydrogen evolution reaction, impurity gas with a certain concentration is mixed into hydrogen on the anode side, a polarization curve during operation is tested by adopting a constant current method, thus, fuel cell anode overpotential caused by hydrogen impurities is determined. The method is simple and easy to implement, and the fuel cell anode overpotential caused by hydrogen impurities can be accurately tested, so that basic data can be provided for optimizing and perfecting the hydrogen quality standard for the vehicle fuel cell in China.

Owner:BEIJING UNIV OF CHEM TECH

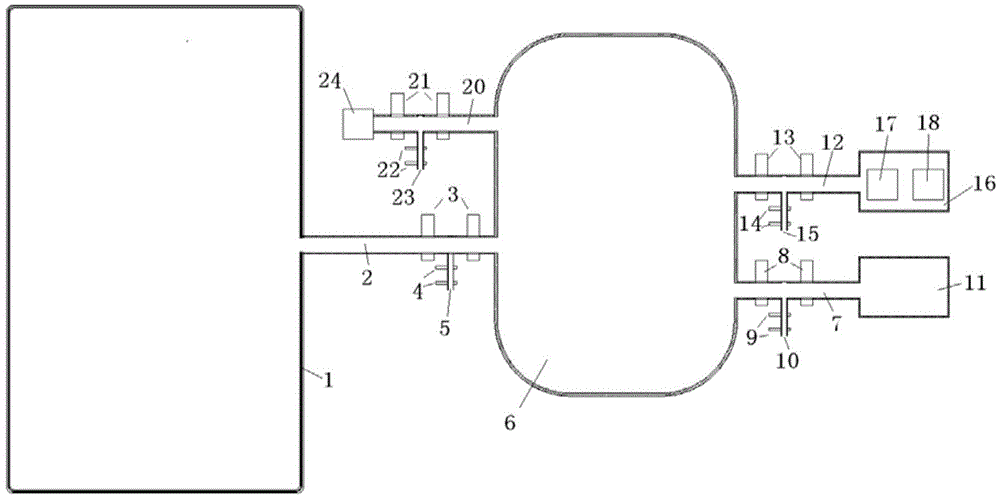

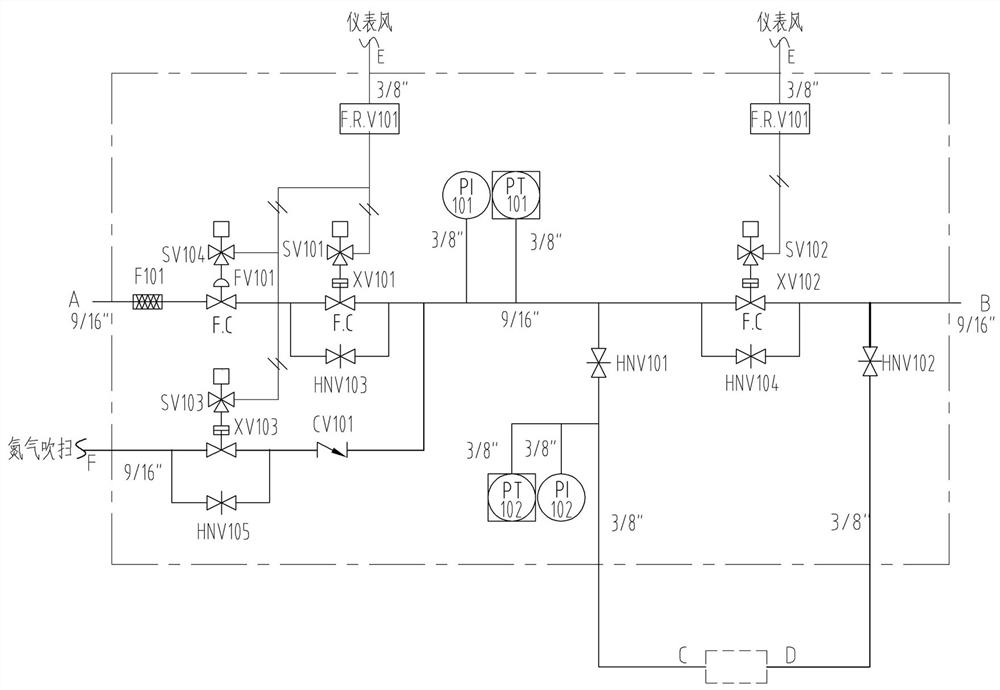

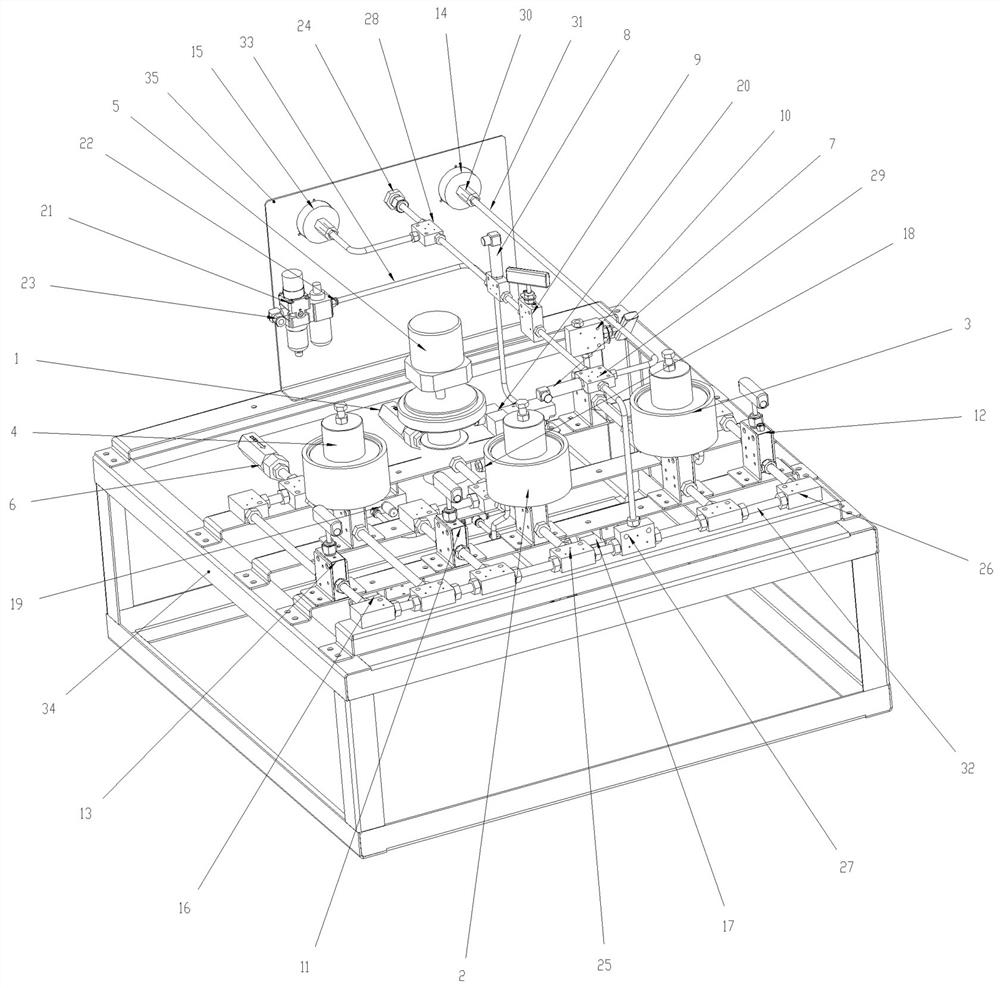

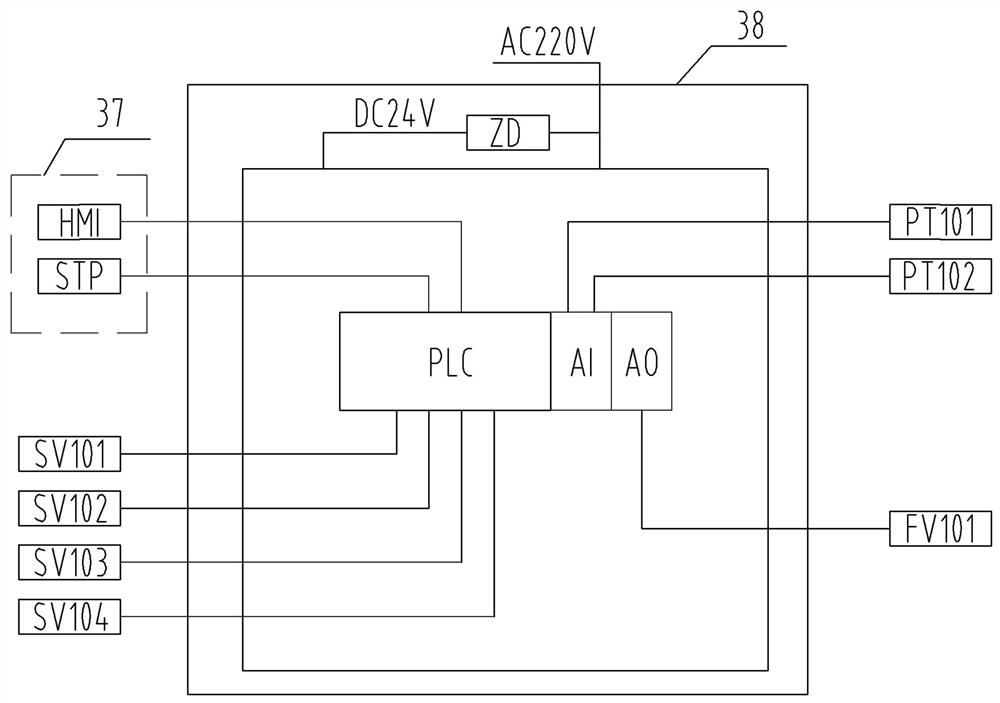

Automatic purging and replacing system and method for hydrogen-related pipe valve testing gas circuit structure

ActiveCN113309984ATimely and effective cleaningImprove accuracyPipeline systemsCleaning using gasesControl cellProcess engineering

The invention discloses an automatic purging and replacing system and method for a hydrogen-related pipe valve testing gas circuit structure. The system comprises a purging gas source, a purging and replacing pipeline used for feeding purging gas into a main pipeline and a testing pipeline, and a PLC control unit; the purging and replacing pipeline comprises a purging inlet, a pneumatic valve and a one-way valve, which are sequentially connected through corresponding pipelines; the purging inlet is connected with the corresponding purging gas source; before testing or debugging of a pipe valve, all stop valves in a tested pipeline structure are opened, and corresponding centralized diffusion pipelines are communicated; after the purging inlet communicates with the purging gas source, the pneumatic valve is opened to release purging gasflow for pipeline purging; and after purging is completed, all the stop valves are closed, the pipe valve to be tested is connected with a mounting piece to be arranged in the corresponding tested pipeline, and subsequent testing or debugging is carried out. The system is simple in structure, practical and low in use cost; and according to the method, residual hydrogen, impurities and waste in the tested pipeline can be effectively purged and cleaned in time, potential safety hazards are eliminated, and the accuracy and reliability of a test result are improved.

