Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about How to "Keep the environment hygienic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

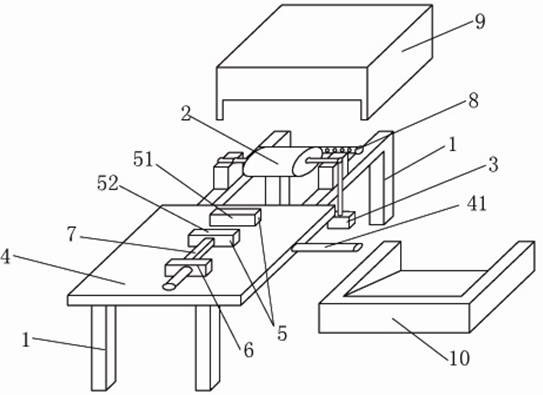

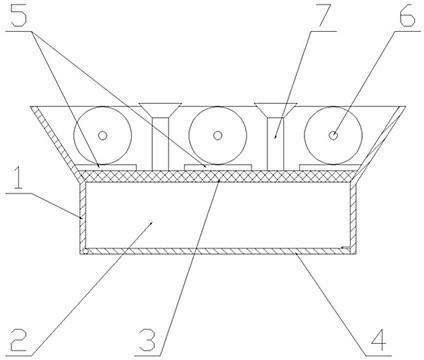

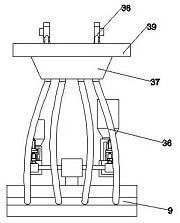

Fan framework machining machine

InactiveCN102689257AAvoid playingProtection securityGrinding machinesGrinding/polishing safety devicesAgricultural engineeringMechanical equipment

The utility model belongs to the technical field of fan manufacturing equipment tools, and particularly relates to a fan framework machining machine. The invention discloses the fan framework machining machine, which comprises a rack, wherein the rack is provided with a grinding wheel; the grinding wheel is connected with a motor; the rack is movably connected with a sliding plate; the sliding plate is provided with a clamp and a cylinder; the clamp comprises a fixed clamp and a movable clamp; the movable clamp is connected with the cylinder through a push rod; the clamp can approach the grinding wheel under the driving of the sliding plate until to the space below the grinding wheel; and a water spray pipe is arranged on the rack on one side of the grinding wheel. According to the fan framework machining machine, mechanical equipment is used for machining a fan framework, the step of grinding the fan framework is finished better and quickly, the efficiency is increased, the labor cost is saved, and meanwhile, large-scale production of fans can be realized, so that the conventional manual machining becomes mechanical production.

Owner:DEQING XINGYITAI ARTS & CRAFTS

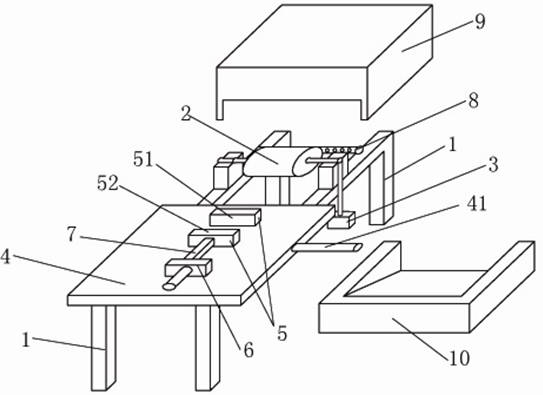

Multifunctional intelligent garbage bin

InactiveCN101580165AChange a single functionAvoid distributingRefuse receptaclesButt jointControl system

The invention discloses a multifunctional intelligent garbage bin which comprises a body, a cover installed at the upper end of the body, an upper garbage inlet arranged on the cover, and an upper cover installed on the upper garbage inlet, wherein the upper cover is formed by the hinge joint of a front cover plate and a rear cover plate, the front cover plate is hinged on the cover; the side wall of the body is provided with a side cover door, and a pull-in magnet is arranged at the butt joint part of the side cover door and the inner side of the body; the body is internally provided with a sealing mechanism, a bag-pushing mechanism and a bag changing mechanism, and the bottom of the body is provided with a sealing motor; the upper end of the cover is provided with an infrared sensor, and the front cover plate is provided with a contact sensor; a cover-opening motor, the sealing motor, a butt-joint heat-sealing device, the infrared sensor and the contact sensor are all connected with a control system, and the control system is arranged at the bottom of the body. The invention has artful structure, can realize the functions of automatic cover opening and cover closing, automatic bag-sealing and bag-pushing and automatic bag-changing, brings convenience to operation for cleaners, improves the labor efficiency of the cleaners, and guarantees the environmental health.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Distributed environmental-friendly pigsty

InactiveCN101946716AReduce momentumReduce flow rateAnimal housingTreatment with aerobic and anaerobic processesEnvironmental hygieneEngineering

The invention relates to a distributed environmental-friendly pigsty which belongs to the technical field of construction of livestock houses. The distributed environmental-friendly pigsty comprises all pigsties and a liquid-liquid separating device, wherein all the pigsties are independently arranged; a microseam floor which is inclined to one side is erected and installed on the ground in each pigsty; a leaked liquid pit which is inclined to one side is arranged under the microseam floor; ceramic tiles are paved on the ground of the leaked liquid pit; a padding groove is arranged outside the wall of each pigsty; an excrement outlet and a liquid outlet are opened on the wall; the liquid outlets are connected with the liquid-liquid separating device outside the walls by pipelines; and a main drainage pipe opening of the liquid-liquid separating device is connected with a water treatment device by a pipeline. By the invention, the problem that pig growth is influenced since excrement and urine of pigs can not be favorably separated and the environment can not be guaranteed in the prior art, and pig excrement, pig urine and an urine and water mixture are effectively separated, thereby generating no waste resources, maintaining environmental sanitation in the pigsty and being beneficial to the growth of the pig.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

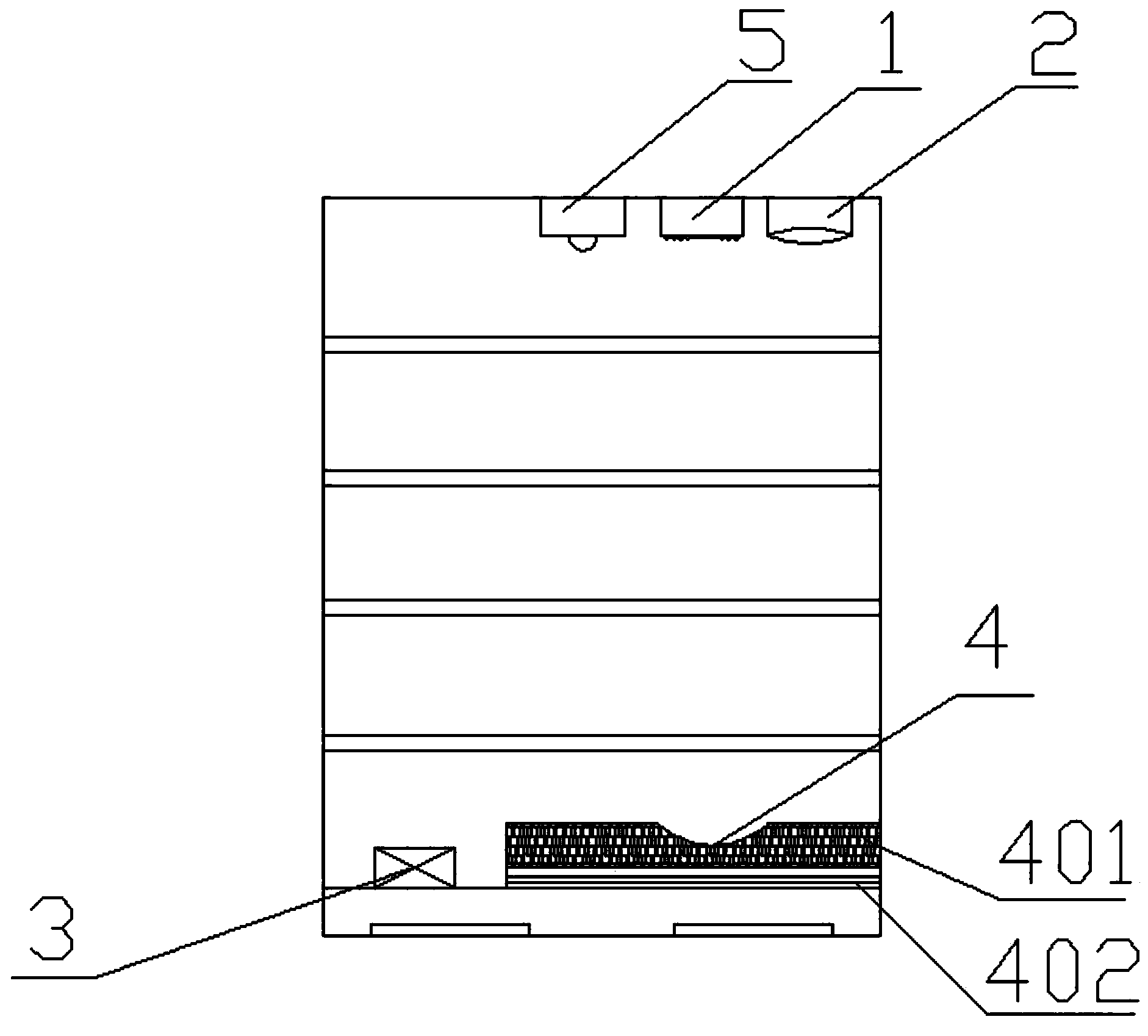

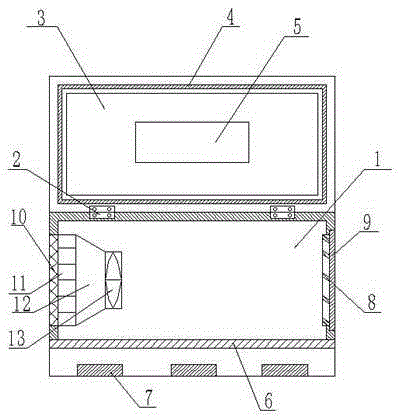

Intelligent shoe cabinet

InactiveCN104068640AReal-time monitoring of humidity valueReduce humidityWardrobesLighting elementsShoe polishBiomedical engineering

The invention discloses an intelligent shoe cabinet. The intelligent shoe cabinet comprises a cabinet body, wherein multiple layers of mutually parallel laminates are arranged inside the cabinet body from the top end to the bottom end; the intelligent shoe cabinet further comprises a sterilization device, a humidity processing module, a power source device, a shoe polishing device and a lighting lamp. The sterilization device of the intelligent shoe cabinet is used for sterilizing bacteria inside the cabinet body and is good for body health of people; the humidity processing module is used for monitoring the humidity value inside the cabinet body, reducing the humidity inside the cabinet body and drying the inside of the cabinet body so as to better protect shoes against going moldy and rotting and increase the service life of the shoes; the shoe polishing device is used for cleaning soles and is convenient as well as practical.

Owner:郭裴哲

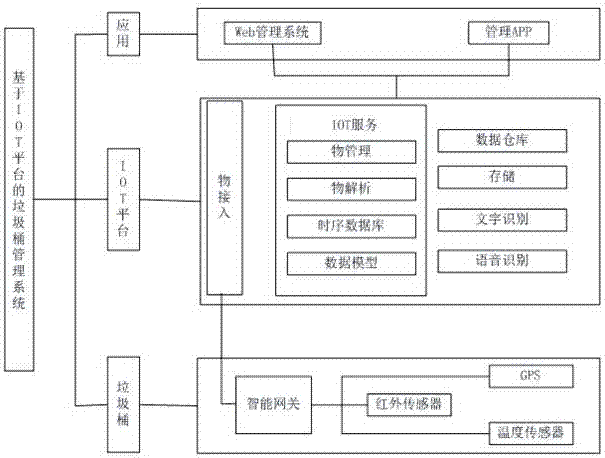

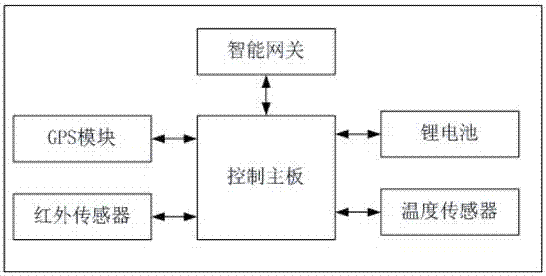

Dustbin management system based on IOT platform

InactiveCN107133698AReduce vehicle fuel and labor costsEnsure urban sanitationForecastingRoute planningCondition monitoring

The invention discloses a trash can management system based on an IOT platform, which belongs to the technical field of the Internet of Things and includes an intelligent trash can, an IOT platform, a PC-side web management system and a mobile terminal management software; the smart trash can is provided with a control board, an intelligent Gateway, GPS module, infrared sensor and battery. The GPS module is used to transmit the location information of the smart trash can to the PC. When the position of the smart trash can moves, it will report to the alarm system; the infrared sensor is used to detect the height of the garbage in the smart trash can ; The data information detected by the GPS module and the infrared sensor is transmitted to the control board, and the data is transmitted through the intelligent gateway regularly. In the present invention, by setting up an intelligent garbage can, the position of the garbage can, the temperature in the bucket and the height of the garbage in the bucket are pushed to the management terminal through the IOT platform, so as to realize the status monitoring and route planning of the garbage can in the area, and reduce the waste of vehicle fuel caused by unnecessary garbage recycling. and labor costs.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

