Titanium-doped high-quality silicon oxide film and preparation method therefor

A silicon oxide, high-quality technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the electrical performance and stability of silicon-based devices that cannot be effectively met, and achieve the effect of reducing the formation of charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

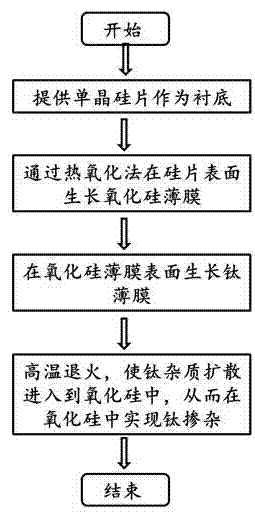

Method used

Image

Examples

Embodiment 1

[0024] (1) Select p-type silicon with a crystal orientation of and a resistivity of 10 Ω.cm;

[0025] (2) Use pure oxygen as a protective atmosphere, and use wet oxygen oxidation process to grow SiO on the surface of the silicon wafer described in step (1). 2 Thin film, the thermal oxidation temperature used is 900 °C, and the silicon oxide thickness obtained is 30 nm;

[0026] (3) growing a 10 nm thick titanium film on the silicon oxide surface described in step (2);

[0027] (4) Using argon as a protective atmosphere, subject the silicon wafer described in step (3) to subsequent annealing at 850 °C.

[0028] The subsequent annealing process described in step (4) is aimed at two aspects: on the one hand, through high-temperature annealing under argon gas, the concentration of oxygen vacancies is reduced, and the electrical properties of silicon-based devices and their stability in harsh environments are improved. On the other hand, high-temperature annealing makes titanium...

Embodiment 2

[0030] (1) Select n-type silicon with a crystal orientation of and a resistivity of 50 Ω.cm;

[0031] (2) Use pure oxygen as a protective atmosphere, and use wet oxygen oxidation process to grow SiO on the surface of the silicon wafer described in step (1). 2 Thin film, the thermal oxidation temperature used is 1250 °C, and the obtained silicon oxide thickness is 300 nm;

[0032] (3) growing a 50 nm thick titanium film on the silicon oxide surface described in step (2);

[0033] (4) Using argon as a protective atmosphere, subject the silicon wafer described in step (3) to subsequent annealing at 1150 °C.

Embodiment 3

[0035] (1) Select p-type silicon with a crystal orientation of and a resistivity of 0.1 Ω.cm;

[0036] (2) Use pure oxygen as a protective atmosphere, and use wet oxygen oxidation process to grow SiO on the surface of the silicon wafer described in step (1). 2 Thin film, the thermal oxidation temperature used is 1250 °C, and the obtained silicon oxide thickness is 300 nm;

[0037] (3) growing a 50 nm thick titanium film on the silicon oxide surface described in step (2);

[0038](4) Using argon as a protective atmosphere, subject the silicon wafer described in step (3) to subsequent annealing at 1150 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com