Owner:正星氢电科技郑州有限公司

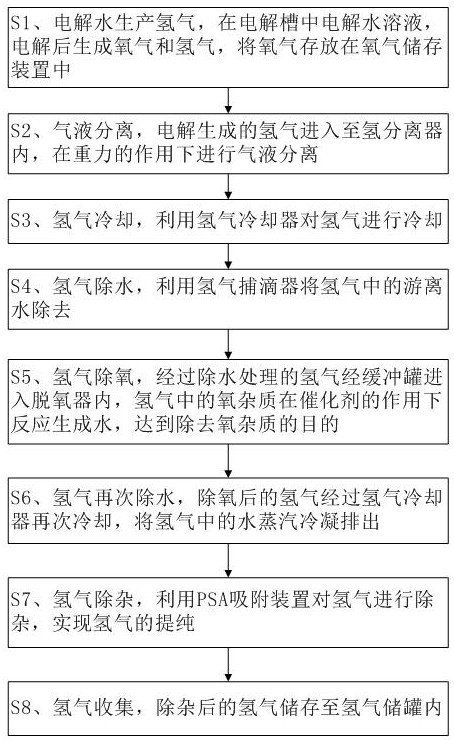

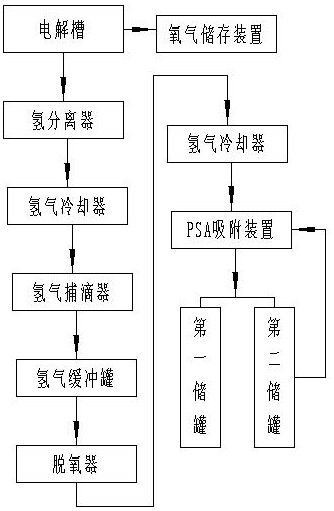

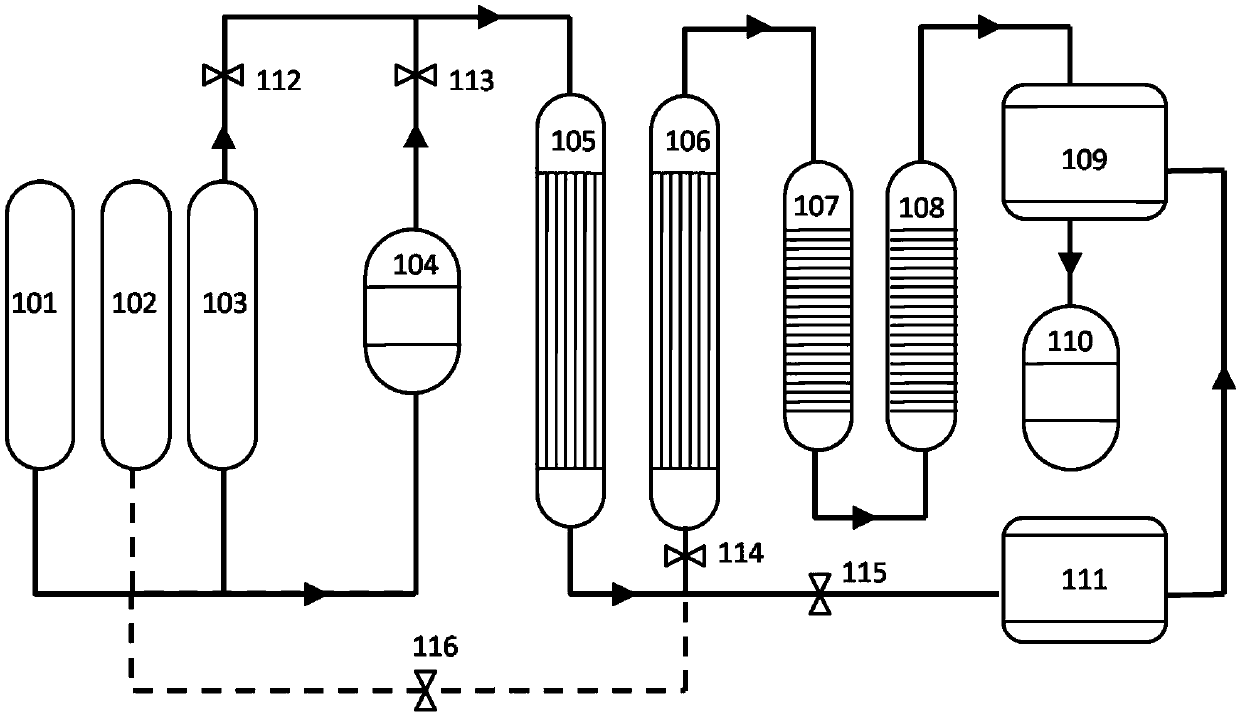

High-purity hydrogen preparation method based on pressure swing adsorption

PendingCN114590779AHigh purityIncrease productivityHydrogen separation by selective and reversible uptakeHydrogen separation at low temperatureElectrolysed waterPhysical chemistry

The invention discloses a high-purity hydrogen preparation method based on pressure swing adsorption. The high-purity hydrogen preparation method comprises the following steps: S1, electrolyzing water to produce hydrogen; s2, gas-liquid separation is conducted, specifically, hydrogen generated through electrolysis enters a hydrogen separator, and gas-liquid separation is conducted; s3, hydrogen cooling, wherein hydrogen is cooled through a hydrogen cooler; s4, hydrogen water removal, wherein free water in hydrogen is removed through a hydrogen drop catcher; s5, hydrogen deoxygenation is conducted, specifically, hydrogen enters a deaerator through a buffer tank, and the purpose of removing oxygen impurities is achieved; s6, the hydrogen is dewatered again, and the deoxygenated hydrogen is cooled again through a hydrogen cooler; s7, hydrogen impurity removal: performing impurity removal on the hydrogen by using a PSA adsorption device to realize purification of the hydrogen; and S8, hydrogen collection: storing the hydrogen subjected to impurity removal into a hydrogen storage tank. The hydrogen is dewatered and deoxidized before being purified, and the hydrogen with lower purity is subjected to secondary pressure swing adsorption, so that the purity of the hydrogen is greatly improved, and the production efficiency of the hydrogen is improved.

Owner:SHANGHAI JIAO TONG UNIV

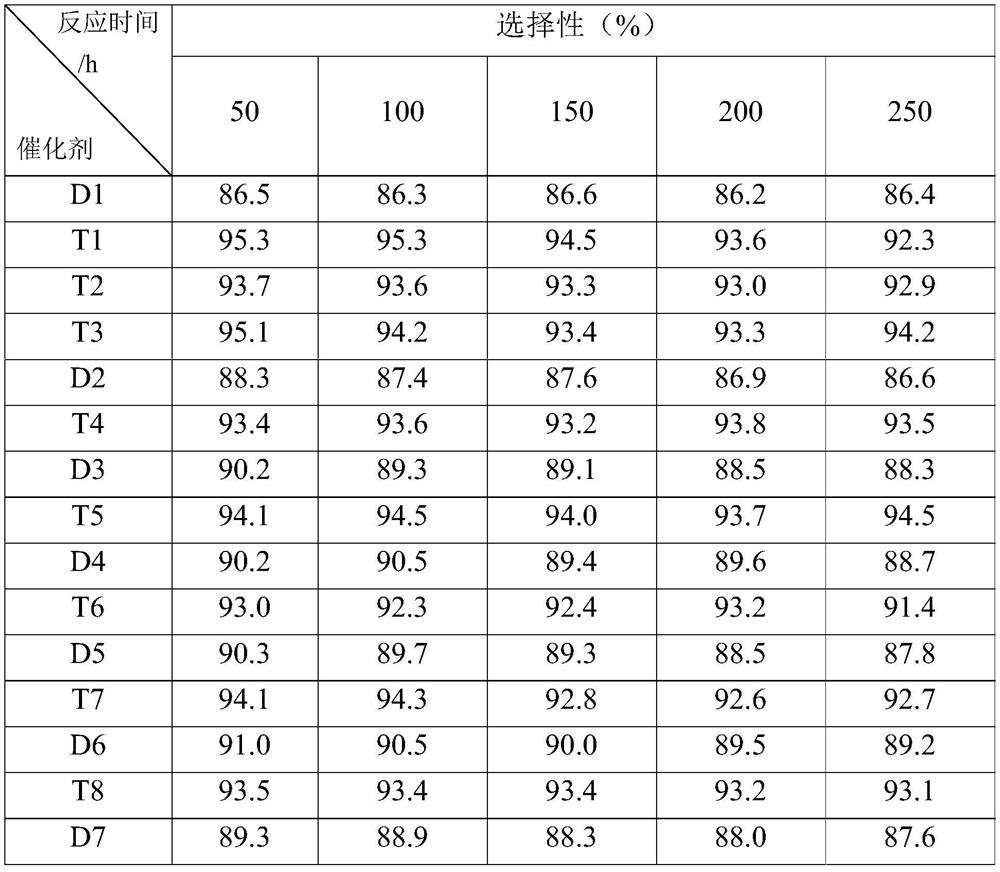

Alkyl anthraquinone hydrogenation method

ActiveCN113135818AExtended service lifeEasily brokenPhysical/chemical process catalystsOrganic compound preparationAnthraquinonesPtru catalyst

The alkylanthraquinone hydrogenation method is characterized by comprising the step of contacting alkylanthraquinone working fluid with hydrogen in the presence of a hydrogenation catalyst, the hydrogenation catalyst is characterized in that the hydrogenation catalyst takes phosphorus-modified activated aluminum oxide as a carrier, palladium and ruthenium as main active components and one or more of silver, copper, cobalt, lanthanum, cerium, manganese, iron and nickel as auxiliary active components, and in the phosphorus-modified activated aluminum oxide carrier, the mass content of phosphorus in the carrier is 0.1-30% the mass content of palladium and ruthenium in the catalyst is 0.01-10%, and the mass ratio of palladium to ruthenium is (0.2-6): 1; and the mass content of the auxiliary active component in the catalyst is 0-8%. According to the method, the requirement for the content of hydrogen impurities such as CO is not strict, and the service life of the catalyst is longer.

