Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "To achieve the purpose of emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

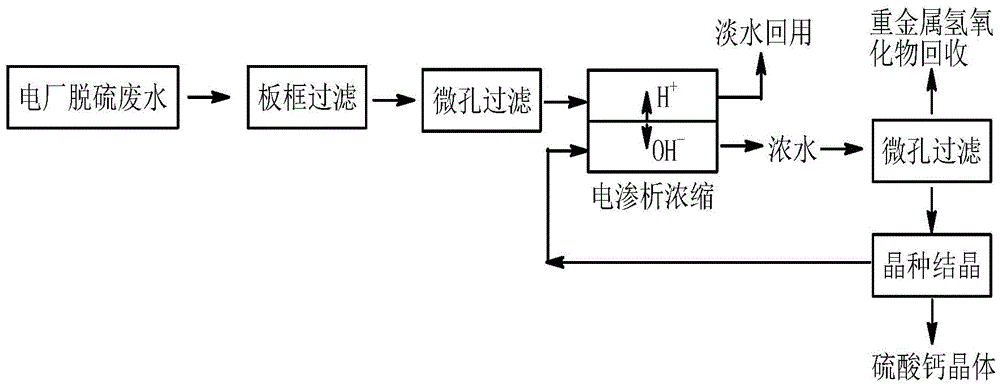

Power plant flue gas desulfurization wastewater treatment process

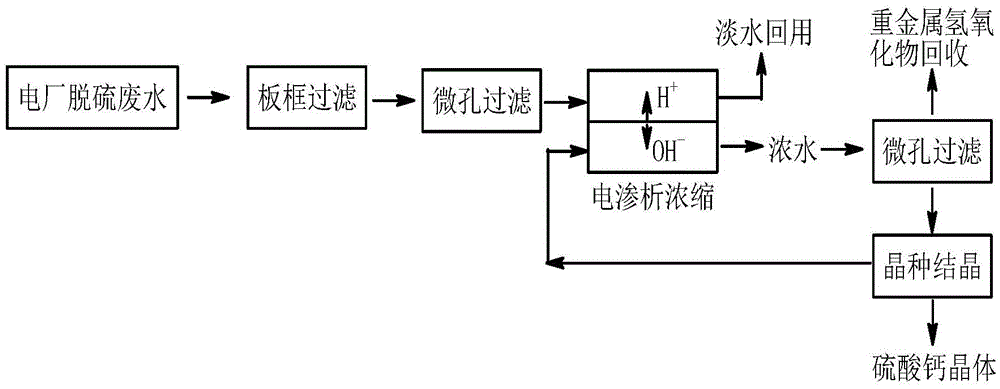

ActiveCN104478141AOvercoming complexityOvercome the disadvantage that heavy metals cannot be recycled and will form waste solidsTreatment involving filtrationWaste water treatment from gaseous effluentsFiltrationFresh water

The invention relates to a wastewater treatment process, and in particular relates to a power plant flue gas desulfurization wastewater treatment process. The process comprises three steps as follows: I, carrying out plate frame filtration on desulfurated wastewater in a power plant, and implementing microporous filtration so as to obtain a clear filtrate without suspended solids; II, concentrating the clear filtrate by virtue of an electrodialysis membrane unit having a pH value regulating function, and recycling concentrated fresh water; and III, carrying out microporous filtration on a mixture in a concentrated water room, recovering filter residue, crystallizing the filtrate in a calcium sulfate crystal seed crystallizing device, and separating out calcium sulfate crystal. The wastewater treatment process disclosed by the invention is simple in process, and capable of effectively recovering heavy metals and achieving a purpose of zero discharge of desulfurized wastewater in a real sense.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

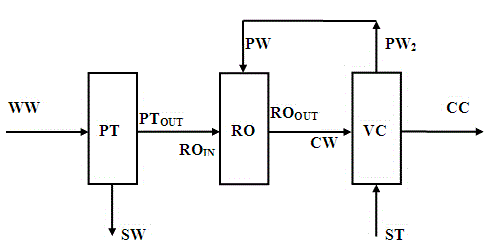

High-salt iron phosphate liquid waste zero-emission treatment device and method

ActiveCN104609631ALow costTo achieve the purpose of emissionGeneral water supply conservationMultistage water/sewage treatmentLiquid wasteEvaporation

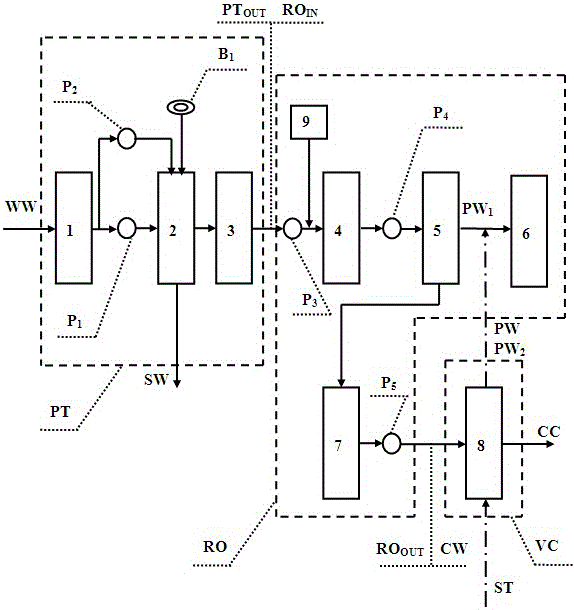

The invention discloses a high-salt iron phosphate liquid waste zero-emission treatment device. The device structurally comprises a pre-treatment (PT) system, a reverse osmosis (RO) treatment system and an evaporative crystallization (VC) treatment system. The high-salt iron phosphate liquid waste zero-emission treatment device has the advantages as follows: the device is designed for high salt of the high-salt iron phosphate liquid waste, the high-salt iron phosphate liquid waste is subjected to pre-treatment to remove part of suspended solids and is subjected to reverse osmosis desalination, concentration reduction and reverse osmosis producing water recycling, reverse osmosis concentrated water is subjected to evaporative crystallization treatment finally, condensate water produced through evaporative crystallization is recycled, waste salt is conveyed outwards, and the purpose of zero liquid emission is achieved. The high-salt iron phosphate liquid waste zero-emission treatment device has the specific advantages as follows: pre-treatment, reverse osmosis and evaporative crystallization are organically combined; 2, the reverse osmosis is adopted for concentration reduction, so that the cost of follow-up evaporative crystallization is reduced; 3, an evaporative crystallization technology combining falling film evaporation and MVR (mechanical vapor recompression) is adopted, energy is saved, the efficiency is high, and the operation cost is reduced; 4, the purposes of water recycling and zero liquid emission are achieved.

