Method for improving the uniformity of rare earth doped quartz glass rod

A quartz glass rod, rare earth doping technology, applied in glass manufacturing equipment, glass fiber products, manufacturing tools, etc., can solve the problems of uneven distribution of the refractive index of the core rod, uneven distribution, volatile dopant ions, etc. Improved laser efficiency and beam quality, low loss, improved axial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

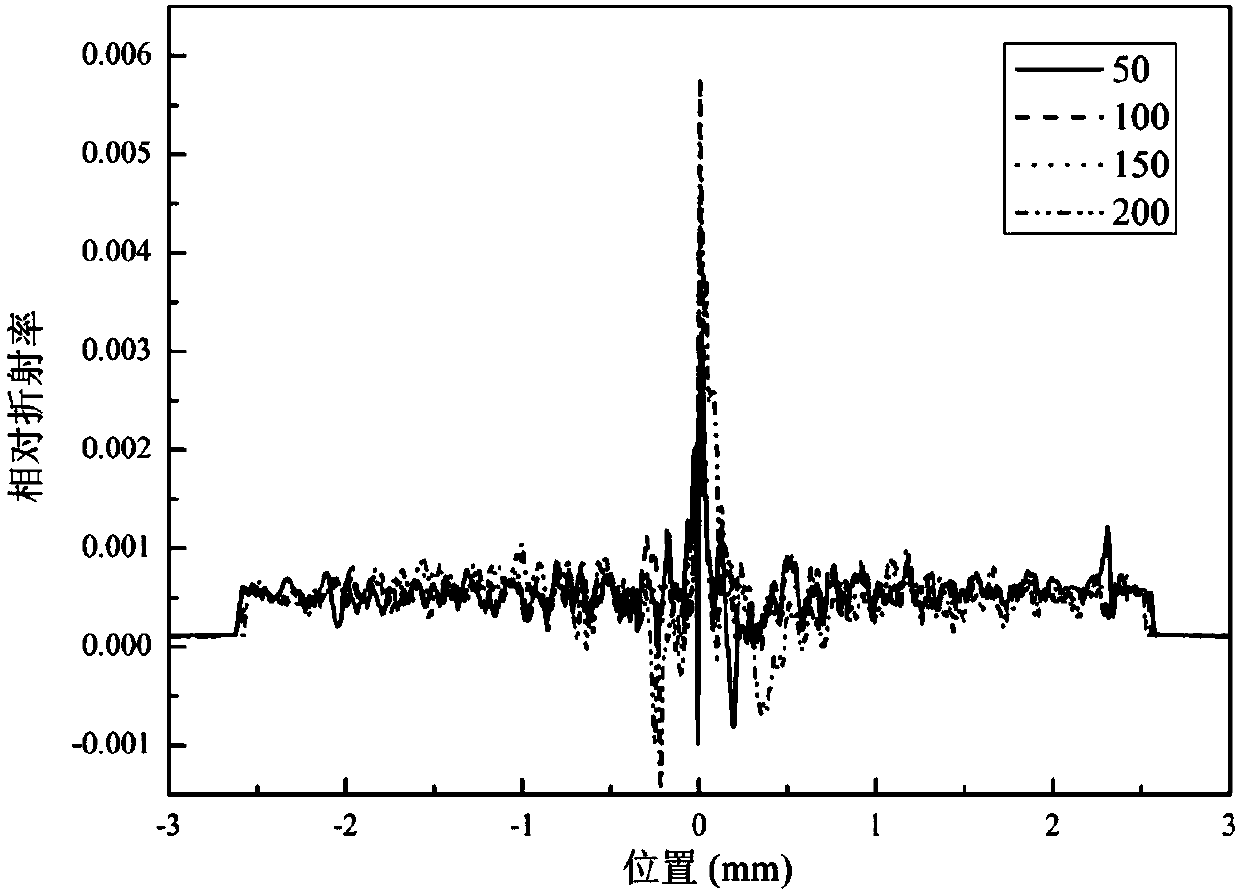

[0026] In this embodiment, the ytterbium-doped quartz glass rod prepared by powder sintering technology is used, and the process of stretching-stacking-stretching is repeated to improve the uniformity of the ytterbium-doped quartz glass rod. The method includes the following steps:

[0027] ①Process 6 ytterbium-doped quartz glass rods prepared based on powder sintering technology into an outer diameter of 10mm and a length of 150mm, and place the glass rods in a high-temperature drawing furnace at 1950°C to make thin rods of Φ1mm. Cut the drawn thin rod into a length of 200 mm, soak it in 10% hydrofluoric acid solution for 30 minutes, and remove surface impurities.

[0028] ②Pile the cleaned thin rods into round rods with an outer diameter of 15mm and a length of 200mm, and place them in a high-temperature drawing furnace at 1950°C to make thin rods of Φ1mm. Cut the thin rod into a length of 170mm, and soak it in a 10% hydrofluoric acid solution for 30 minutes to remove surfa...

