[0003] The existing rice planters have the following disadvantages: 1. The steps of matrix delivery, plate loading and matrix brushing are respectively processed by a split mechanism, that is, the matrix transport is processed by the conveying mechanism, and the plate is loaded by the matrix. The plate mechanism is processed, and the matrix

brush leveling is processed by the matrix brush

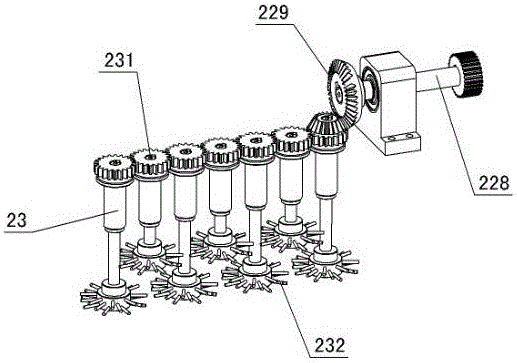

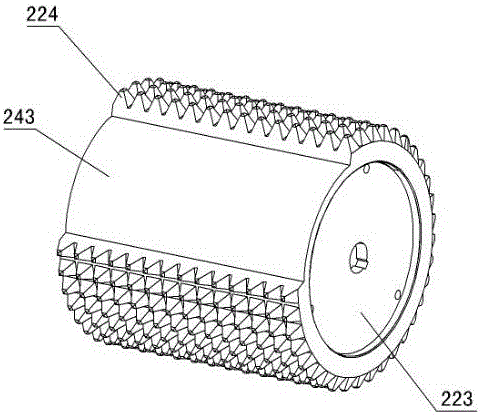

leveling mechanism. These three mechanisms are in the form of splits, which are large in size, occupy a large space, and increase the manufacturing cost. In addition, the volume of the feed bin is small, and workers need to constantly Feeding materials into the feed bin will result in high labor intensity, high labor costs, and high production costs, and although the existing substrates will be stirred before being packed during transportation, there will still be some hard block substrates that cannot After being broken up, the growth of seeds will be affected after loading; 2. The pressure hole mechanism in the rice planter generally adopts roller type and flat plate type, and the

conveyor belt of the roller type hole pressure mechanism and the

conveyor belt of the whole machine are a whole structure, and the conveying The output shaft of the belt drives the drum to rotate synchronously through the synchronous belt, that is, the

conveyor belt of the whole machine and the drum share a motor for transmission, which leads to insufficient output power. When the drum presses the substrate on the

seedling tray, the pressure is insufficient. The bumps on the roller can still press the holes normally in the initial stage of pressing the holes (that is, when the bumps are just pressed into the matrix), but in the latter stage of the pressure holes (that is, when the bumps rotate out of the matrix), there will be insufficient pressure, causing the points to tilt , offset, thereby affecting the shape of the

acupuncture points, and due to insufficient power, it is impossible to install the bristles that share the power. When making holes, the conveyor belt must be stopped to press holes, which affects production efficiency, and the bumps of the holes are located at the lower end of the flat plate, so the

bristle structure cannot be set, and the surface of the bumps is also easy to adhere to the matrix, which affects the next hole pressing; 3.

Sowing The mechanism only has a feeding hopper and a receiving hopper. The volume of the feeding hopper is small, and the number of stored seeds is small, requiring workers to add seeds continuously, so the labor intensity of the operators is high, and the production efficiency is reduced; 4.

Sowing A plurality of separate and independent seed suction holes are set on the sowing drum of the mechanism, so that only one seed is sown in each

acupuncture point of the seedling tray. People adopt two groups of sowing mechanisms before and after being set on the frame, so that each

acupuncture point can sow 2 seeds, but the two groups of sowing mechanisms increase the volume of the complete machine and increase the manufacturing cost of the complete machine; five, sowing When the seed suction hole on the drum sucks the seeds, several seeds often stick together, so that many seeds will be sucked. If the excess seeds are not removed, after two sowings, there will be 3, 4 or even 5 seeds, resulting in serious seed waste; 6. After pouring seeds into the feeding hopper of the seeding mechanism, due to the wide feeding hopper, uneven seed distribution is likely to occur (that is, more seeds are distributed on one side) , and less on the other side), this will cause the seeds on one side of the feeding hopper to be sown, while there are more seeds on the other side, which will affect the sowing effect; 7. Only one watering mechanism is used, that is, after the seedling tray is sown, Cover the soil and then sprinkle water, so that the water cannot be directly sprinkled on the seeds, which will affect the water absorption of the seeds Harvesting, thereby affecting the growth and development of seeds; 8. The watering device adopts a water hole under the watering

pipe, and the water is sprayed from the water hole under the action of the water pump. Due to the high

water pressure, the sprayed water is easy to disperse the substrate. Dispersion, making the surface of the substrate pitted and uneven, too much or too little covering soil on the seeds is not conducive to seed growth

Login to View More

Login to View More  Login to View More

Login to View More