Owner:深圳市华虹清源环保科技有限公司

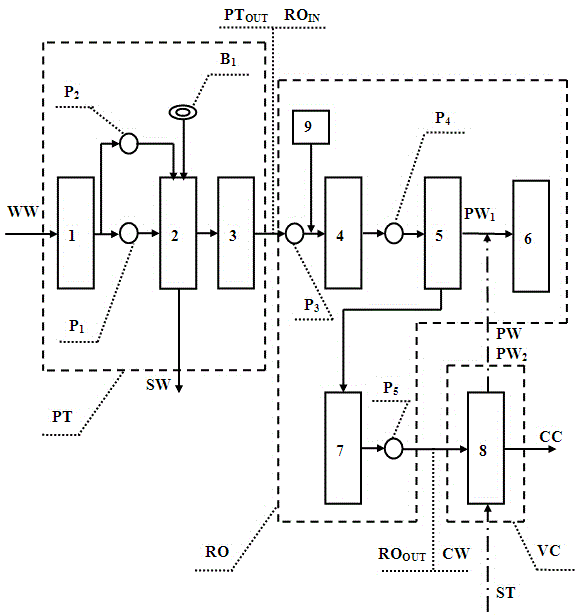

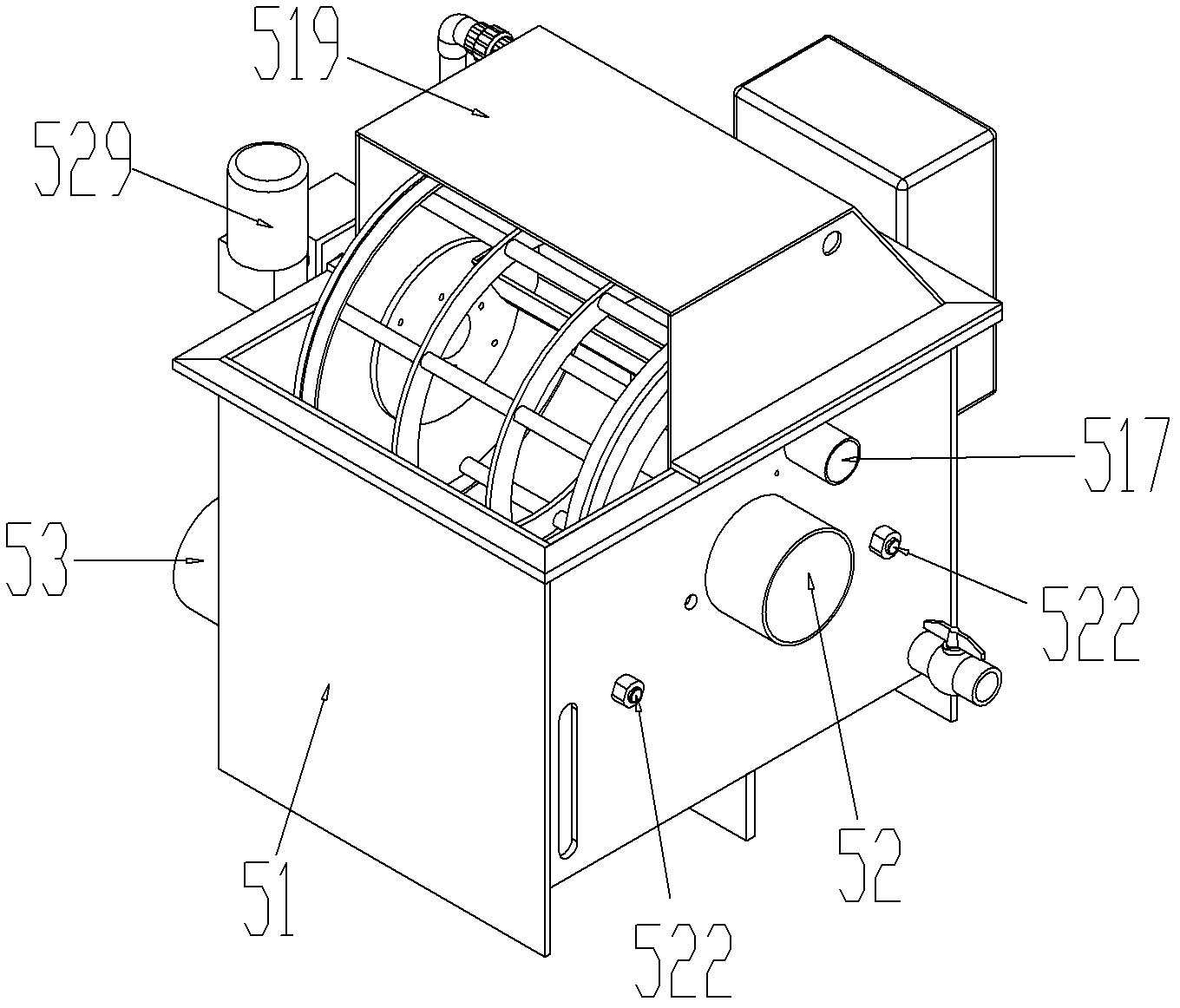

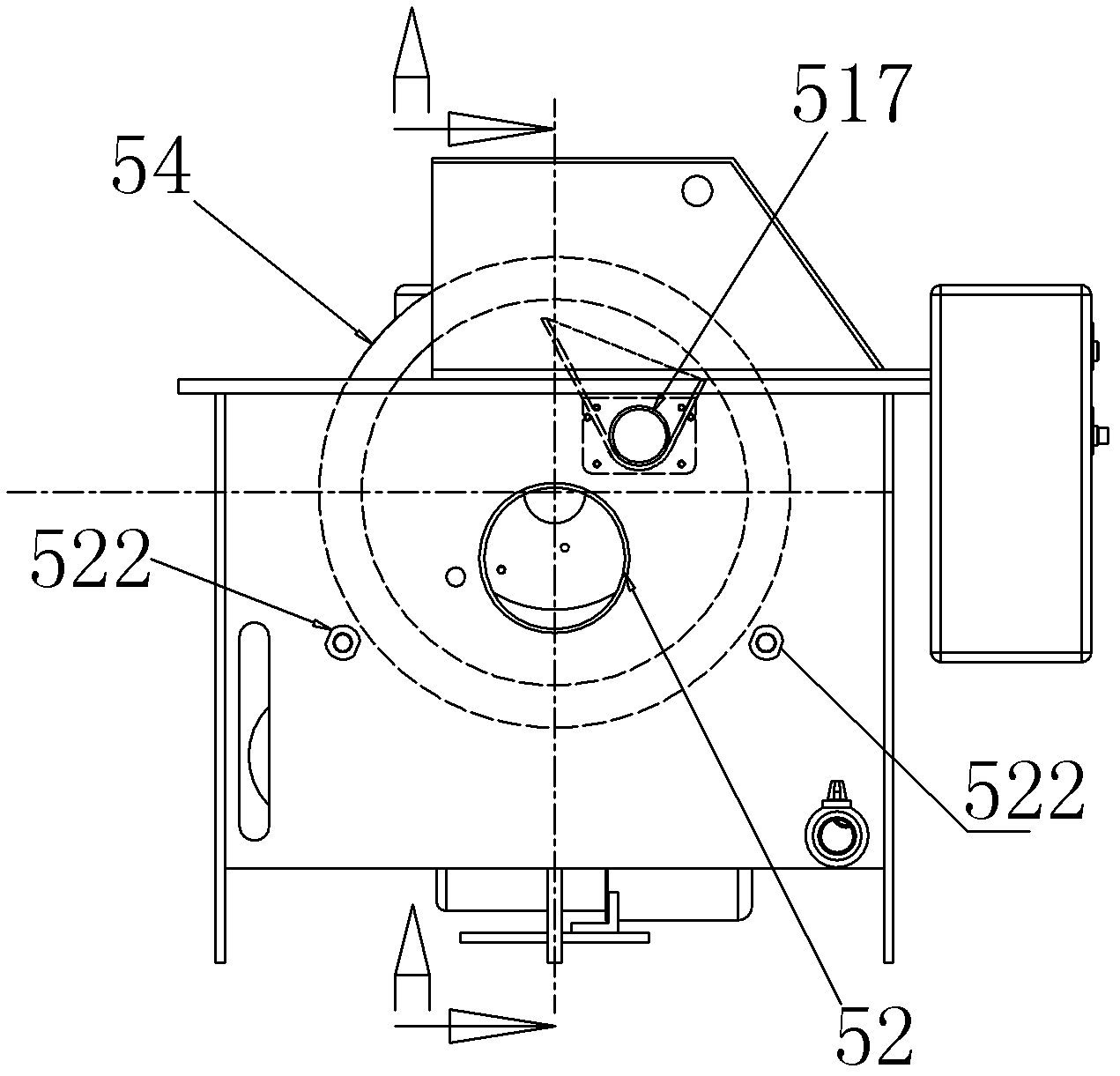

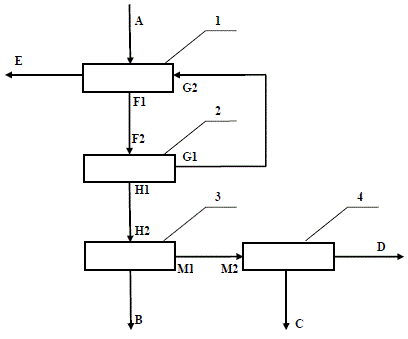

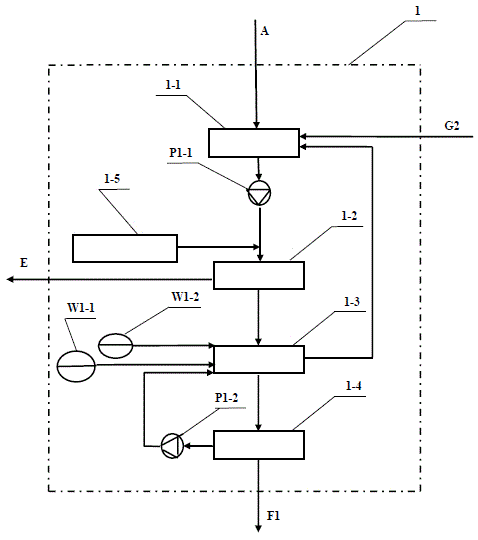

Brine waste water processing reusing device and method

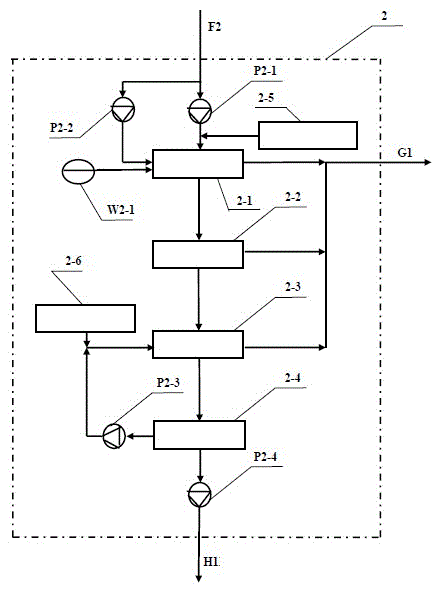

ActiveCN104003569ASolve the hardnessEvaporation energy saving and high efficiencyMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention discloses a brine waste water processing reusing device and method. The structure of the device comprises a preprocessing system 1, an ultrafiltration processing system 2, a reverse osmosis processing system 3 and a negative pressure spray evaporation processing system 4. The device has the advantages that the device can be suitable for water draining, circulating water sewage draining, boiler sewage draining, demineralized water station resin regenerating water draining and the like of brine waste water primary treatment; organic pollutants and hardness in brine waste water are removed, and salinity is lowered; (3) the purposes of reusing and zero emission by efficient evaporating on thick water are achieved; (4) preprocessing, ultrafiltration and reverse osmosis are combined organically; (5) rolling type reverse osmosis and flat plate reverse osmosis are combined, and decrement is concentrated to the maximum degree; and (6) energy is saved, efficiency is high in low-temperature negative-pressure spray evaporation, and the purposes of reusing and zero emission are achieved.