Owner:CHINA PETROLEUM & CHEM CORP +1

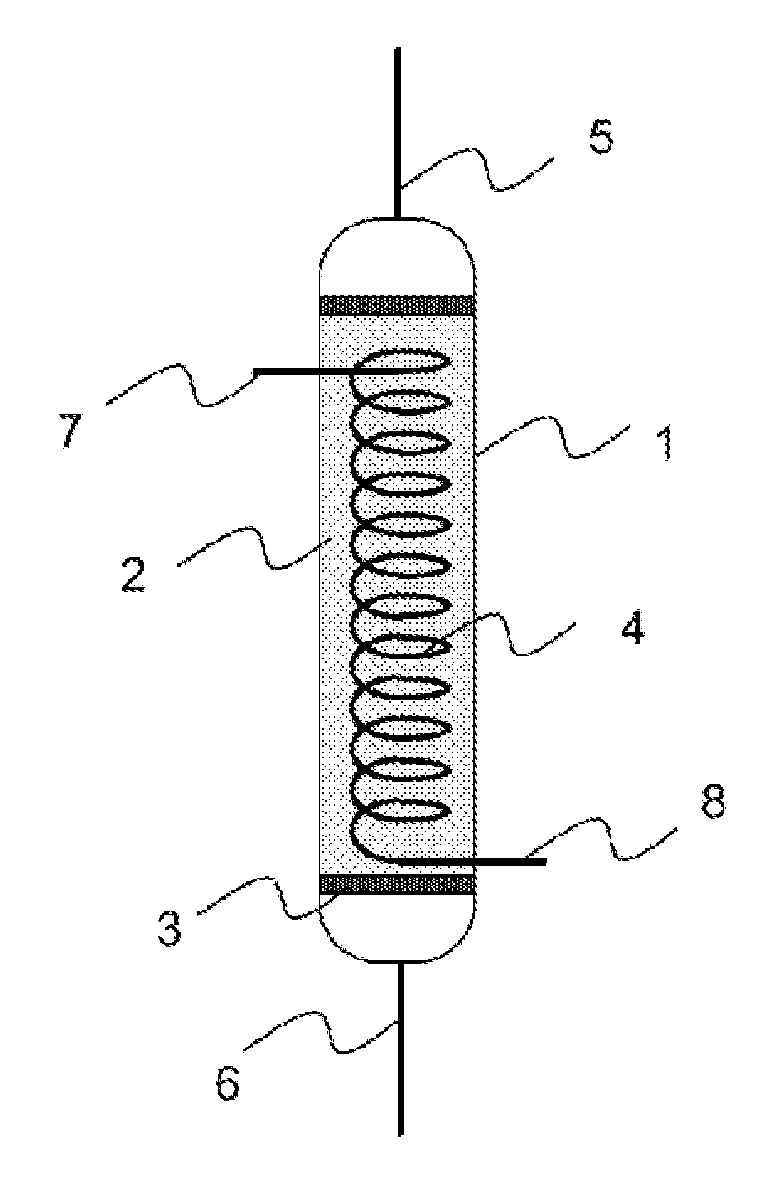

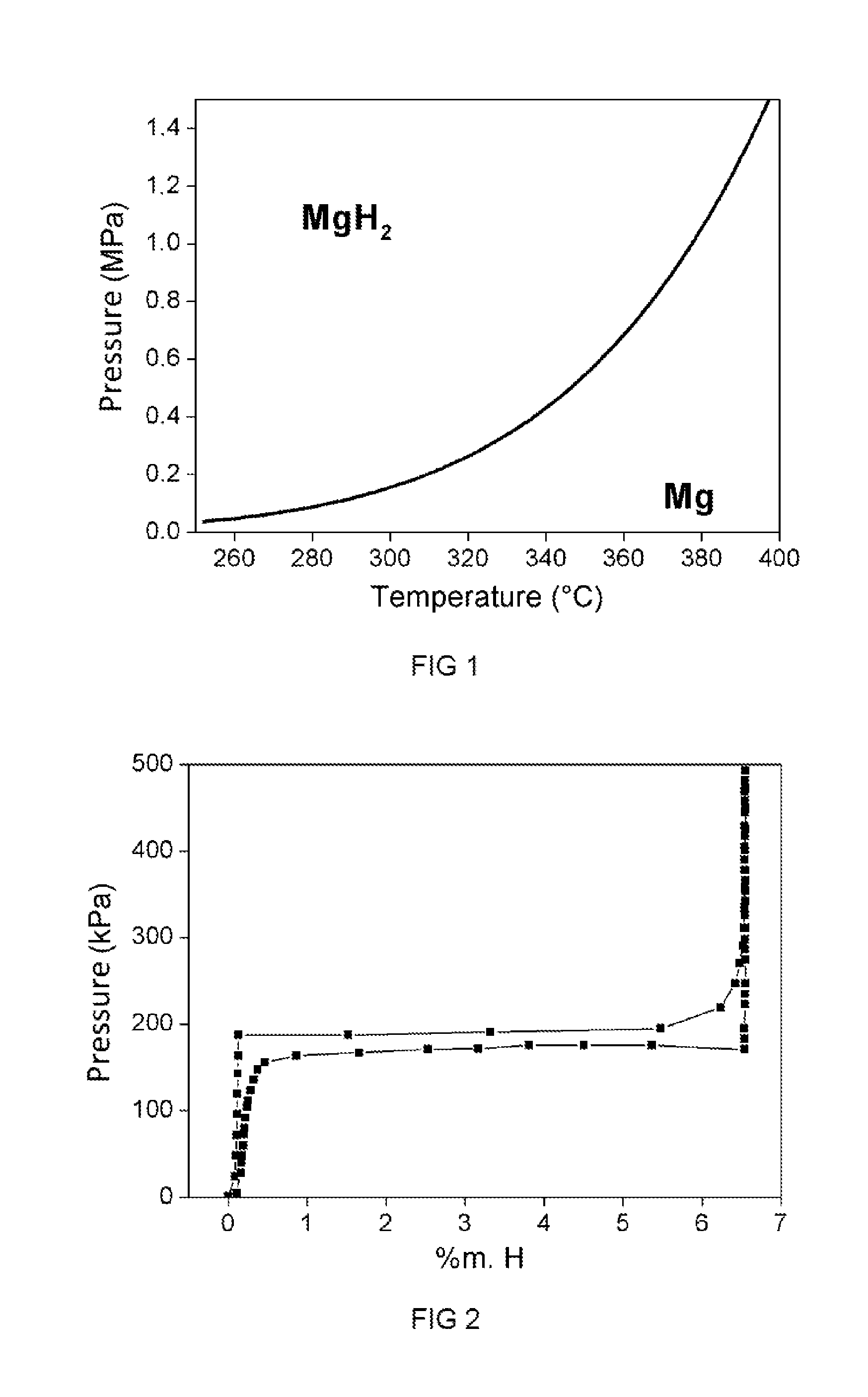

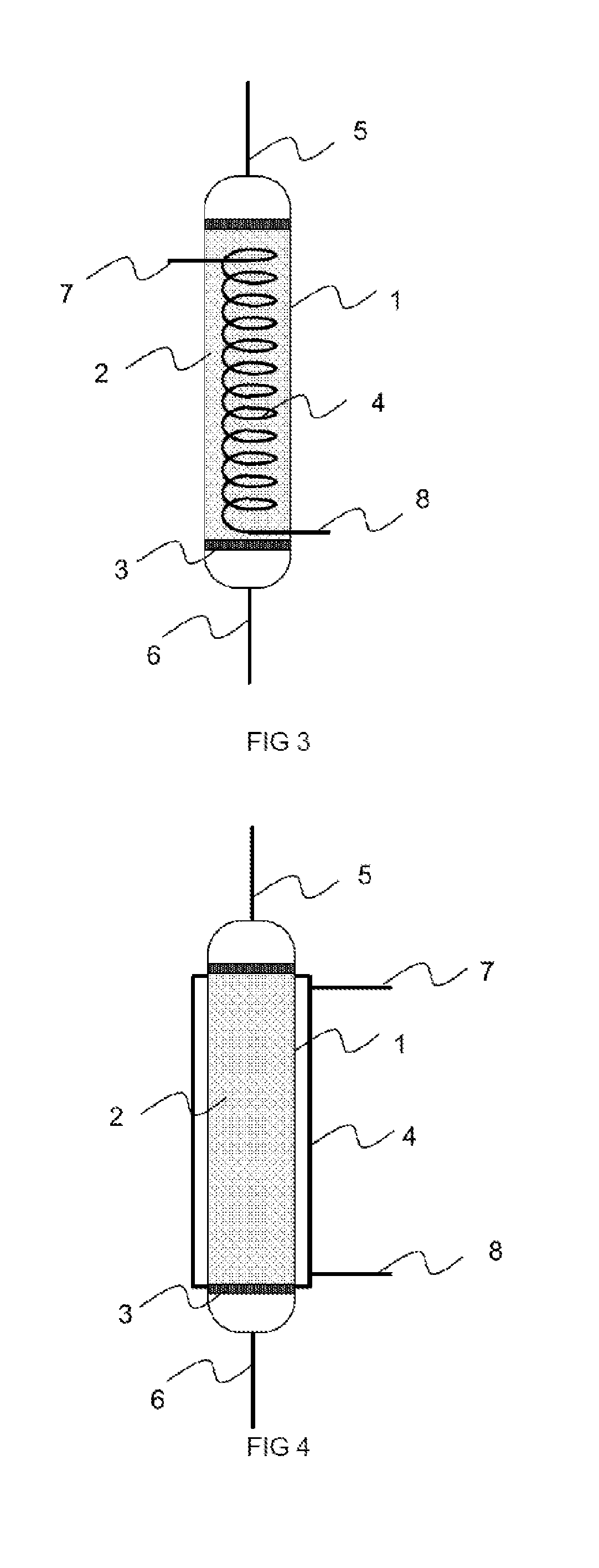

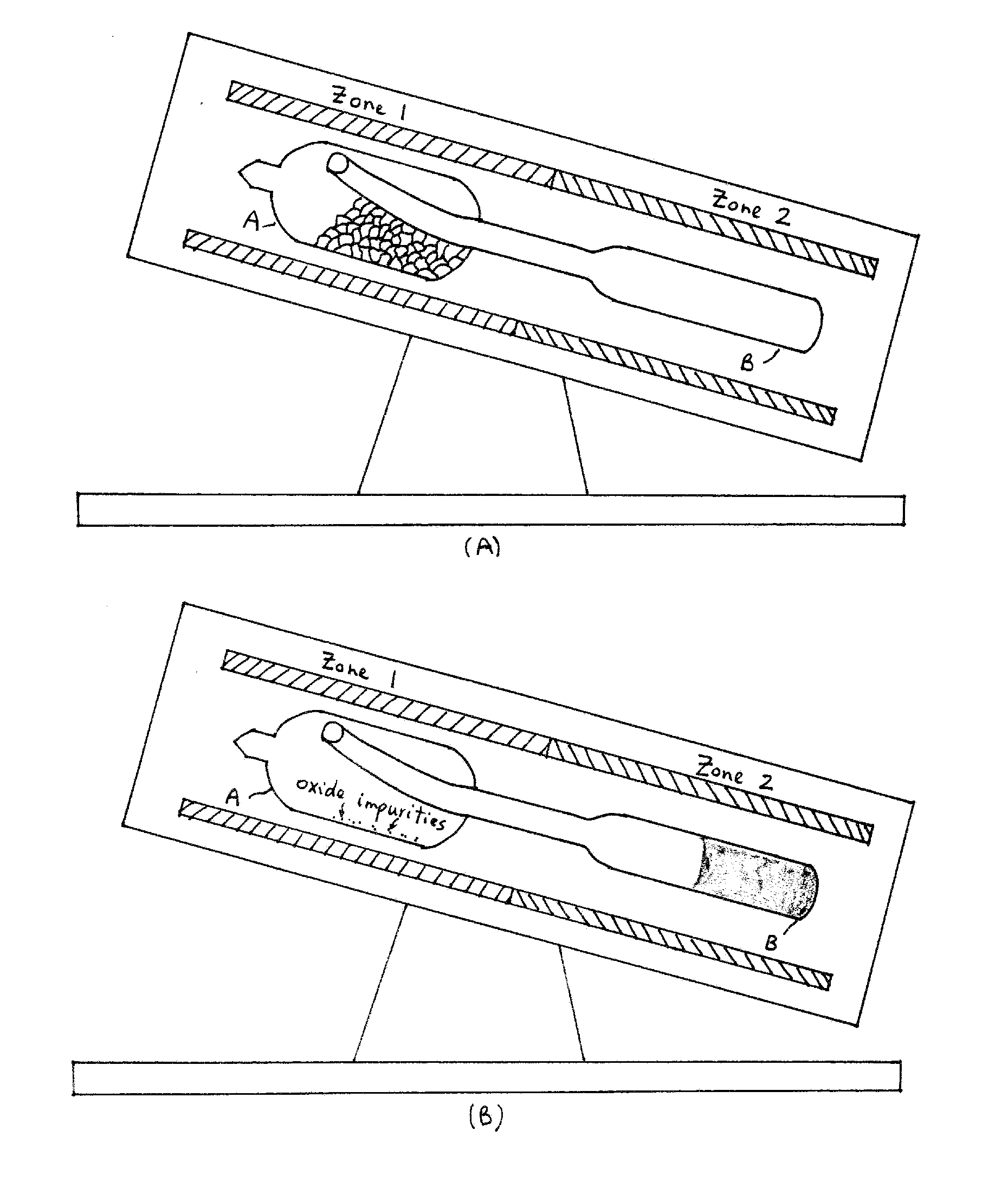

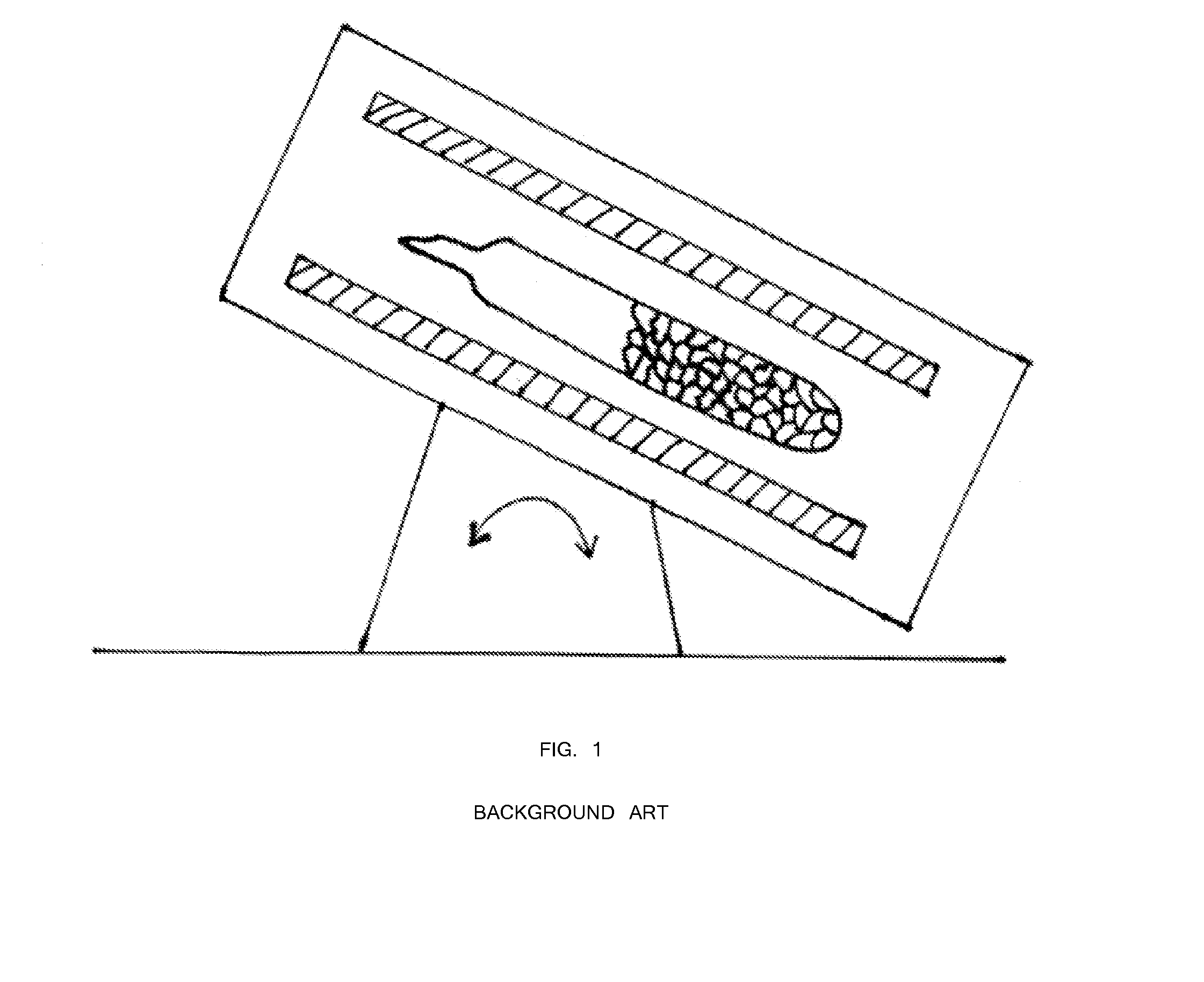

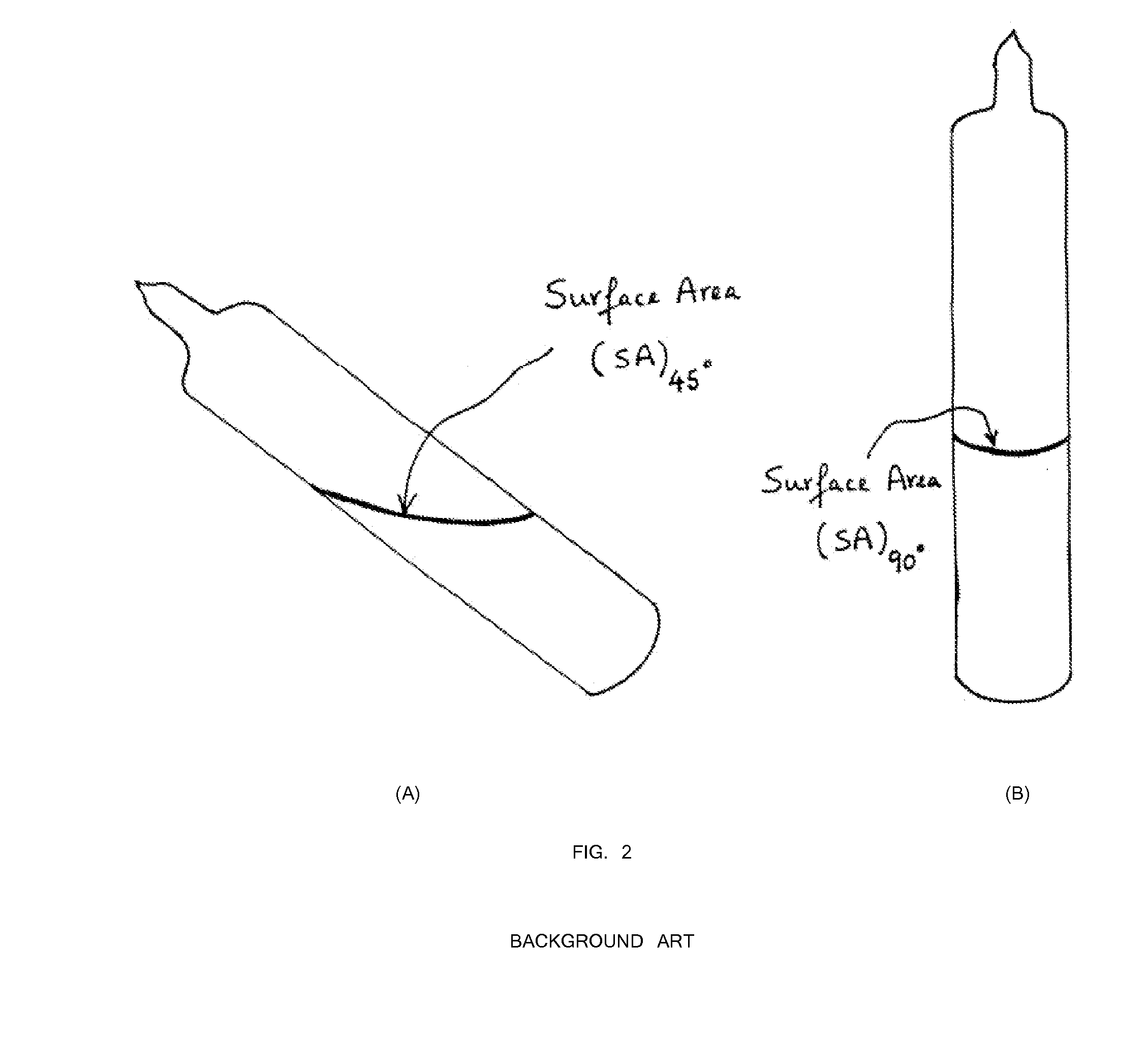

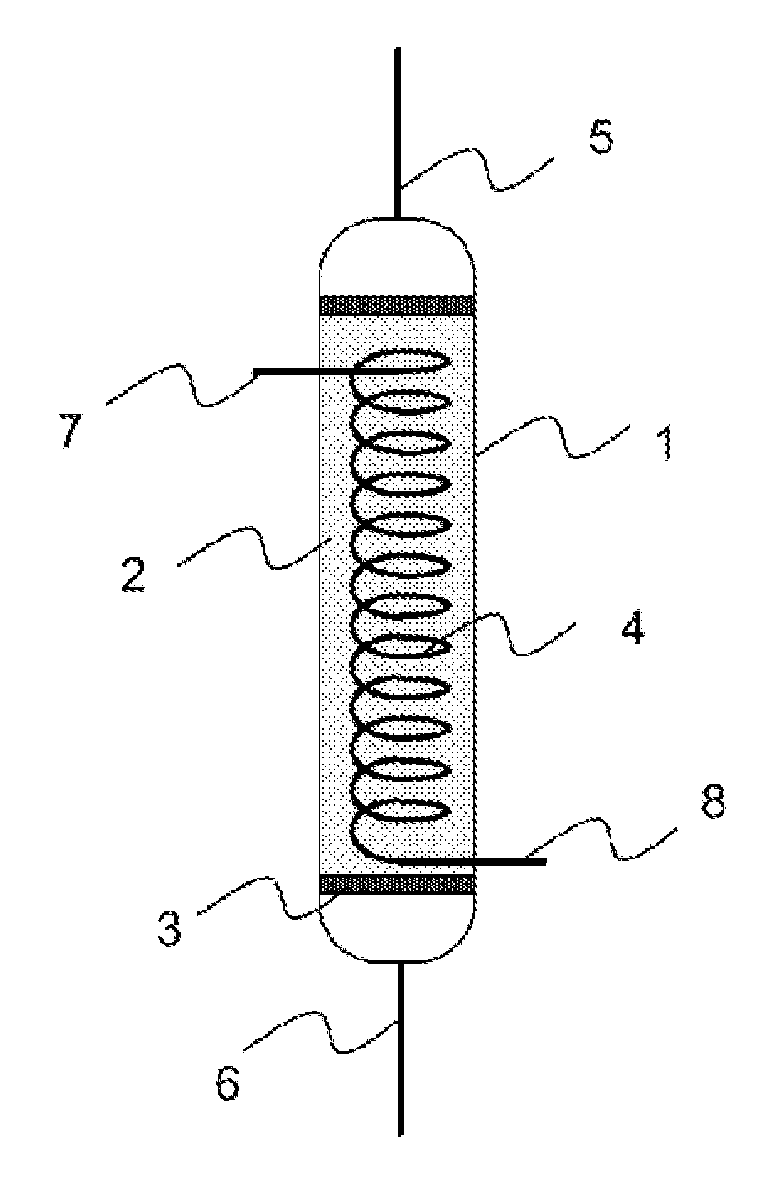

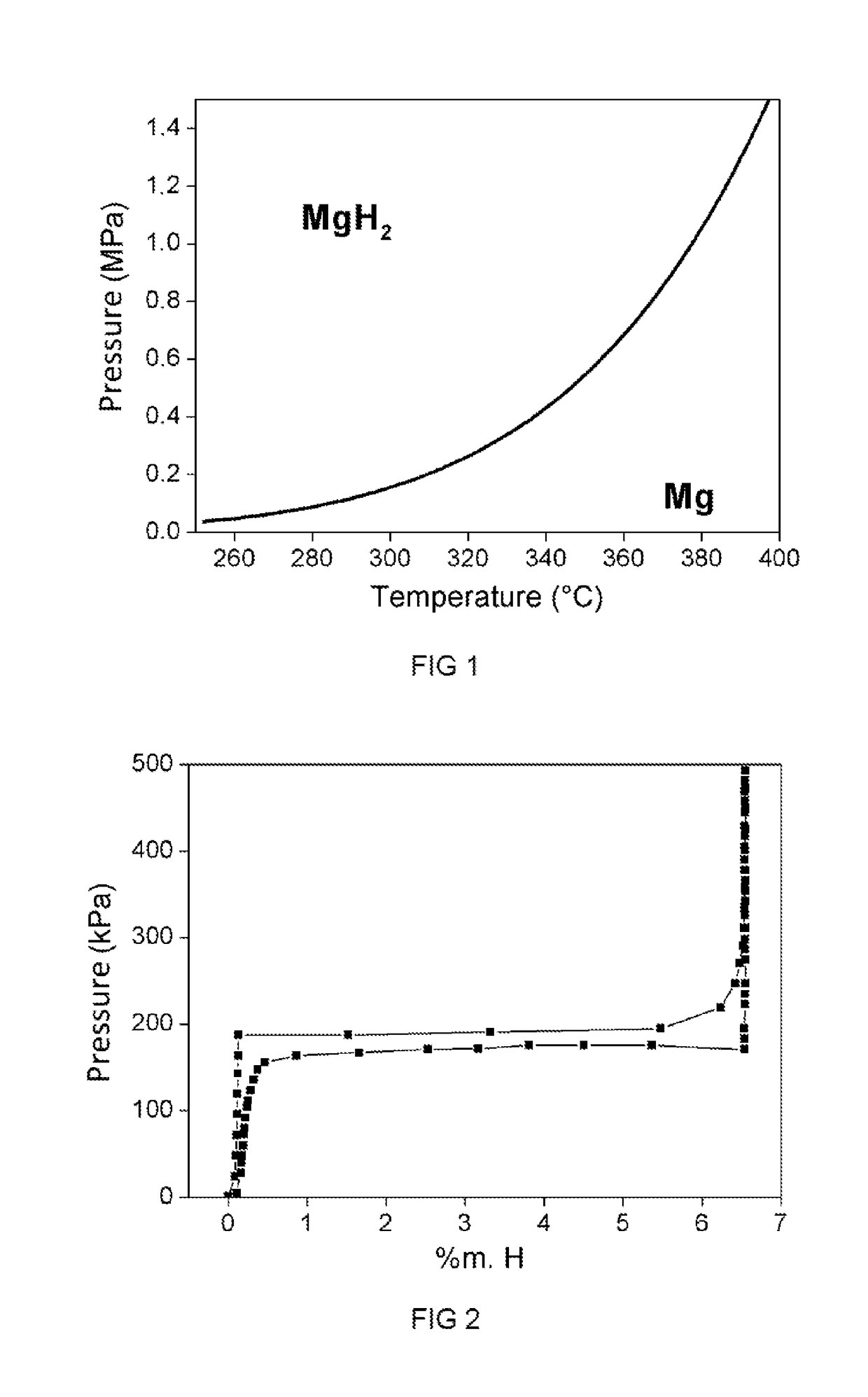

