Automatic purging and replacing system and method for hydrogen-related pipe valve testing gas circuit structure

A technology of pipe valve and gas circuit, which is applied in the field of automatic purge replacement system for hydrogen-related pipe valve parts test gas circuit structure, can solve the problem that the hydrogen energy pipe valve part test system lacks effective and reliable removal of residual hydrogen and impurities, etc. Achieve the effects of simple structure, low maintenance cost and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings and examples, but the following examples are only used to describe the present invention in detail, and do not limit the scope of the present invention in any way.

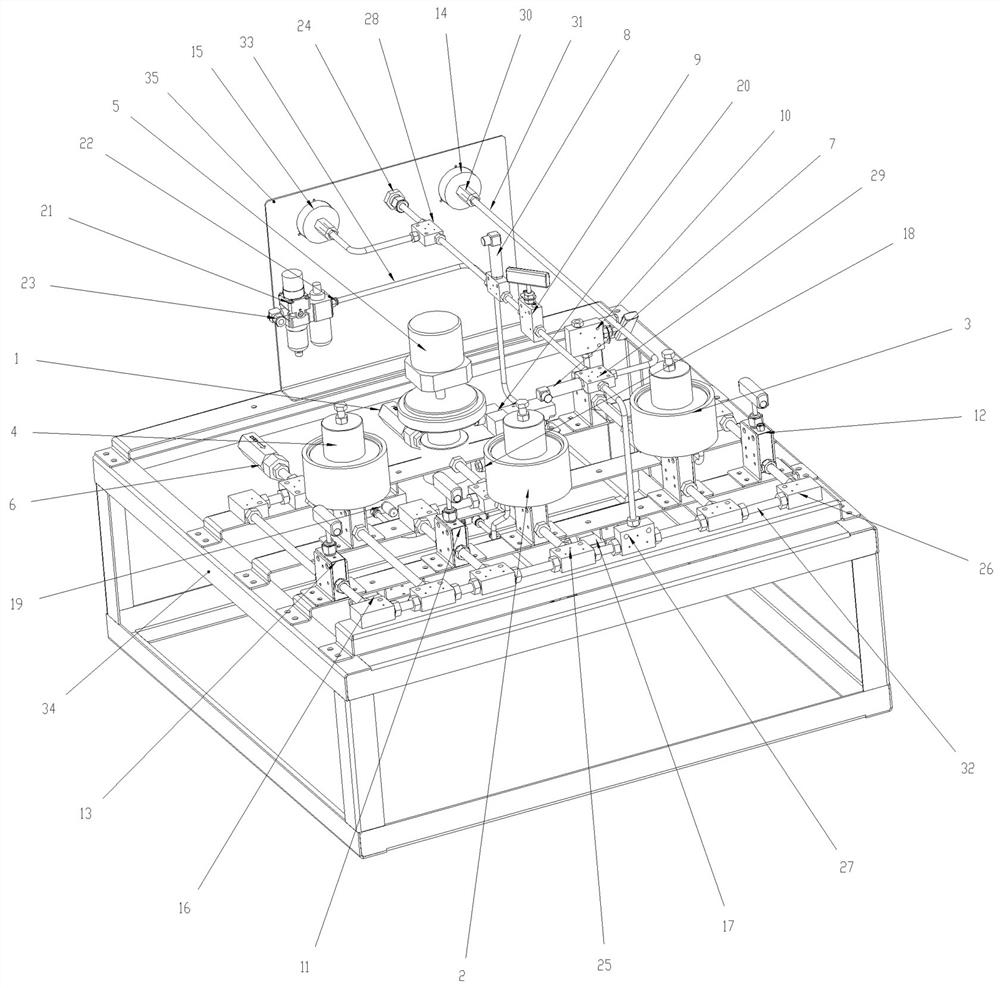

[0027] Example: Automatic purge replacement system for hydrogen-related pipe valve parts test gas path structure, see Figure 1 to Figure 5 ,mainly includes:

