High-purity hydrogen preparation method based on pressure swing adsorption

A pressure swing adsorption and hydrogen technology, which is applied in separation methods, chemical instruments and methods, and hydrogen separation through selective and reversible absorption, can solve the problems of low production efficiency and low hydrogen purity, and achieve improved production efficiency and purity. , the effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

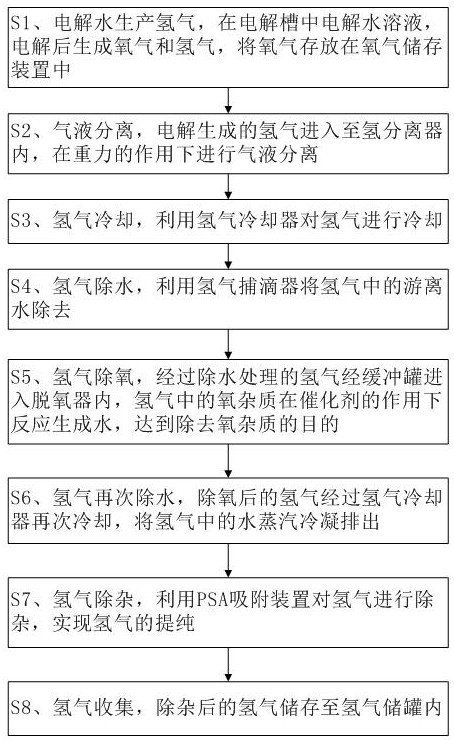

[0044] combine figure 1 As shown, a method for preparing high-purity hydrogen based on pressure swing adsorption includes the following steps:

[0045] S1, electrolyze water to produce hydrogen, electrolyze the aqueous solution in an electrolytic cell, generate oxygen and hydrogen after electrolysis, and store the oxygen in an oxygen storage device;

[0046] S2, gas-liquid separation, the hydrogen generated by electrolysis enters the hydrogen separator, and the gas-liquid separation is carried out under the action of gravity;

[0047] S3. Hydrogen cooling, using a hydrogen cooler to cool the hydrogen;

[0048] S4. Hydrogen water removal, using a hydrogen drop catcher to remove free water in the hydrogen;

[0049] S5. Deoxygenation of hydrogen, the hydrogen treated by dewatering enters the deaerator through the buffer tank, and the oxygen impurities in the hydrogen react under the action of the catalyst to generate water, so as to achieve the purpose of removing the oxygen im...

Embodiment 2

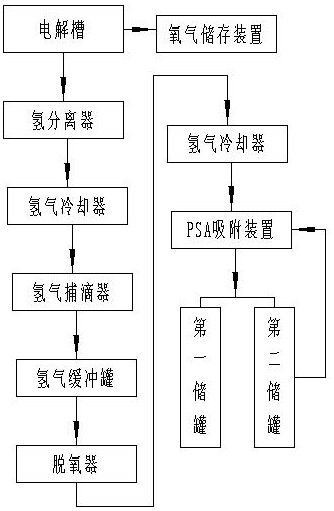

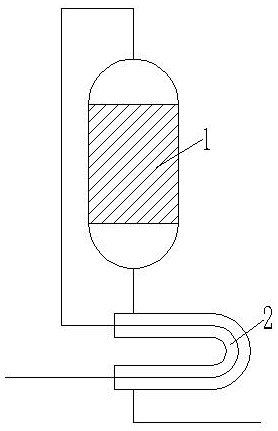

[0059] like Figure 2-5 As shown in the figure, a method for preparing high-purity hydrogen based on pressure swing adsorption includes: an electrolytic cell, wherein a KOH solution is contained in the electrolytic cell, an oxygen storage device is connected to the oxygen end of the electrolytic cell, and an oxygen storage device is connected to the oxygen end of the electrolytic cell. The hydrogen end is connected with a hydrogen separator, the hydrogen containing lye enters the hydrogen separator, and under the action of gravity, gas-liquid separation is realized, the hydrogen separator is connected with a hydrogen cooler, and the hydrogen is cooled by the hydrogen cooler. The hydrogen cooler is connected with a hydrogen drop catcher, the hydrogen drop catcher removes the free water in the hydrogen, the hydrogen drop catcher is connected with a hydrogen buffer tank, the hydrogen buffer is connected with a deaerator, and the deaerator is connected with a trace amount of water....

Embodiment 3

[0067] A method for preparing high-purity hydrogen based on pressure swing adsorption, comprising: an electrolytic cell, wherein a KOH solution is contained in the electrolytic cell, an oxygen storage device is connected to an oxygen end of the electrolytic cell, and a hydrogen end of the electrolytic cell is connected to There is a hydrogen separator, the hydrogen containing lye enters the hydrogen separator, and under the action of gravity, gas-liquid separation is realized, the hydrogen separator is connected with a hydrogen cooler, and the hydrogen is cooled by the hydrogen cooler, and the hydrogen cooler is A hydrogen drop catcher is connected, the hydrogen drop catcher removes the free water in the hydrogen, the hydrogen drop catcher is connected with a hydrogen buffer tank, and the hydrogen buffer is connected with a deaerator, and the deaerator is filtered by trace oxygen impurities. Under the action of the catalyst, the reaction generates water to achieve the purpose o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com