Infrared glass preparation method and water removing device thereof

A technology of infrared glass and glass, which is applied in the combination of methods to dry solid materials, lighting and heating equipment, drying, etc., can solve the problem that it is difficult to effectively remove hydrogen and oxygen impurities in infrared glass, and achieve the effect of eliminating hydrogen impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

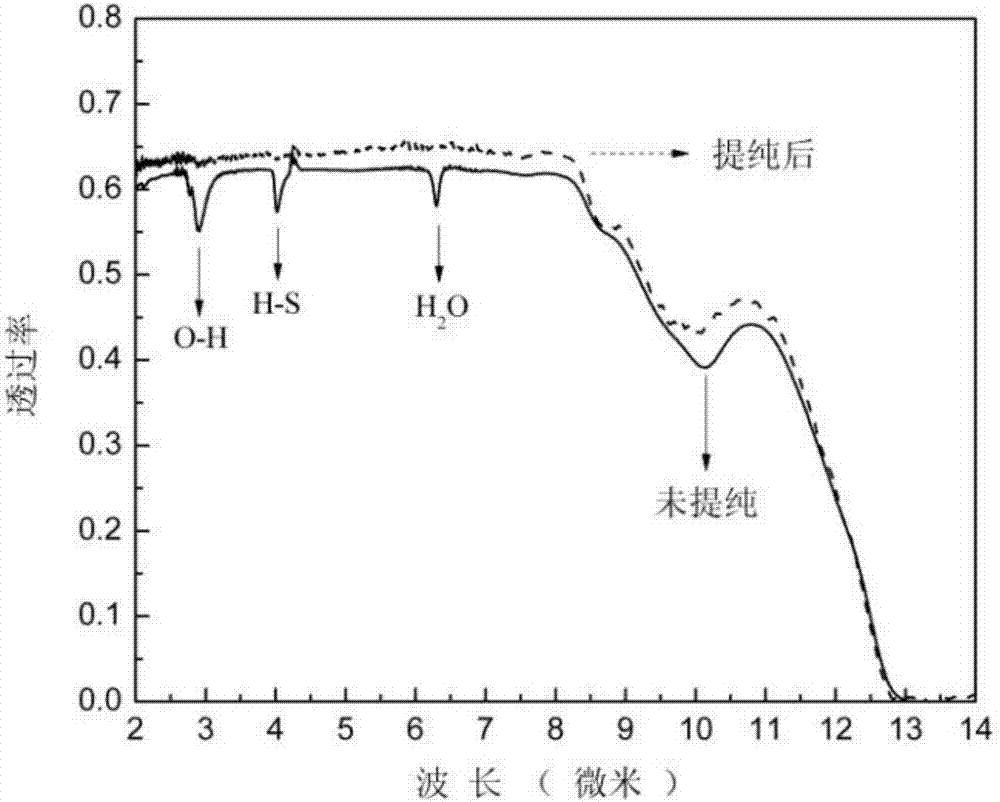

[0037] Example 1: Taking the component as As 2 S 3 The preparation of high-purity chalcogenide glass is taken as an example, including the following specific steps:

[0038] 1) According to As 2 S 3 The formula takes sulfur and arsenic elemental raw materials with a purity of 99.999%, raises the temperature to 800°C in a traditional swing furnace, and melts it for 12 hours to obtain glass clinker;

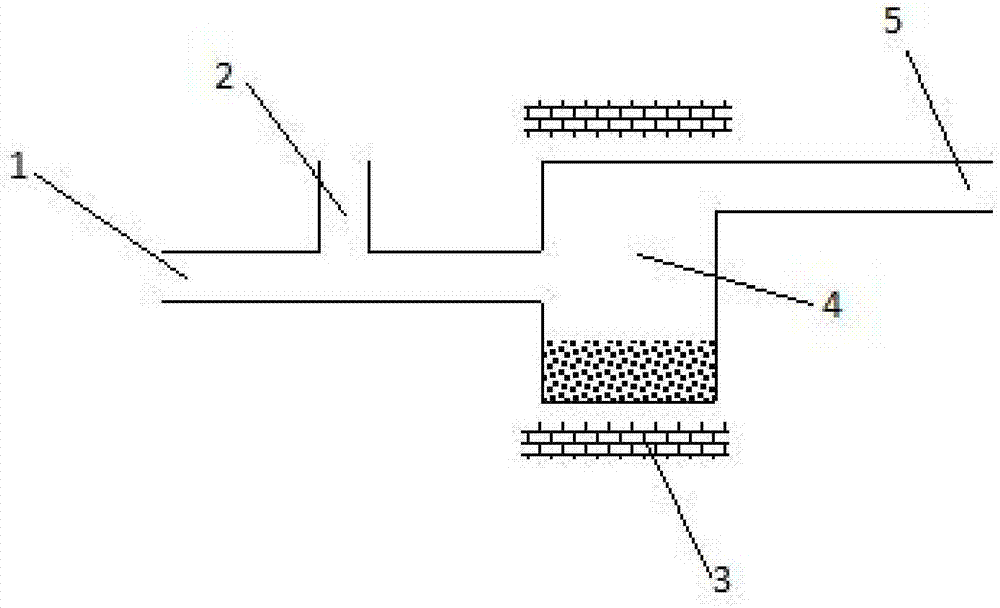

[0039] 2) As 2 S 3 The glass clinker is placed in the raw material pipe 4, the inert gas inlet pipe 1 and the chlorine gas inlet pipe 2 are connected to the nitrogen pipeline and the chlorine gas pipeline respectively, and the nitrogen gas is passed first, the flow rate is 30ml / min, and the time is 120 minutes;

[0040] 3) Keep the inert gas flow rate, turn on the heating furnace 3, heat up to 500°C, turn on the chlorine gas, the flow rate is 10ml / min, and the time is 40 minutes;

[0041] 4) Keep the inert gas flow rate, stop feeding chlorine gas, stop heating, and wait for t...