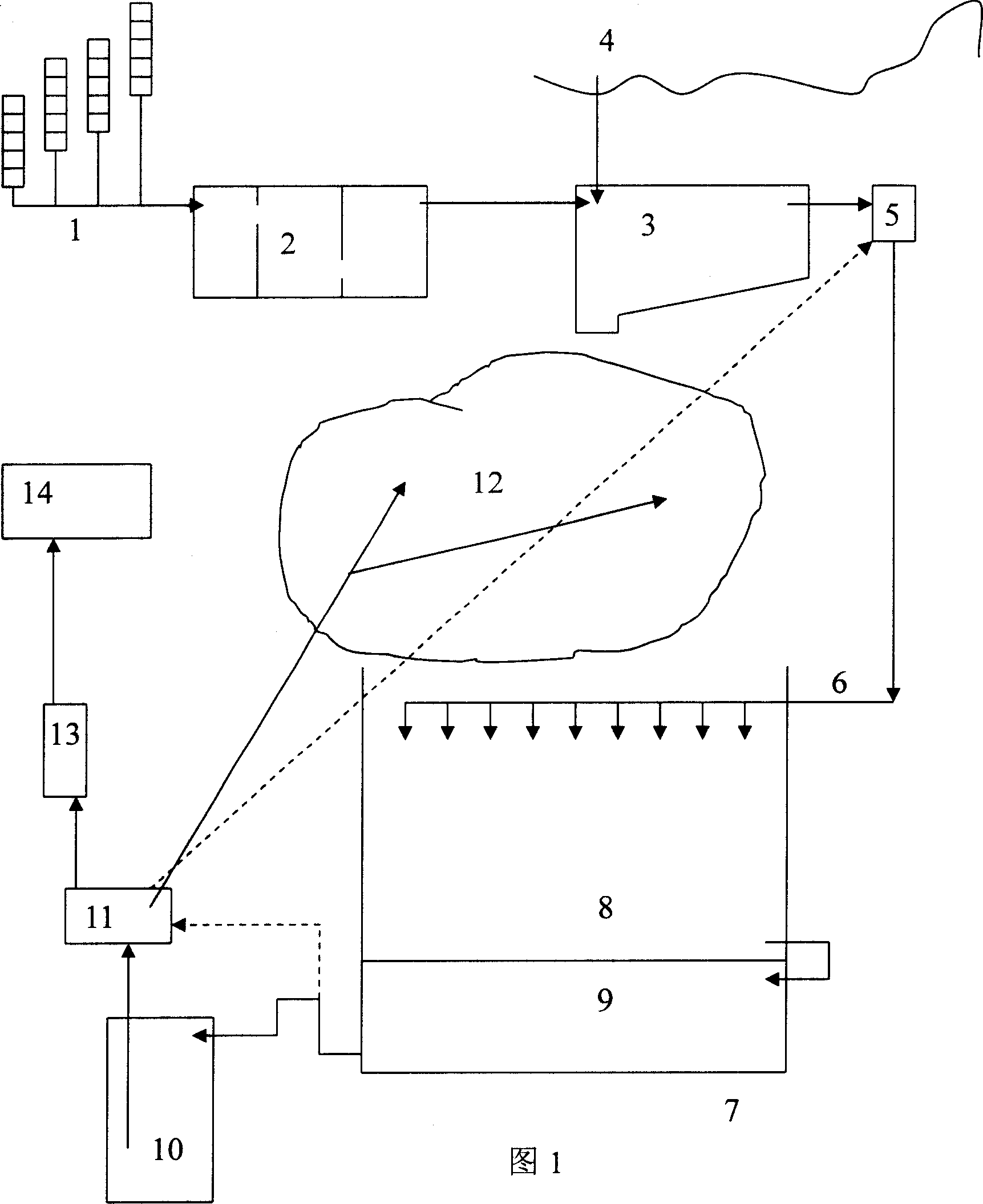

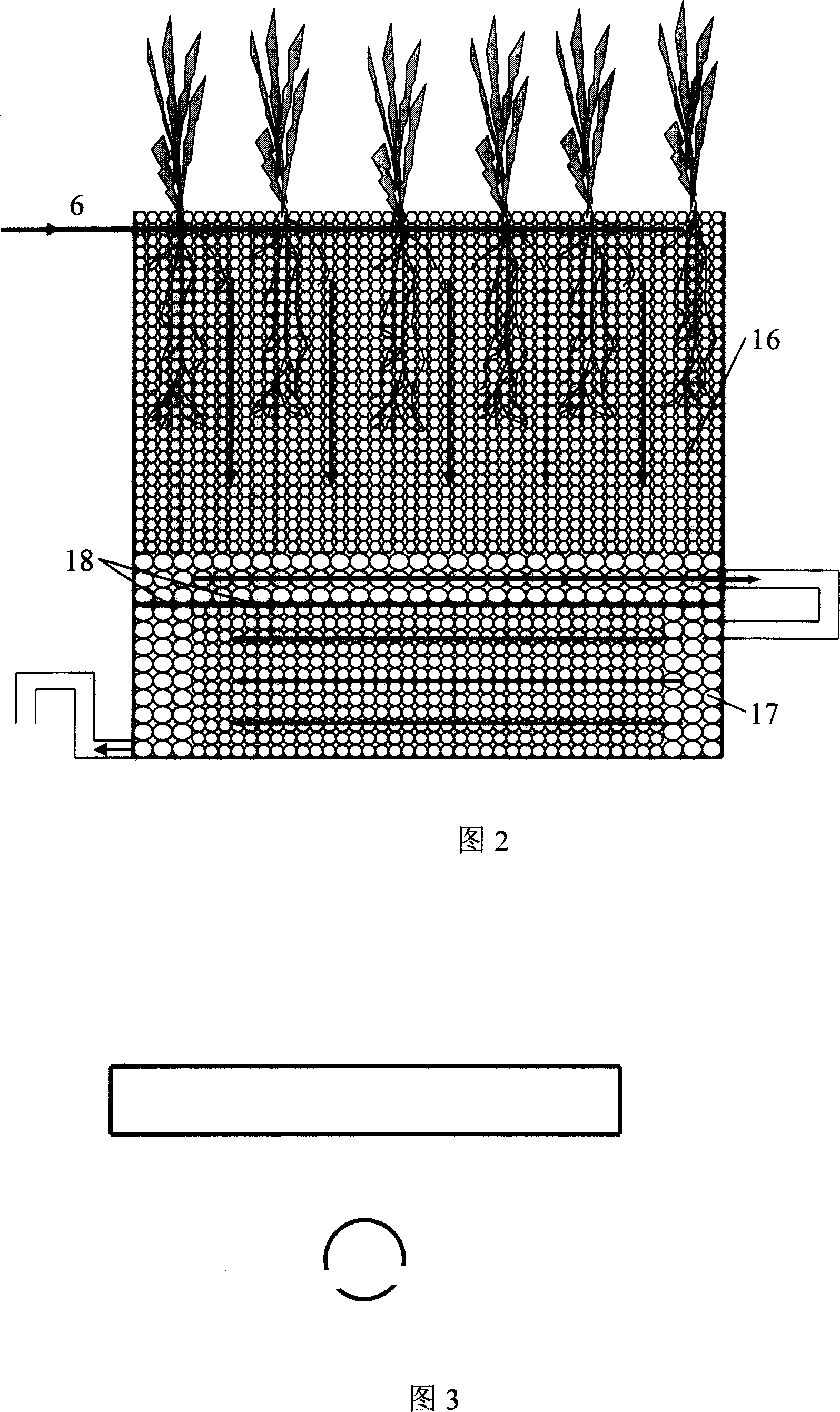

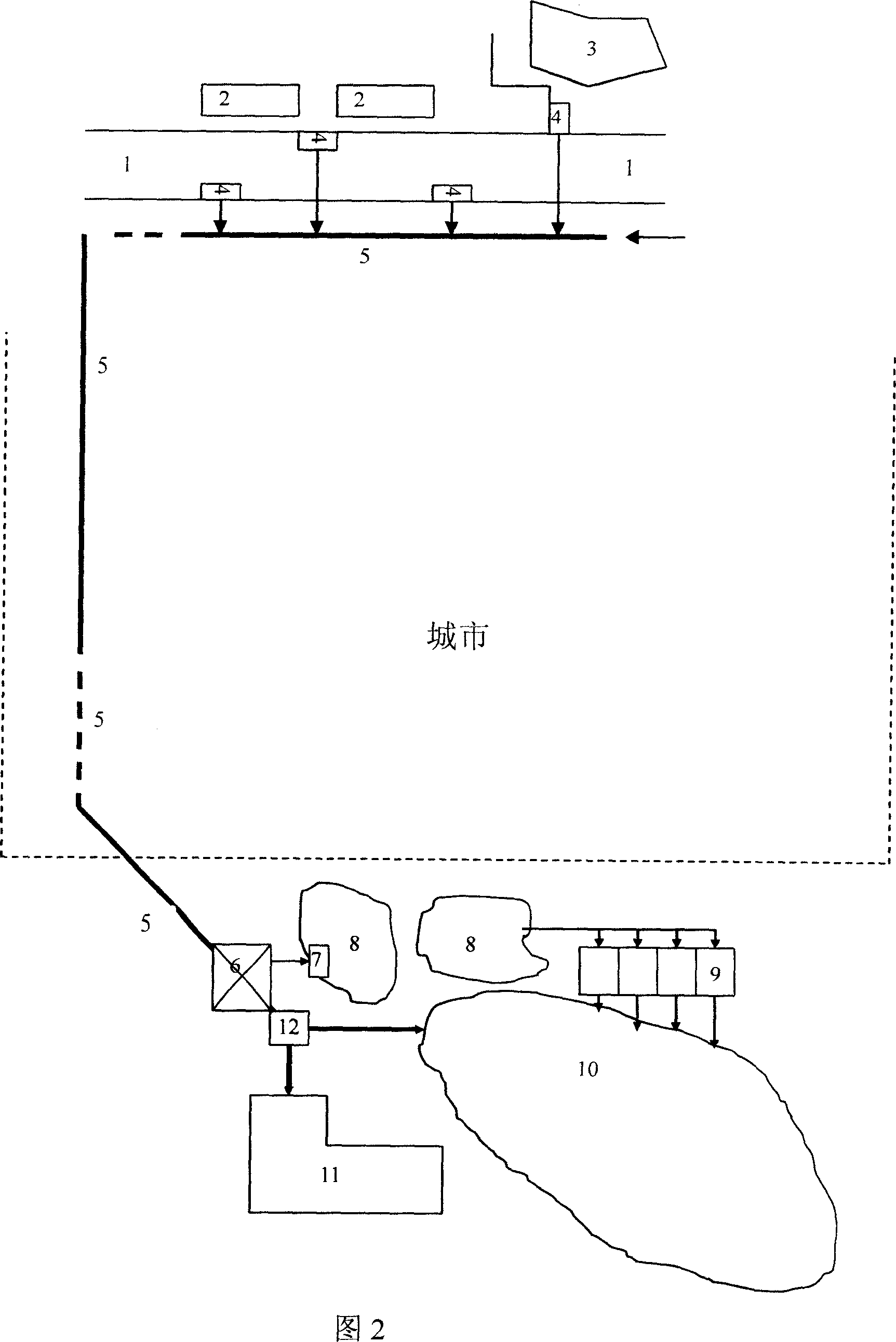

Comhined-flow artificial wet land and its application system

InactiveCN1978342ASmall footprintUnique nitrogen removal effectSustainable biological treatmentBiological water/sewage treatmentProcess systemsMarsh

This invention relates to a complex flow artificial marsh composed of a vertical flow artificial marsh unit at the top and a level flow gravel bed at the bottom to become an integral structure, which is a solid sewage zoology process system, the level flow gravel bed is under the vertical flow marsh unit to reduce occupied areas with exclusive nitrogen-removing effect, in which, TSS, BOD and TN in the sewage are removed effectively and processed water can be collected by collecting wells and used in pouring greenbelt in local areas, besides, rain flows can be stored in underground deposition tanks and processed and re-used by the complex flow artificial marsh to realize situ processing life sewage and rain flows.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Barbecue oven

ActiveCN103989414ASmooth flowUniform temperature riseRoasters/grillsAutomatic controlCombustion chamber

The invention discloses a barbecue oven which comprises an oven body, an oven cover used for sealing the oven body, a bottom frame used for supporting the oven body, a combustor used for combusting fuel and a feeding device used for conveying the fuel to the combustor. The combustor comprises a combustion chamber, a heating pipe, an air guide box and a fan, the heating pipe is arranged at the bottom of the combustion chamber, the fan is arranged on the box wall of the air guide box, the top of the combustion chamber is communicated with the bottom of the oven body, the bottom of the combustion chamber is embedded into the air guide box, and a ventilation opening communicated with the air guide box is formed in the combustion chamber. The feeding device comprises a hopper used for loading the fuel, a fuel guide pipe, a feeding screw rod arranged in the fuel guide pipe and a feeding motor used for driving the feeding screw rod to rotate. According to the barbecue oven, the feeding quantity of the fuel and the air volume of the fan can be automatically controlled, temperature in the oven can be changed evenly, and the heat preservation effect is good.

Owner:佛山市高明区荷城俊毅模具厂

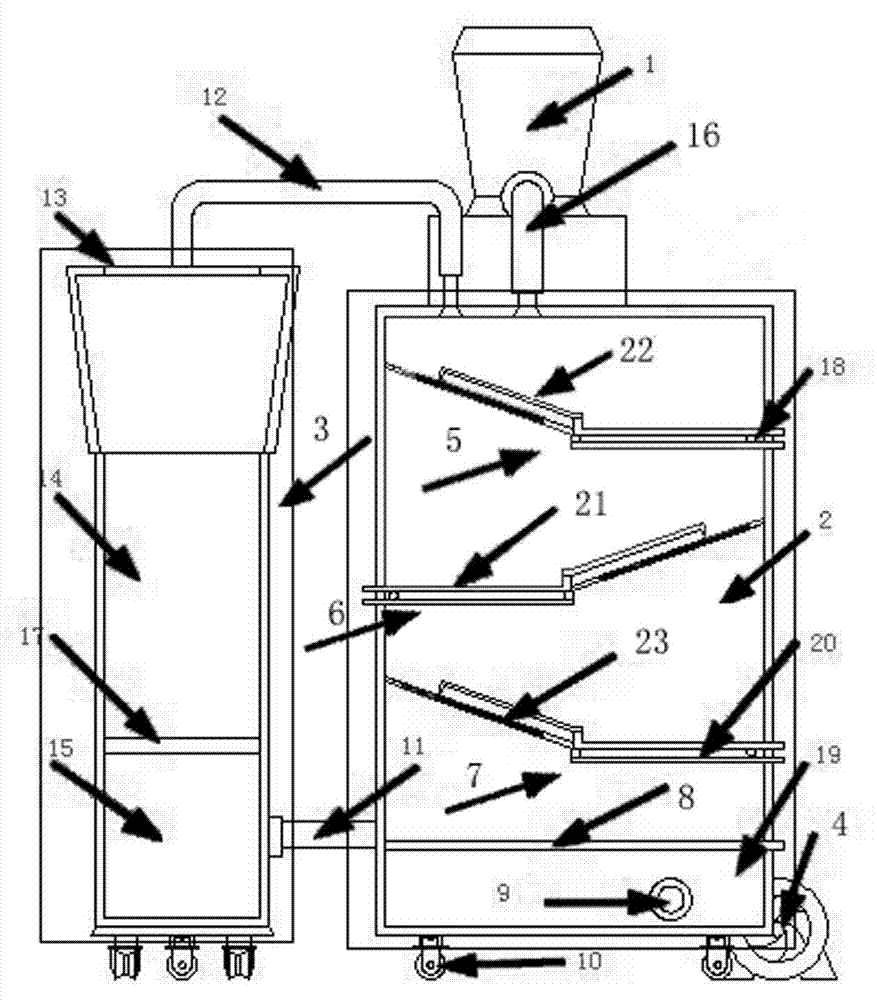

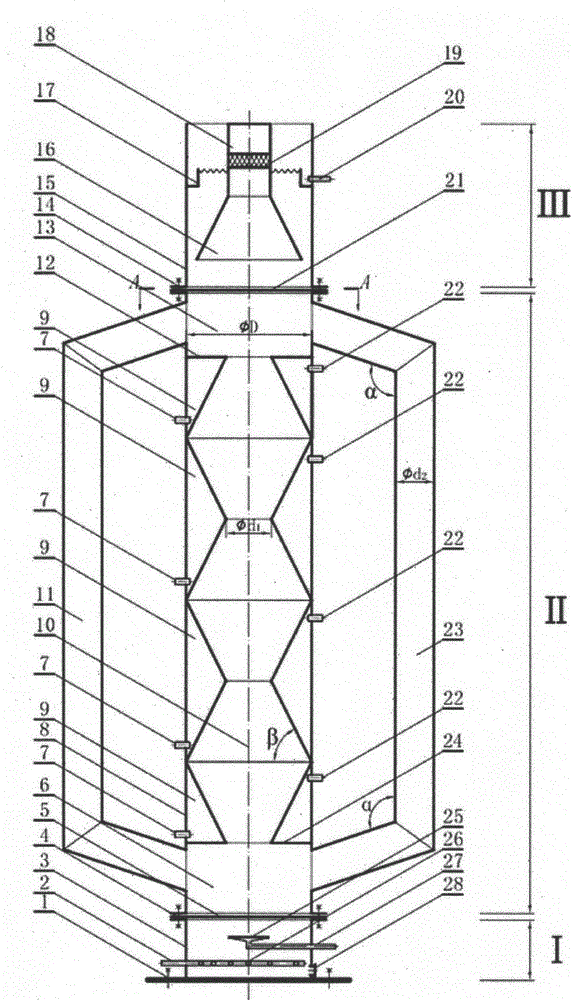

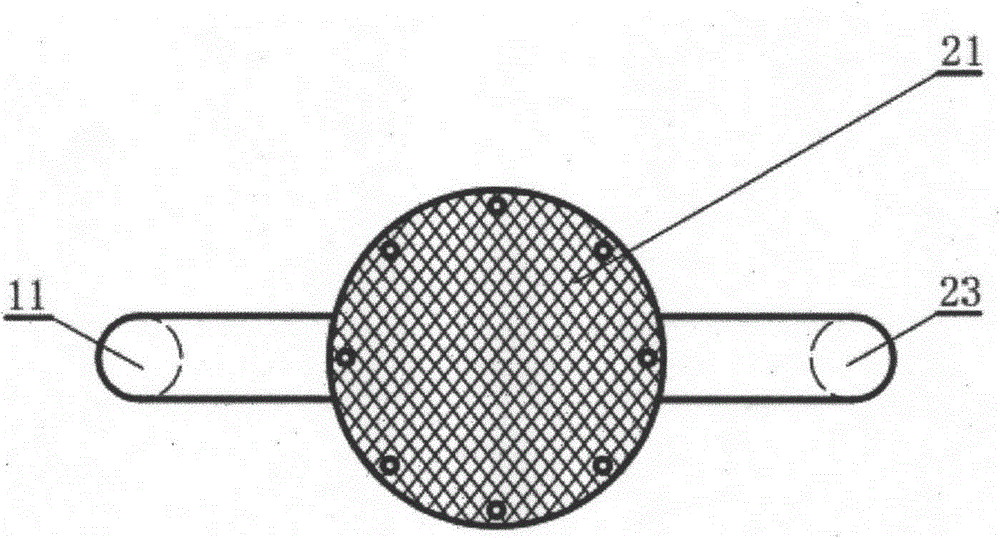

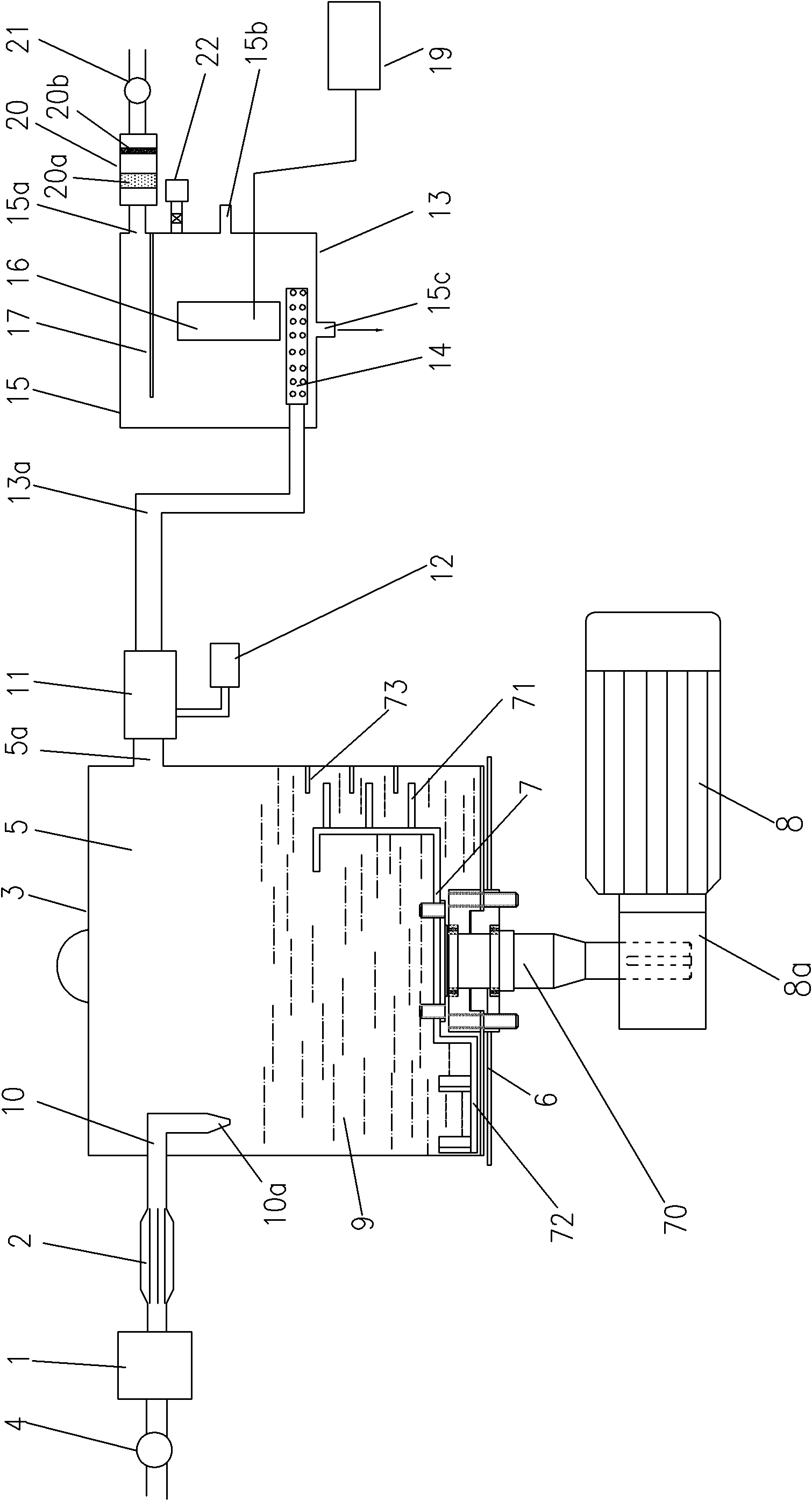

Biodegradable waste processor and method for producing mycoprotein by using same

The invention discloses a biodegradable waste processor. The waste processor is characterized by consisting of four parts, including a waste crushing system, a waste fermentation system, a waste gas and waste liquid treatment system and a ventilation system. Meanwhile, the invention also discloses a method for producing mycoprotein by biodegrading wastes, and the method comprises the following steps: step 1, crushing raw materials; step 2, fermenting and separating; step 3, circulating bacterium strains; step 3, culturing and collecting. The waste processor is used for processing degradable parts of kitchen wastes, town refuses and the like to obtain the mycoprotein, the protein content of the mycoprotein is above 30% and the mycoprotein can be applied to a feed additive. Meanwhile, the processor is also provided with a flower and grass culture chamber and can be used for processing waste gas generated during fermentation and also making a contribution to the improvement of environment quality. The equipment is simple to manufacture, convenient to use and capable of truly realizing reclamation, minimization and benefits of waste treatment.

Owner:SHENYANG POLYTECHNIC UNIV

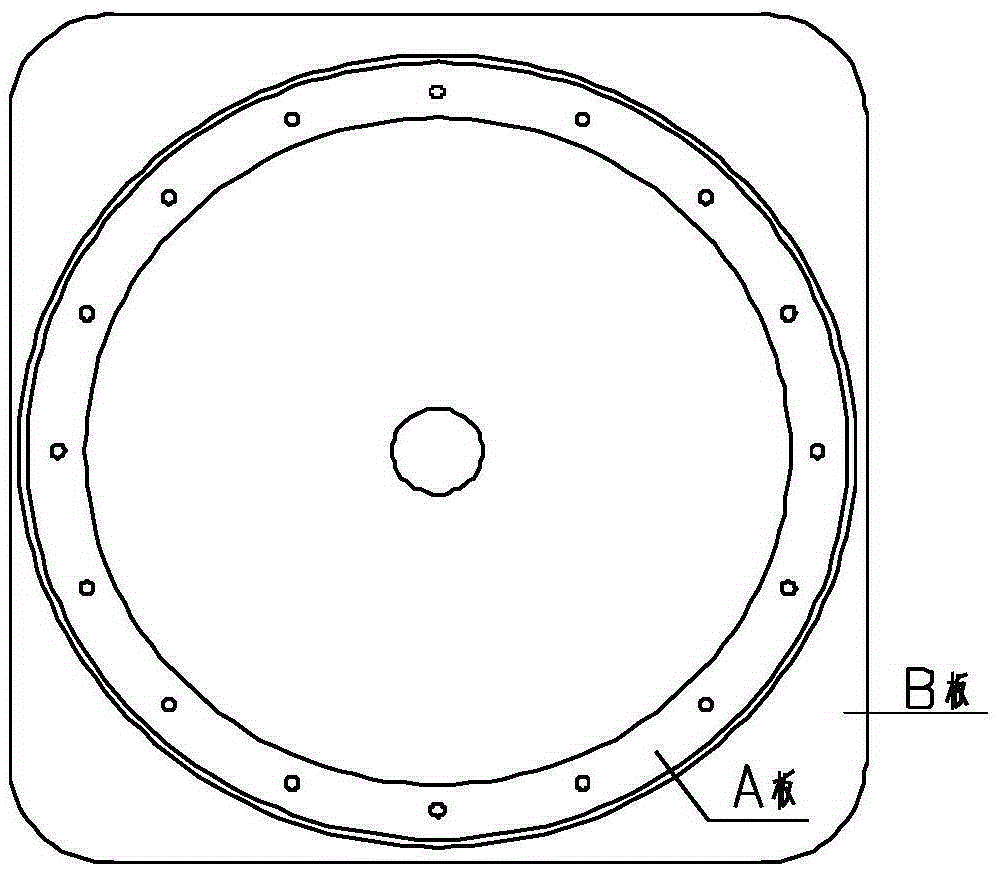

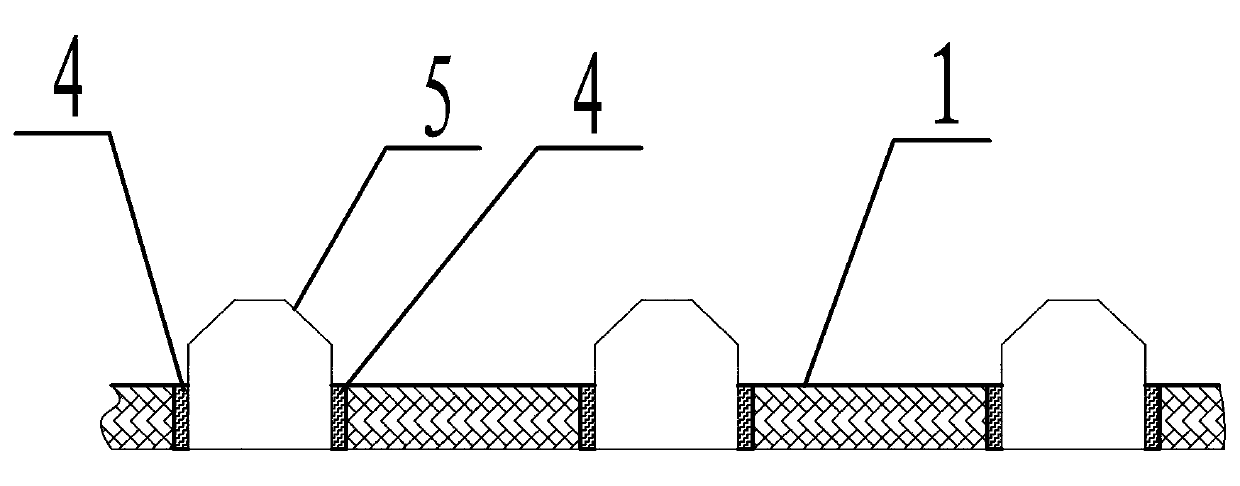

Dustless blackboard eraser

The invention discloses a dustless blackboard eraser which comprises a blackboard eraser body (1) and is characterized in that a dust collection cavity (2) is arranged inside the blackboard eraser body (1), a metal static filter screen (3) is arranged above the dust collection cavity (2), a flip-open cover (4) at the rear end of the blackboard eraser body (1) is communicated with the dust collection cavity (2), a ground-glass plate (5) is fixedly arranged on the metal static filter screen (3), a roller (6) supported in a rotating manner is arranged inside the blackboard eraser body (1), a silk layer is arranged on the outer surface of the roller (6), when the roller (6) rolls, the roller (6) and the ground-glass plate (5) are in mutual friction, and an erasing strip (7) is arranged inside the blackboard eraser body (1). The dustless blackboard eraser has a simple structure, is unique in design, can prevent chalk ash from flying by using the principle of electrostatic adsorption, and can uniformly collect the chalk ash.