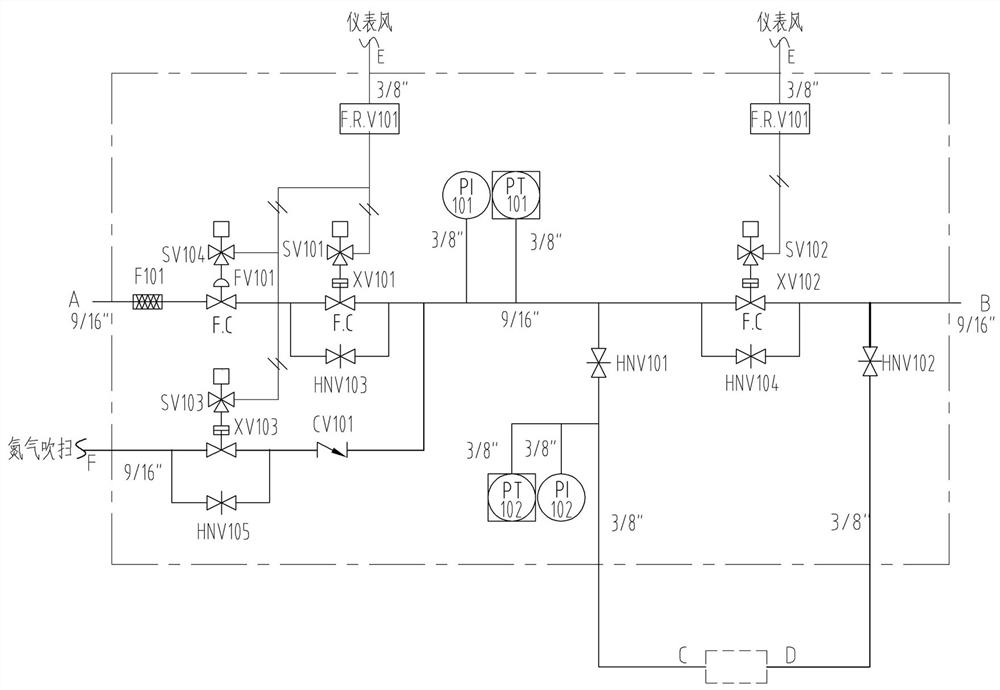

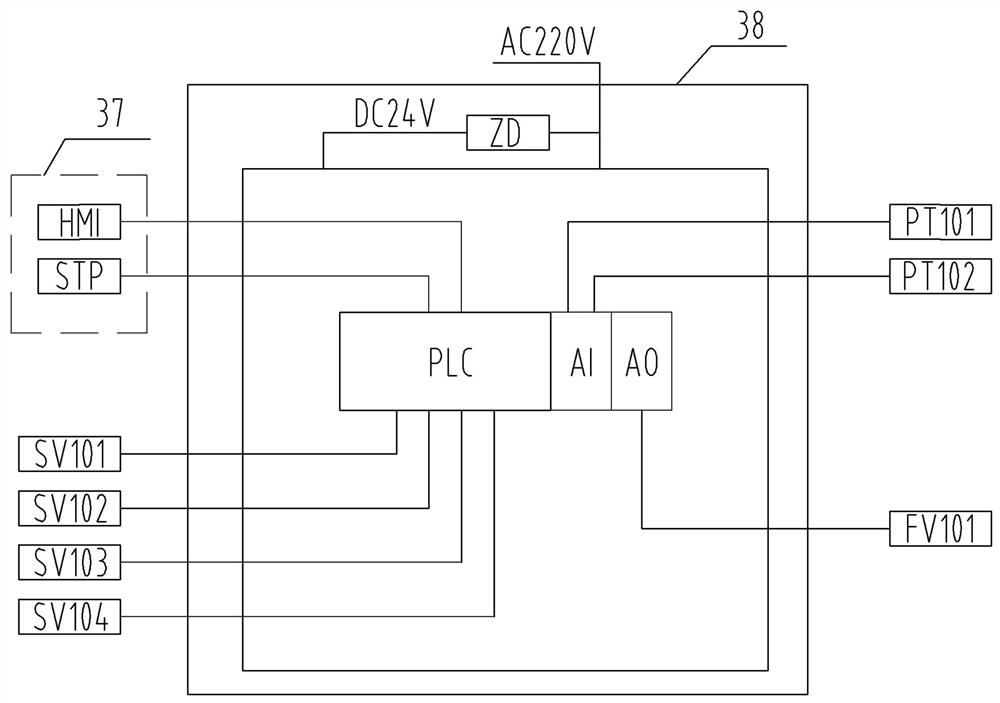

[0028] It includes a purge gas source, a PLC control unit, and a purge replacement pipeline for sending purge gas into the corresponding main pipeline and test pipeline, and the purge replacement pipeline includes purge inlets connected in sequence by corresponding pipelines F, purge pneumatic valve (XV103) 4, check valve (CV101) 6, the purge inlet F is connected to the corresponding purge gas source (compressed nitrogen); the purge pneumatic valve (XV103) 4 is connected in parallel Corresponding bypass branches, and each bypass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com