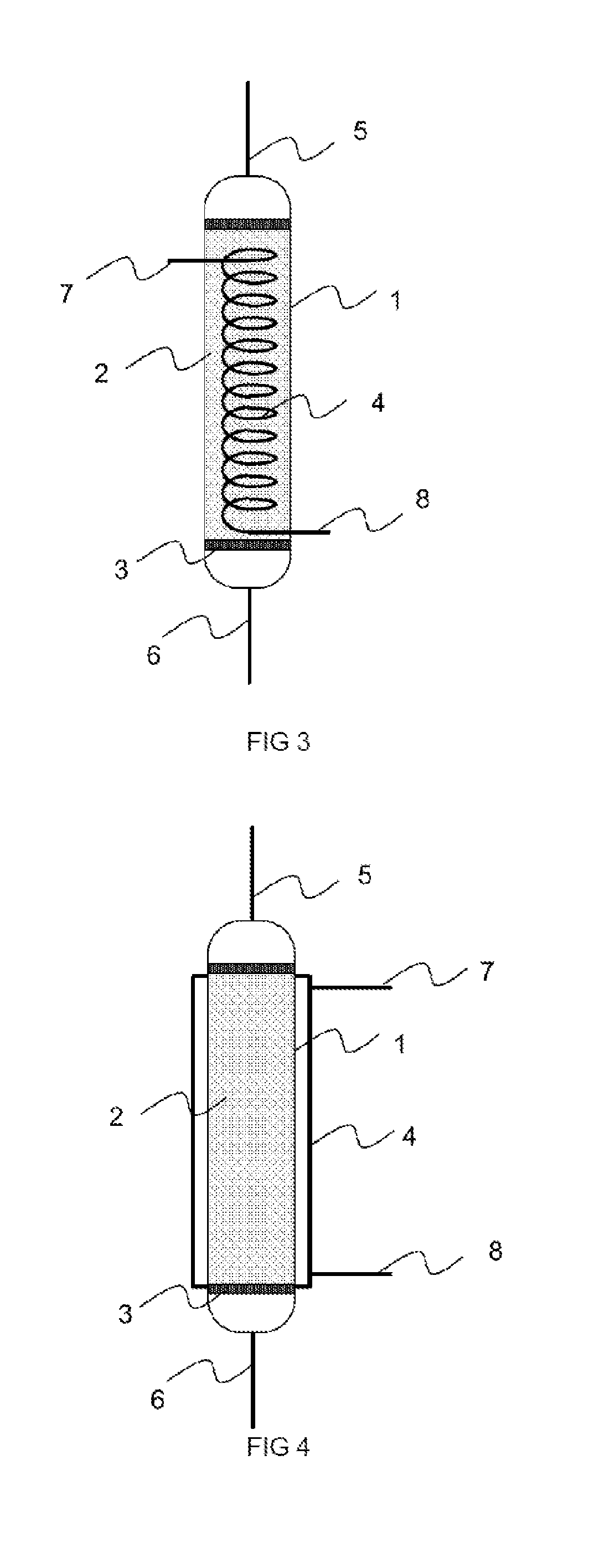

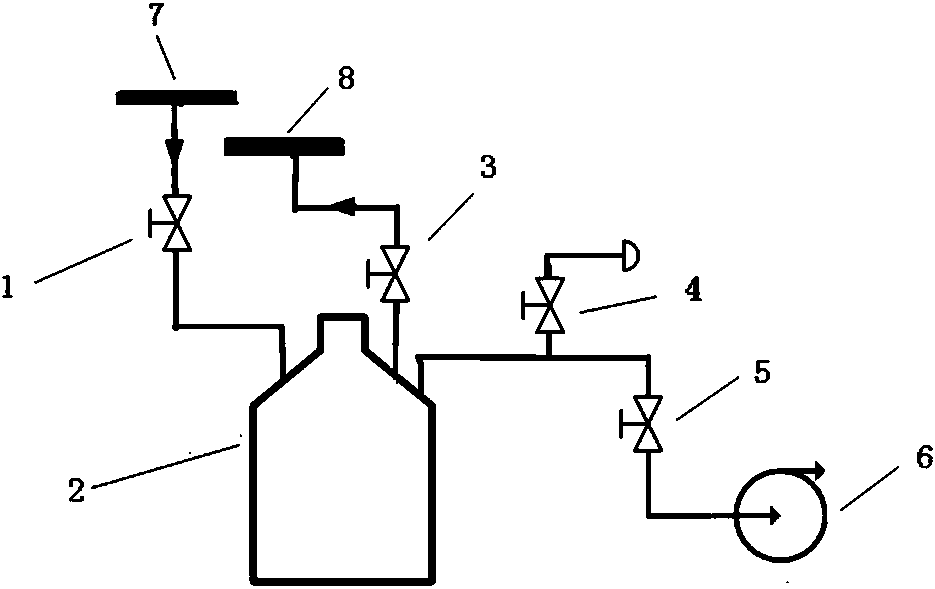

Regeneration of a hydrogen impurity trap using the heat exiting a hydride tank

ActiveUS20160206989A1Improve purification effectPromote regenerationGas treatmentReversible hydrogen uptakeNuclear engineeringHydrogen impurity

The storing and destocking of hydrogen in a hydride tank (10) comprises purification performed in at least one trap (1, 1A, 1B) filtering the impurities contained in the hydrogen entering the tank to be stored and regeneration of said at least one trap, using the heat carried by the hydrogen exiting the tank after it has been destocked.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Manufacturing process for chalcogenide glasses