Owner:安徽森诺膜技术有限公司

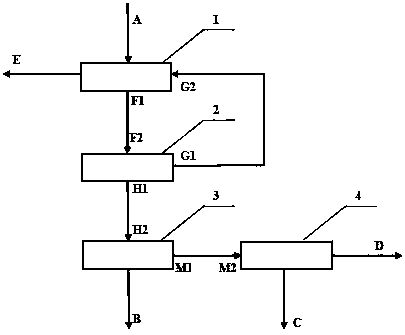

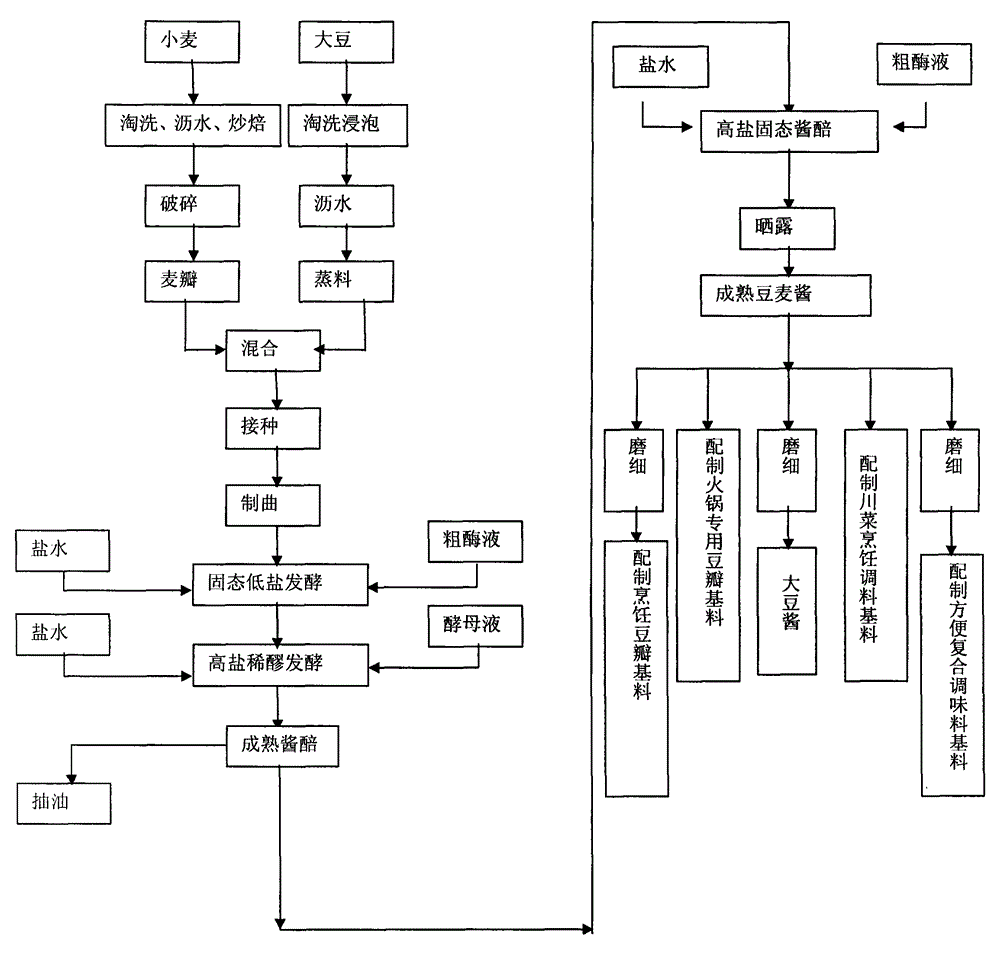

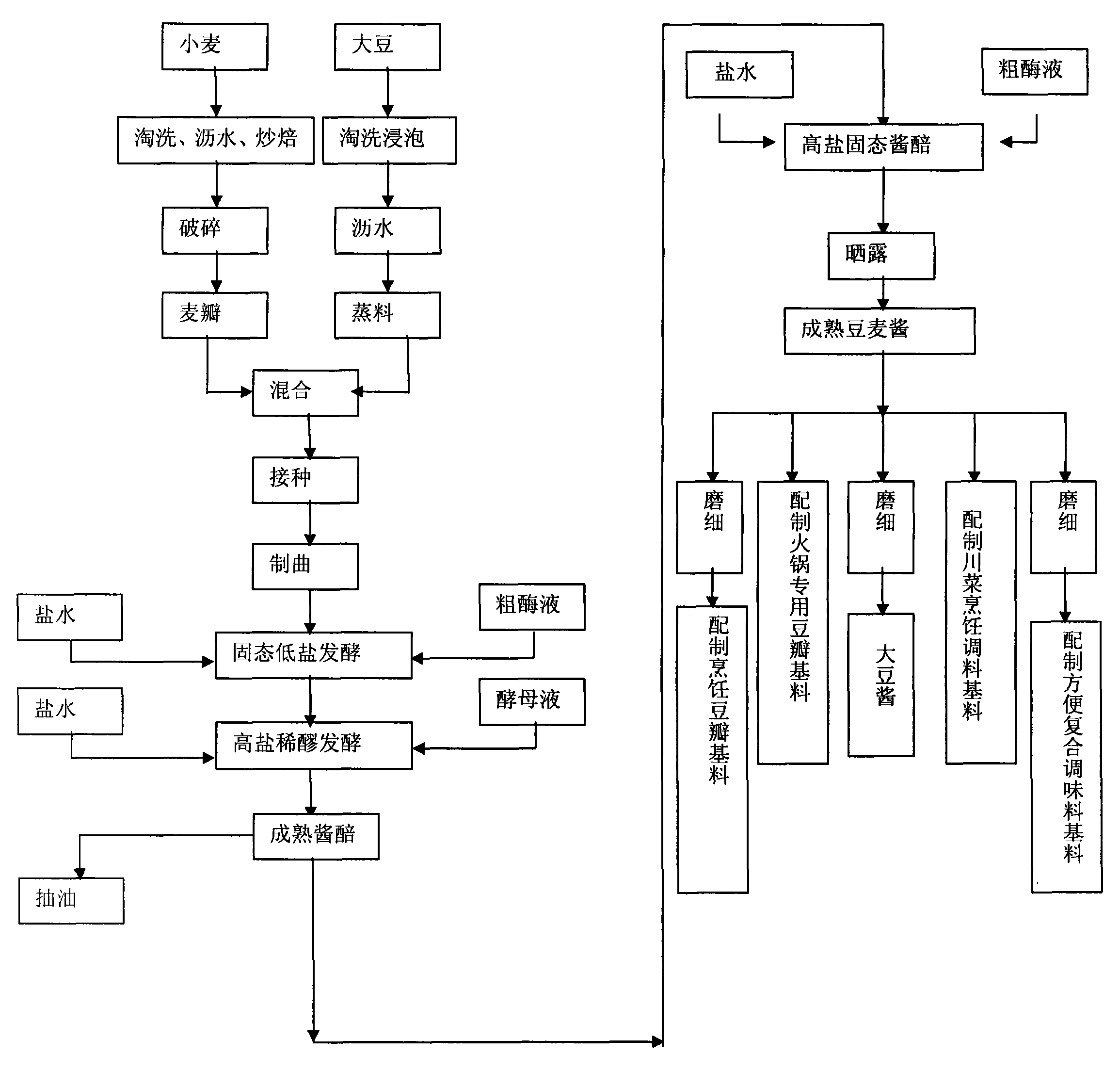

Fermenting method utilizing soy sauce and grains fully

ActiveCN102715490AAchieve energy saving and emission reductionTo achieve the purpose of emissionFood processingAnimal feeding stuffFlavorActive ingredient

The invention discloses a fermenting method utilizing soy sauce and grains fully. The method comprises the steps of A1 preparation of raw materials, A2 charging and steaming of raw materials, A3 mixing, wherein steamed soybeans are cooled quickly and are evenly mixed with stir-fried wheat kernels, A4 inoculation and starter preparation, A5 starter propagation, A6 solid-state low-salt 'double-mildew' fermentation, A7 dilute mash fermentation, A8 soy sauce sterilization, A9 clarification and checkout and A10 fermentation of solid-state sauce paste dried dew. Except the soy sauce required by production, sauce paste is enabled to be dense to prepare enzyme liquid and perform traditional technological dried dew fermentation, so that active ingredients in the raw materials are further disintegrated, and accordingly a bean-kernel sauce finished product with heavy sauce flavor and special taste and fragrance of traditional soybean paste and sweet soybean paste is obtained and used as a basic material of the soybean paste and composite seasonings. Accordingly, the purpose of no waste residue discharge in the soy sauce production is achieved, and the purposes of energy saving, emission reduction and full utilization of the grains in food manufacturing industry are achieved finally.

Owner:重庆天厨天雁食品有限责任公司

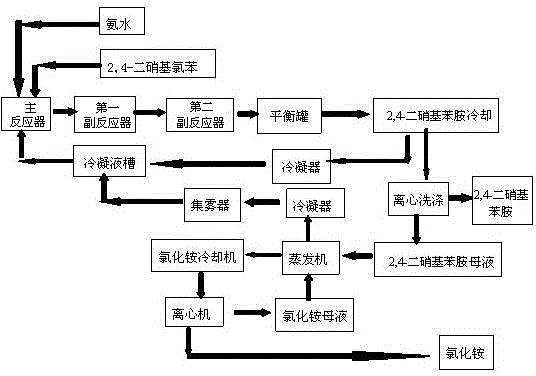

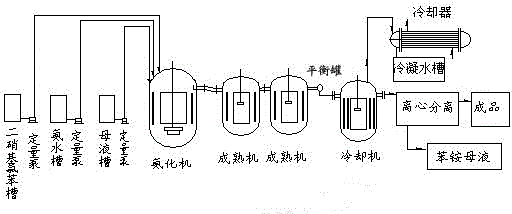

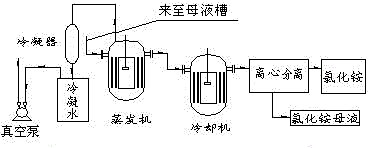

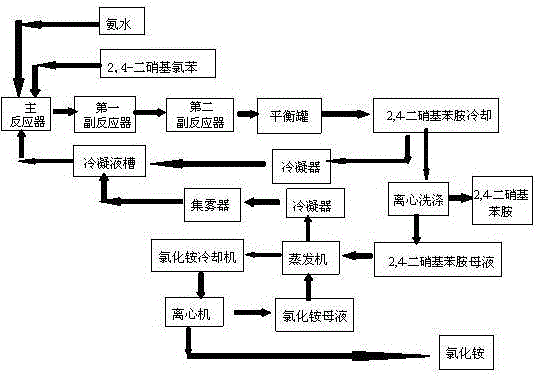

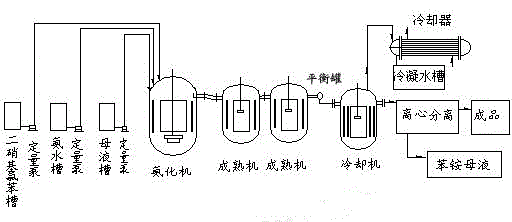

2,4-dinitraniline continuous ammonification production technology

ActiveCN104130138ATo achieve the purpose of emissionIncrease productivityOrganic compound preparationAmino compound preparationEconomic benefitsReaction temperature

The invention relates to a 2,4-dinitraniline continuous ammonification production technology, which is characterized in that 2, ,4-dinitraniline and ammoniacal liquor are taken as raw materials, the raw materials are reacted at temperature of 160-170 DEG C and pressure of 0.5-1.0 MPa, and then continuously added in an ammonification reactor; when the raw materials exceeds a discharge hatch, and are successively flowed to two auxiliary reactors, wherein the reaction temperature is controlled at 160-170 DEG C, and the reaction pressure is controlled at 0.5-1.0 MPa, reaction time of an ammonification reactor is 42 minutes, and reaction time of each auxiliary reactor is 15 minutes. The production technology has the advantages of high production efficiency, low energy consumption, environmental protection, economy, low labor intensity and safety, waste heat during an ammonification reaction process can be fully used, by-product ammonium chloride can be simultaneously recovered, no waste water is generated, and the production technology has the advantages of green production and good economic benefit.