Owner:DALIAN OCEAN UNIV

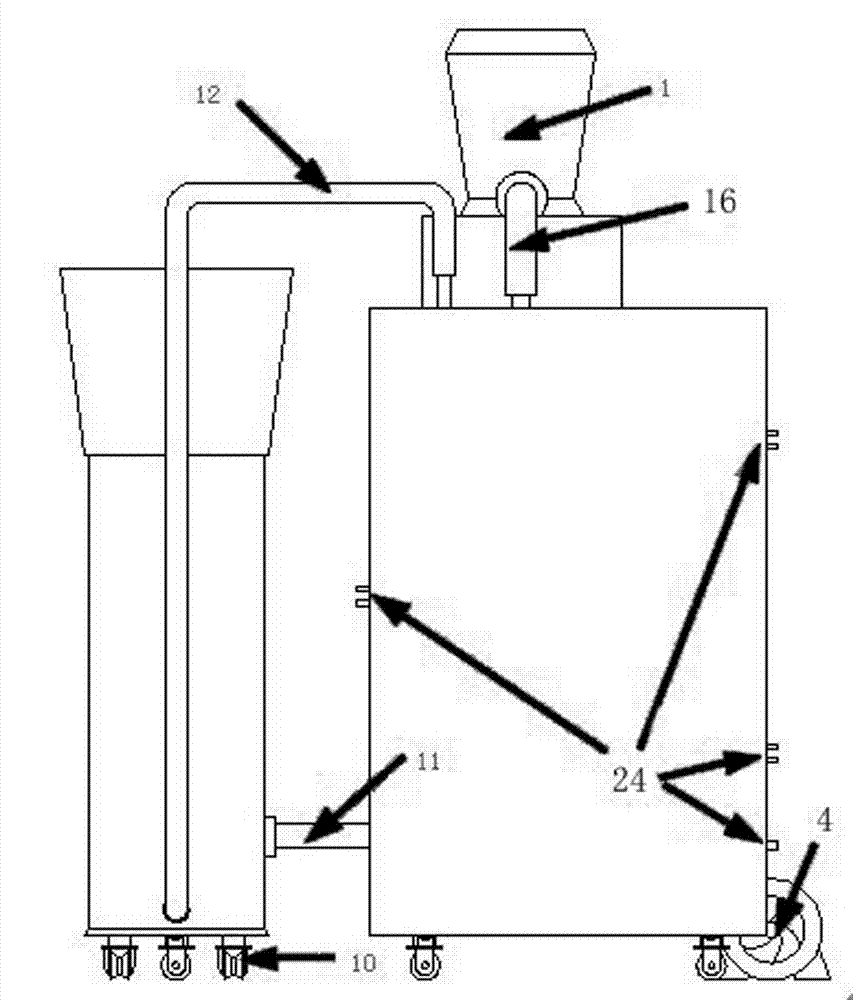

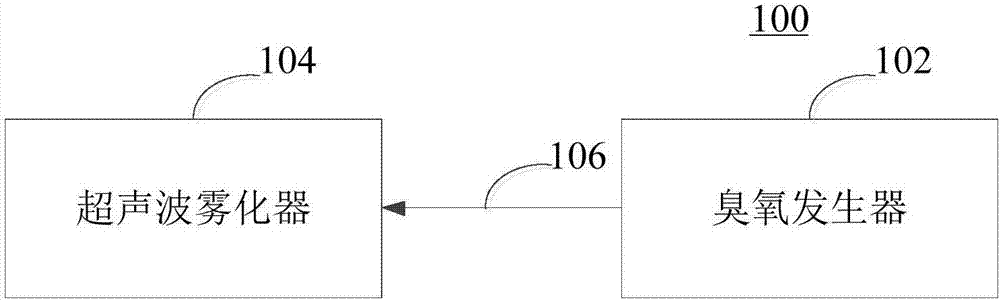

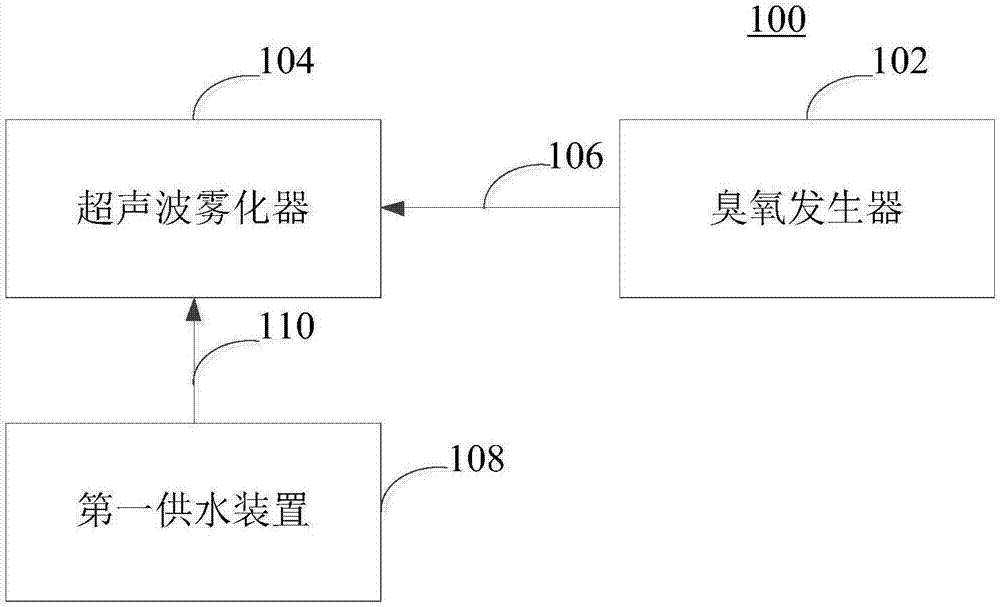

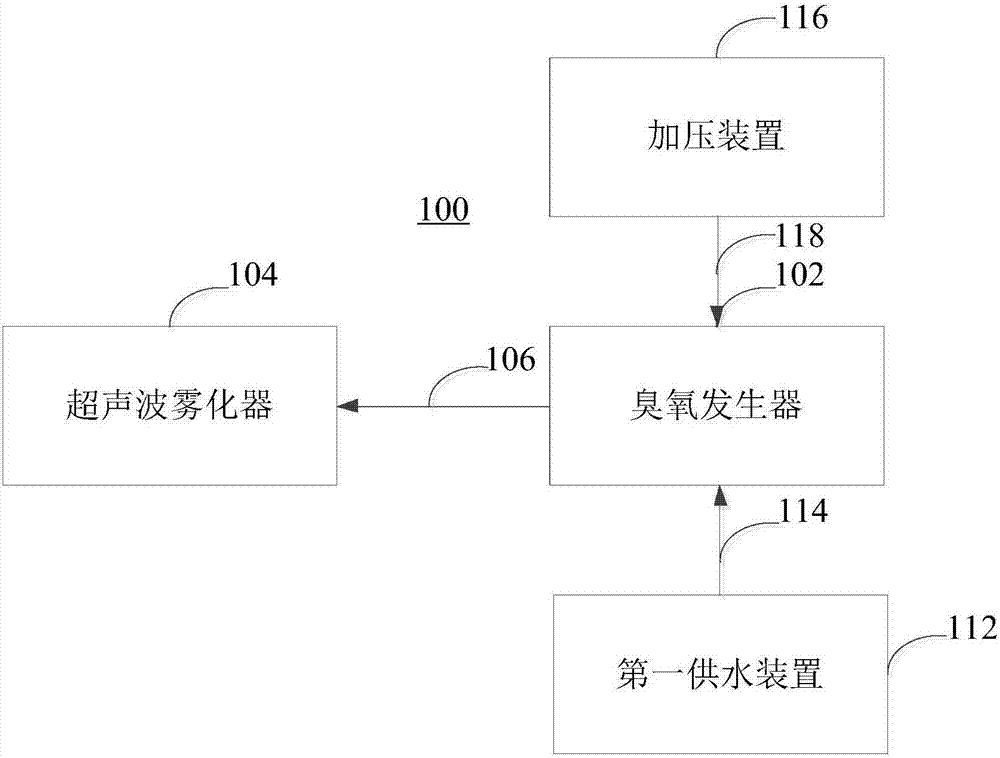

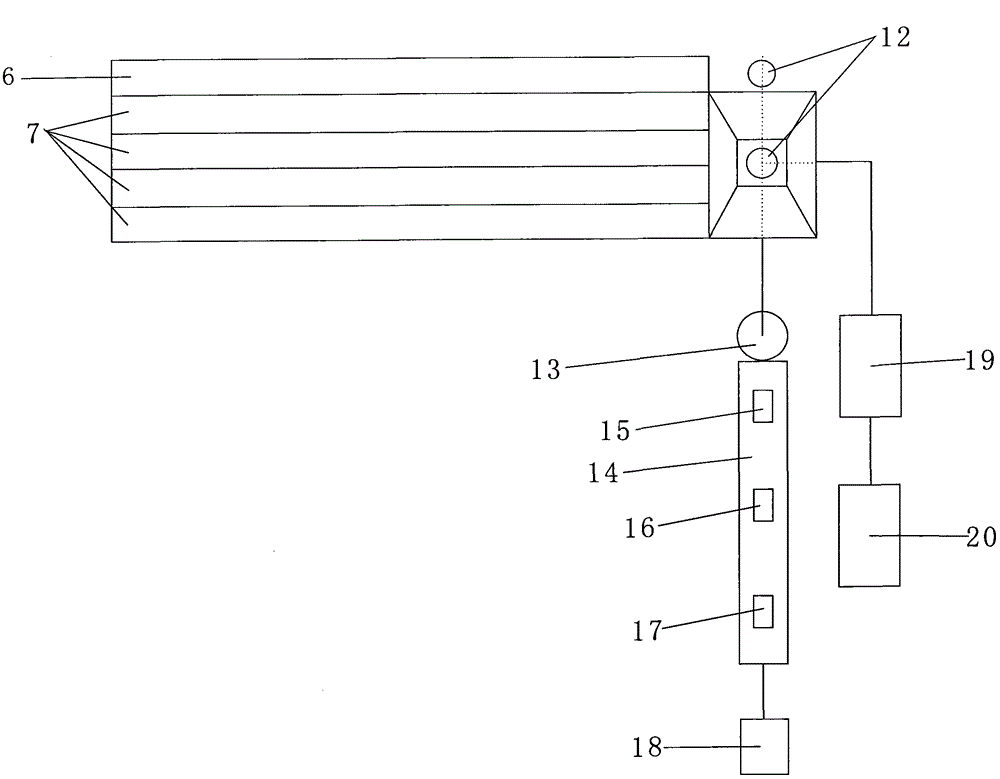

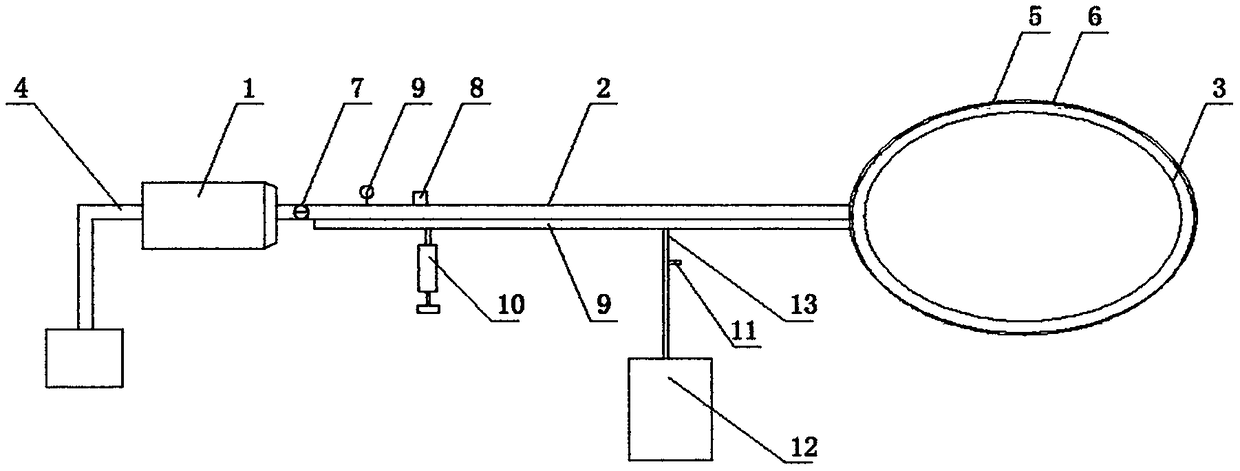

Apparatus and method for making ultrasonically atomized ozone water

InactiveCN107308833AKeep the environment hygienicShaking/oscillating/vibrating mixersFlow mixersOzone generatorCleansing Agents

The invention provides an apparatus and a method for making ultrasonically atomized ozone water, and relates to the field of environment treatment. The apparatus for making ultrasonically atomized ozone water comprises an ozone generator, an ultrasonic atomizer and a first pipeline, and the ozone generator communicates with the ultrasonic atomizer through the first pipeline, wherein the ozone generator is used for receiving oxygen supplied by an oxygen production system, converting the oxygen into ozone and feeding the ozone into the ultrasonic atomizer through the first pipeline, and the ultrasonic atomizer is used for atomizing water by an ultrasonic technology, mixing the atomized water with the ozone fed by the ozone generator to form the atomized ozone water or is used for atomizing ozone water formed through dissolving the ozone in the water by the ultrasonic technology to form the atomized ozone water. The apparatus and the method for making the ultrasonically atomized ozone water provide a cleaning agent for cleaning air, dissolving chemical gases and guaranteeing the healthiness of the environment.

Owner:GRN CONSULTANT HONG KONG LTD

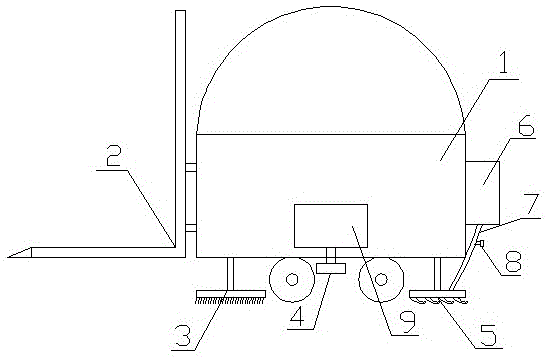

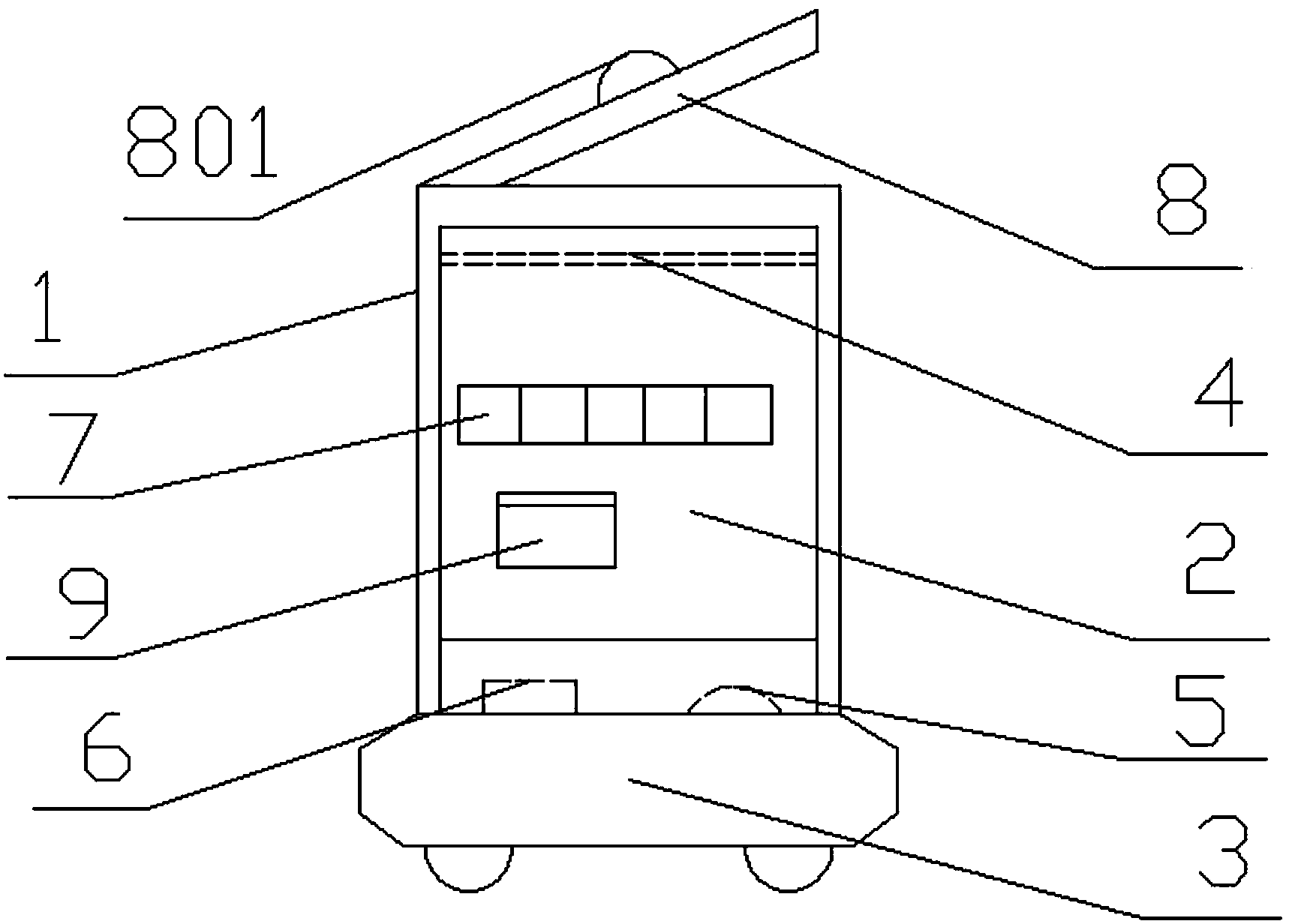

Cleaning forklift

InactiveCN103598859AImprove work efficiencyKeep the environment hygienicFloor sweeping machinesFloor-scrubbing machinesEngineeringHygiene

The invention aims at providing a cleaning forklift which comprises a forklift body and a fork. The fork is arranged at the left end of the forklift body, a sweeping device is arranged below the left end of the forklift body, a dust suction device is arranged on the right side of the sweeping device, and a mop is arranged on the right side of the dust suction device. By arranging the sweeping device and the dust suction device on the forklift body, when the forklift works, ground dust in a workshop is cleaned. By arranging the mop additionally, workshop cleaning is thorough. When the workshop is not required to be cleaned, the sweeping device and the mop can be folded and arranged on two sides of the forklift body, working efficiency of the forklift is improved, environment hygiene of the workshop is kept, and the working efficiency of workers is improved.