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

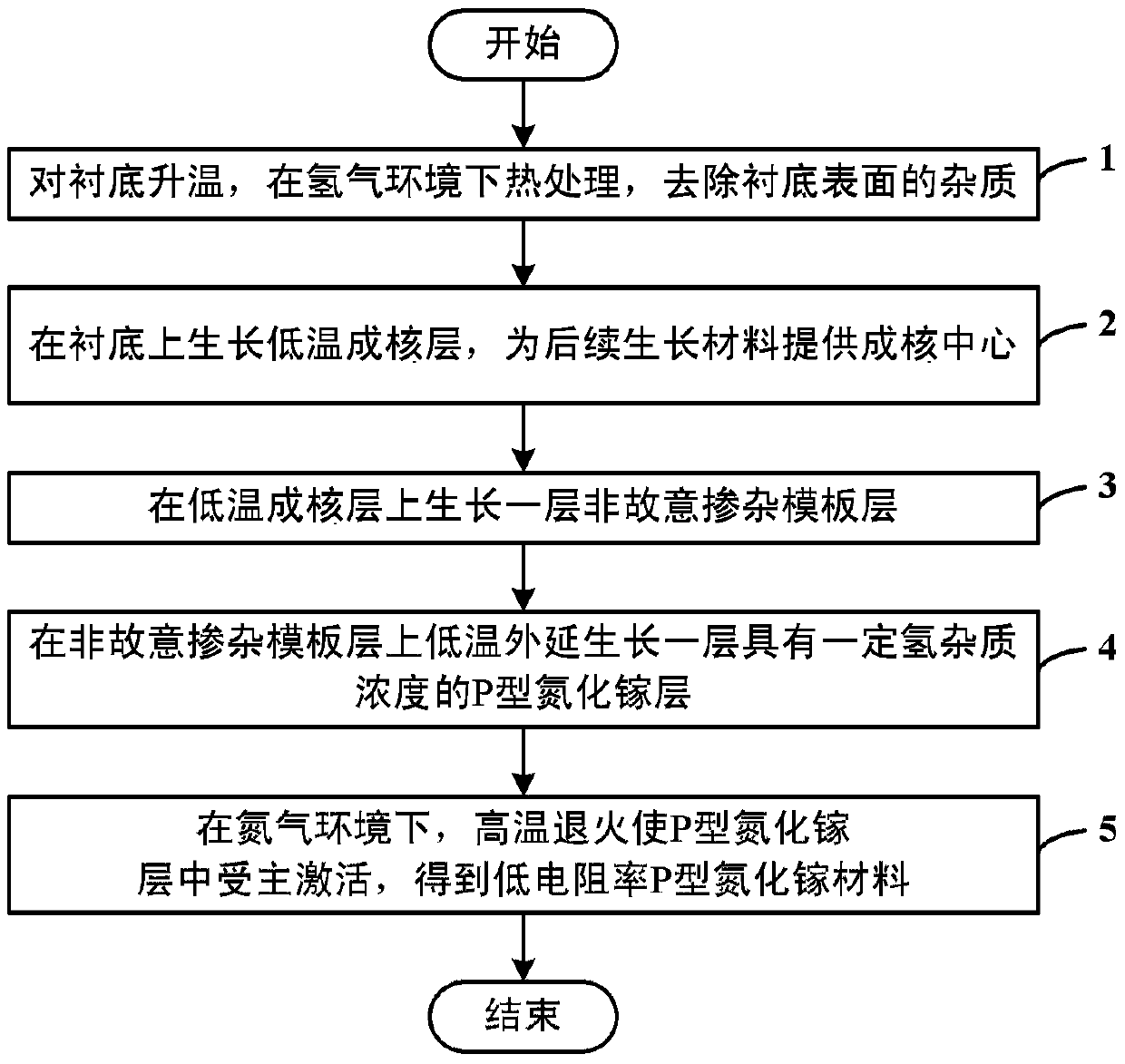

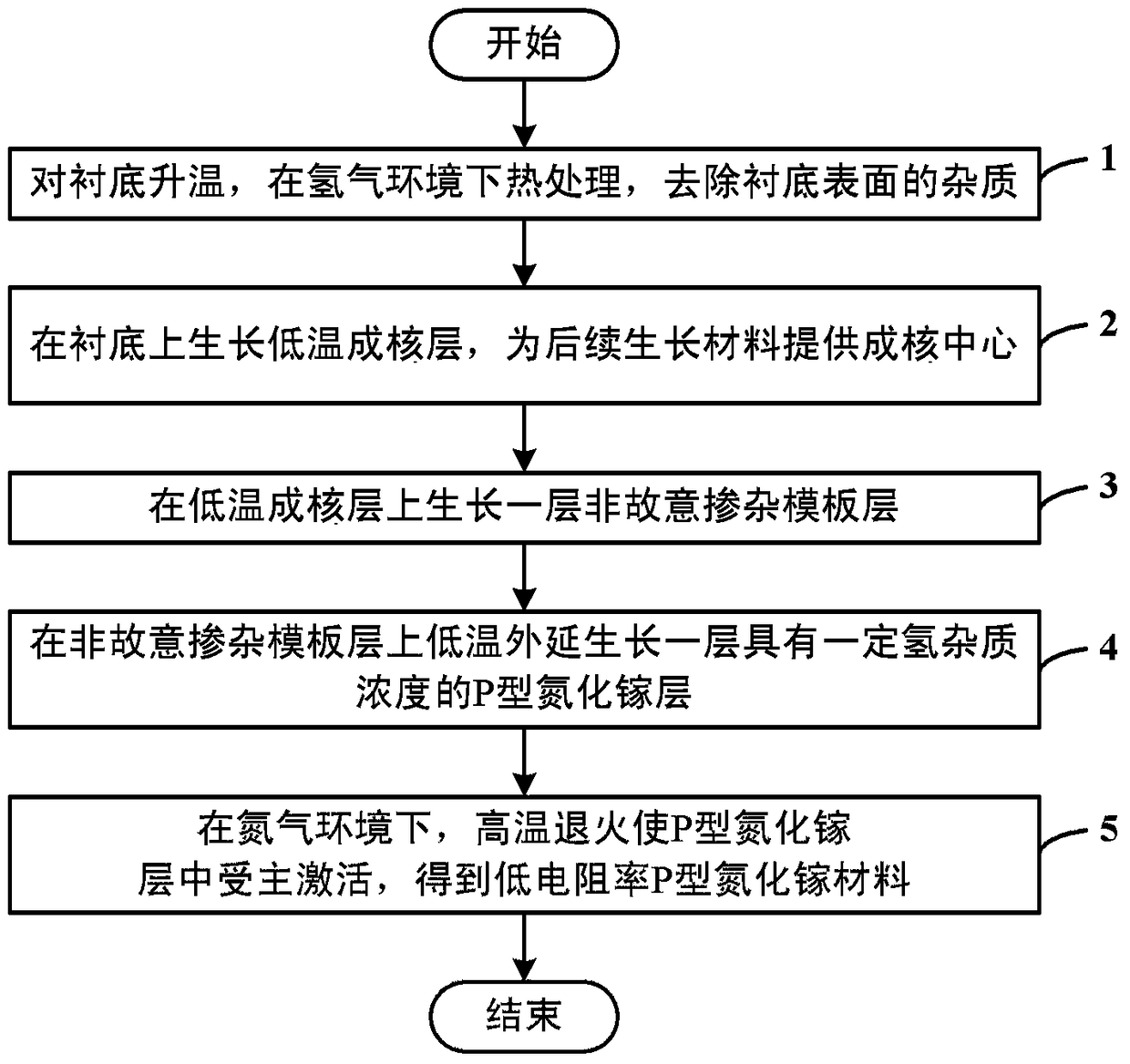

Low-resistivity P type gallium nitride material and preparation method thereof

ActiveCN105513951ALow resistivityReduced series resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMaterial growthCompensation effect

The invention discloses a low-resistivity P type gallium nitride material and a preparation method thereof. The preparation method comprises the following steps that: a substrate is heated, heat treatment is performed on the substrate under a hydrogen environment, so that impurities of the surface of the substrate can be removed; a low-temperature nucleating layer is grown on the substrate so as to provide a nucleation center for subsequent material growth; a non-intentionally-doped template layer is grown on the low-temperature nucleating layer; a P type gallium nitride layer with a certain hydrogen impurity concentration is grown on the non-intentionally-doped template layer through low-temperature epitaxial growth; under a nitrogen environment, high-temperature annealing is carried out, so that an acceptor in the P type gallium nitride layer is activated, so that the low-resistivity P type gallium nitride material can be obtained. According to the method of the invention, hydrogen impurities and donor defects (such as nitrogen vacancies) form complexes, so that donor defects can be passivated, and therefore, an acceptor compensation effect in the P type gallium nitride material can be reduced, and the resistivity of the P type gallium nitride material can be decreased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

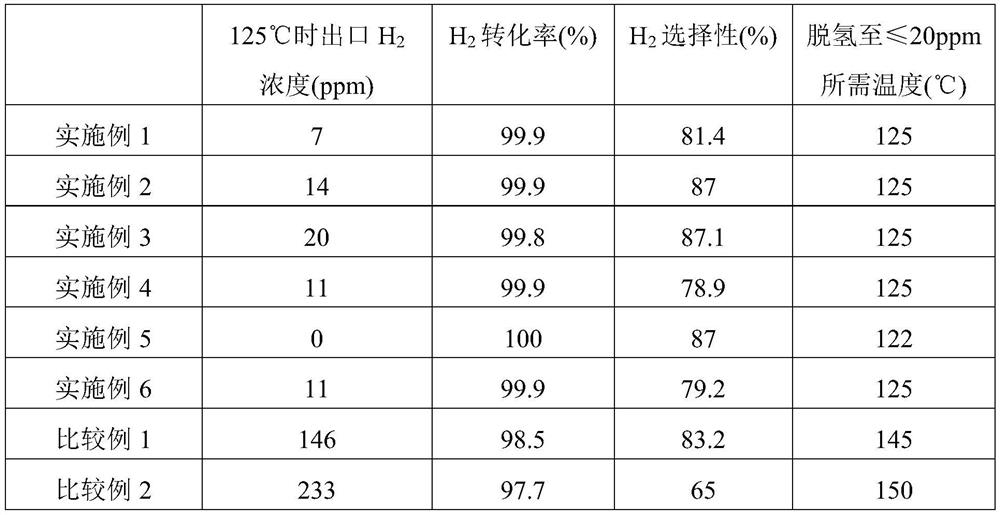

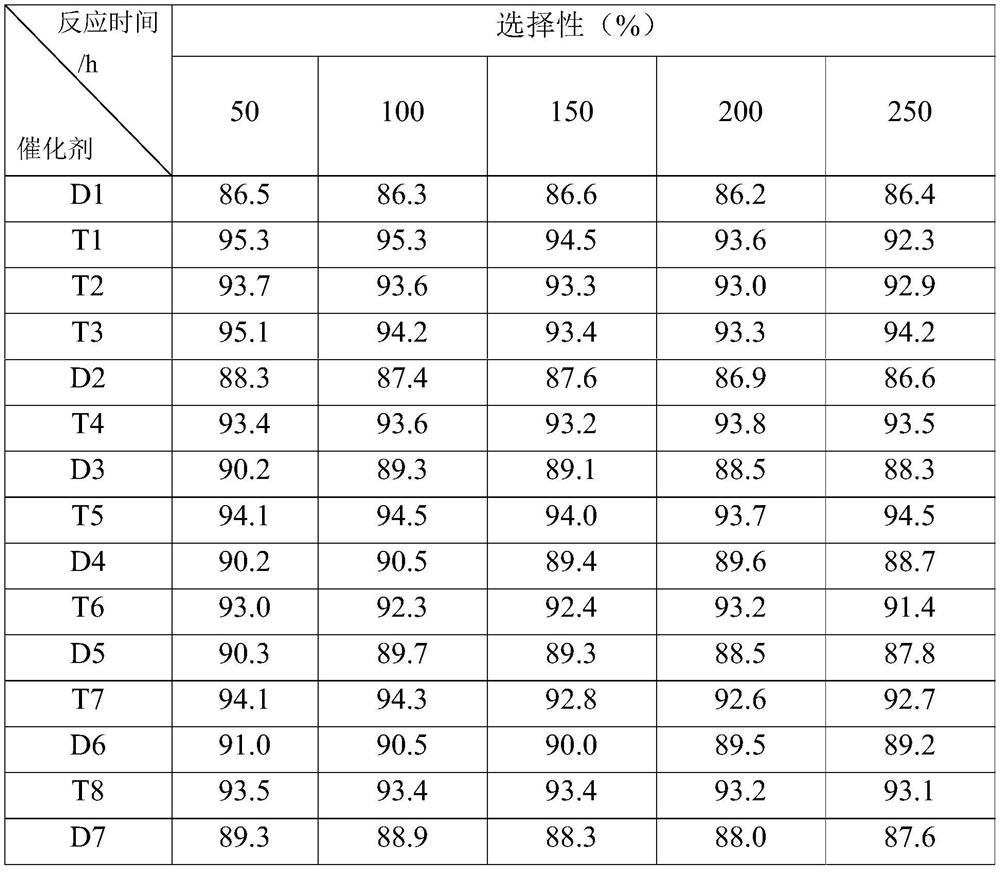

Method for removing hydrogen impurities in CO feed gas by using three-stage catalyst filling method

ActiveCN111762783AImprove low temperature dehydrogenation efficiencyReduce the risk of high temperature sinteringCarbon monoxideWaterPtru catalystProcess equipment

The invention provides a method for removing H2 impurities in CO feed gas by using a three-stage catalyst filling method. According to the change trend of the concentrations of reactants and productsin the whole catalyst bed layer and the difference of reaction heat effects, three catalysts with specific chemical structures and properties are designed and selected, the three catalysts are packedin different concentration intervals of a reaction bed layer according to a specific sequence and specific proportions, and reaction heat effect and a side reaction rate are synergistically controlledby utilizing respective chemical properties of the three catalysts. According to the method for removing H2 impurities in CO feed gas by using the three-stage catalyst filling method in the invention, on the basis that catalyst preparation cost and process equipment cost are not increased, the reaction temperature of the catalyst is reduced to 125-130 DEG C from 145-150 DEG C in the prior art, soenergy consumption can be substantially reduced, the thermal sintering risk of the catalyst is reduced, and the service life and the replacement period of the industrial catalyst can be easily prolonged; and the method has large-scale industrial application prospects.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Treatment methods for silicon nitride thin films

PendingCN111684566ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysical chemistryThin membrane

Embodiments herein provide for radical based treatment of silicon nitride layers deposited using a flowable chemical vapor deposition (FCVD) process. Radical based treatment of the FCVD deposited silicon nitride layers desirably increases the number of stable Si-N bonds therein, removes undesirably hydrogen impurities therefrom, and desirably provides for further crosslinking, densification, and nitridation (nitrogen incorporation) in the resulting silicon nitride layer. In one embodiment, a method of forming a silicon nitride layer includes positioning a substrate on a substrate support disposed in the processing volume of a processing chamber and treating a silicon nitride layer deposited on the substrate. Treating the silicon nitride layer includes flowing one or more radical species ofa first gas comprising NH3, N2, H2, Ar, He, or combinations thereof and exposing a silicon nitride layer to the radical species.