Owner:LIANYUNGANG DIPU CHEM

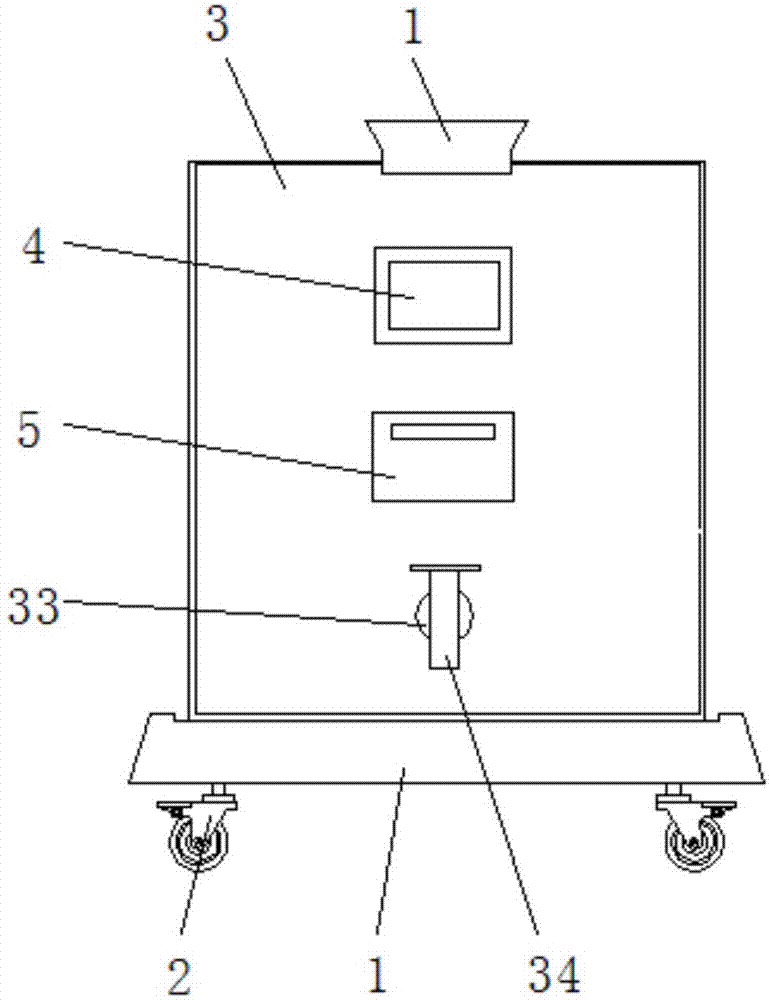

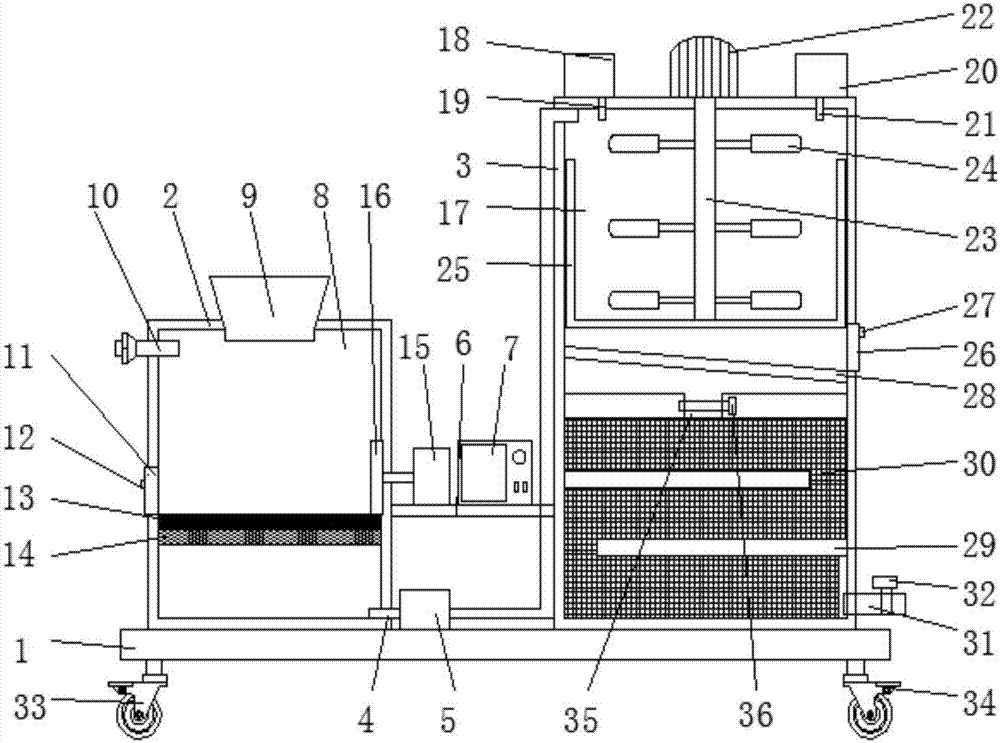

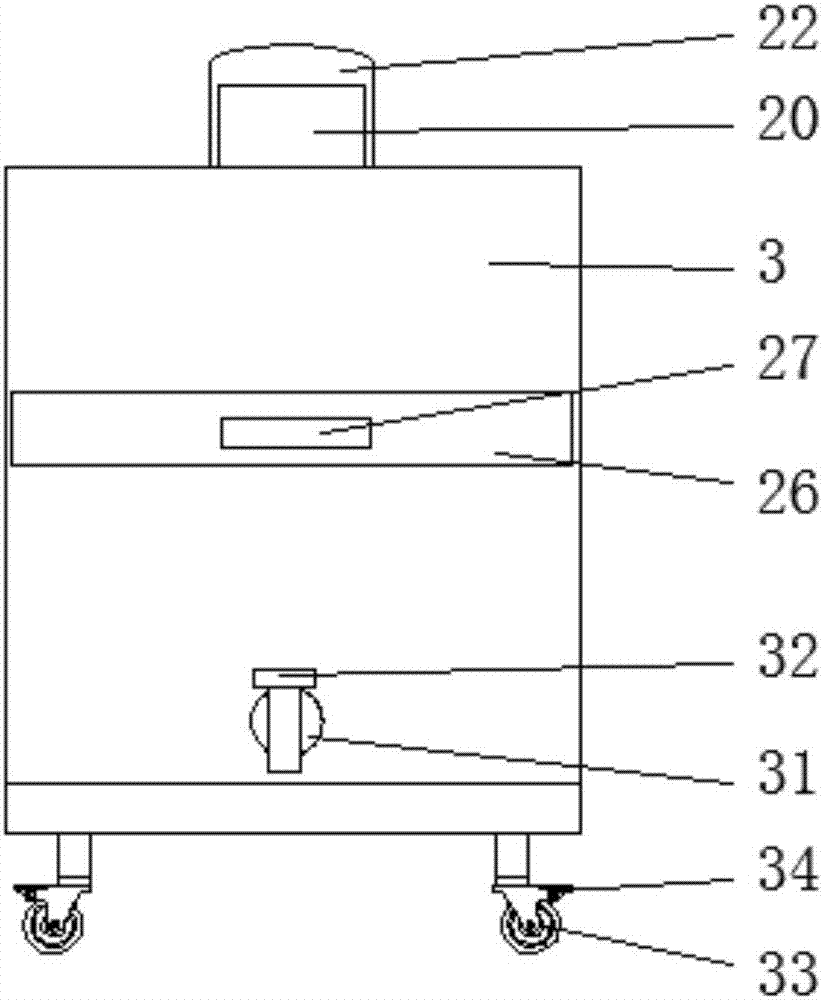

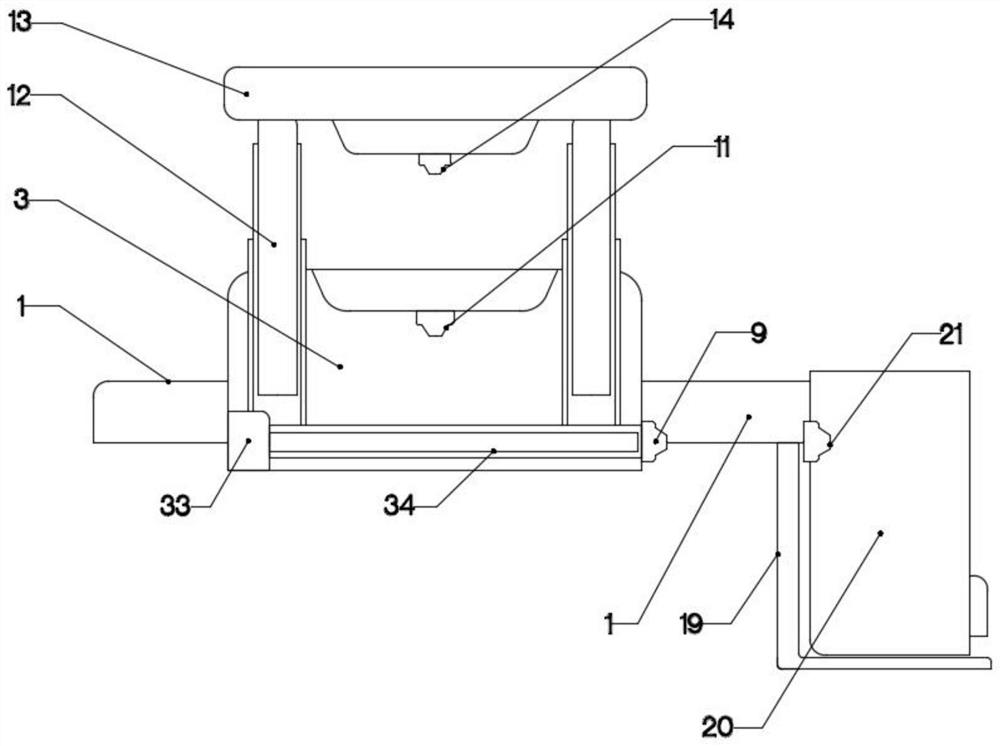

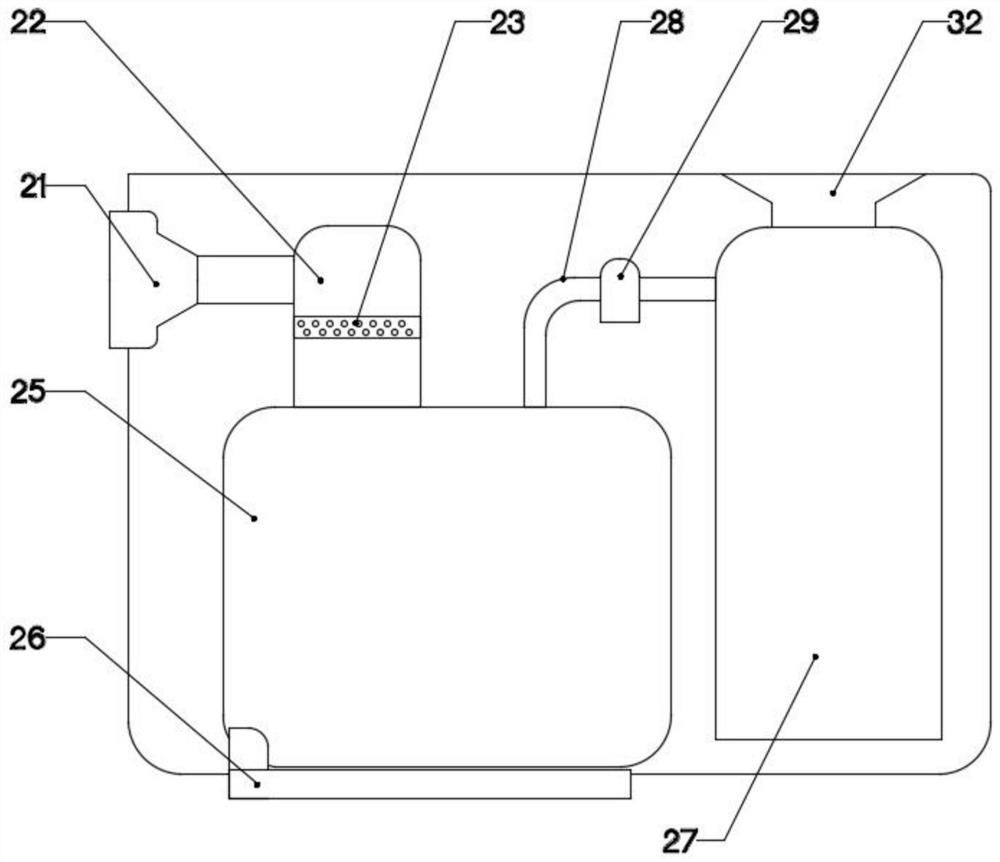

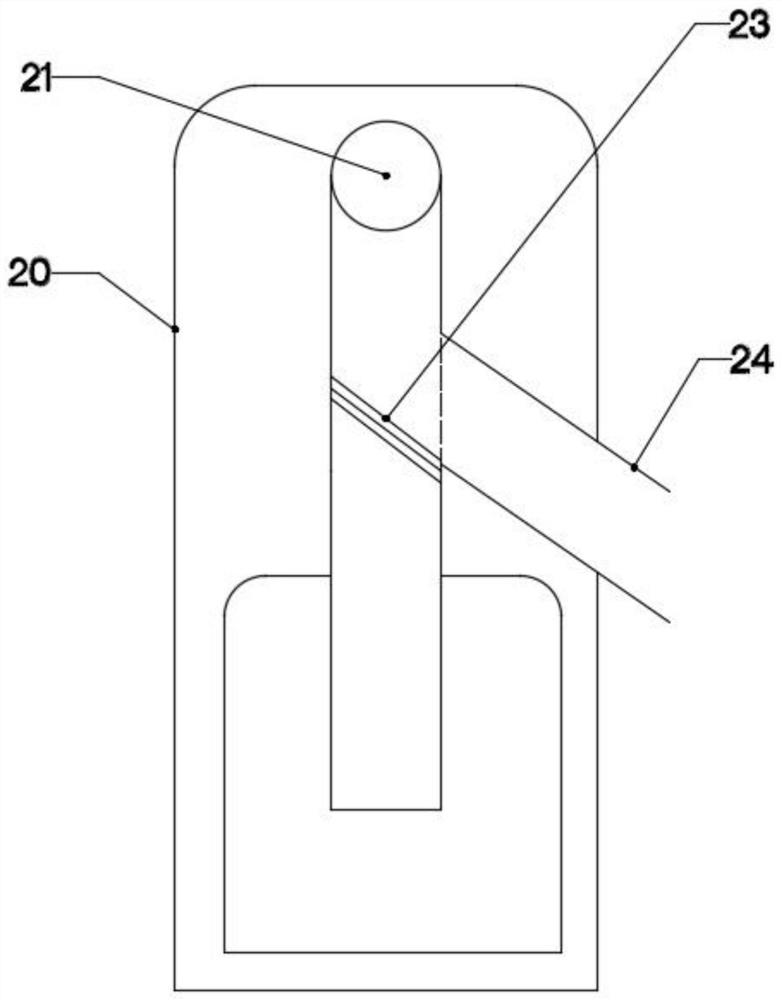

Marine living sewage treatment device

InactiveCN107285532AEasy to moveImprove processing efficiencyTreatment involving filtrationMultistage water/sewage treatmentOzone generatorDisplay device

The invention provides a marine living sewage treatment device. The marine living sewage treatment device comprises a base, a first filter net and a second filter net, and casters are arranged at the bottom of the base; an outer shell is arranged at the top of the base, a controller is arranged on the right side wall of the exterior of the outer shell, and a displayer is further arranged on the right side wall of the exterior of the outer shell and below the controller; a flocculant dosing system is arranged on the left side wall of the exterior of the outer shell, and a diversion pipe is arranged at the left end of the flocculant dosing system; an ozone generator is also arranged on the left side wall of the exterior of the outer shell, and an air guiding pipe is arranged at the left end of the ozone generator; a filter chamber is arranged at the top end of the interior of the outer shell, and a sewage inlet is formed in the top of the filter chamber. According to the marine living sewage treatment device, through the design of the casters, the marine living sewage treatment device can be moved conveniently; a collection device is more stable through the base; in the filter chamber, sediments in sewage are filtered under the function of the filter nets.

