A constant molten pool shape electroslag remelting method based on electrode speed control

A technology of speed control and electroslag remelting, which is applied in the field of electroslag remelting, can solve problems such as the deterioration of the ingot surface quality, the drop of the edge temperature of the molten pool, and the decrease of production efficiency, so as to improve the melting efficiency, reduce the temperature, and improve the production efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

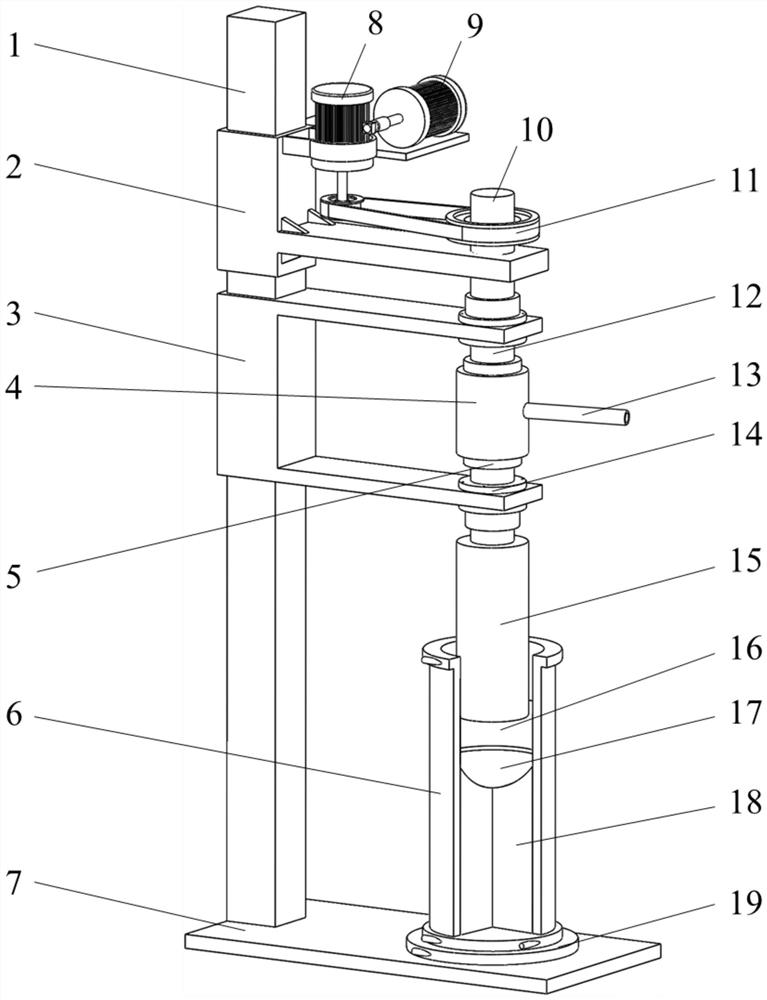

[0040] Such as figure 1 The shown device can realize the electroslag remelting method of constant molten pool shape based on the electrode speed control, including the crystallizer 6, the bottom water tank 19, the consumable electrode 15, the conductive rod 12 and the column 1, and the bottom water tank 19 is fixed On the operation platform 7, the crystallizer 6 is placed on the bottom water tank 19. The consumable electrode 15 is welded to the end of the conductive rod 12, and the front end of the conductive rod 12 and the end of the rotating shaft 10 are fixed through a flange. The rotating shaft 10 is connected to the reducer 8 and the servo motor 9 through the belt drive 11, and the reducer 8 and the servo motor 9 are fixed on the load-bearing cross arm 2. The conductive rod 12 is covered with a copper shell 5, and the copper shell 5 is connected to the power supply system through a carbon brush conductive slip ring 4 and a conductive copper tube 13. The end and front end...

Embodiment 2

[0092] A device in this embodiment that can realize the electroslag remelting method with a constant molten pool shape based on electrode rotational speed control is the same as in Embodiment 1, the difference is that the size of the crystallizer is 120 mm in inner diameter and 1000 mm in height, and the size of the consumable electrode is It is 60mm in diameter and 2000mm in length, and the consumable electrode is made of 201 stainless steel. Using the above-mentioned device to carry out the electroslag remelting method based on the constant molten pool shape controlled by the electrode speed is carried out according to the following steps:

[0093] S1. Weld the consumable electrode and the end of the conductive rod coaxially, and the front end of the conductive rod is installed on the end of the rotating shaft through the flange;

[0094] S2. Start the cooling water circulation of the crystallizer and the bottom water tank, move the consumable electrode into the crystallizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com