Embodiment 2

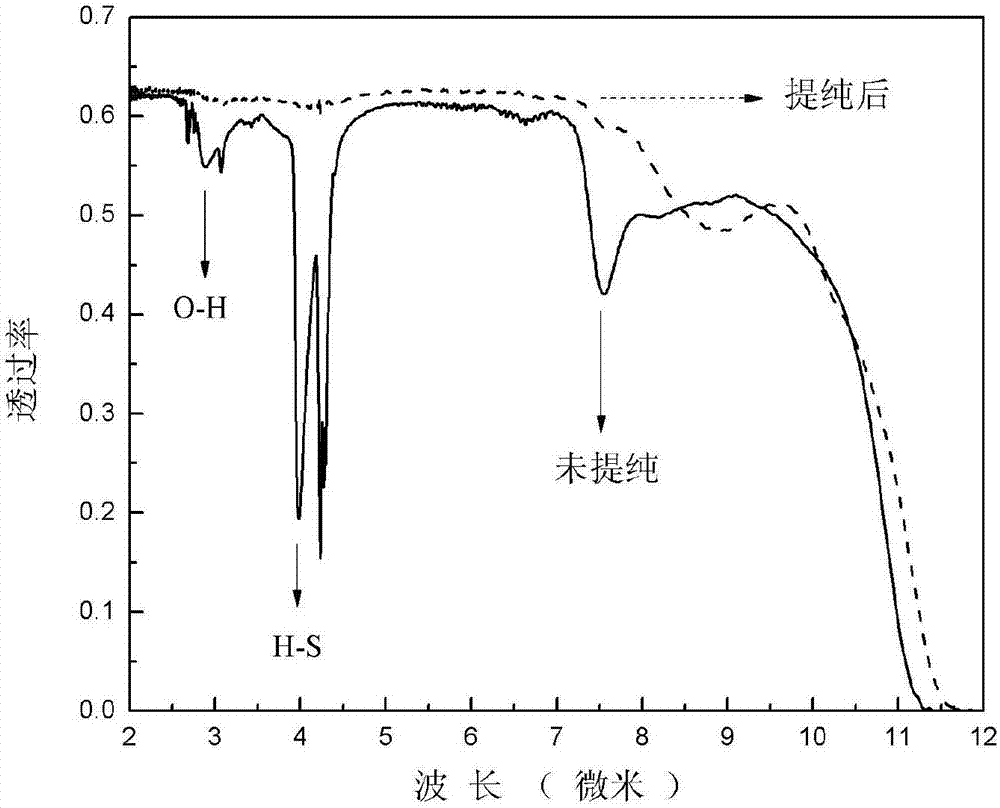

[0044] Embodiment two: take component as Ge 20 Ga 5 Sb 10 S 65 The preparation of high-purity chalcogenide glass is taken as an example, including the following specific steps:

[0045] 1) According to Ge 20 Ga 5 Sb 10 S 65 The formula takes germanium, gallium, antimony and sulfur elemental raw materials with a purity of 99.999%, raises the temperature to 950°C in a traditional swing furnace, and melts them for 12 hours to obtain glass clinker;

[0046] 2) Add Ge 20 Ga 5 Sb 10 S 65 The glass clinker is placed in the raw material pipe 4, and the inert gas inlet pipe 1 and the chlorine gas inlet pipe 2 are connected to the argon and chlorine gas pipelines respectively, and the argon gas is passed first, with a flow rate of 80ml / min for 30 minutes;

[0047] 3) Keep the inert gas flow rate, turn on the heating furnace 3, heat up to 650°C, turn on the chlorine gas, the flow rate is 4ml / min, and the time is 100 minutes;

[0048] 4) Keep the inert gas flow rate, stop feed...

Embodiment 3

[0051] Embodiment three: the composition is 60TeO 2 The preparation of high-purity tellurite glass of –20BaO–20ZnO is taken as an example, including the following specific steps:

[0052] 1) According to 60TeO 2 –20BaO–20ZnO formulation weighs TeO with a purity of 99.99% 2 , BaO and ZnO raw materials, put into a gold crucible, place in a muffle furnace, heat up to 800°C, and melt for 2 hours to obtain glass clinker;

[0053] 2) Add 60TeO 2 –20BaO–20ZnO glass clinker is placed in the raw material pipe 4, the inert gas inlet pipe 1 and the chlorine gas inlet pipe 2 are respectively connected to the helium and chlorine gas pipelines, and the helium gas is passed first, the flow rate is 50ml / min, and the time is 60 minutes ;

[0054] 3) Keep the inert gas flow rate, turn on the heating furnace 3, heat up to 700°C, turn on the chlorine gas, the flow rate is 6ml / min, and the time is 60 minutes;

[0055] 4) Keep the inert gas flow rate, stop feeding chlorine gas, stop heating, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com