Owner:APPLIED MATERIALS INC

Regeneration of a hydrogen impurity trap using the heat exiting a hydride tank

ActiveUS20170157552A9Improve purification effectPromote regenerationGas treatmentReversible hydrogen uptakePhysical chemistryHydride

The storing and destocking of hydrogen in a hydride tank (10) comprises purification performed in at least one trap (1, 1A, 1B) filtering the impurities contained in the hydrogen entering the tank to be stored and regeneration of said at least one trap, using the heat carried by the hydrogen exiting the tank after it has been destocked.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for removing hydrogen impurity in CO feed gas by selective oxidation of NO

ActiveCN107235492BSolving the Problem of Synthetic Catalyst EfficiencySimple processGas treatmentDispersed particle separationGas compositionDecomposition

The invention discloses a method for removing an H2 impurity from CO raw gas through selective oxidation of NO. According to the method, NO completely or partially replaces O2 to serve as an oxidizing agent, and the H2 impurity in the CO raw gas can be removed through a selective oxidation reaction. The technical method comprises two stages of dehydrogenation processes, two catalysts with different ingredients and different effects are adopted for driving respectively, by means of layered dehydrogenation, the proportion of No, N2O and O2 in tail gas can be controlled flexibly, an operator performs specific adjustment conveniently according to the requirement of a follow-up CO synthetic process for raw gas composition, the whole process has higher efficiency and operability, and the problems of excessive O2 in the original dehydrogenation process, proneness of nitrite to decomposition in the follow-up CO synthetic process and the like are solved. The method can be applied to dehydrogenation purification of CO raw gas for synthesis of oxalate, carbonate and ethylene glycol.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

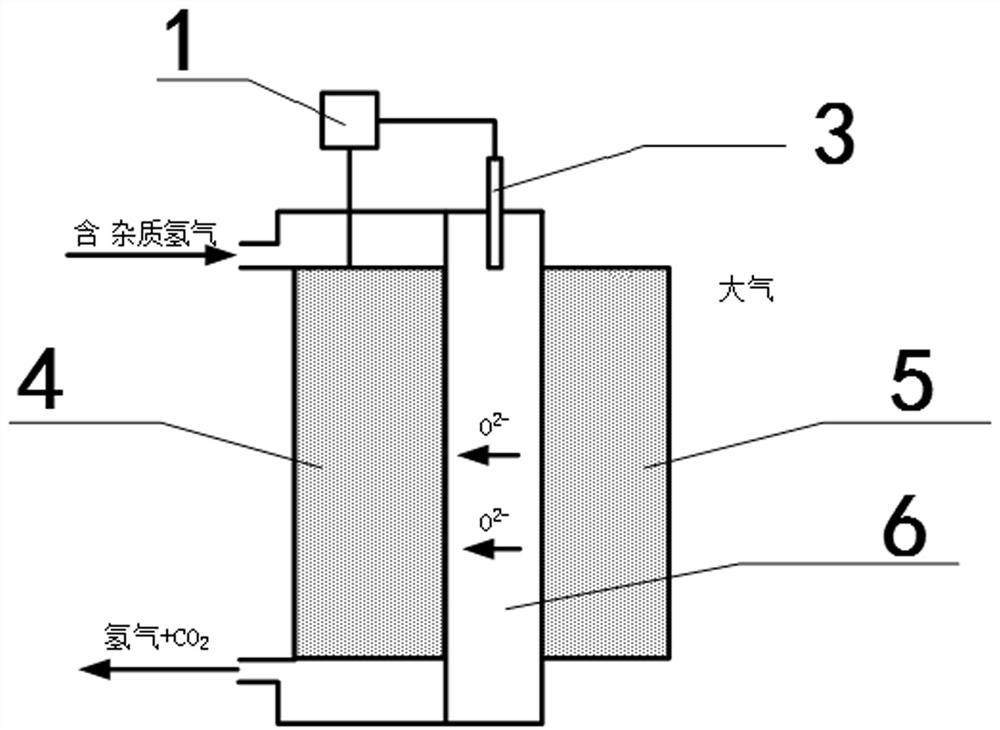

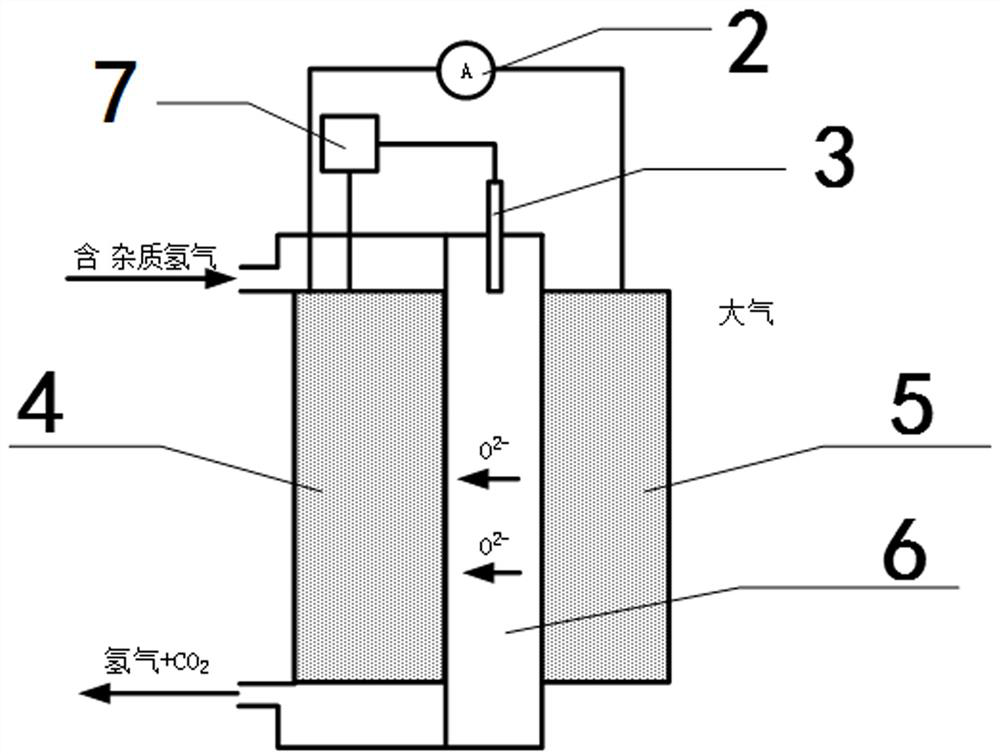

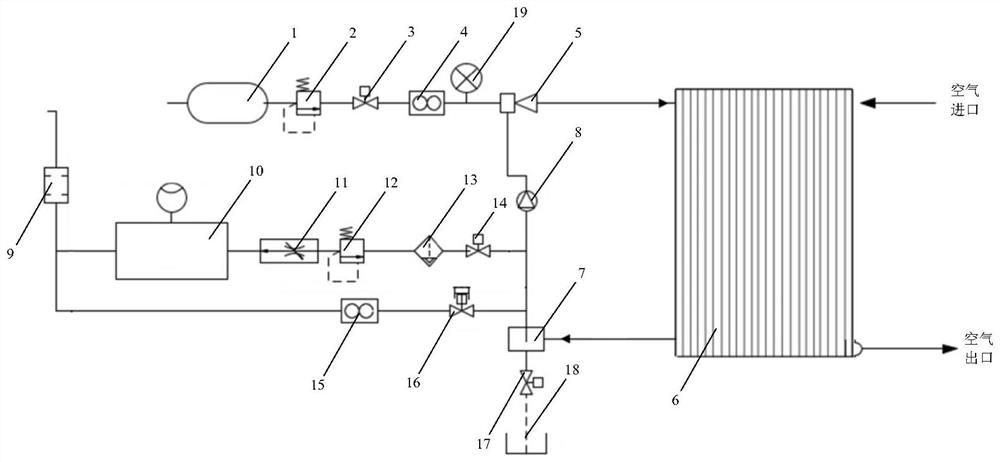

Hydrogen impurity purification device for fuel cell

ActiveCN114377525ALow purity requirementExpanding Hydrogen SourcesGas treatmentDispersed particle separationElectrochemical responseOxygen ions

The invention provides a hydrogen impurity purification device for a fuel cell, belongs to the technical field of fuel cells, and solves the problems that the existing PSA (Pressure Swing Adsorption) technology has more working procedures, complicated equipment and large occupied area, so that the use is limited. The apparatus includes a solid state electrochemical reactor and a controller. Wherein the solid-state electrochemical reactor further comprises an anode diffusion electrode layer, an electrolyte layer for transmitting oxygen ions, a cathode diffusion electrode layer and a reference electrode. A to-be-purified hydrogen inlet and a purified hydrogen outlet are respectively formed in two sides of the anode diffusion electrode layer; the cathode diffusion electrode layer is in contact with air and is isolated from the anode diffusion electrode layer through the electrolyte layer; the reference electrode is arranged in the electrolyte layer; and the controller is used for controlling the potential of the anode diffusion electrode layer of the solid-state electrochemical reactor to be the oxidation-reduction potential of the impurities after being started, so that the impurities are subjected to oxidation-reduction reaction to be converted into other component substances which have no or less influence on the fuel cell.

Owner:BEIJING SINOHYTEC

A kind of method of alkylanthraquinone hydrogenation

ActiveCN113135818BExtended service lifeEasily brokenPhysical/chemical process catalystsOrganic compound preparationAnthraquinonesPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

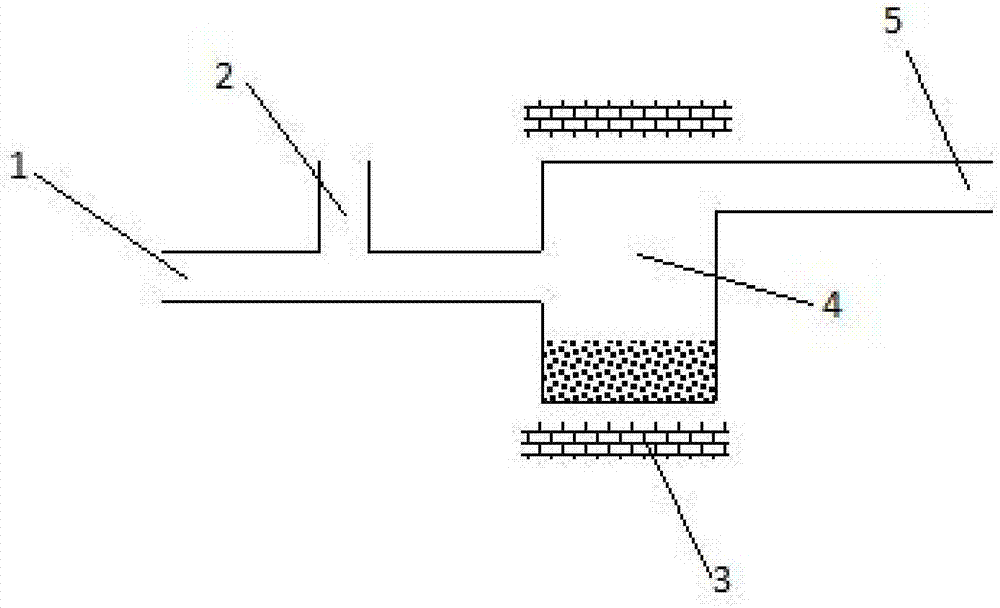

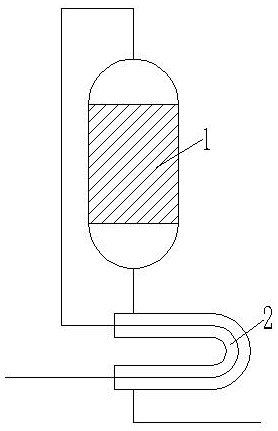

A device and method for removing hydrogen impurities in a cold neutron source system

ActiveCN106365133BImprove adsorption capacityNot easy to polluteNoble gas compoundsSpecific gas purification/separationPressure differenceHigh pressure