Owner:ANNTO LOGISTICS

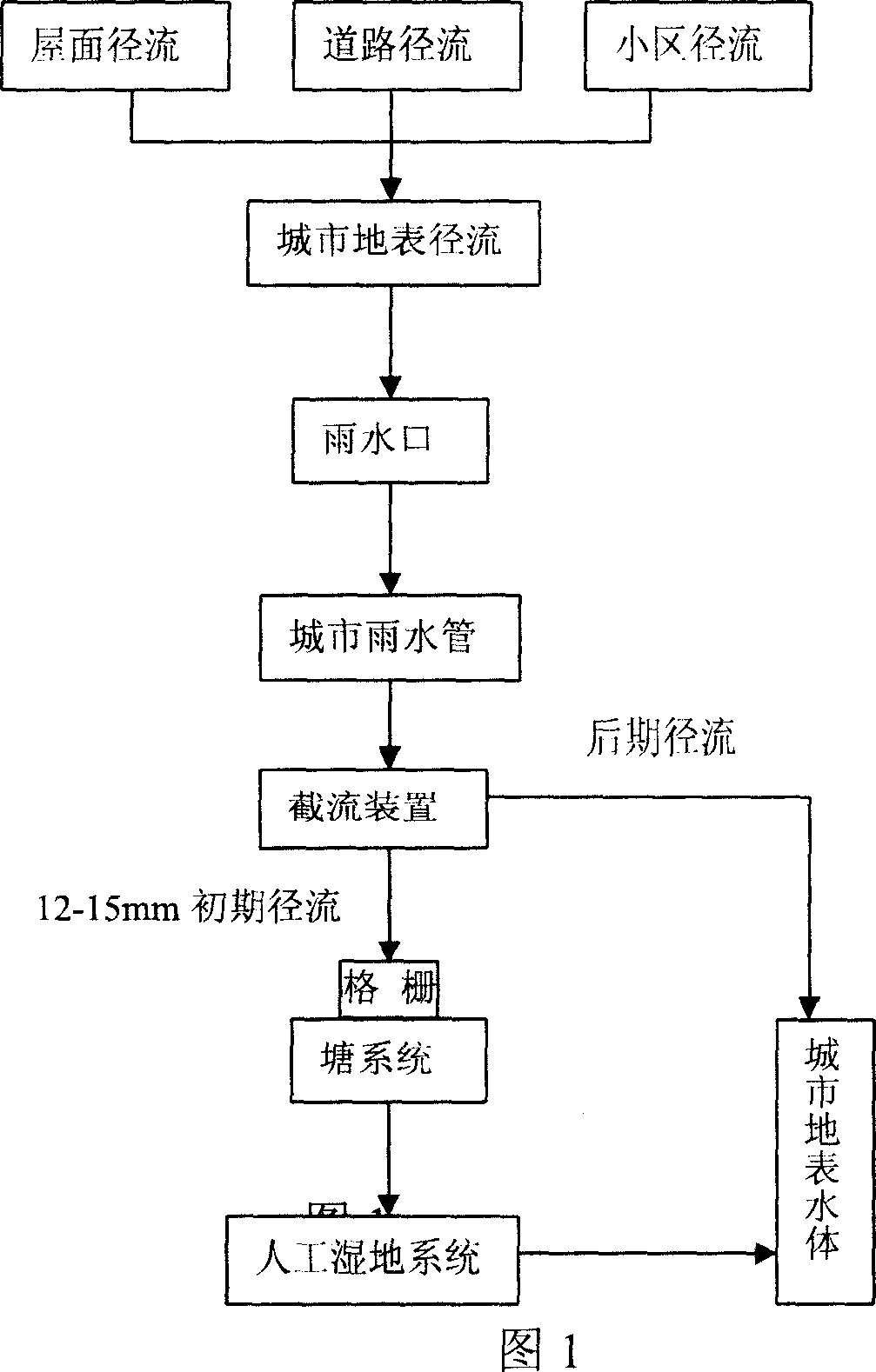

Ecology treatment method of city overland runoff

InactiveCN1923721AImprove operational efficiencyHigh removal rateBiological water/sewage treatmentConstructed wetlandEngineering

The invention discloses an urban surface radial flow ecological disposing method, which is characterized by the following: intercepting primary radial flow of urban rain less than 15mm in the disposing system within pond system and artificial marshland; sedimenting; purifying; draining flow in the natural water.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

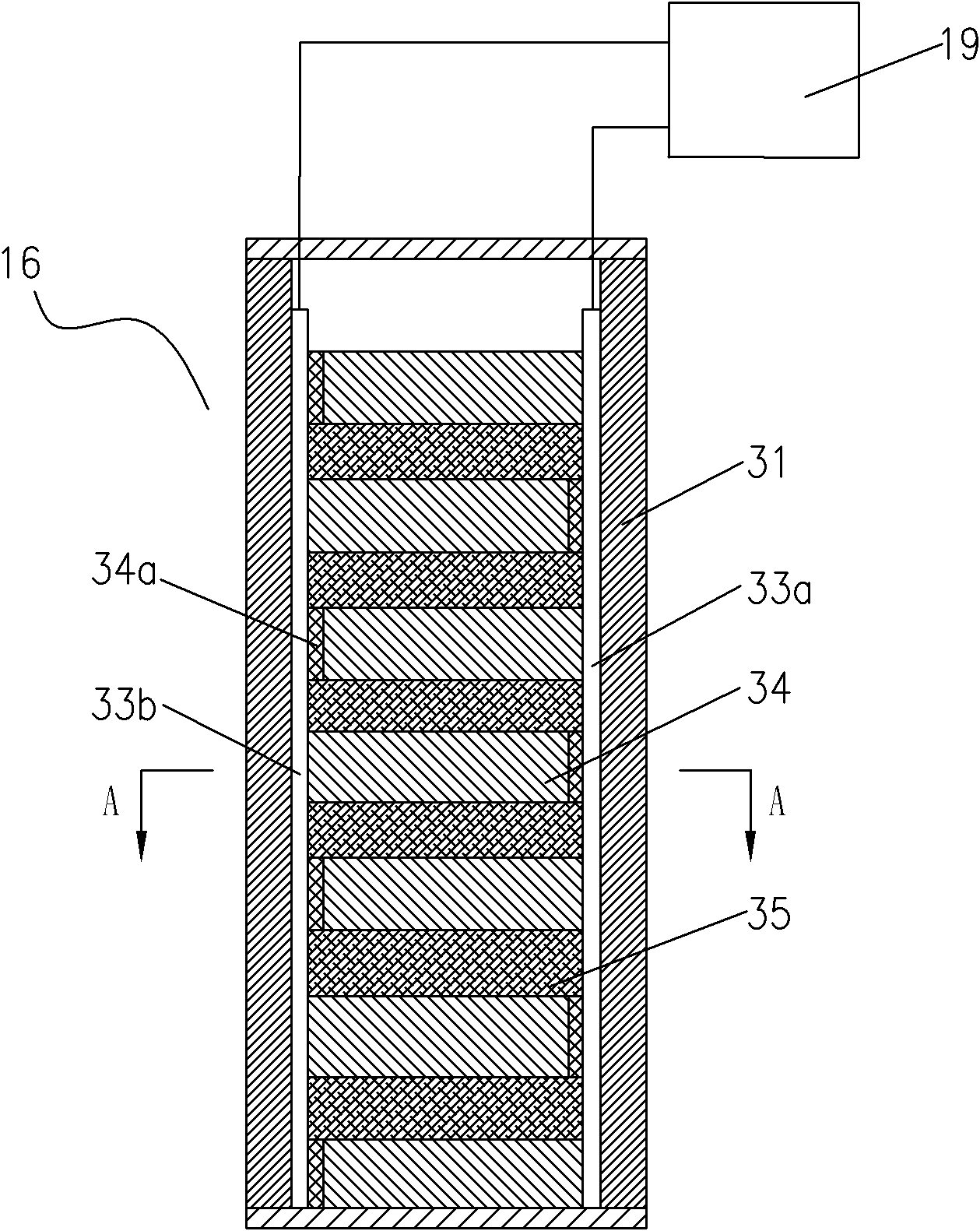

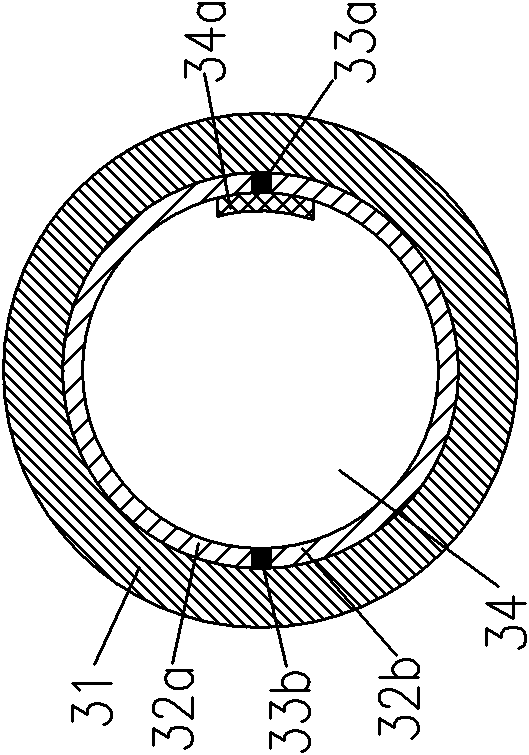

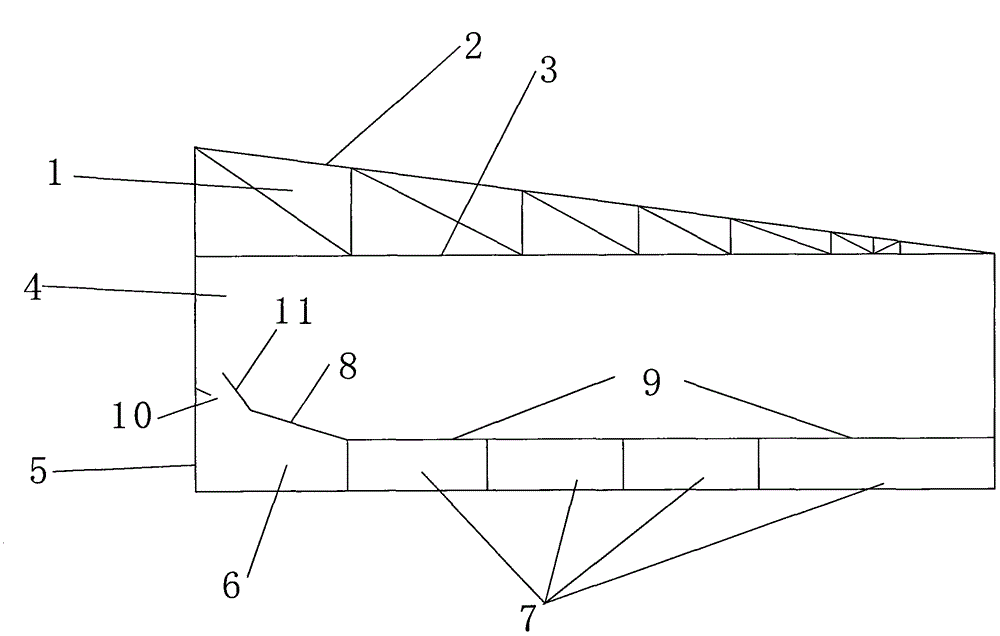

Air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor

InactiveCN104085986AImproved resistance to shock loadsSimple structureTreatment with aerobic and anaerobic processesNitrogen removalOxygen

The invention discloses an air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor. The air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor is characterized by comprising a water distributing section, a reaction section and a separating section, wherein the water distributing section comprises a lower short circular barrel; a water distributor and a microporous aeration plate are arranged in the barrel, and the water distributor is communicated with a water inlet tube; the microporous aeration plate is communicated with a gas inlet tube; the reaction section comprises a long circular barrel, and a multi-stage Venturi tube is arranged in the long circular barrel; a flow-splitting region and a mixing region are respectively formed between the two ends of the multi-stage Venturi tube and the port of the long circular barrel, and are communicated by left and right circulating tubes to form circulation; the separating section comprises an upper short circular barrel, and a water outlet and gas outlet system is arranged in the barrel. By virtue of arranging the microporous aeration plate, the mixing region and the multi-stage Venturi tube, vortex flow fields are formed in the multi-stage Venturi tube, so that the mass transfer efficiency among gas, liquid and solid phases is effectively enhanced. Besides, the structure is combined with the flow-splitting region, the left circulating tube and the right circulating tube to form external circulation, so that an aerobic-anoxic alternating environment is formed, and therefore, the reactor has a nitrification and denitrification biological nitrogen removal function.