Owner:浙江安吉铭瑞汽车销售有限公司

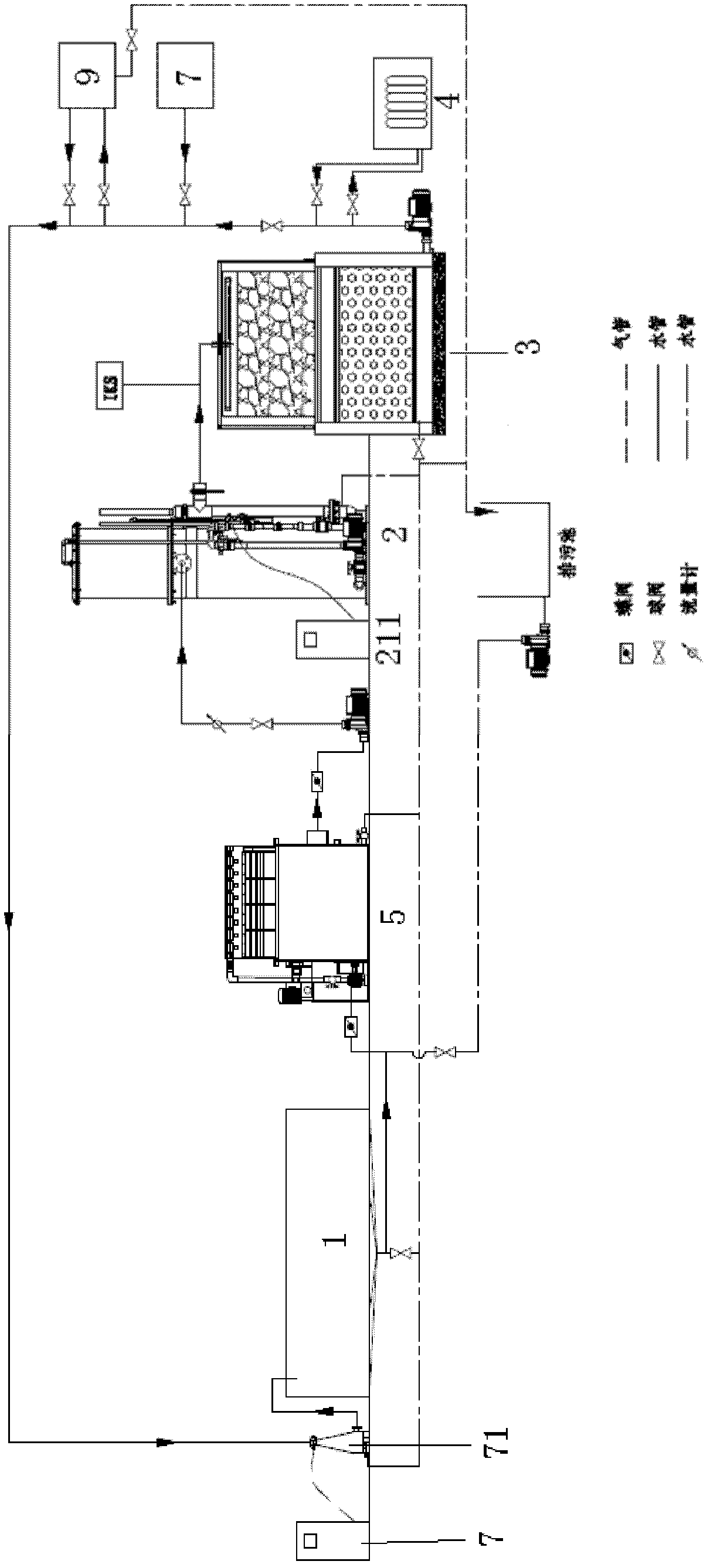

Water environment processing system of aquatic culture

InactiveCN102657132ATo achieve the purpose of emissionAdjust the water temperaturePisciculture and aquariaDecompositionNitrifying bacteria

The invention discloses a water environment processing system of aquatic culture, comprising a microstrainer, a protein separator, a denitrification degasser and an ozone generator which is connected with the protein separator. A water outlet pipe of the denitrification degasser communicates with an aquatic culture pond. A pipe communicating the denitrification degasser and the aquatic culture pond is provided with a thermostat to keep constant temperature of the water therein, a denitrator to remove nitrate from the water, and a total alkalinity regulator to regulate the pH value of the water environment. Solid-liquid separation of the culture water in the aquatic culture pond is realized by the microstrainer, the dissolved organic matter separation by the protein separator, and the poisonous ammonia nitrogen compounds and nitrous compounds decomposition by nitrobacteria and nitrite bacteria in the denitrification degasser. The processed culture water is recycled into the aquatic culture pond for use. The bacteria and other pathogen microbe are removed by the ozone generator to achieve the aim of culture water zero release.

Owner:叶勤

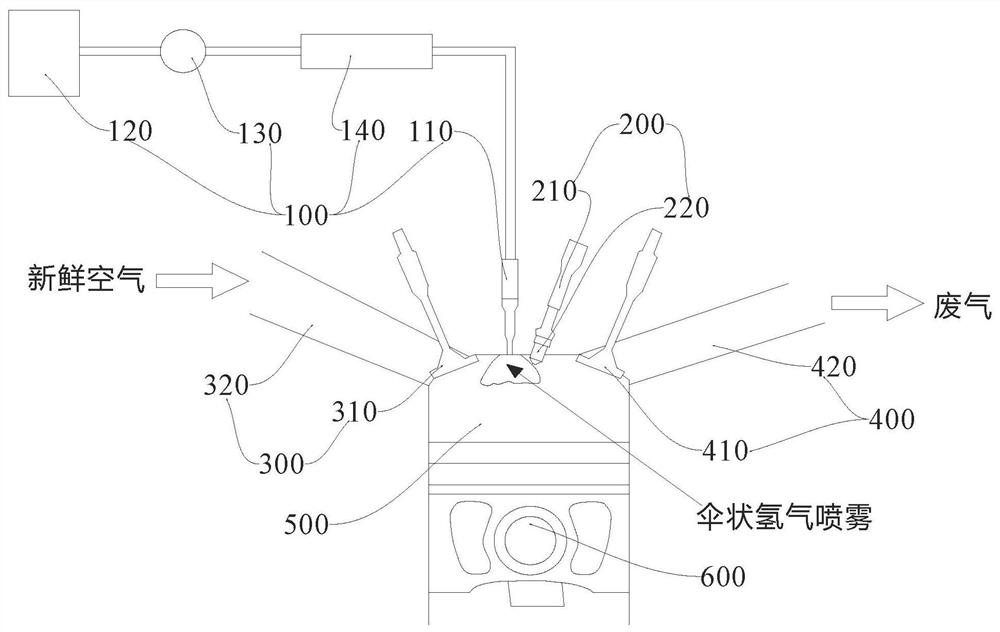

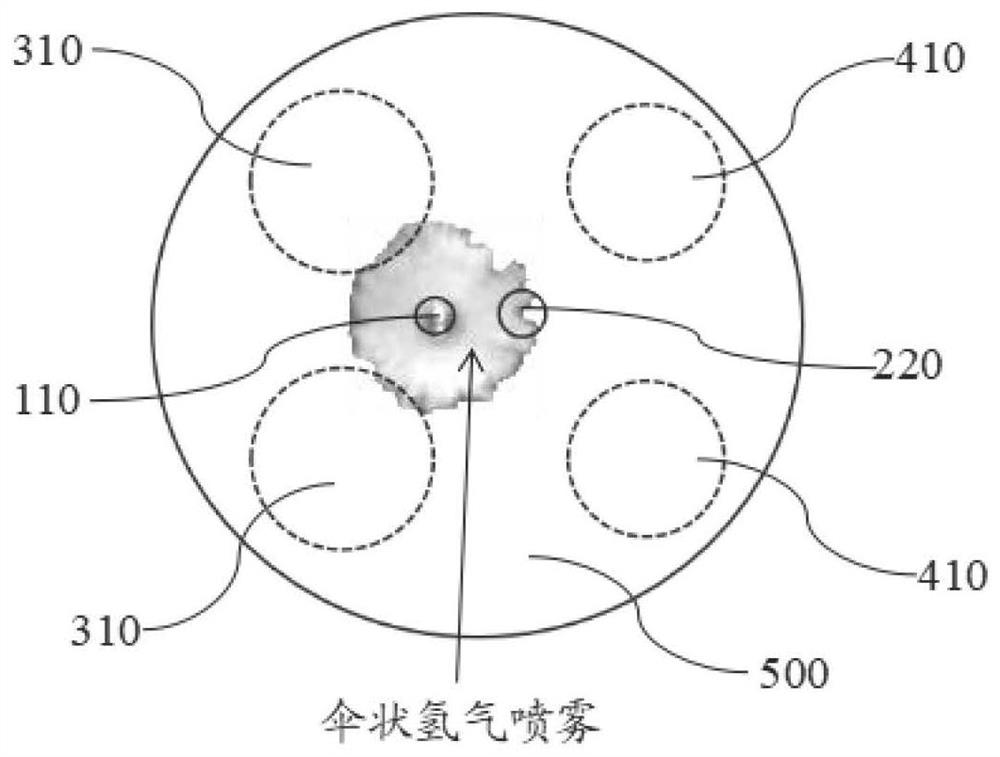

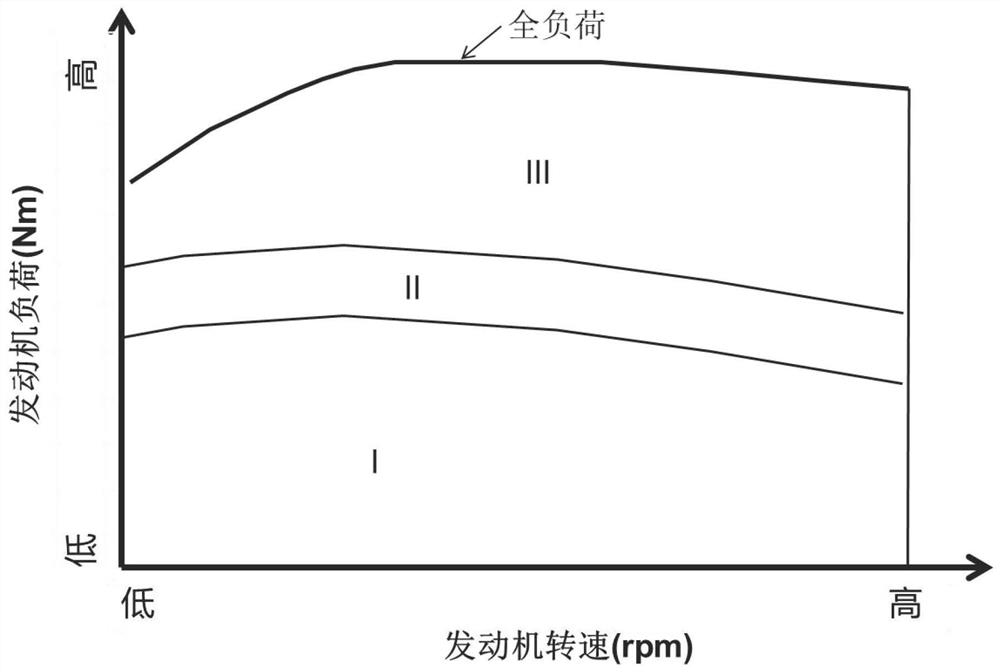

Lean burning system, method and engine

ActiveCN112761780AIncrease contact areaWell mixedValve arrangementsElectrical controlCombustion chamberExhaust valve