Embodiment 2

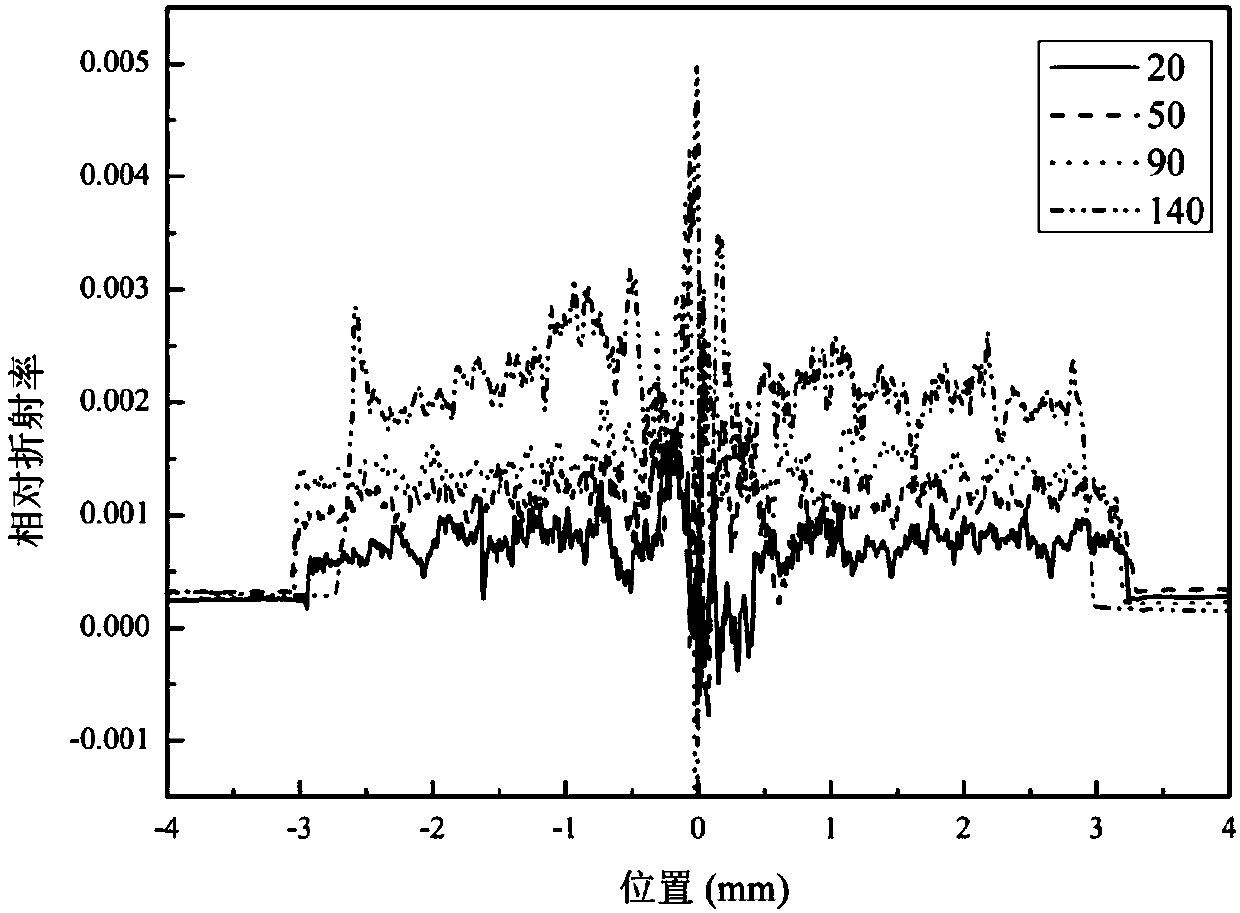

[0034] In this embodiment, the ytterbium-doped quartz glass rod prepared by powder sintering technology is used, and the process of stretching-stacking-stretching is repeated to improve the uniformity of the ytterbium-doped quartz glass rod. The method includes the following steps:

[0035] ① Process 10 ytterbium-doped quartz glass rods prepared based on powder sintering technology into diameters of 10 mm and lengths of 150 mm, and place the glass rods in a high-temperature drawing furnace at 2000°C to make thin rods of Φ0.8 mm. Cut the drawn thin rod into a length of 200 mm, and soak it in a 5% hydrofluoric acid solution for 60 minutes to remove surface impurities.

[0036] ②Pile the cleaned thin rods into round rods with an outer diameter of 20mm and a length of 200mm, and place them in a high-temperature drawing furnace at 2050°C to make thin rods of Φ0.5mm. Cut the thin rod into a length of 180 mm, and soak it in a 5% hydrofluoric acid solution for 30 minutes to remove su...

Embodiment 3

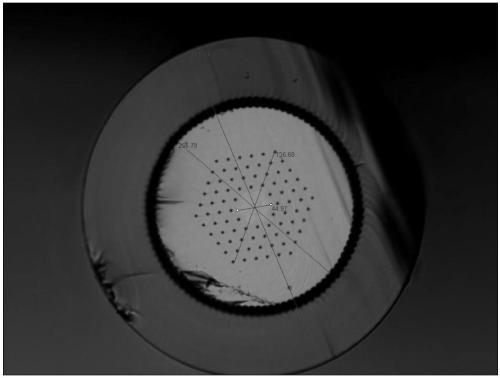

[0041] In this embodiment, the ytterbium-doped quartz glass rod prepared by powder sintering technology is used, and the process of stretching-stacking-stretching is repeated to improve the uniformity of the rare earth-doped quartz glass rod. The method includes the following steps:

[0042] ① Eight ytterbium-doped quartz glass rods prepared by powder sintering technology were processed into diameters of 10 mm and lengths of 150 mm, and the glass rods were placed in a high-temperature drawing furnace at 2000°C to make thin rods of Φ1.2 mm. Cut the drawn thin rod into a length of 200mm, soak it in 15% hydrofluoric acid solution for 20min, and remove surface impurities.

[0043] ②Pile the cleaned thin rods into round rods with an outer diameter of 15mm and a length of 200mm, and place them in a high-temperature drawing furnace at 1980°C to make thin rods of Φ1.5mm. Cut the thin rod into a length of 160 mm, and soak it in a 15% hydrofluoric acid solution for 20 minutes to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com