Owner:DONGHUA UNIV +1

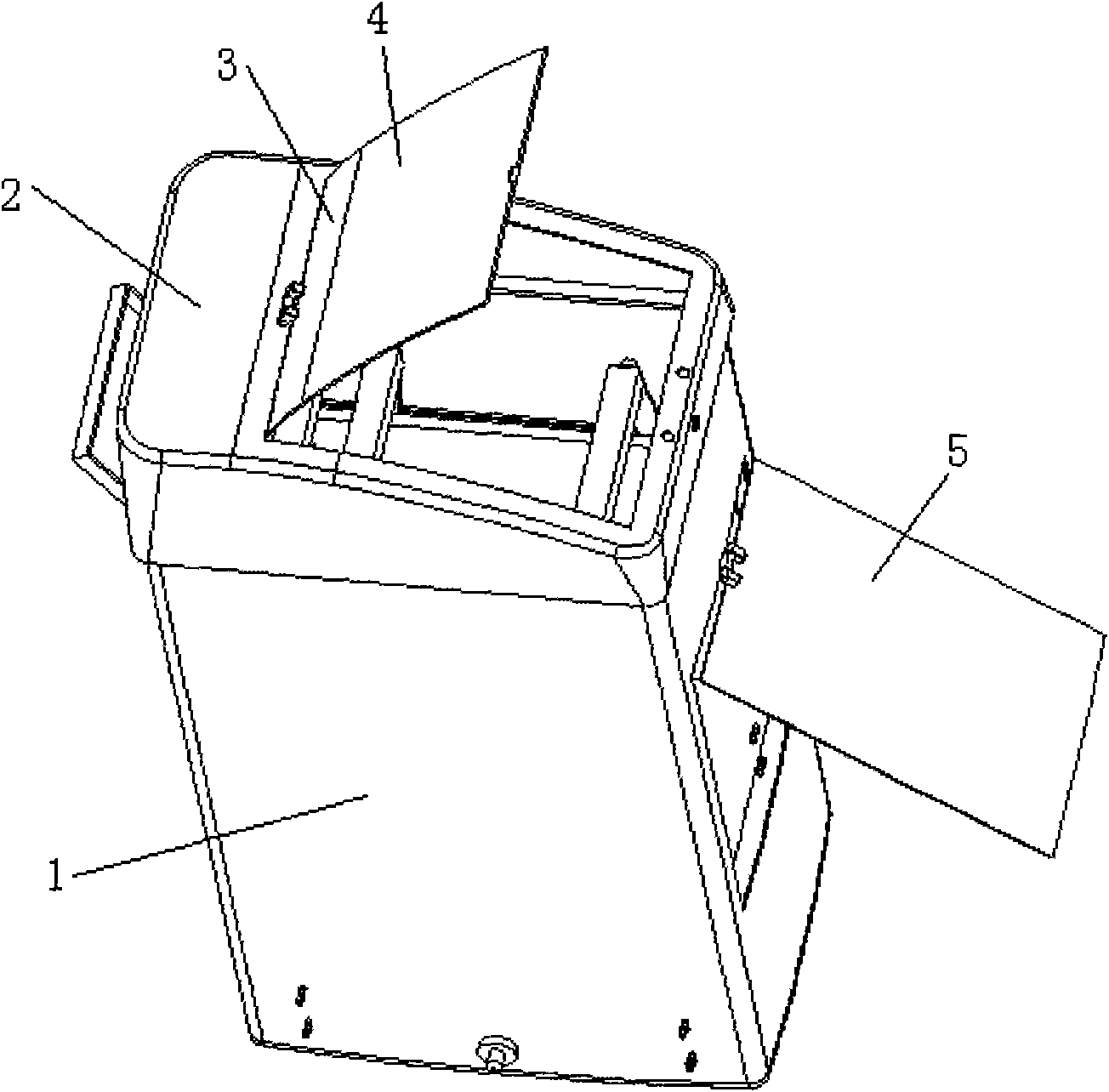

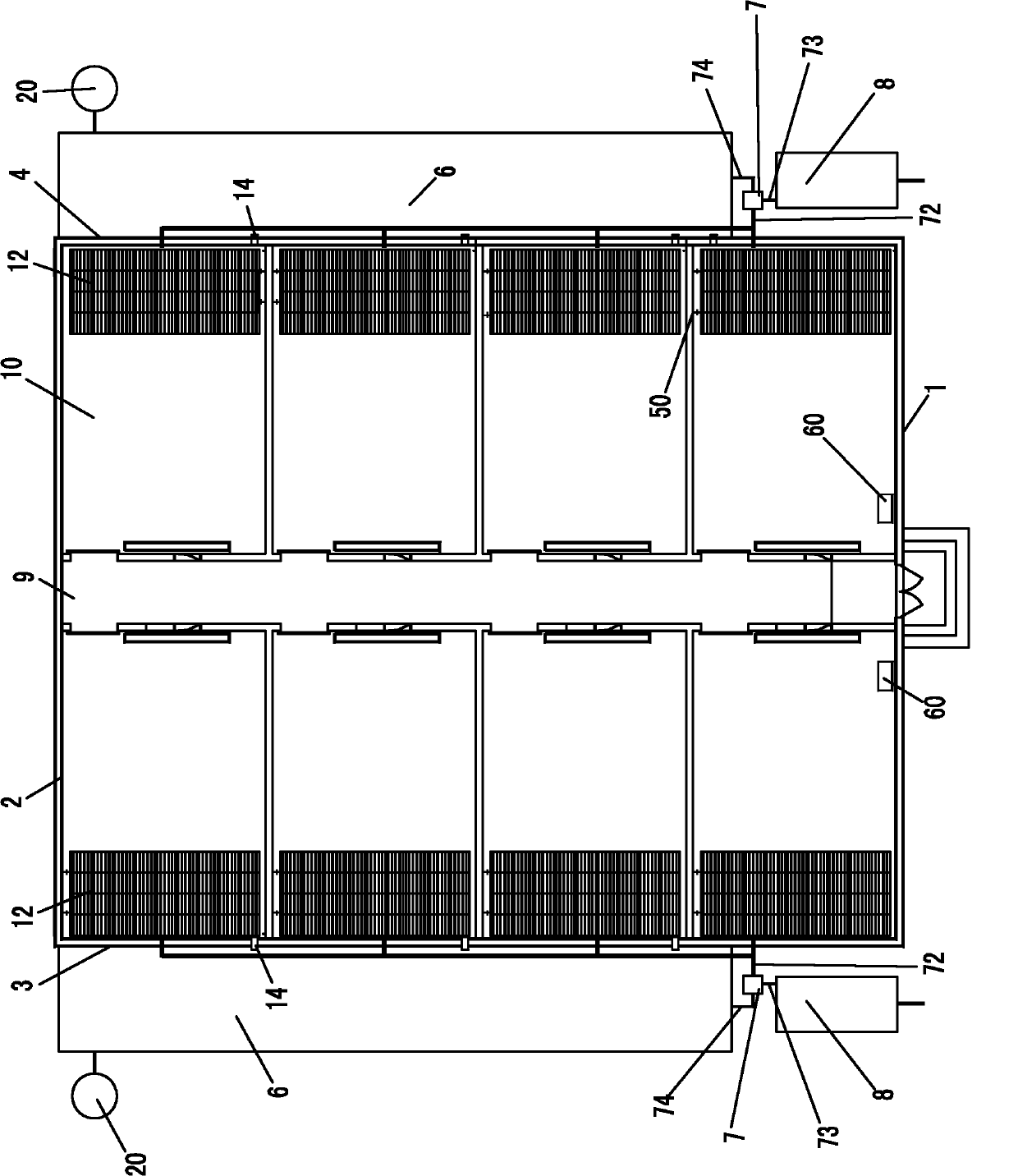

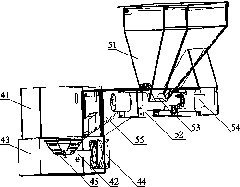

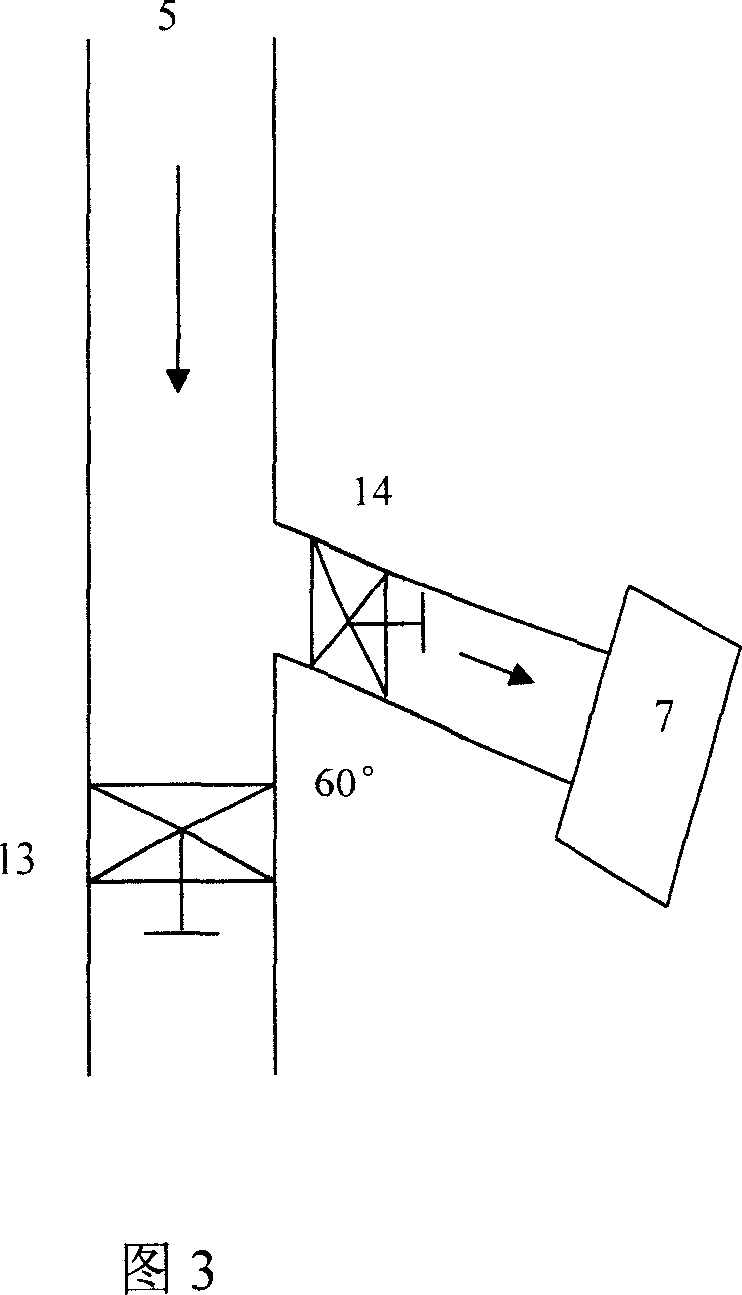

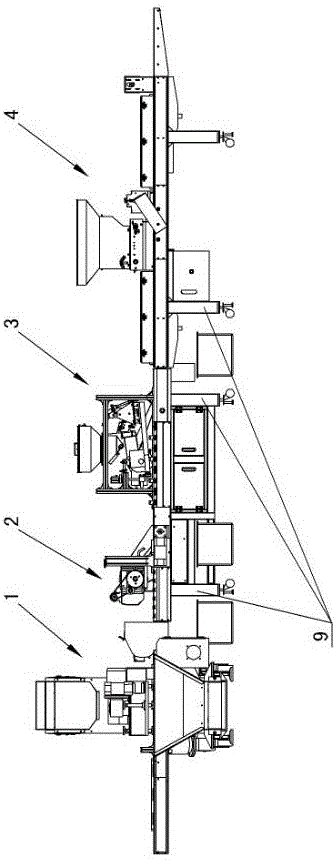

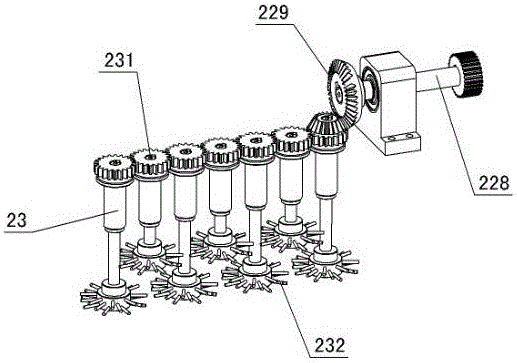

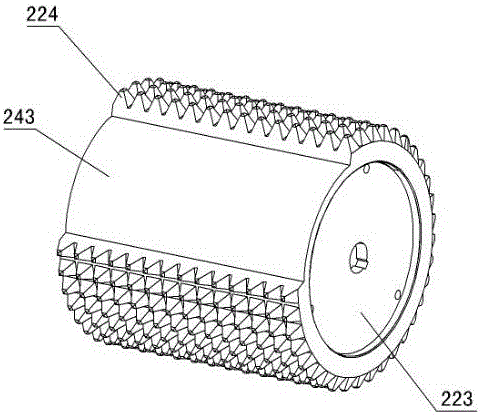

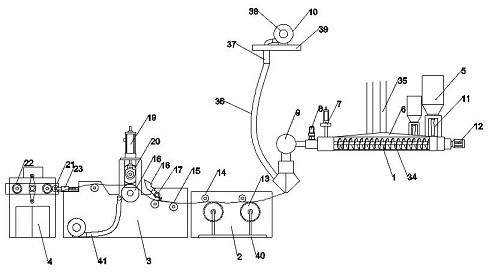

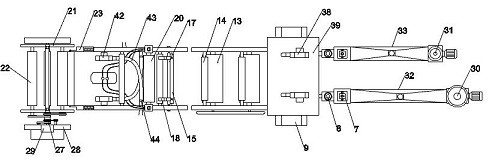

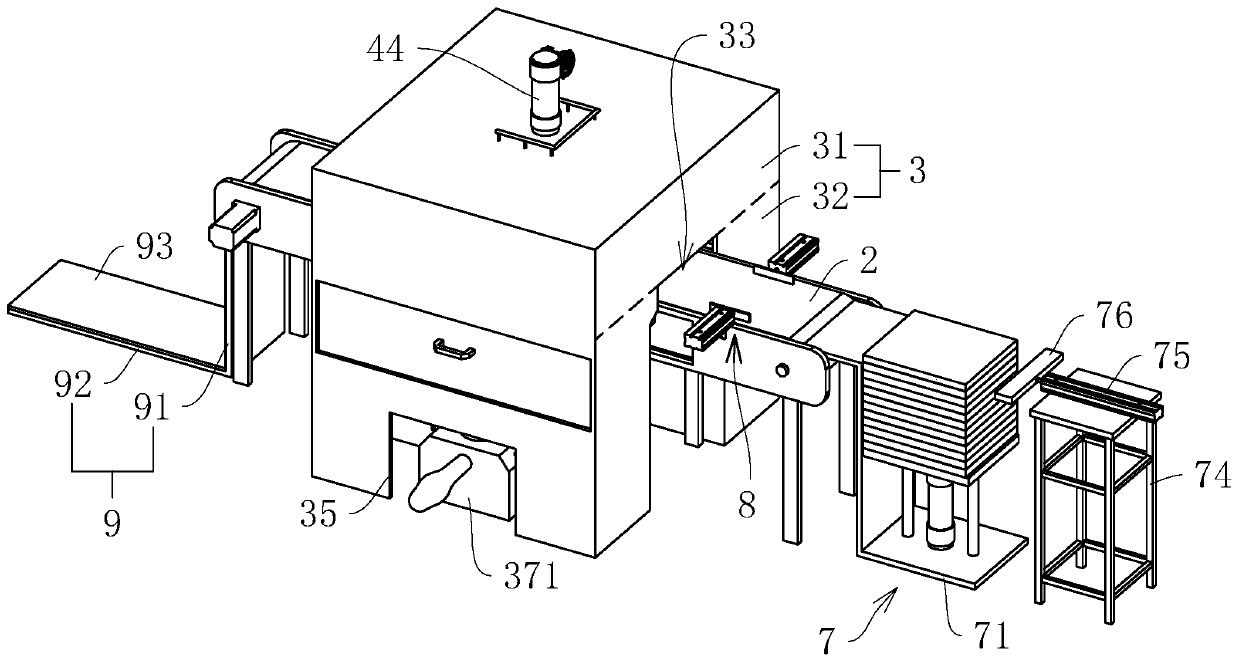

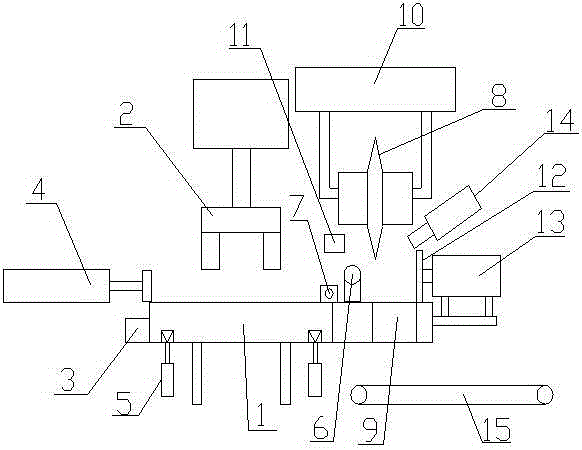

Production device for rice precision drilling assembly line

PendingCN106817988ARealize up and down adjustmentKeep the environment hygienicPlantingSelf-acting watering devicesEngineeringAssembly line

The invention discloses a production device for a rice precision drilling assembly line, which is characterized by comprising a frame, wherein the frame is provided with a matrix scattering and loading mechanism, an independent power drum-type pressing cave mechanism, a dual-sowing mechanism and multiple buffer type watering and earthing mechanisms; the matrix scattering and loading mechanism comprises a feeding cabin, an oblique matrix conveying device, a scattering device, a seedling disk conveying belt and a matrix brushing device; the a dual-sowing mechanism comprises a sowing conveying belt; a sowing bracket and an oblique bracket are arranged on the frame, and a storage hopper and a blowing device are arranged on the sowing bracket; the outer wall of the storage hopper is provided with an automatic loading control device; multiple buffer type watering and earthing mechanisms comprise watering earthing conveying belts, watering brackets and earthing brackets; strip watering devices or plate watering devices are arranged on the watering bracket; earthing devices are arranged on the earthing brackets.

Owner:杭州赛得林智能装备有限公司

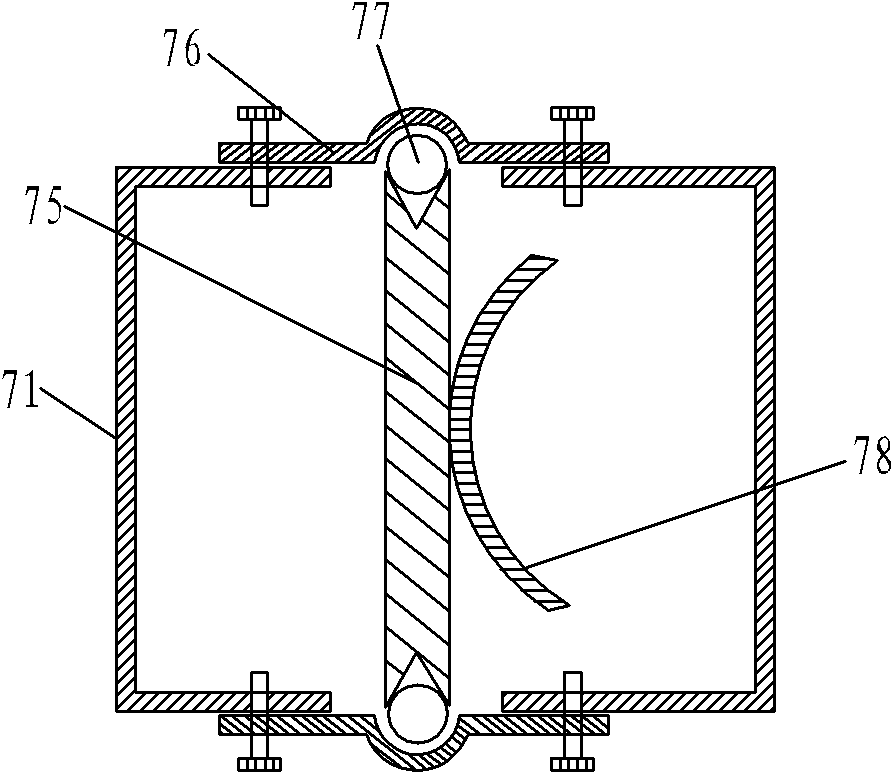

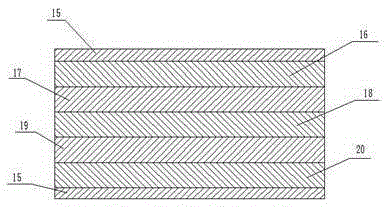

Iridescent film production equipment and application method thereof

The invention relates to iridescent film production equipment. The equipment comprises an extrusion device, a cooling setting device, a trimming device and a winding device distributed in sequence from right to left. The equipment is characterized in that the extrusion device comprises a storage barrel, a hot melt conveying pipe, a filter, a flow regulator, a co-extrusion die and a cooling exhaustmechanism, a cooling roller and a pressure shaft are arranged inside the cooling setting device, the trimming device comprises a guide shaft, a feeding roller, a knife shaft, a pressure roller and awaste collection mechanism, and the winding device comprises a rotating frame, a pressing mechanism, a belt drive mechanism and a bracket. The equipment uses the hot melt conveying pipe to complete two processes of heating melting and transportation at the same time, the equipment structure is helpfully simplified, the occupied area of the equipment is reduced, the production efficiency and energyutilization are improved, through the arrangement of the cooling exhaust mechanism and the waste collection mechanism, smog generated during solidification of the iridescent film can be collected andprocessed, the environmental pollution is reduced, the environmental sanitation of a production site is maintained, and recycling and reuse of wastes are achieved.

Owner:义乌市五环印刷有限公司

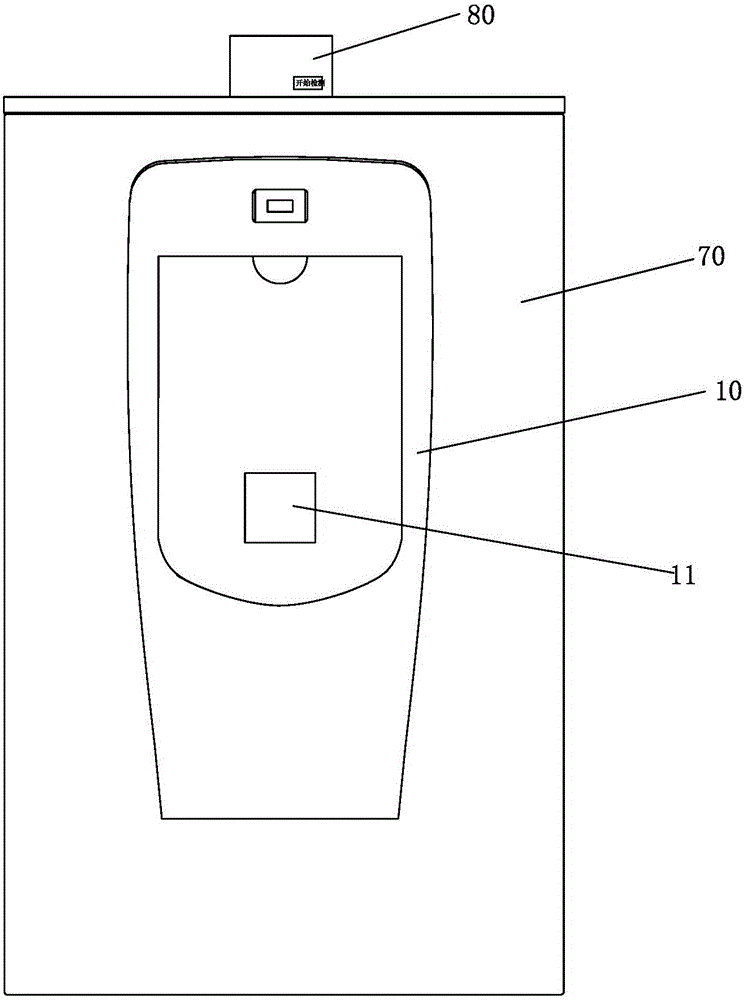

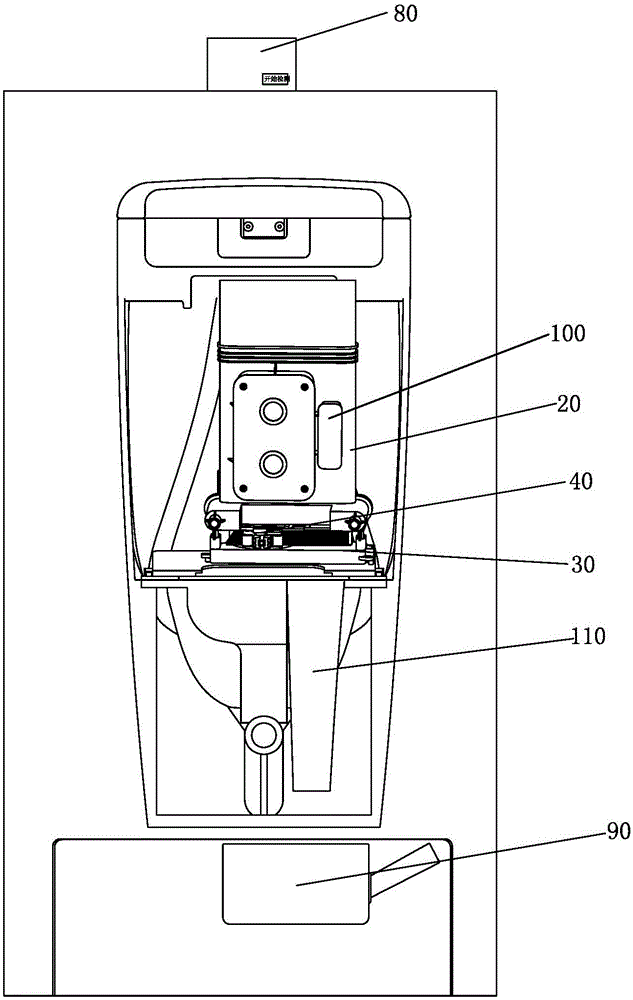

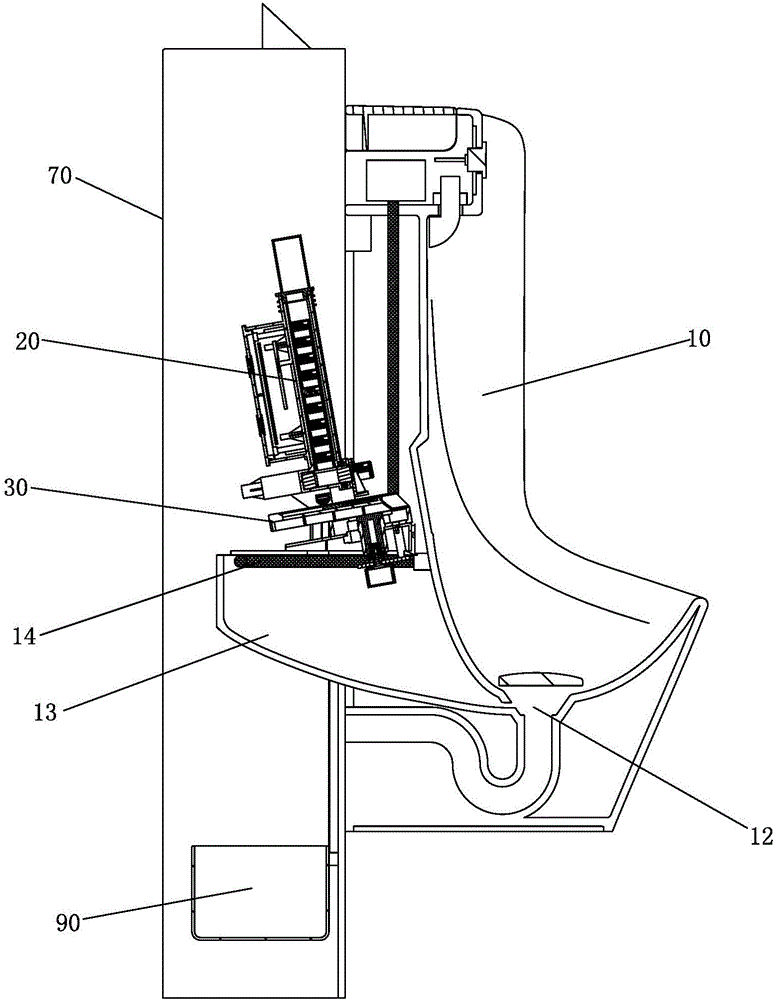

Urine detection device and method

ActiveCN106248920AHigh degree of automationImprove work efficiencyMaterial analysisComputer scienceTest strips

The invention discloses a urine detection device and method. The urine detection device comprises a urine detection assembly. The urine detection assembly comprises a feeding module, a conveying module and a data obtaining module, wherein the feeding module comprises a storage box, the storage box is provided with a plurality of test paper boxes, the test paper boxes contain urine detection test paper, the storage box is provided with a test paper box outlet, the conveying module drives the test paper boxes output from the outlet of the storage box to move so as to achieve urine sampling or urine detection data obtaining or discharging, and the data obtaining module is used for obtaining urine detection data of urine detection test paper soaked with urine in the test paper boxes. The device can automatically complete test paper box feeding, urine sampling, urine detection data obtaining, and is high in automation degree and working efficiency, more intelligent, low in overall cost, high in practicability and easier to popularize.