The invention provides a lean burning system, method and an engine. The lean burning system comprises a high pressure spraying unit, an ignition unit, an air inlet unit, an exhaust unit, a combustion chamber and a piston. The piston can reciprocate in the combustion chamber. The high pressure spraying unit, the ignition unit, the air inlet unit and the exhaust unit are arranged on the top of the combustion chamber. The high pressure spraying unit comprises a high pressure hydrogen sprayer which is an umbrella-shaped spraying oil atomizer, and the high pressure hydrogen sprayer is used for spraying umbrella-shaped hydrogen spray directly to the burning chamber. The air inlet unit comprises an air inlet door and an air inlet flue connected with each other. The exhaust unit comprises an exhaust door and an exhaust channel connected with each other. The ignition unit is used for burning a fuel in the combustion chamber. The lean burning comprises at least one lean burning system. The lean burning method is applied to the engine. The system can low emission and even zero emission of NOx and the heat efficiency is improved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

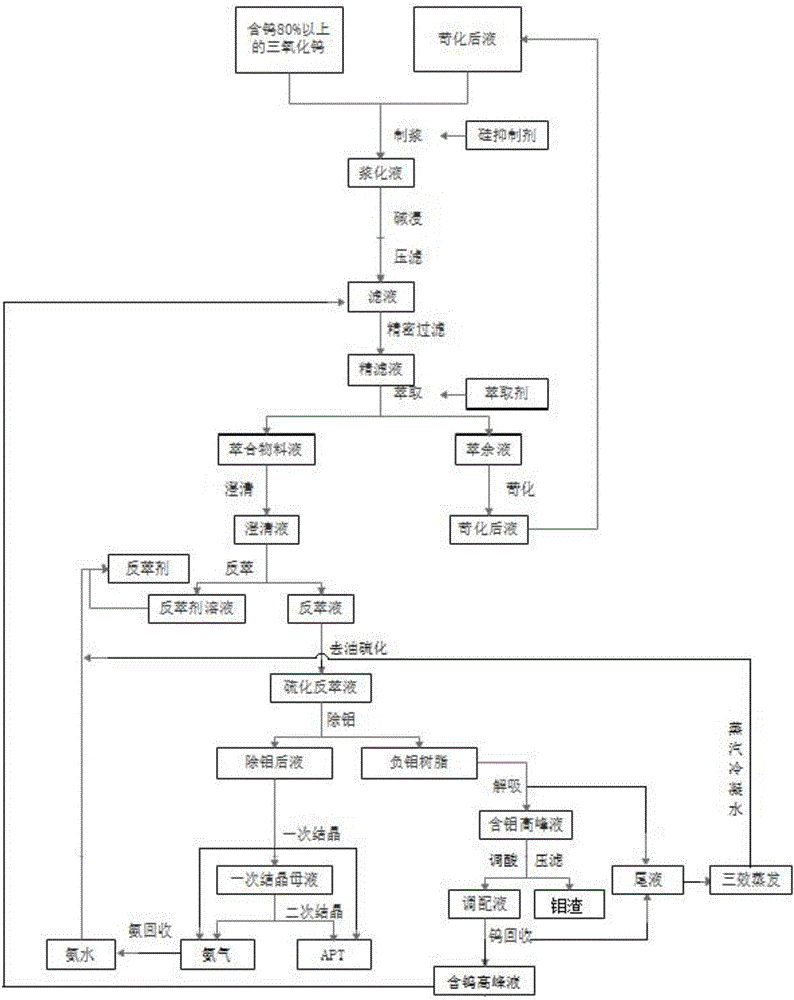

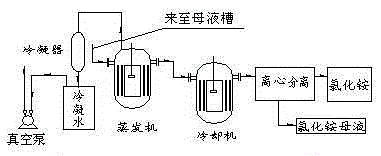

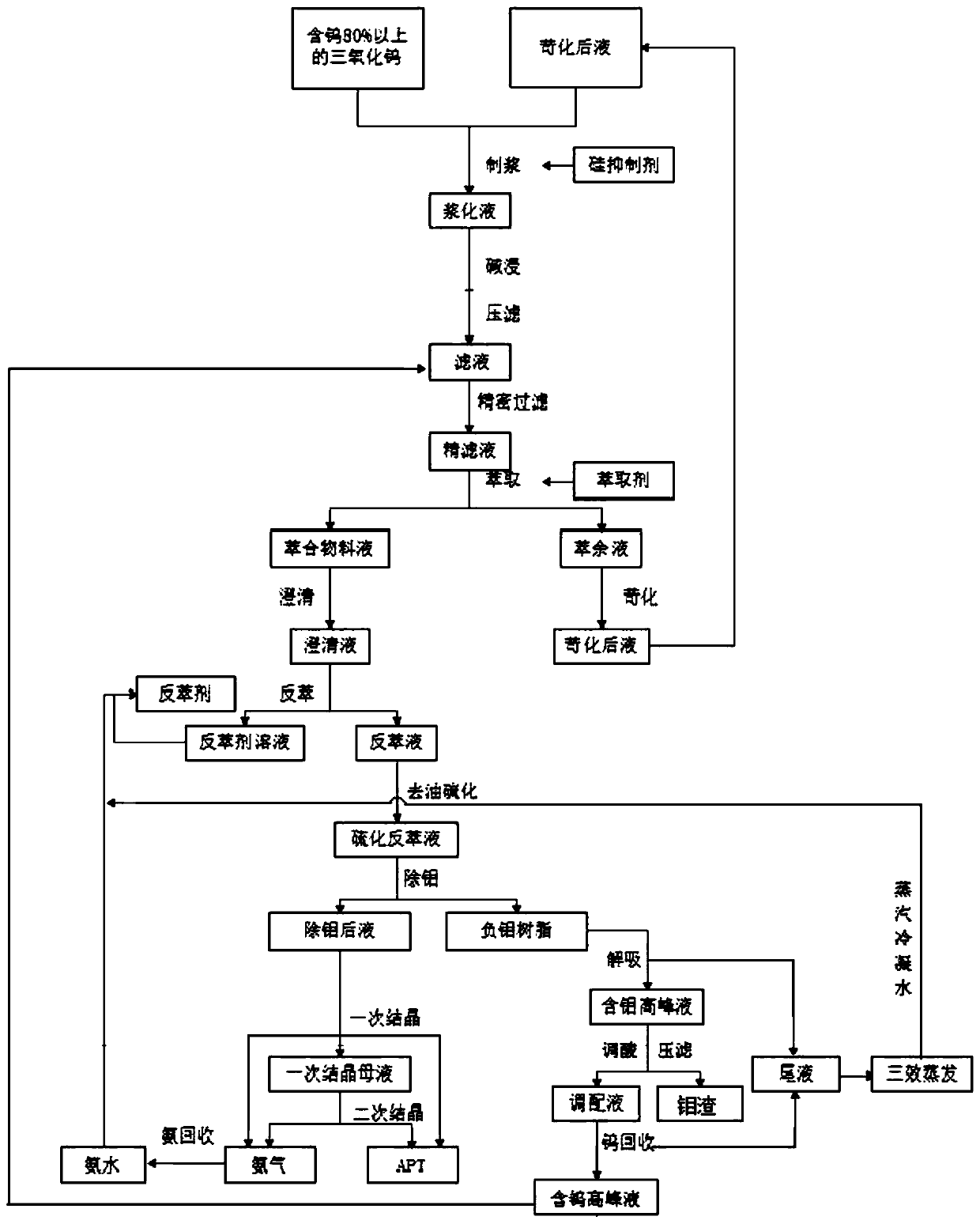

APT (ammonium paratungstate) production wastewater recycling method

ActiveCN106430787AAvoid churnIncrease added valueWater treatment parameter controlFatty/oily/floating substances removal devicesProduction lineAmmonium paratungstate

The invention discloses an APT (ammonium paratungstate) production wastewater recycling method. An APT production line which can realize zero emission of wastewater and is high in water recycling rate can be established, tungsten, molybdenum and other useful metals in a tail liquid can be recycled, loss of tungsten can be avoided, and the added output value can be increased, so that the economic benefit is increased; one part of the discharged tail liquid is recycled to be used for pulping, the other part is evaporated, steam condensate is recycled to be used for preparation of a back washing agent, and thus, zero emission of wastewater is realized. A conventional steam heating manner is changed in a caustification process, a good effect can also be realized through storage tank standing treatment, and the utilization rate of lime can reach 80%, so that steam is saved. Produced APT can meet the notational 0-level standard.

Owner:HUNAN MAOTIAN SHIJIE NEW MATERIALS CO LTD

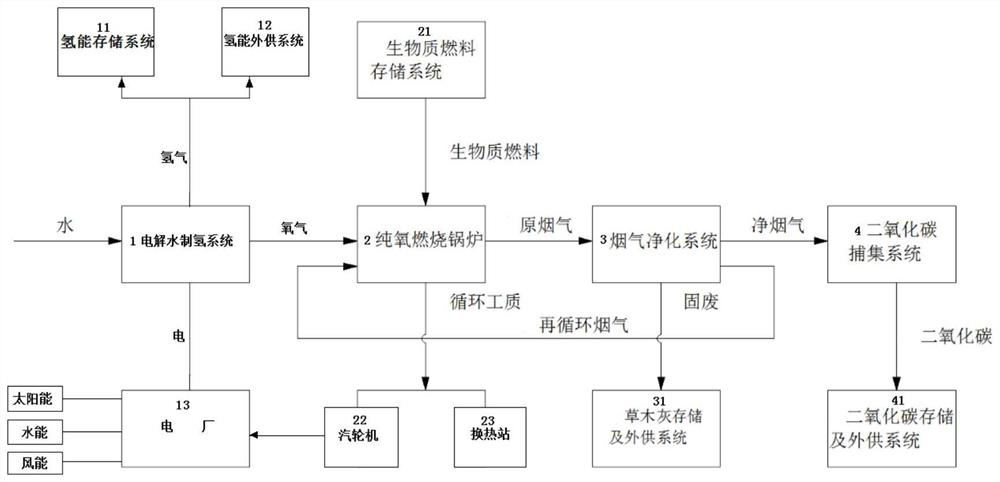

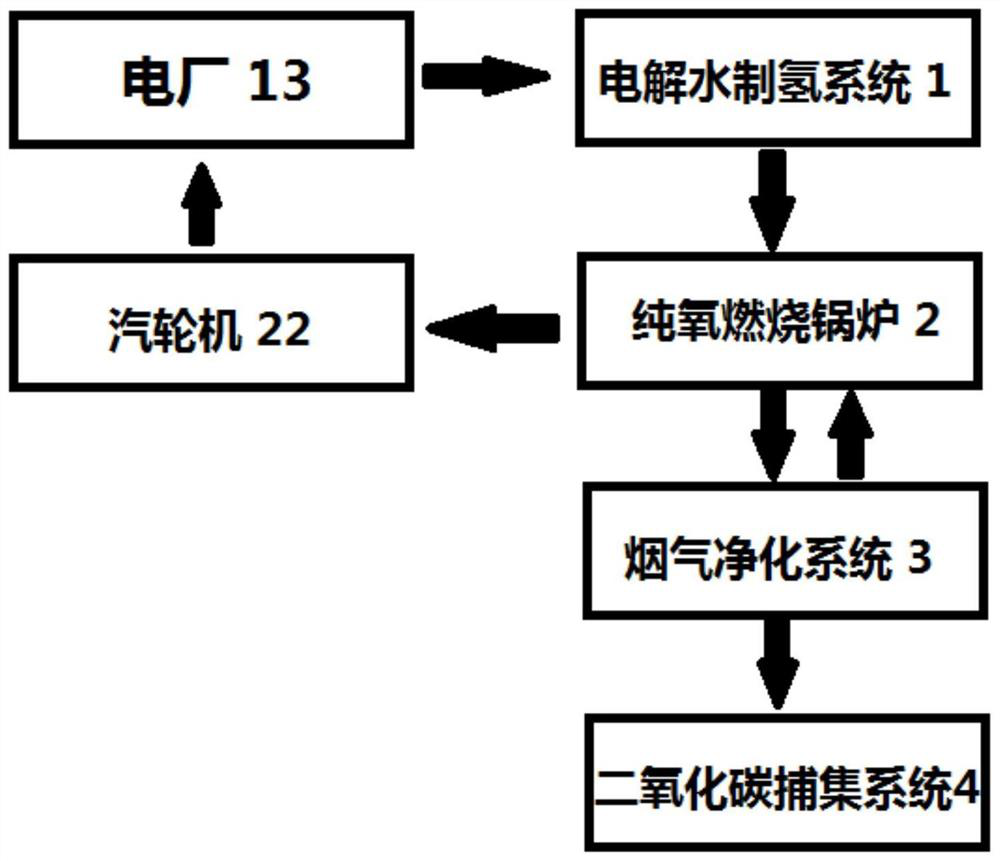

Biomass pure oxygen combustion power generation system and method

PendingCN113187571ALow costTo achieve the purpose of emissionElectrolysis componentsLighting and heating apparatusElectrolysisWaste material

