Preparation process of cobalt pellets in cobalt regulating rod assembly

A technology of cobalt regulating rod and preparation process, which is applied in the field of manufacturing nuclear fuel elements, and can solve problems such as high impurity content, low production efficiency, and complicated preparation process

Active Publication Date: 2011-03-30

CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Additives, such as polyvinyl alcohol or paraffin, etc., lead to high impurity content after sintering, and due to the complicated preparation process of cold and other green bodies, resulting in

Makes production inefficient and not suitable for mass production of components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

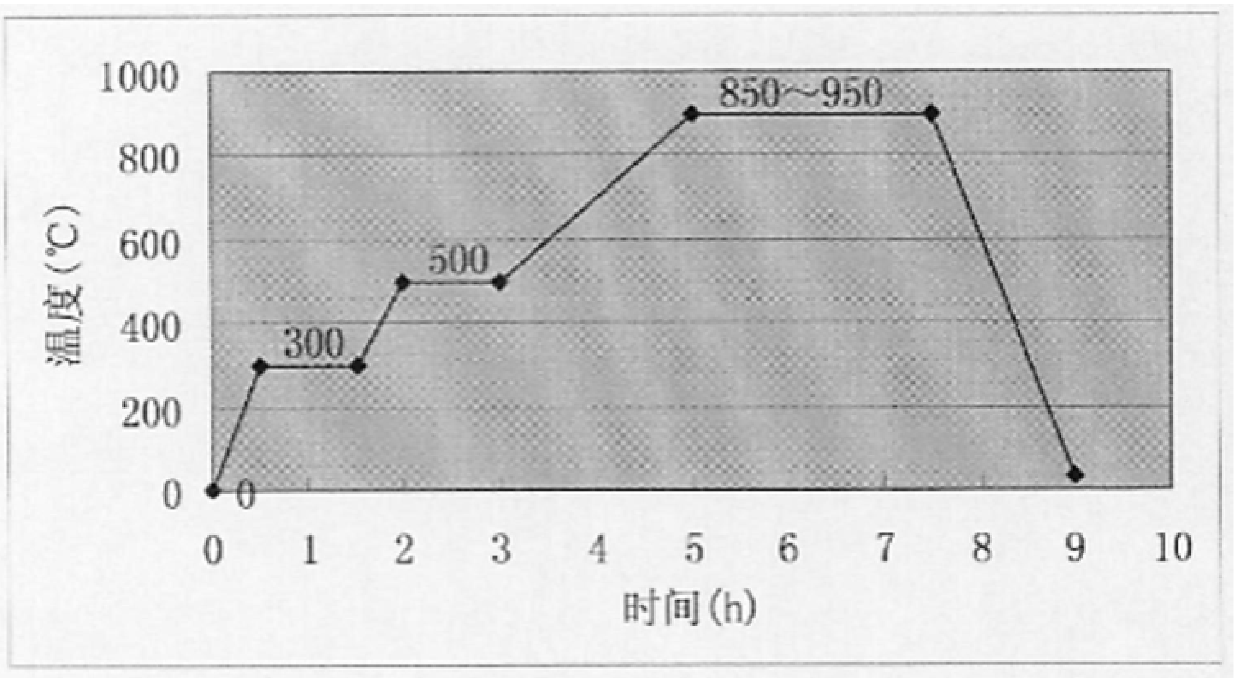

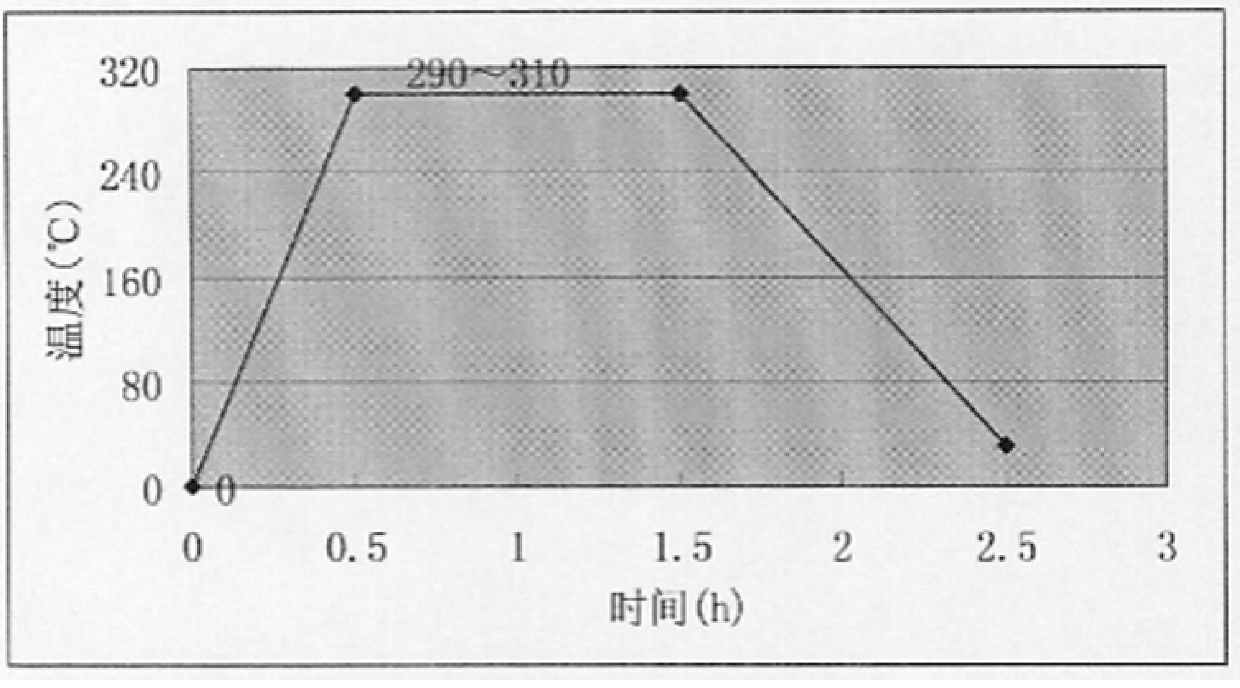

[0054] The cobalt pellet green body detected by the surface quality is placed in a vacuum atmosphere sintering furnace for pellet sintering. in H2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the manufacturing technology of nuclear fuel elements, in particular to a preparation process of pellets in cobalt regulating rod assemblies used in nuclear reactors. The process of the invention comprises the following steps: (1) powder granulation; (2) powder molding; (3) pellet sintering; (4) pellet degassing and sintering. The aspect ratio of the cobalt pellets produced by the process of the present invention is greater than 4, and the