The present invention discloses an apparatus and a method for removing hydrogen impurities in a cold neutron source system. The apparatus makes use of the pressure difference of helium between high pressure helium pipelines and low pressure helium pipelines in the cold neutron source system, the hydrogen impurities in the cold neutron source system are removed by an adsorption device, wherein the adsorption device has strong adsorption capacity and the adsorbent in the adsorption device is easy to reproduce; the absorbed hydrogen impurities are concentratedly discharged to the outside of the cold neutron source system, so that process gas in the cold neutron source system is not easy to be polluted, and bad consequences that the accumulation of the hydrogen impurities in a low temperature region of the cold neutron source system leads to hydrogen embrittlement of structural materials to make the structural materials lose efficacy can be effectively avoided.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Low-resistivity p-type gallium nitride material and preparation method thereof

ActiveCN105513951BLow resistivityReduced series resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMaterial growthCompensation effect

The invention discloses a low-resistivity P type gallium nitride material and a preparation method thereof. The preparation method comprises the following steps that: a substrate is heated, heat treatment is performed on the substrate under a hydrogen environment, so that impurities of the surface of the substrate can be removed; a low-temperature nucleating layer is grown on the substrate so as to provide a nucleation center for subsequent material growth; a non-intentionally-doped template layer is grown on the low-temperature nucleating layer; a P type gallium nitride layer with a certain hydrogen impurity concentration is grown on the non-intentionally-doped template layer through low-temperature epitaxial growth; under a nitrogen environment, high-temperature annealing is carried out, so that an acceptor in the P type gallium nitride layer is activated, so that the low-resistivity P type gallium nitride material can be obtained. According to the method of the invention, hydrogen impurities and donor defects (such as nitrogen vacancies) form complexes, so that donor defects can be passivated, and therefore, an acceptor compensation effect in the P type gallium nitride material can be reduced, and the resistivity of the P type gallium nitride material can be decreased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

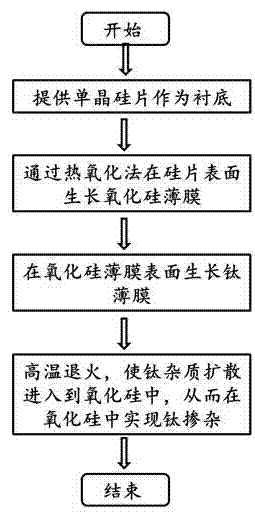

Titanium-doped high-quality silicon oxide film and preparation method therefor

InactiveCN106876448AReduce formationImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesOxygen vacancyProton

The invention provides a titanium-doped high-quality silicon oxide film and a preparation method therefor. A related device includes but is not limited to an MOS device and a bipolar transistor. Through the adding of titanium impurity to gate oxide or buried oxide, the combination between oxygen vacancy and hydrogen impurity can be weakened, and the inhibition of the release of protons follows. Finally, the forming of charges at a SiO2 / Si interface state and in SiO2 is inhibited at the same time. Titanium-doped silicon oxide serves as the gate oxide or buried oxide, so the film can iron out the defects that the conventional Al, Cr, O and Si doping just can inhibit the forming of charges in the SiO2 but cannot remarkably reduce the SiO2 / Si interface state, thereby remarkably improving the electrical performance of MOS and BJT and other silicon-base devices and the stability in a severe environment.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

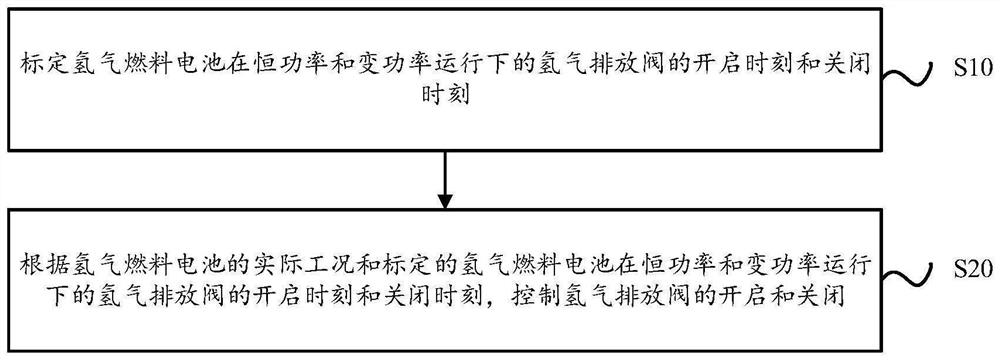

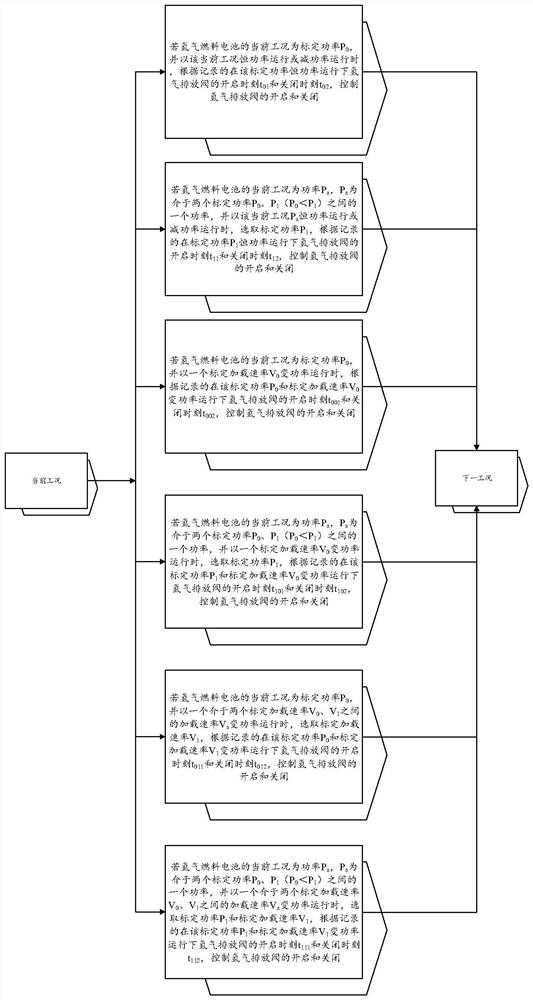

Hydrogen emission control method for hydrogen fuel cell

The invention discloses a hydrogen emission control method for a hydrogen fuel cell, and relates to the technical field of fuel cells, and the method comprises the following steps: step S10, calibrating the opening time and the closing time of a hydrogen emission valve of the hydrogen fuel cell under constant-power and variable-power operation; and step S20, controlling the opening and closing of the hydrogen discharge valve according to the actual working condition of the hydrogen fuel cell and the calibrated opening time and closing time of the hydrogen discharge valve when the hydrogen fuel cell operates at constant power and variable power. The hydrogen discharge amount can be accurately controlled, on one hand, performance reduction of the hydrogen fuel cell caused by accumulation of hydrogen impurity gas and redundant water vapor can be prevented, on the other hand, over-high-frequency hydrogen discharge is prevented, and the hydrogen utilization rate is increased.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

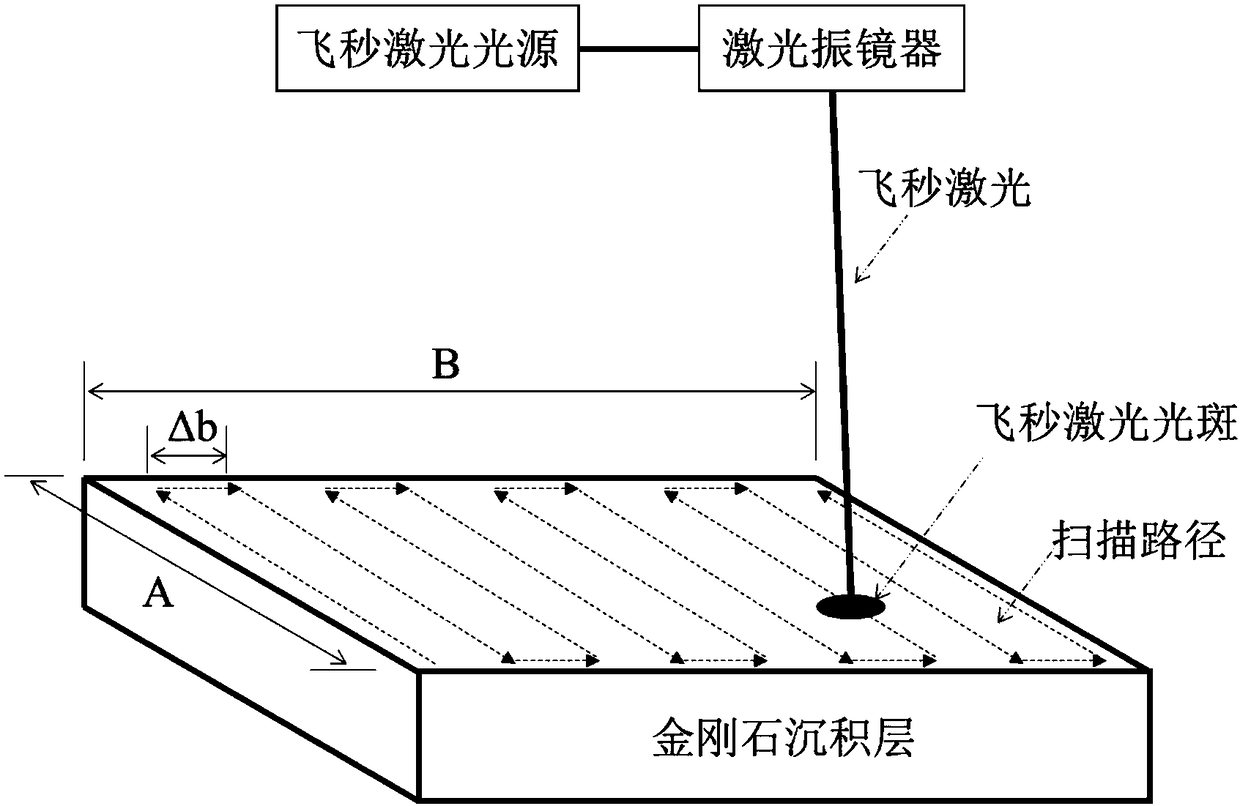

Method and device for removing hydrogen impurities in preparation process of n-type phosphorus doped diamond membrane

The invention discloses a method and device for removing hydrogen impurities in the preparation process of an n-type phosphorus doped diamond membrane. According to the method, femtosecond laser and atemperature field are simultaneously applied in the preparation process of an n-type phosphorus doped diamond membrane, only phosphorus hydrogen bond electrons in the n-type phosphorus doped diamondmembrane are excited to an excited state by the femtosecond laser, and only phosphorus bonds of valence electrons at the excited state are broken through the temperature field, so that the hydrogen element in the membrane can be removed. By applying the femtosecond laser and the temperature field in the preparation process of the n-type phosphorus doped diamond membrane, the phosphorus hydrogen bonds in the n-type phosphorus doped diamond membrane are broken, the hydrogen element in the membrane can be removed, and furthermore the electric properties of n-type phosphorus doped diamonds can beimproved.

Owner:WUHAN UNIV

A simulation method for removing hydrogen impurities from n-type phosphorus-doped diamond films

ActiveCN108425106BReduce hydrogen contentImprove electrical performanceAfter-treatment detailsChemical vapor deposition coatingValence electronFirst principle

The invention discloses a simulation method for removing the hydrogen impurity in an n-type phosphorus doping diamond film. According to time dependent density functional theory and the molecular dynamics theory, the first principle and molecular dynamics calculation is conducted on an n n-type phosphorus doping diamond film model, photon absorption, valence electron transition and chemical bond breakage in the model are simulated under a laser field and a temperature field, and the method for removing the hydrogen element impurity in the n-type phosphorus doping diamond film is further provided. The strength, the frequency and the range value of the temperature of femtosecond lasers which can break phosphorus and hydrogen bonds and remove the hydrogen impurity are calculated.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com