Helium processing device of high yield neutron generator

A neutron generator and processing device technology, applied in nuclear technology and application fields, can solve problems such as vacuum drop, neutron yield reduction, insulation performance deterioration, etc., to achieve extended service life, increased yield, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

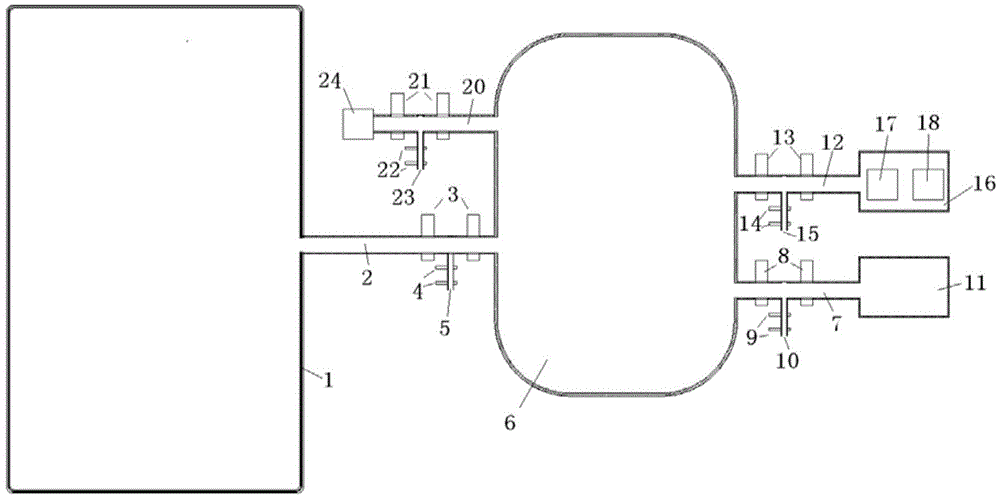

Image

Examples

Embodiment 1

[0041] The size of the vacuum chamber of a high-yield neutron generator is 700mm×Φ300mm, the size of the target is 500×Φ10mm, and the volume of the vacuum system is about 50L. The deuterium-tritium gas pressure is 0.5Pa, the ratio is 1:1, using self-forming targets, and the neutron yield of deuterium-tritium reaction is 10 13 n / s.

[0042] Considering only the decay of gaseous tritium in the vacuum container of the main body of the neutron generator, the helium production rate is 8.6×10 10 n / s, the time required for the partial pressure of helium to reach 0.025Pa is about 700 hours. At this time, the partial pressure of helium is 5%, and the output drops by at least 5%. Part of the helium produced by the decay of tritium in other parts and the helium produced by the deuterium-tritium reaction enters the vacuum system in gaseous form, plus the O released by the materials bombarded by helium particles, deuterium ions and tritium particles. 2 and other impurity gases, the actua...

Embodiment 2

[0048] The main parameters of the neutron generator are the same as above. In order to increase the speed of removing helium and other impurity gases, or improve the stability of the neutron yield, the volume of the vacuum container of the helium processing system is changed to a cylindrical container with a diameter of 500mm and a height of 1000mm. About 200L, which is 4 times the vacuum volume of the neutron generator, and the volume of the vacuum connecting pipe can be ignored.

[0049] Considering only the decay of gaseous tritium in the vacuum container of the main body of the neutron generator, the helium production rate is 8.6×10 10 n / s, the time required for the partial pressure of helium to reach 0.025Pa is about 700 hours. At this time, the partial pressure of helium is 5%, and the output drops by at least 5%. Part of the helium produced by the decay of tritium in other parts and the helium produced by the deuterium-tritium reaction enters the vacuum system in gaseou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com