The invention discloses a biomass pure oxygen combustion power generation system and method. The method comprises the steps that hydrogen and oxygen are obtained through water electrolysis, and the oxygen is fed into a pure oxygen combustion boiler; the oxygen and fuel are burnt in the pure oxygen combustion boiler, generated original flue gas is discharged to a flue gas purification system, the heat generated by combustion of the biomass fuel is fed into a steam turbine through steam of a steam pipeline to do work, a generator of a power plant is driven to generate power, meanwhile, power is supplied to a water electrolysis hydrogen production system, and heat energy conversion of combustion of the biomass fuel is achieved; and the flue gas purification system processes the original flue gas to obtain solid waste and purified flue gas, the purified flue gas is discharged into a carbon dioxide capture system, the purified flue gas is treated to obtain pure carbon dioxide, and the pure carbon dioxide is collected, stored and utilized. According to the biomass pure oxygen combustion power generation system and method, residual electricity in production of energy sources such as abandoned wind, abandoned light and abandoned water is converted into the oxygen and hydrogen energy, the oxygen is adopted to support combustion of the biomass fuel, the generated heat, waste materials and waste gas are stored, energy conversion is achieved while the emission amount of the carbon dioxide can be reduced, and negative emission of carbon is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Sewage treatment device with high practicability

InactiveCN107399853APracticalImprove processing efficiencySpecific water treatment objectivesTreatment involving filtrationSludgeSewage

The invention provides a sewage treatment device with high practicability. The sewage treatment device comprises a base and a controller, wherein a first housing is arranged at the left side of the top end of the base; a second housing is arranged at the right side of the top end of the base; the first housing is connected the second housing through a water pipe with a water pump; the water pump is arranged at the top end of the base and is electrically connected with a controller; a support plate is horizontally arranged between the first housing and the second housing and is arranged at the upper part of the water pump; the controller is arranged at the top of the support plate; trundles are arranged at four corners of the bottom end of the base; a filter chamber is formed in an internal space of the first housing; a sewage inlet is formed in the top of the first housing. Through the design of a hydraulic machine, a hydraulic plate and a first box door, the sewage can be thoroughly filtered, a lot of sundries, such as sludge, left on the net can be filtered, the hydraulic plate moves towards the left through the hydraulic machine, and the sundries, such as the sludge, are discharged from the first box door.

Owner:湖州练市成宇丝织厂

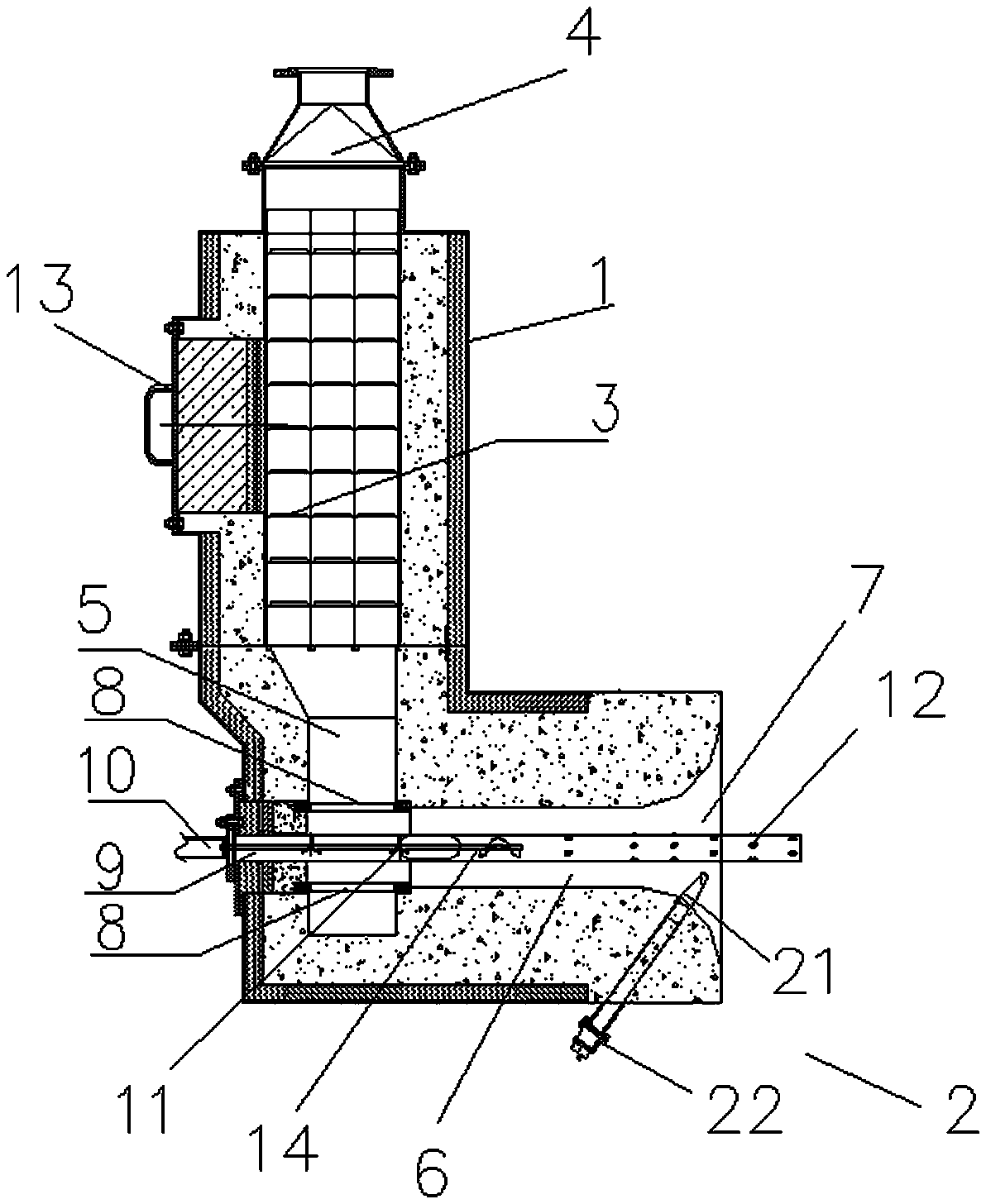

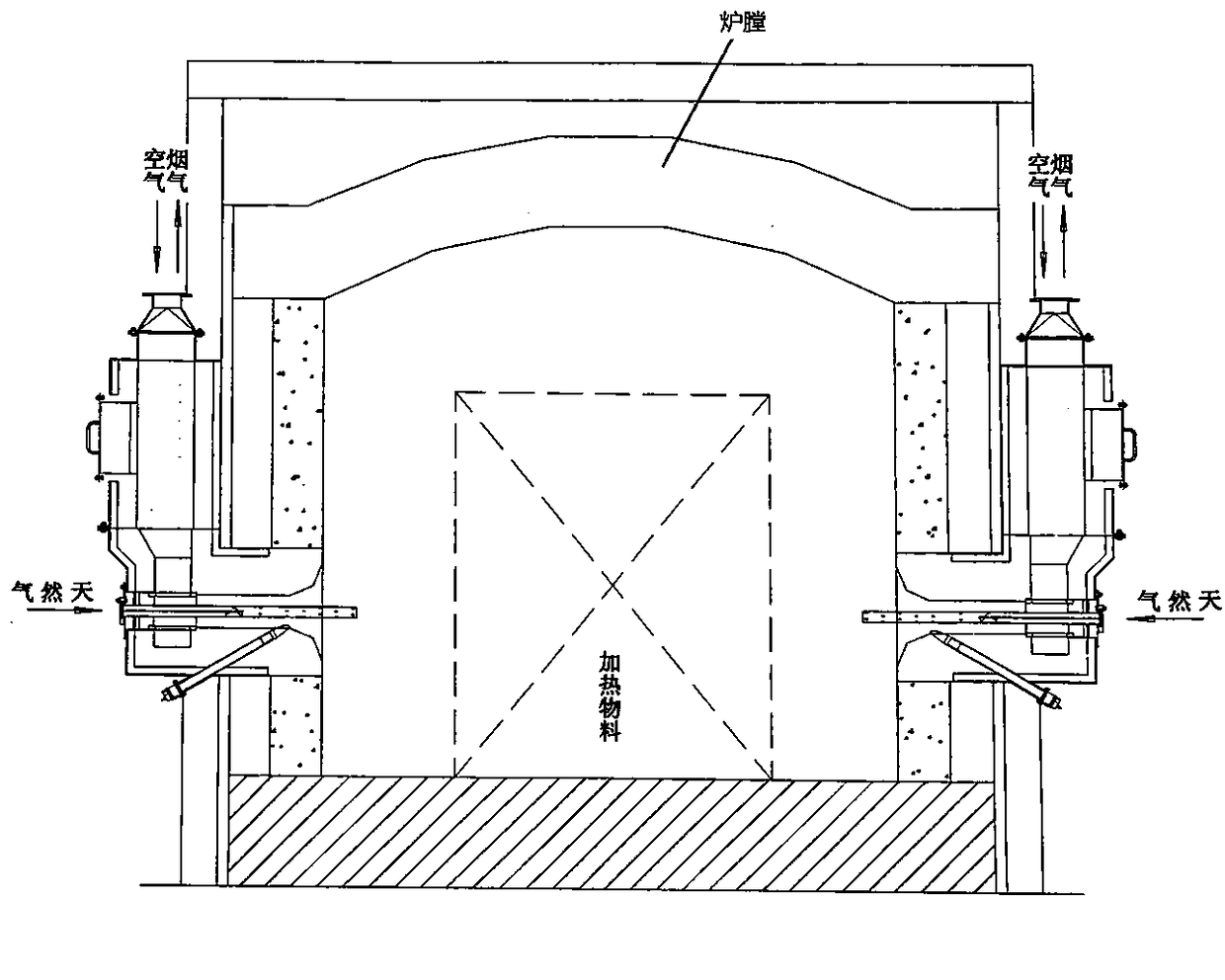

Low nitrogen oxide heat accumulating type flat burner

PendingCN108954310AReduce volumeIncrease powerIndirect carbon-dioxide mitigationGaseous fuel burnerNitrogen oxidesLow nitrogen

The invention relates to a low nitrogen oxide heat accumulating type flat burner, and relates to the field of heat treatment fuel industrial furnaces. A heat accumulating body is installed in a vertical shell, an air inlet is formed in the top of the heat accumulating body, a vertical ventilation hole below the heat accumulating body communicates with a horizontal ventilation hole, and the other end of the horizontal ventilation hole is provided with a spraying nozzle of a horn-shaped gradually-widening structure; an air rotational flow device is installed at the connecting position of the vertical ventilation hole and the horizontal ventilation hole, a natural gas pipe is coaxially installed in the horizontal ventilation hole, one end of the natural gas pipe penetrates a shell to be connected with a natural gas inlet, the other end of the natural gas pipe extends out of the spraying nozzle, a plurality of guide blades are installed in the positions, at one end of the natural gas inlet, in the natural gas pipe at intervals and are fixed through a center shaft, and a plurality of layers of natural gas spraying openings are formed in the positions, at one end of the spraying nozzle,of the pipe wall of the natural gas pipe in the tangential direction at intervals. The burner is small in size, large in power, less in nitrogen oxide emission, good in energy-saving effect and convenient to install.