Owner:JOMOO KITCHEN & BATHROOM

Processing technology of boards for solid wood furniture

ActiveCN111070364ARealize environmentally friendly preparationKeep the environment hygienicWood working apparatusSolid woodPolishing

The invention relates to a processing technology of boards for solid wood furniture. The technology comprises the following steps of first, board drying, wherein drying treatment is carried out on theboards while the moisture content of the boards is controlled to range from 12.5% to 15.5%; second, balancing, wherein the dried boards stand for 3 days to 7 days; third, rough planing, wherein thickness unification is carried out on the boards obtained in the second step to form raw log boards; fourth, wind shearing, wherein each raw log board is adjusted to be 10 millimeters to 20 millimeters longer than the actually needed length; fifth, trimming, wherein raw edges and burrs on the surfaces of the raw log boards are removed; sixth, wide sanding and thickness unification, wherein rough sanding and polishing sanding are carried out on the raw log boards as required to form flat boards; seventh, accurate cutting, wherein width determination and width determination are carried out on the flat boards; eighth, groove making preparation, wherein a preset mortise processing equipment is started up; and ninth, mortise processing, wherein the mortise processing equipment is used to process the flat boards obtained in the seventh step to form mortises, and generated saw dust are collected. The processing technology of the boards for solid wood furniture has the advantages that the environment health can be guaranteed, and environment-friendly manufacturing is benefited.

Owner:苏州鼎和家具有限公司

Steel tube cutting-off machine for manufacturing liquid storage device

InactiveCN105215460AReduce damage rateReduce manufacturing costTube shearing machinesMetallurgyEconomic benefits

The invention provides a steel tube cutting-off machine for manufacturing a liquid storage device. A material supplementing mechanical arm is arranged above a steel tube containing groove. A residual material detector is arranged on the side edge of the steel tube containing groove. A material push air cylinder is arranged on the left side of the steel tube containing groove. Jacking air cylinders are arranged below the steel tube containing groove. A containing table is arranged on the right side of the steel tube containing groove. An infrared sensor is arranged on the left side of the steel tube containing groove. A rotary cutter is arranged above the containing table. A discharging through groove is formed below the containing table. The rotary cutter is connected through a lifting air cylinder above the rotary cutter. The right side of the rotary cutter is provided with a position detector. A stop block is arranged below the position detector. A position adjusting device is arranged behind the stop block. The lifting air cylinder controls the rotary cutter through the position detector to cut a steel tube. The cut steel tube falls into a discharging track through the discharging through groove and enters an assigned box. In this way, the whole cutting-off machine is safe and fast, the damage rate of the steel tube is reduced, the production cost is reduced for enterprises, and economic benefits are increased for the enterprises.

Owner:WUHU HAN FENG TECH

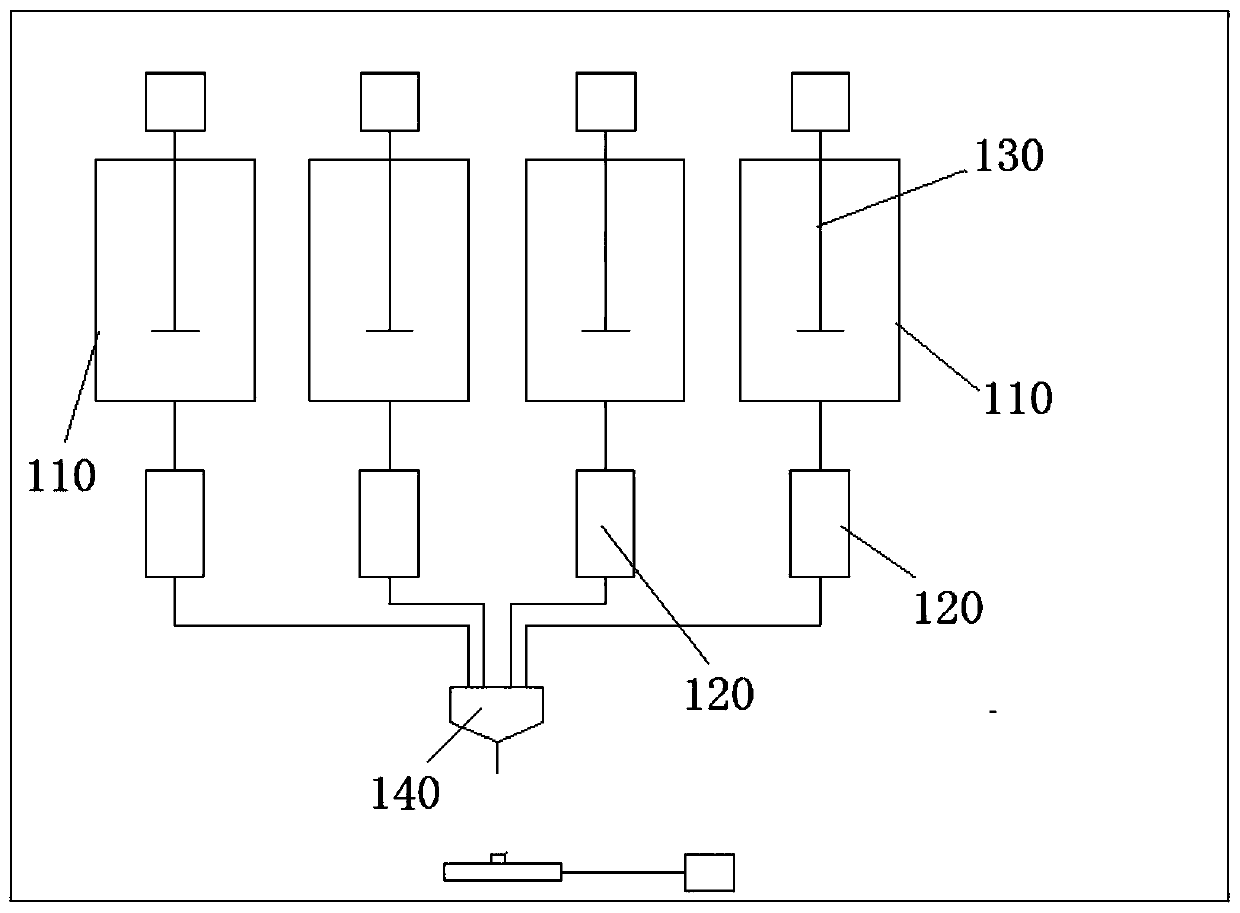

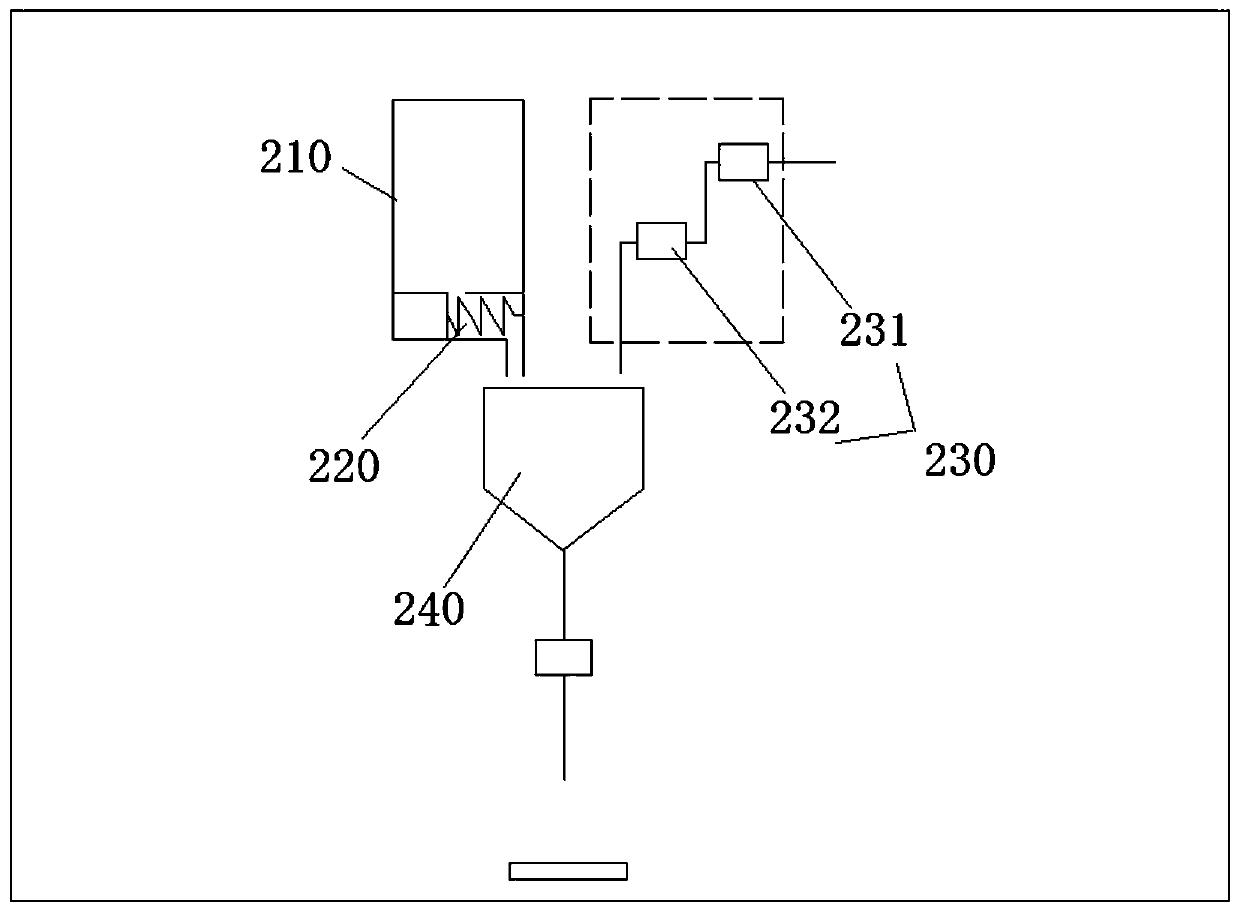

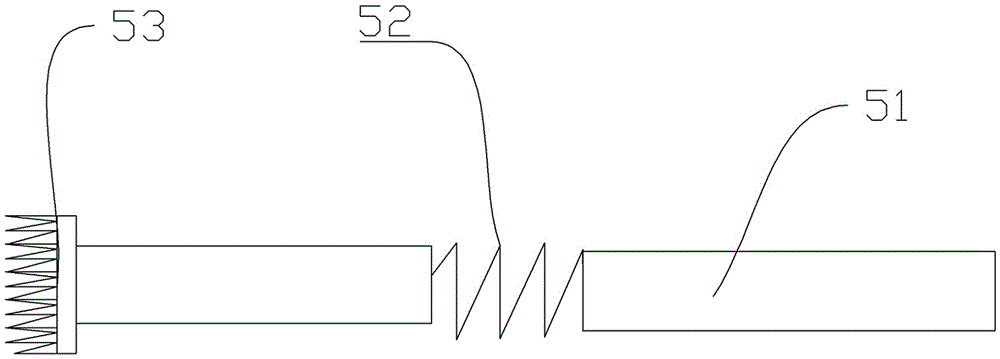

Seasoning system

The invention provides a seasoning system which comprises a quantifying subsystem, a transportation sub system and a feeding sub system, wherein the quantifying sub system is used for quantitatively outputting seasonings, the transportation sub system is used for receiving the seasonings output by the quantifying sub system and transporting the seasonings to the feeding sub system, and the feedingsub system is used for outputting the received seasonings. Therefore, seasonings of different types can be quantitatively fetched through the quantifying sub system, the seasonings output by the quantifying sub system are transported to the charging sub system through the transportation sub system, and the seasonings are fed to a cooking apparatus through the feeding sub system. Therefore, quantitative and hermetical transportation and manual and automatic feeding of the seasonings can be achieved, continuous action of a seasoning treatment process is achieved, and the workload of an operatoris alleviated greatly, so that the seasonings are added more simply and conveniently in a cooking process.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