hydrogen impurity content is less than 1 μg / g, which meets the preparation requirements of high aspect ratio, high density, and defect-free cobalt pellets, and meets the requirements of the cobalt regulating rod assembly in the reactor. The technical requirements of the work are suitable for batch preparation.

Description

The preparation process of cobalt pellets in cobalt regulating rod assembly technical field The present invention relates to the manufacture technology of nuclear fuel element, be specifically related to a kind of nuclear reactor core with cobalt regulating rod assembly Block preparation process. Background technique Use cobalt regulating rod to replace stainless steel regulating rod in nuclear reactor, capture neutron by cobalt-59 and obtain cobalt-60 radioactive source. The cobalt-59 pellet is the core part of the cobalt regulating rod assembly, and its quality directly affects the yield of the radioactive source and the safety of the reactor and other issues. Cobalt pellet has its special requirement: cobalt pellet size is diameter Φ 6.22mm ± 0.02mm, height 25.1mm±0.05mm, belonging to high aspect ratio; density of cobalt pellets is 8.55~8.65g / cm 3 , the density control range is narrow; the total cobalt content ≥ 99.7%, the total amount of impurities ≤ 0.3%,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G21C3/04

CPCY02E30/30

Inventor 田春雨王玉敏聂皓张宇陈连重马春英魏晨光

Owner CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com