Regeneration of a hydrogen impurity trap using the heat exiting a hydride tank

a technology of hydride tank and heat exiting, which is applied in the direction of fixed capacity gas holders, gas/liquid distribution and storage, gas treatment, etc., can solve the problems of degrading the storage performance of hydrides, inapplicable to large amounts of hydrogen to be purified, and done at the expense of weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

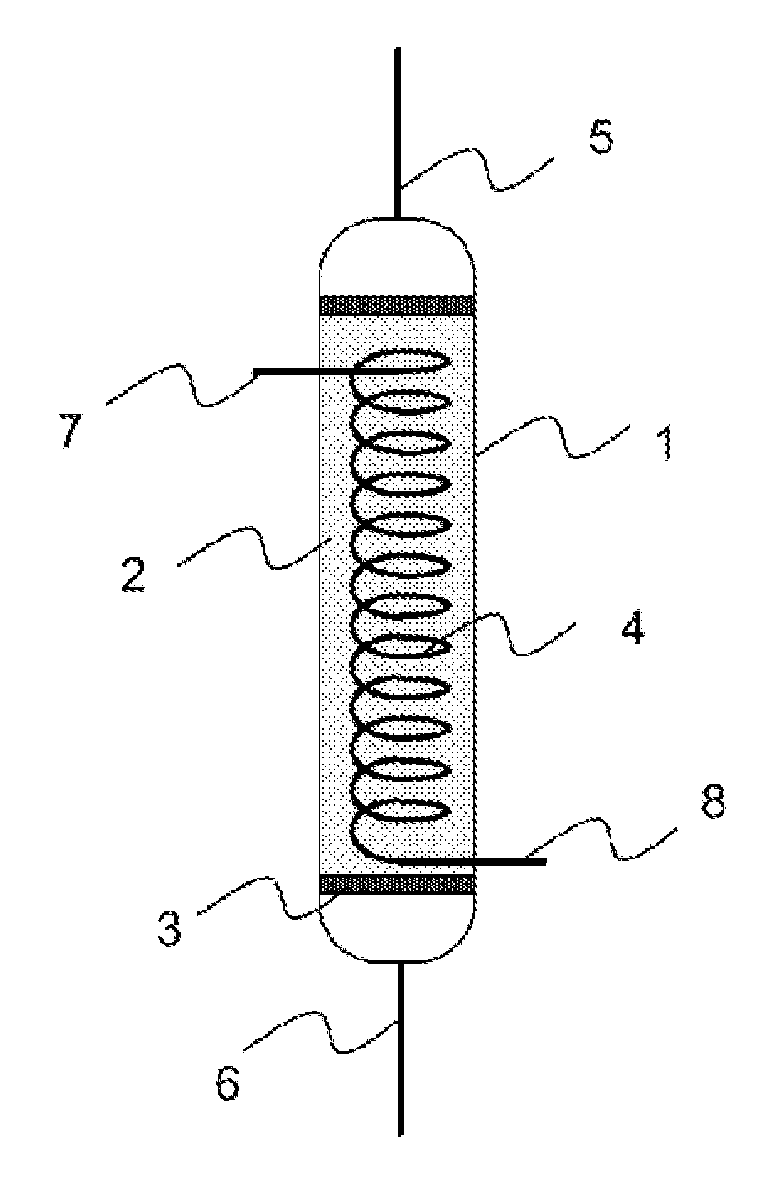

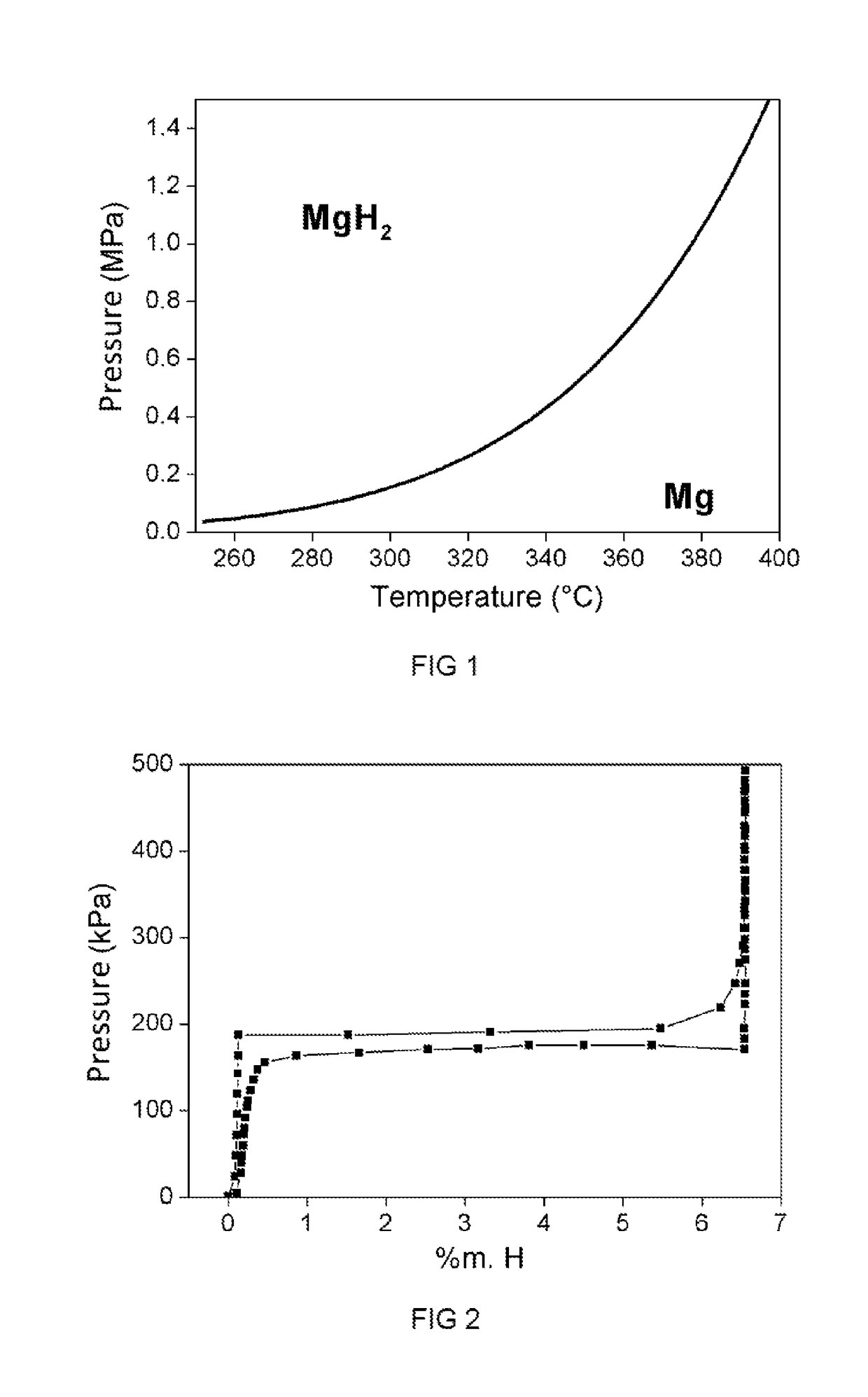

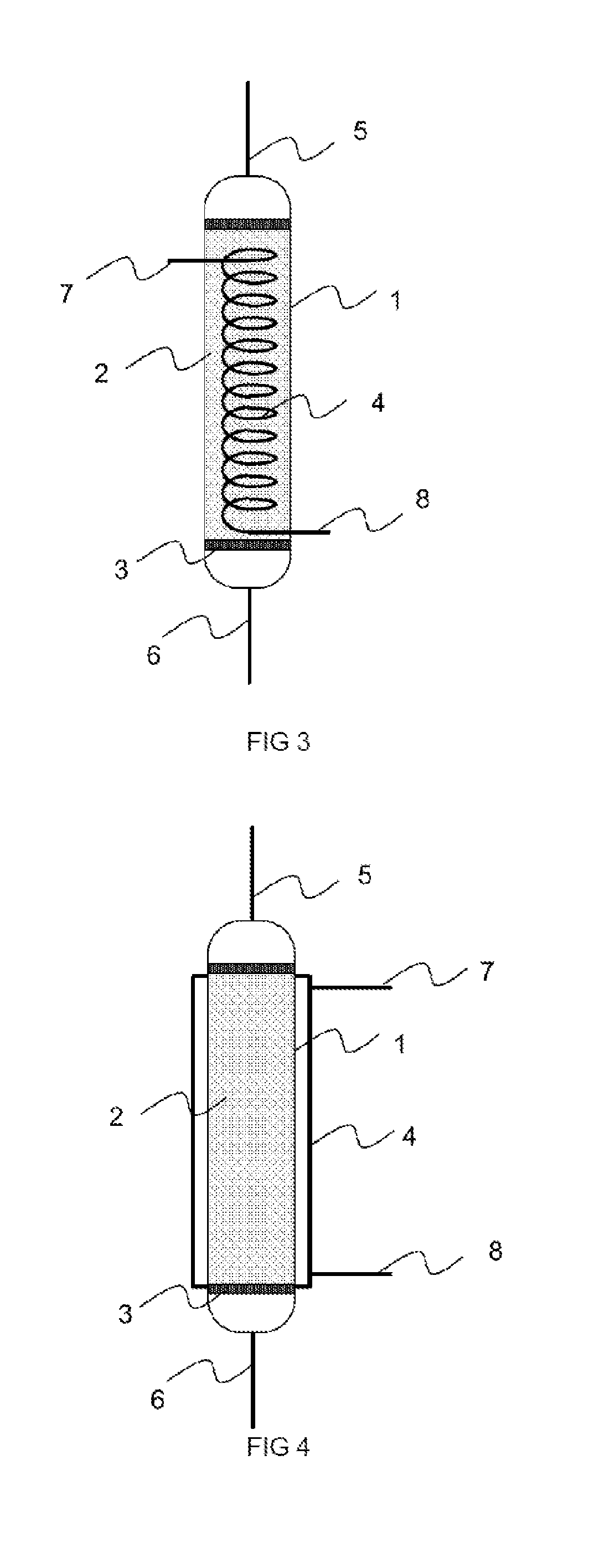

[0070]In general, and with reference to FIGS. 3 to 10, the invention relates to a process and an installation for storing and destocking hydrogen in a hydride tank 10. The hydride tank 10 may especially comprise magnesium-based hydrides, without this limiting the field of application.

[0071]The solution proposed is particularly suited to hydrides operating at low pressure (1 to 20 bar) and at high temperature (between 200 and 400° C.). These hydrides must, by their nature, be brought to high temperature in order to be able to release the stored hydrogen. The hydrogen then exits hot from the tank. This may concern the field of hydrogen storage for feeding fuel cells, hydrogen turbines, heat engines or the industry using hydrogen.

[0072]The process comprises a purification step performed on at least one trap that filters out the impurities contained in the hydrogen entering the tank 10 for storage and a step of regenerating said at least one trap, using the heat carried by the hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com