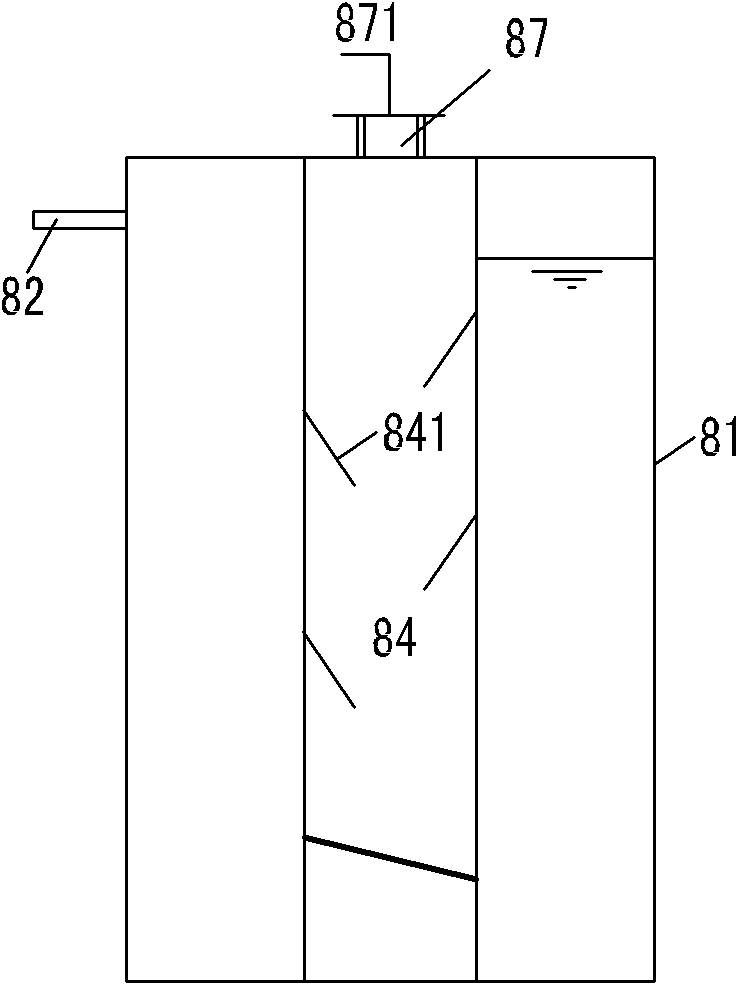

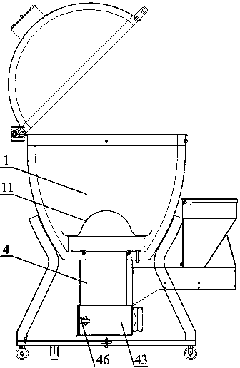

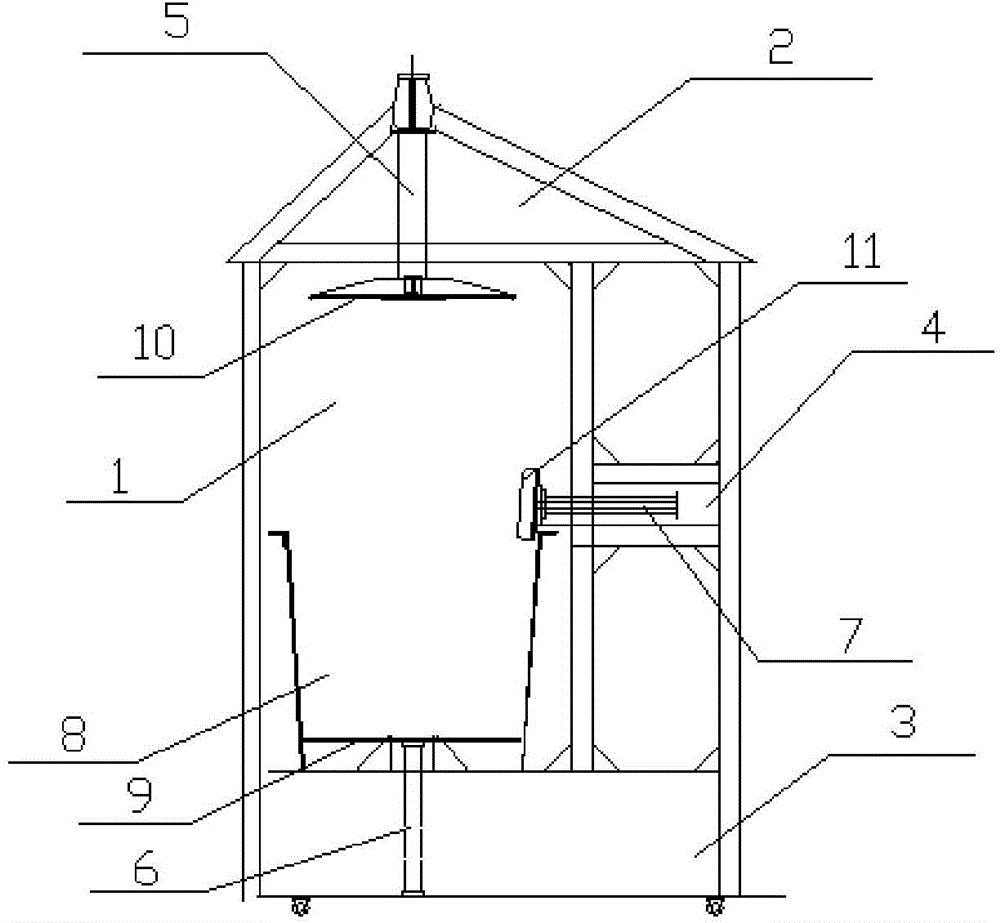

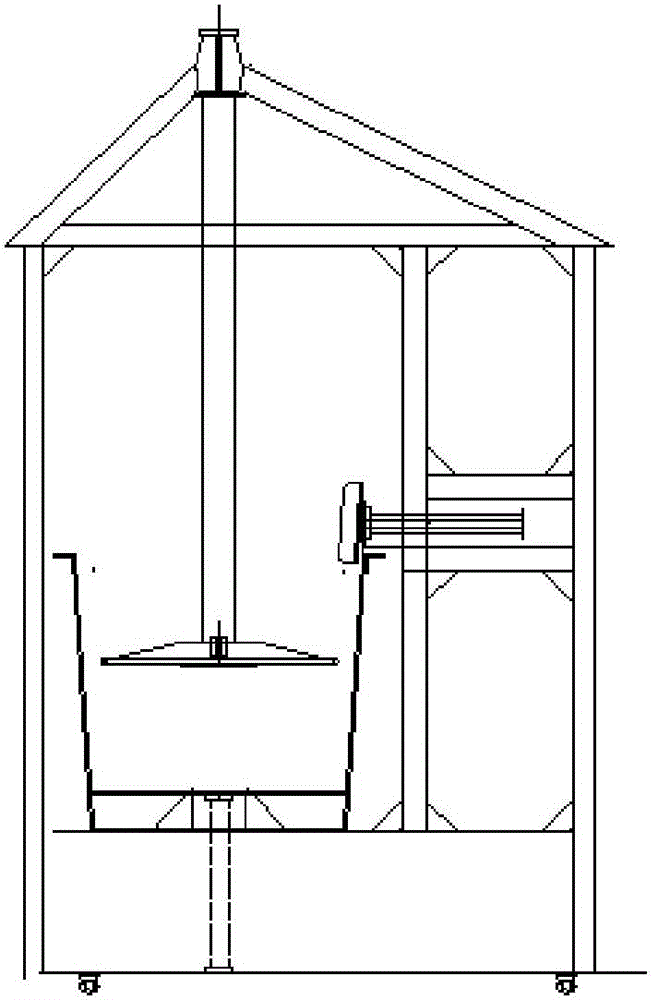

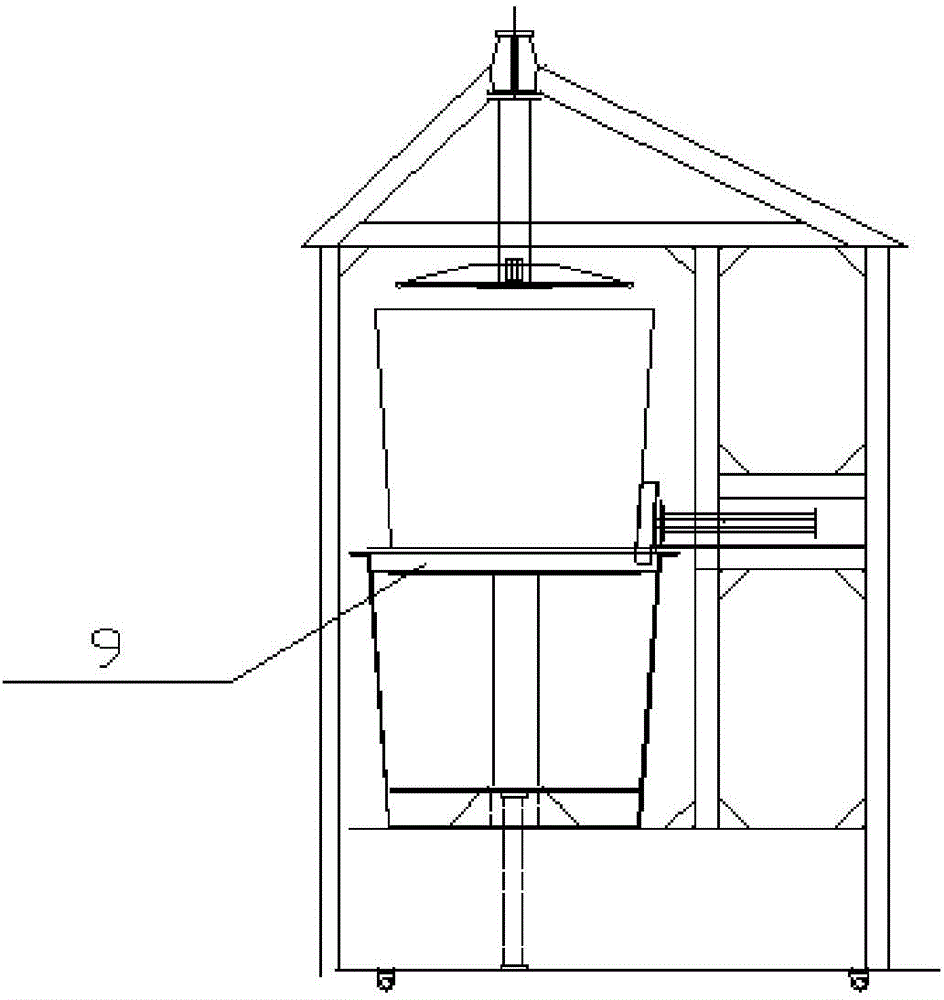

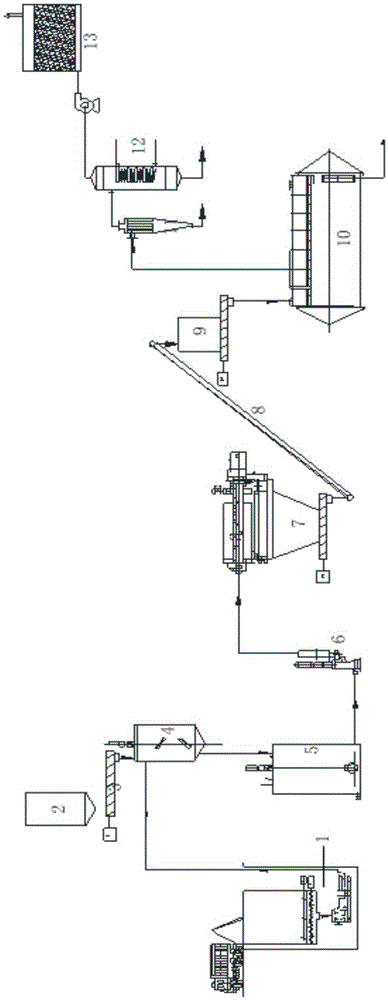

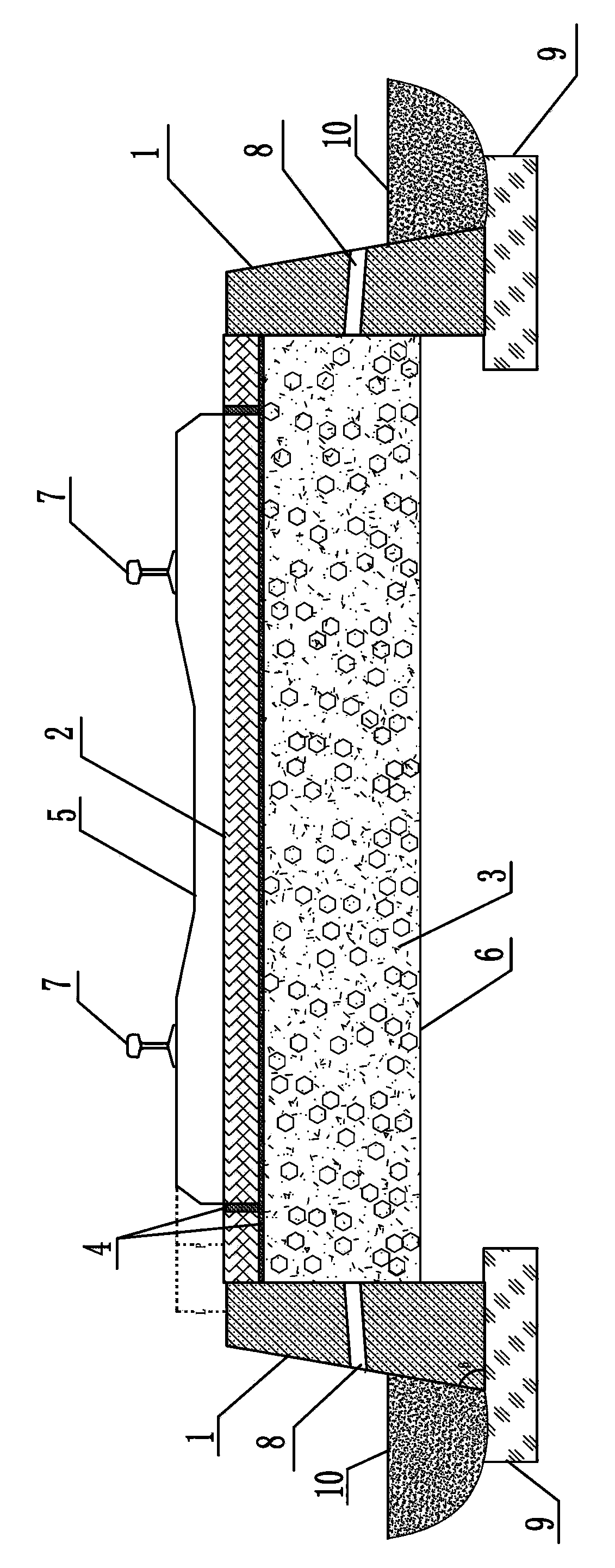

Apparatus and method for quickly converting swill to organic fertilizer

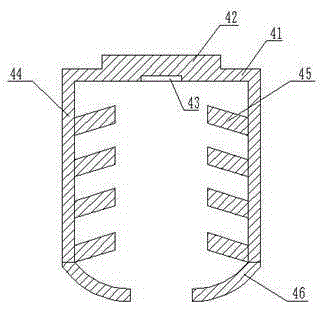

ActiveCN102887733BSimple structureCompact structureClimate change adaptationOrganic fertilisersOrganic fertilizerWaste management

The invention relates to an apparatus for converting swill to organic fertilizer. The apparatus comprises a conversion chamber (5) for placing the to-be-treated swill therein and having an air inlet pipe (10) extending into the conversion chamber; a stirring device arranged in and located at the lower part of the conversion chamber (5); a heating device (6) arranged at the bottom of the conversion chamber (5) and used for heating the to-be-treated swill in the conversion chamber; and air supplying devices (1, 2) used for supplying oxygen-containing gas into the conversion chamber and communicated with the conversion chamber (5) through the air inlet pipe so as to supply the air. The apparatus enables the to-be-converted organic waste to contact with high-temperature oxygen in the conversion chamber, and accelerates the conversion of the to-be-treated swill, so as to mildly and quickly complete conversion and achieve the purpose of organic degradation.

Owner:北京国资环境保护技术有限公司

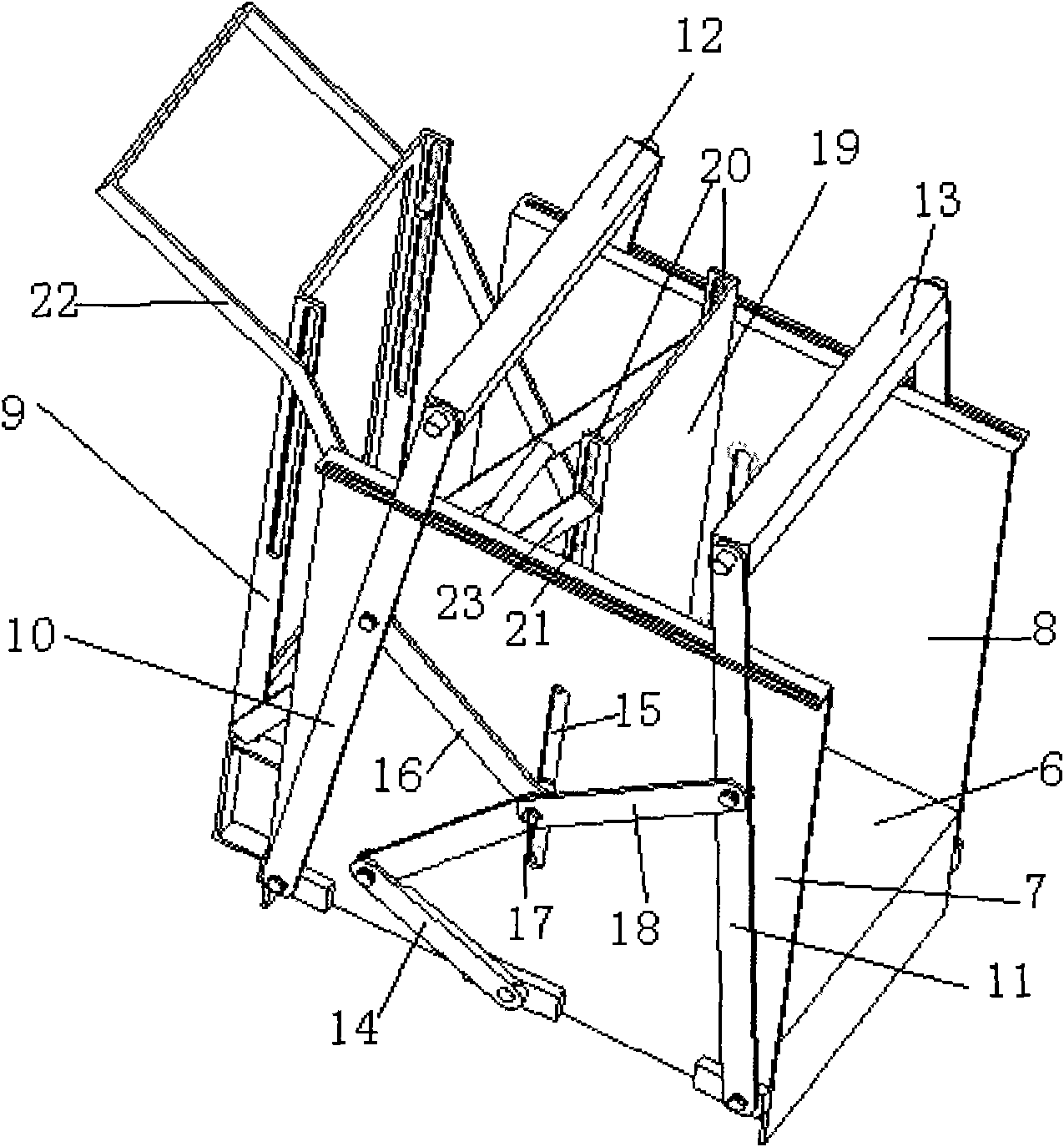

Green and environment-friendly novel marine trash can

InactiveCN105015977AFully compressedKeep the environment hygienicRefuse receptaclesEngineeringPiston rod

The invention provides a green and environment-friendly novel marine trash can. The green and environment-friendly novel marine trash can comprises a can body and a frame body used for containing the can body. An oil cylinder device acting together with the can body is arranged in the frame body. A trash bag is arranged in the can body. The oil cylinder device is connected with a hydraulic station through a pipeline. A reversing valve is arranged at the position, close to the oil cylinder device, on the pipeline. The green and environment-friendly novel marine trash can has the beneficial effects that a novel oil cylinder system is adopted, trash in the can body can be sufficiently compressed, space can be saved, and the environment of a ship body can be kept sanitary; three oil cylinders have clear division of labor, cooperate with one another and can complete the extrusion and ejection process of the trash; and the oil cylinder device can have multiple sections of oil cylinders, and therefore the phenomenon that that the push length can not be achieved when the length of piston rods in the oil cylinders is not enough is avoided.

Owner:TIANJIN HUARONG PNEUMATIC & HYDRAULIC COMPLETE SYST

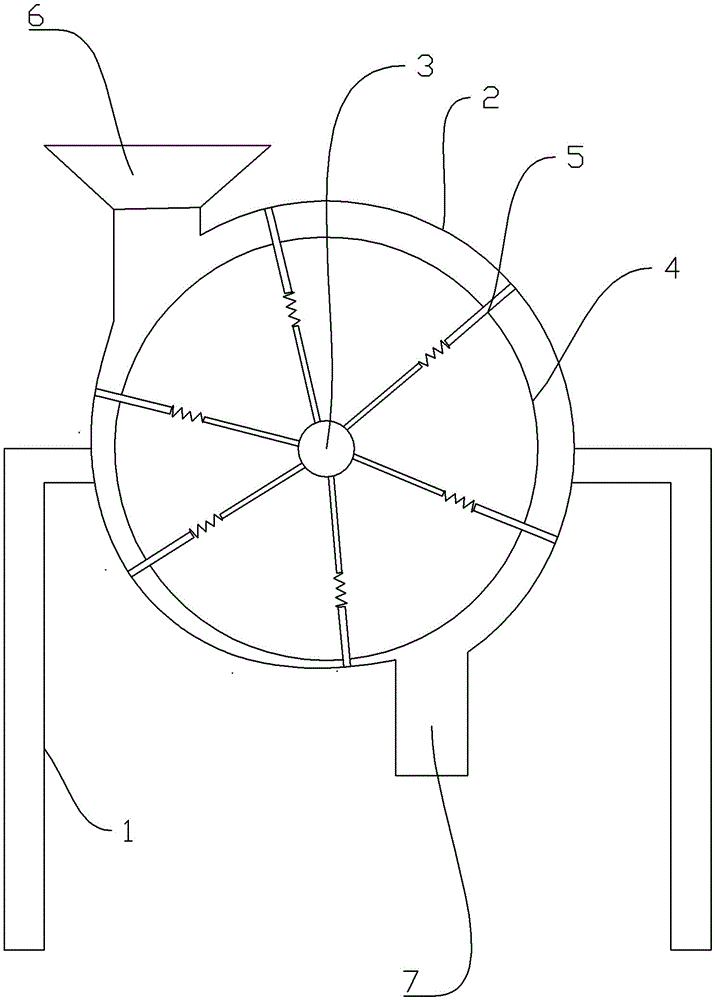

Cow dung water removing machine convenient to clean

The invention relates to the field of cow dung processing equipment, and in particular to a cow dung water removing machine convenient to clean. The cow dung water removing machine comprises a support. A fixed cylinder is arranged on the support, and an inlet and an outlet are formed in the top and the bottom of the fixed cylinder respectively. A drum is arranged in the fixed cylinder. A rotating shaft is arranged in the center of the drum. Scrapers which are perpendicular to the rotating shaft and extend out of the drum are evenly distributed on the drum. A screen is arranged between the inlet and the outlet. Meshes are formed in the attached part of the fixed cylinder and the screen. A gap between the drum and the screen is gradually reduced from a feeding port to a discharging port. Each scraper comprises two end plates linearly arranged, wherein a spring is arranged between the two end plates. The ends of the scrapers are attached to the inner wall of the fixed cylinder. Cleaning brushes are arranged at the ends of the parts, attached to the fixed cylinder, of the end plates, and the cleaning brushes and the end plates are detachably connected. When the screen is blocked through cow dung, the cleaning brushes can be installed at the ends of the scrapers, water is introduced into the water removing machine, the cleaning brushes can clean the inner wall of the drum and the screen, and the problem of blockage of the screen is solved.

Owner:CHONGQING YINIU AGRI DEV CO LTD

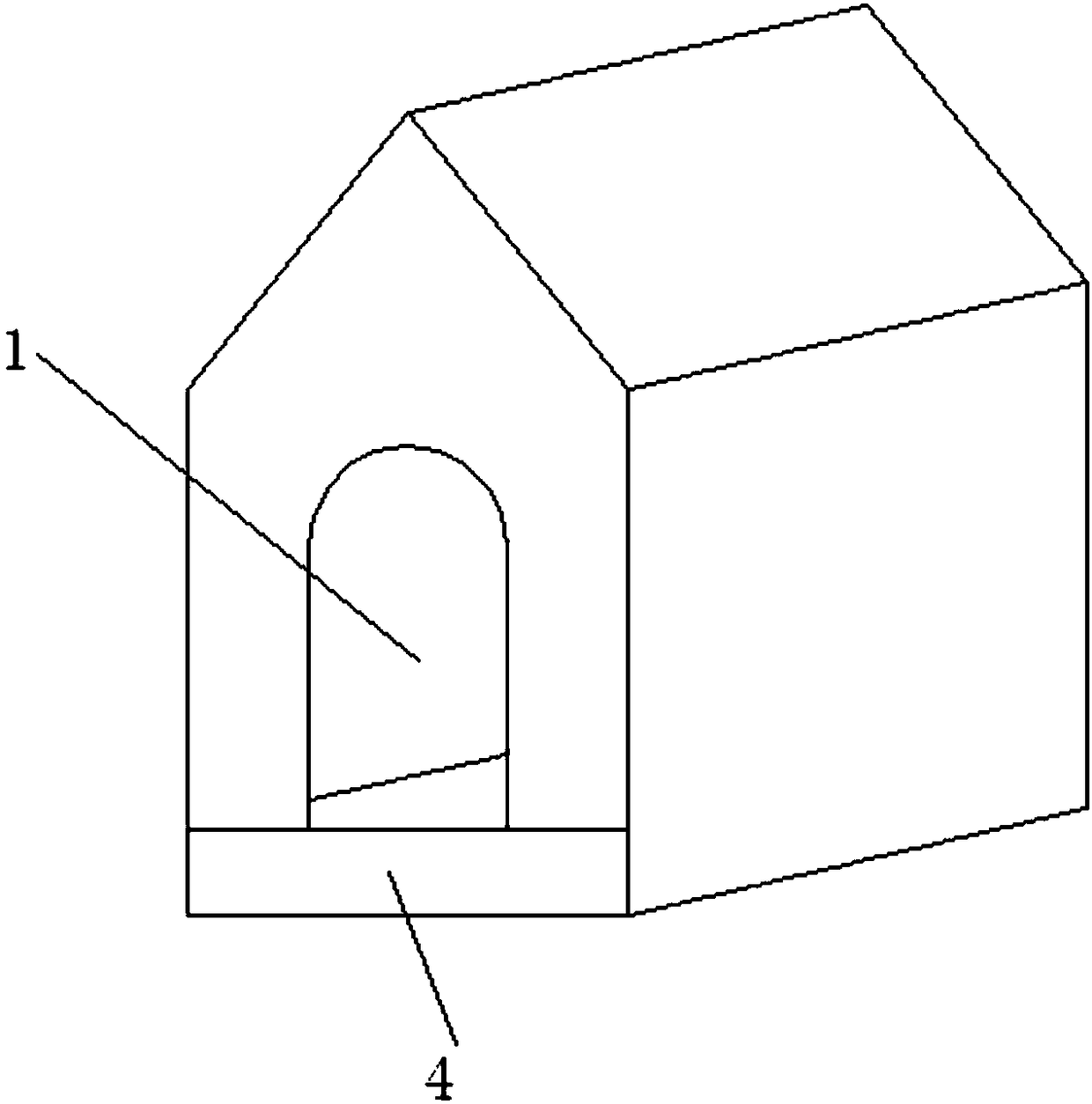

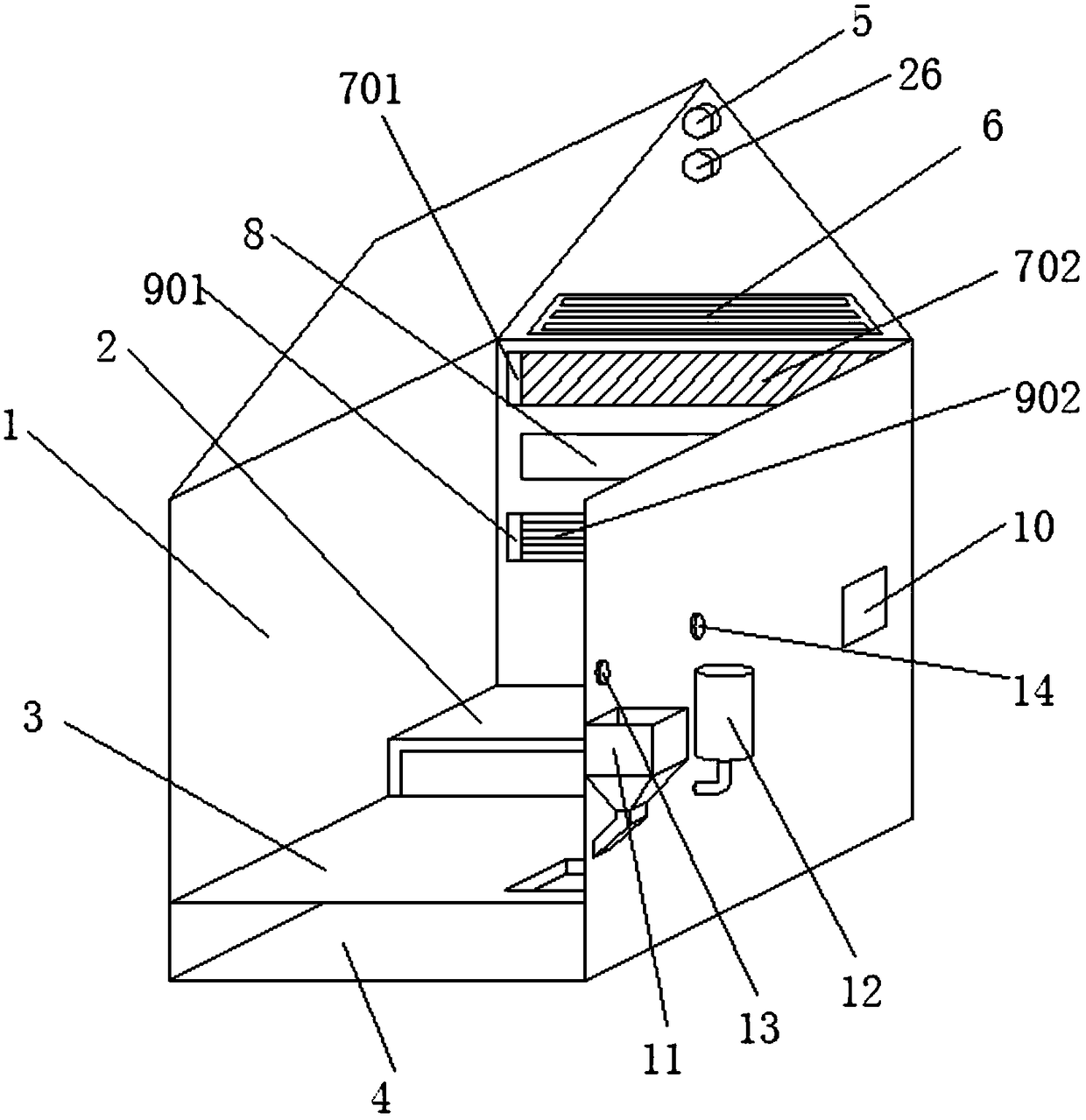

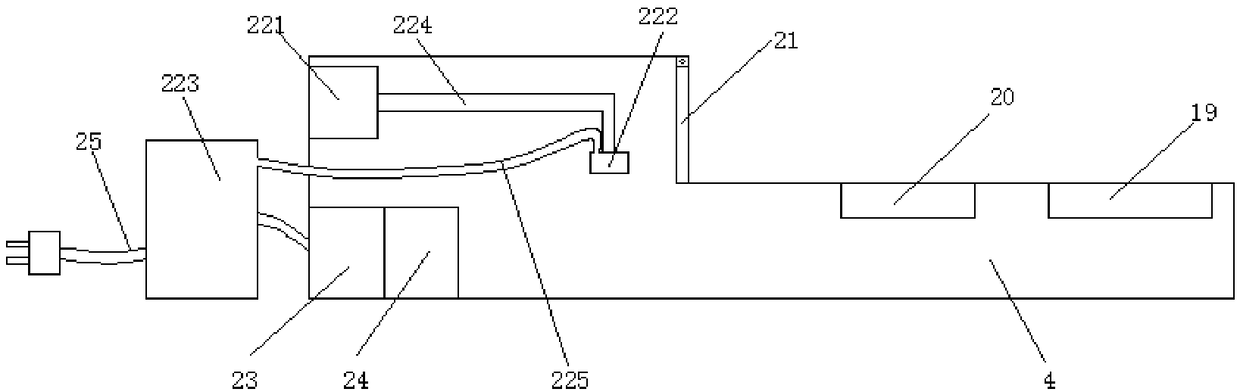

Pet cage which can be controlled remotely

InactiveCN108541608AKeep the air freshKeep healthyAnimal housingSimultaneous control of multiple variablesTemperature controlWater storage tank

The invention provides a pet cage which can be controlled remotely. The pet cage comprises a pet activity chamber, a pet rest platform, a partition and a lower-layer chamber body, an illuminating lamp, a camera and a ventilation opening are arranged at the inner wall of the top of the pet activity chamber, and a first sensor and a temperature control device are embedded in the inner wall of the back face of the pet activity chamber; a disinfection and sterilization device is embedded below the first sensor and the temperature control device, a second sensor and a humidity removing device are embedded below the disinfection and sterilization device, and a food storage device and a water storage tank are arranged at the outer side of one side wall of the pet activity chamber; a first LED lamp and a second LED lamp are respectively arranged above the food storage device and the water storage tank, a cleaning device is arranged inside the lower-layer chamber body, and the cleaning device comprises a motor, a dust collector head and a dust collector body. According to the pet cage, self-timing feeding and water feeding are achieved, the temperature in the pet cage can be remotely controlled by a phone, disinfection and sterilization are achieved, automatic humidity removing is achieved, the pet cage can be automatically cleaned, and the intelligence is high.

Owner:湖州曜东服饰有限公司

Intelligent waste bin

InactiveCN104071499AKeep the environment hygienicWaste collection and transferRefuse receptaclesElectric energyInfra-red color

The invention discloses an intelligent waste bin which comprises an outer barrel and an inner barrel which sleeves inside the outer barrel. A cavity exists between the outer barrel and the inner barrel; the intelligent waste bin further comprises a remote control car with a remote controller, an infrared sensor, a prompter and a processing unit; the waste bin is fixedly connected to the upper end of the remote control car, so that the waste bin can walk under remote control; the infrared sensor can sense whether the waste are full of the waste bin; the processing unit controls the prompter to send out an alarm so as to remind a user that the waste bin is full, so that the environmental health can be kept; the intelligent waste bin further comprises a solar cell panel which provides electric energy to the processing unit. Therefore, the intelligent waste bin is environment-friendly and economic.

Owner:郭裴哲

Disposable feces treatment system with energy-saving, environment-friendly and ecologic recycling functions

ActiveCN103947561AAchieve recyclingSuitable growth environmentGas production bioreactorsWaste based fuelHuman wasteAutomatic control

The invention discloses a disposable feces treatment system with energy-saving, environment-friendly and ecologic recycling functions. The system is characterized in that the treatment system comprises a pigsty system, a solid and liquid separating system and a solid and liquid treatment system, wherein the pigsty system adopts a greenhouse structure, the bottom of a pigsty is provided with a feces leaking plate, the solid and liquid separating system is arranged under the pigsty, the bottom of the solid and liquid separating system is provided with an automatic control system, the liquid treatment system of the solid and liquid separating system consists of a concentration tank and a biogas tank, and the solid treatment system sequentially consists of a feces stirring machine, a fermentation tank, a turning and throwing device, a pressing device, a push and pull device and a packaging machine. The feces in the pigsty are separated and treated to form biogas and fertilizer, and then the recycling and reutilization can be realized. The feces treatment system has the advantages that the clean and sanitary level of the pigsty is fully improved, the environment of the pigsty is improved, the zero emission of feces and urine is truly realized, and the system is suitable for various types of culturing farms.

Owner:SHANDONG XINJI ANIMAL HUSBANDRY

Ammeter box with waterproof and dustproof functions

The invention discloses an ammeter box with waterproof and dustproof functions. The ammeter box is simple in structure and convenient to use. A filtering net is set to affectively prevent dust and flies entering the ammeter box, so that unnecessary loss caused to electrical equipment in the ammeter box is avoided; a drying agent is arranged, so that the inner part is kept dry; multiple structures are arranged, so that water and dust are effectively prevented, and the safety and the effective heat dissipation of electrical elements in the ammeter box are ensured; sealing strips in the ammeter box are relatively low in hardness, so that the installation convenience, the damping effect and the sealing effect are improved; arc-shaped strips are further formed at the inner side of the bottom part of a sealing body, the sealing performance is improved, the waterproof and dustproof effects are ensured, and the appearance is beautiful; a waterproof film of the ammeter box is nontoxic, pollution-free long in service lifetime and especially continuous in antibiosis capability, so that the growth of bacteria and fungi is inhibited, the environment health is ensured, and the super-high waterproof performance is provided.

Owner:RUYANG COUNTY ELECTRIC POWER BUREAU +1

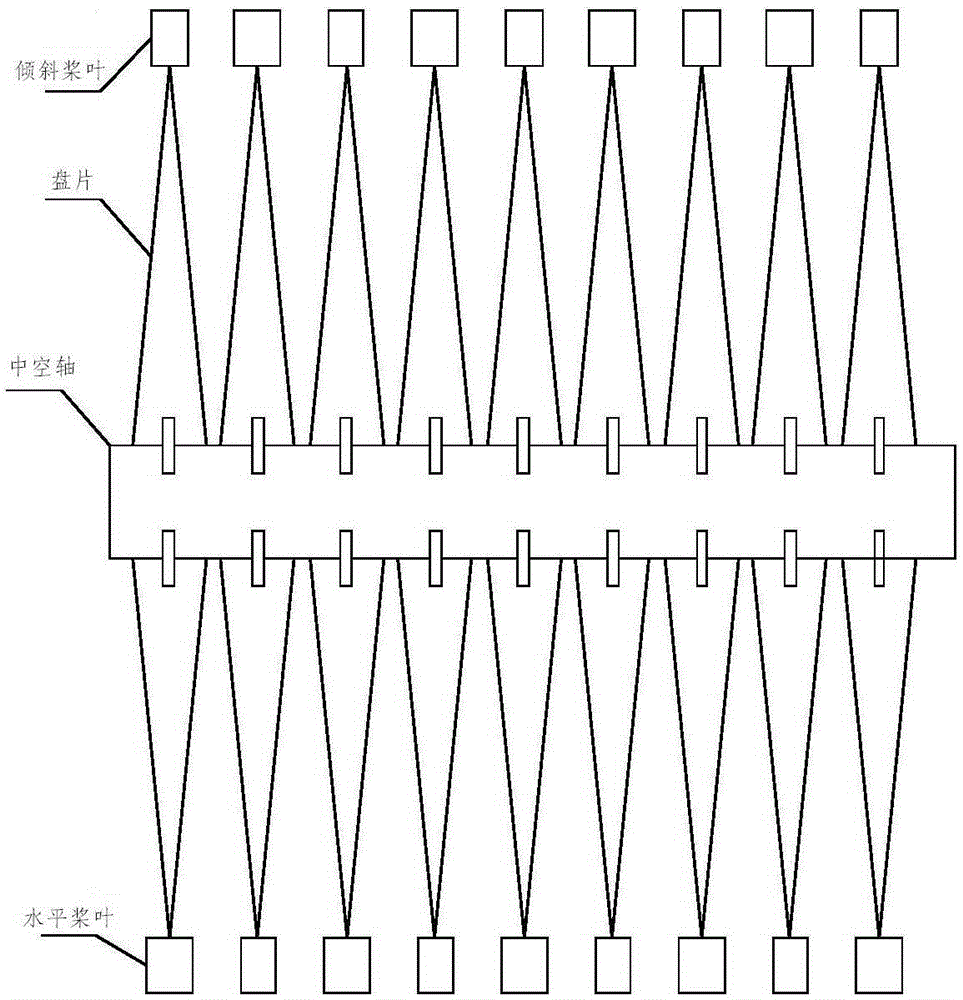

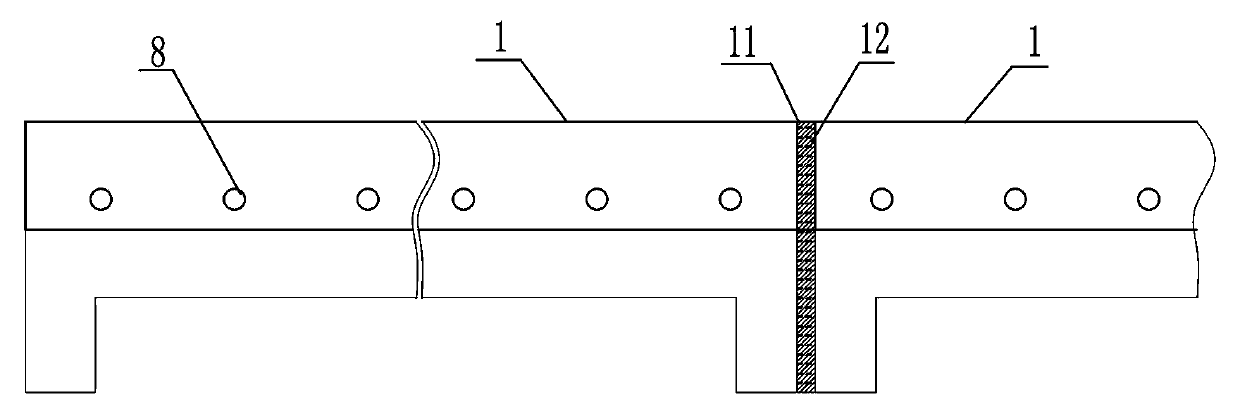

Dehydration and desiccation device and method for sewage sludge

InactiveCN105271629AKeep the environment hygienicHigh work pressureSludge treatment by de-watering/drying/thickeningSewageHigh pressure

The invention relates to a dehydration and desiccation device and method for sewage sludge. The device comprises a wet sewage sludge storage and delivery system, a sludge dehydration system and a sludge desiccation system which are communicated through closed type pipelines and used for delivering, storing and modifying sludge, dehydrating the sludge and desiccating the sludge into grains respectively, wherein the sludge dehydration system comprises high pressure elastic press filtering equipment at a minimum so that working pressure of a filter press can be raised; the sludge desiccation system comprises horizontal type disc desiccation equipment at a minimum so that the sludge obtained after modification and dehydration can be desiccated. The dehydration and desiccation device is applicable to treatment and disposal of sludge of different water contents, and the sludge from different sewage treatment plants can all be treatment through the process. The sludge is sent into a sludge bin in the mode of vehicle carrying and transportation and then delivered through a pump and the pipelines, environmental pollution caused by delivery of the sludge is not caused, and environmental sanitation is good.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +1

Hemostasis bag for gynaecology and obstetrics

InactiveCN109350163AReasonable designEnsure sanitationBalloon catheterObstetrical instrumentsInjectorSyringe

The invention relates to a hemostasis bag for the gynaecology and obstetrics. The hemostasis bag comprises a handle, an air inflation tube and an airbag, one end of the air inflation tube is connectedwith the handle, and one end of the air inflation tube is connected with an air inflation device; the other end of the air inflation tube is communicated with the airbag, a hemostasis bag body wrapsthe outer side of the airbag, and the airbag and the hemostasis bag body are arc; hemostasis medicine cotton wraps the outer side of the hemostasis bag body, and multiple medicine outlets are evenly formed in the hemostasis bag body. According to the hemostasis bag, the air bag is inflated through the air inflation device, the hemostasis bag body is expanded, even compression hemostasis can be conducted, hemostasis medicine liquid is injected to a medicine application tube through an injector and flows out from the medicine outlets of the hemostasis bag body, and hemostasis treatment is achieved; a pressure sensor between the airbag and the hemostasis bag body can detect the contact pressure between the hemostasis bag body and the vaginal wall and is used for controlling starting and closing of a micro electric air inflation pump, waste liquid can be discharged through a liquid discharge pipe, environment sanitation can be guaranteed, and the burden of medical personnel is reduced.

Owner:魏秀玲

Dustproof cutting machine for polypropylene (PP) slices

ActiveCN109291129AImprove processing efficiencyKeep it flatMetal working apparatusEngineeringPolypropylene

The invention belongs to the field of polypropylene (PP) slice processing, in particular to a dustproof cutting machine for PP slices. The invention aims to solve the technical problem so as to provide the dustproof cutting machine for the PP slices, and the dustproof cutting machine for the PP slices can be used for carrying out dustproof treatment on the PP slices, and cutting and punching the PP slices at the same time. The dustproof cutting machine for the PP slices comprises a first installation plate, a first support seat, a first arc-shaped plate, a first electric push rod, an exhaust pipe, a cutting table, a third installation plate, a first lifting plate, a drive roller, a second electric push rod, a support frame, a dustproof cover, a feeding pipe, a first butterfly bolt, a thirdsupport seat and the like, wherein the first arc-shaped plate is fixedly connected to the top part of the first installation plate; and the cutting table is fixedly connected to the top part of the first installation plate through a second support seat. The dustproof cutting machine for the PP slices provided by the invention achieves the effects on carrying out dustproof treatment on the PP slices during the cutting process, punching the PP slices at the same time, and improving the PP slice processing efficiency.

Owner:刘宝义

Railway solidified and closed ballast bed and solidification and closing method

ActiveCN104195890AEasy to cleanEasy to scatterBallastwayRailway track constructionFilling materialsBallast

The invention relates to a railway solidified and closed ballast bed and a solidification and closing method. The railway solidified and closed ballast bed comprises ballast blocking walls, filling materials and an anti-crack concrete layer, the ballast blocking walls are arranged on the two sides of the railway ballast bed respectively, the filling materials are arranged in the ballast bed, and the anti-crack concrete layer is arranged at the top of the ballast bed. The solidification and closing method of the railway ballast bed comprises the following steps of ballast bed clearing and screening, ballast blocking wall pouring, ballast bed tamping and ballast bed closed pouring and solidification. The ballast blocking walls and ballast bed ballast can form a firm whole conveniently, conveyed materials can be cleared up, loaded and unloaded conveniently, the ballast bed of a railway line is closed, it is guaranteed that the ballast bed is firm, it can be guaranteed that the materials passing through a railway cannot be scattered on the ballast any more, meanwhile, the materials scattered on the railway line in the transportation, loading and unloading process can be cleared up conveniently, waste is reduced, and environmental sanitation is guaranteed.

Owner:刘义安 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com