Owner:宜兴市华宇窑炉制造有限公司

Salt wastewater treatment and reuse device and method thereof

ActiveCN104003569BSolve the hardnessEvaporation energy saving and high efficiencyMultistage water/sewage treatmentUltrafiltrationReverse osmosis

Owner:安徽森诺膜技术有限公司

Zero-discharge treatment device and method for ferric phosphate high-salt waste liquid

ActiveCN104609631BLow costTo achieve the purpose of emissionGeneral water supply conservationMultistage water/sewage treatmentLiquid wasteSalt-wasting

The invention is a zero-discharge treatment device for ferric phosphate high-salt waste liquid, and its structure includes a pretreatment system (PT), a reverse osmosis treatment system (RO), and an evaporation crystallization treatment system (VC). Advantages, the present invention is designed for the high salinity of ferric phosphate high-salt waste liquid. The ferric phosphate high-salt waste liquid is firstly treated to remove part of the suspended matter, and then desalted by reverse osmosis, concentrated and reduced, and the water produced by reverse osmosis is reused , The reverse osmosis concentrated water is finally treated by evaporation and crystallization, the condensed water from evaporation and crystallization is reused, and the waste salt is transported outside to achieve the purpose of zero liquid discharge. The specific advantages are: ① organically combine pretreatment, reverse osmosis, and evaporation crystallization; ② use reverse osmosis to concentrate and reduce weight, and reduce the cost of subsequent evaporation crystallization; ③ use falling film evaporation combined with MVR (steam mechanical recompression) Advanced evaporation and crystallization technology, energy-saving and high-efficiency, reducing operating costs ④ It not only achieves water reuse, but also achieves the purpose of zero liquid discharge.

Owner:深圳市华虹清源环保科技有限公司

Novel semi-dry flue gas desulphurization technology

InactiveCN102228787AAchieve purificationTo achieve the purpose of emissionDispersed particle separationDevice typeFlue gas

Owner:JIANGSU ZHENGTONG HONGTAI INC

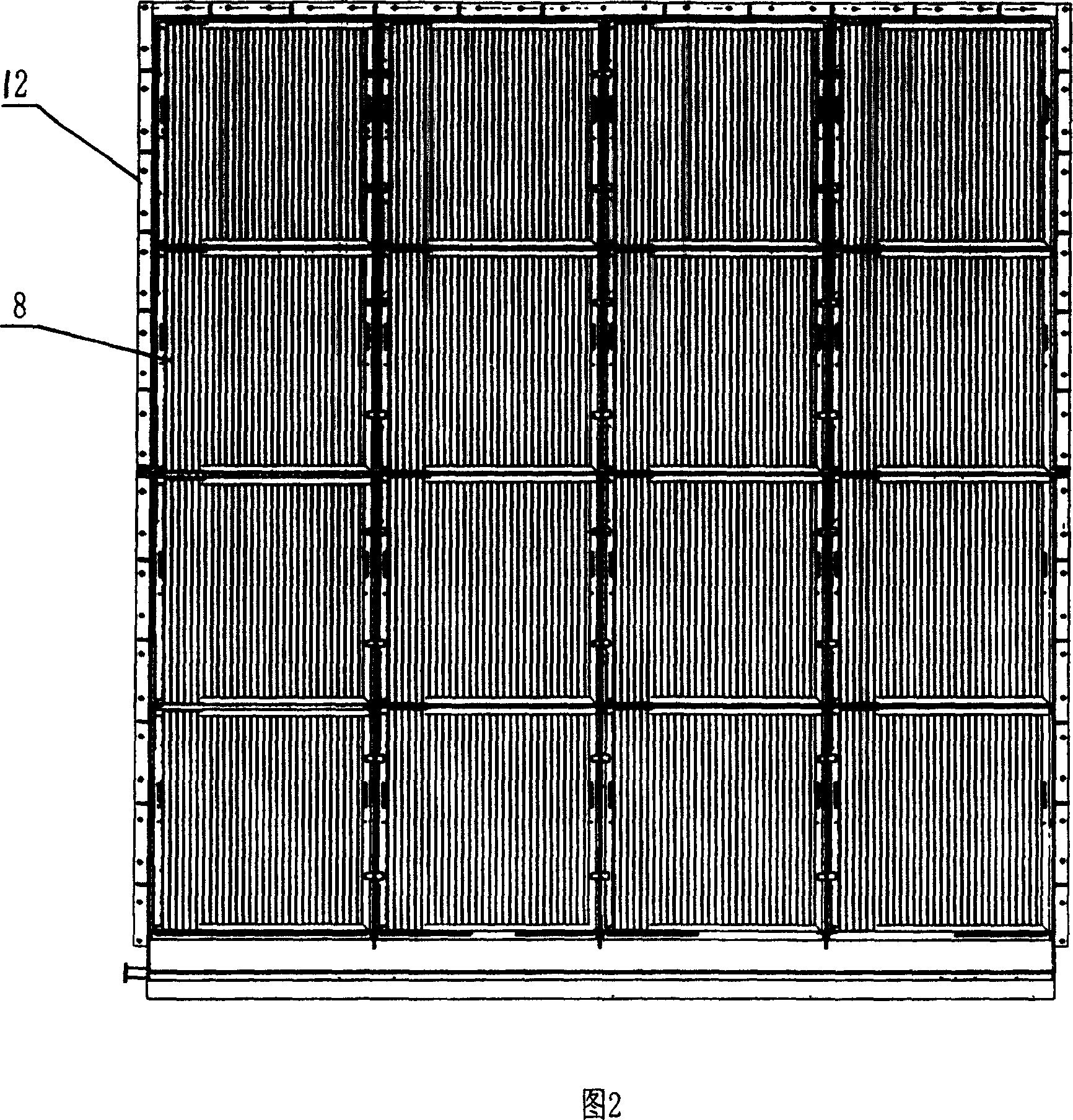

Water-cooling gas furnace core and vacuum hot water boiler comprising same

PendingCN114484435AFully stable combustionUniform flameCombustion technology mitigationWater heatersThermodynamicsFlue gas

The embodiment of the invention provides a water-cooling gas furnace core and a vacuum gas-fired hot water boiler comprising the same. The water-cooling gas furnace core comprises a first clamping flange, a heat exchange tube cluster and a second clamping flange, the heat exchange tube cluster is arranged between the first clamping flange and the second clamping flange to jointly form a wall face restraining smoke circulation, the heat exchange tube cluster at least comprises a first heat exchange tube cluster and a radiation heat dissipation tube cluster, and the first heat exchange tube cluster and the radiation heat dissipation tube cluster are arranged on the wall face. And a heat exchange medium is packaged in the heat exchange tube cluster. According to the embodiment, the average heat exchange coefficient can be increased, deep cooling of high-temperature flue gas is achieved, ultralow NOx emission is guaranteed, and meanwhile the heat utilization efficiency is greatly improved.

Owner:三木舜锅炉(江苏)有限公司

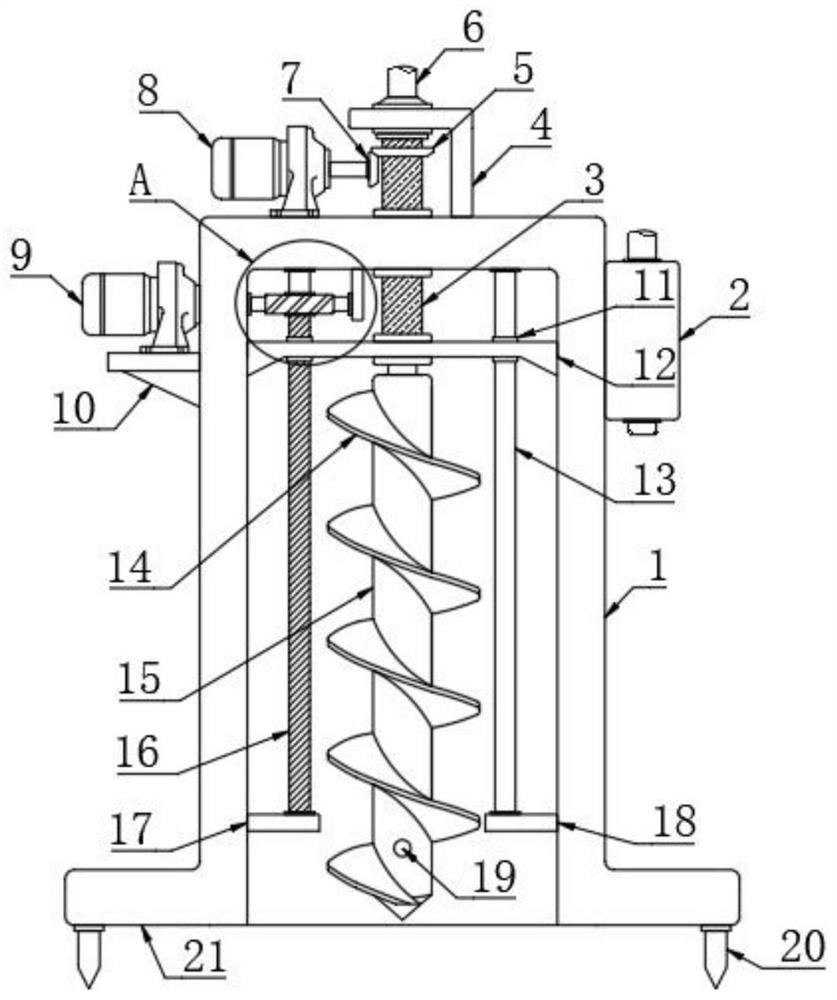

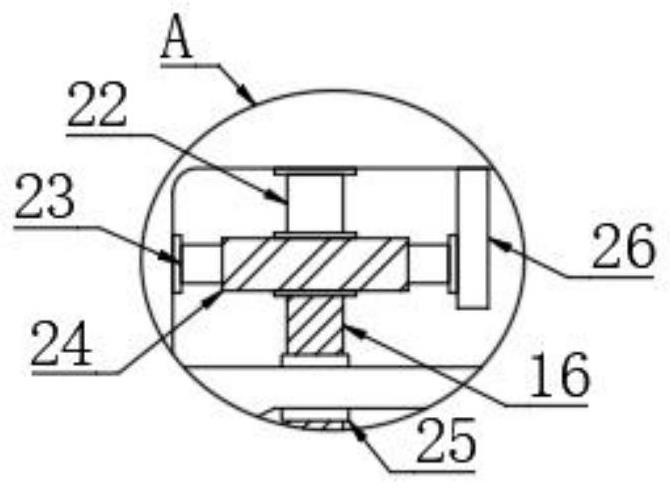

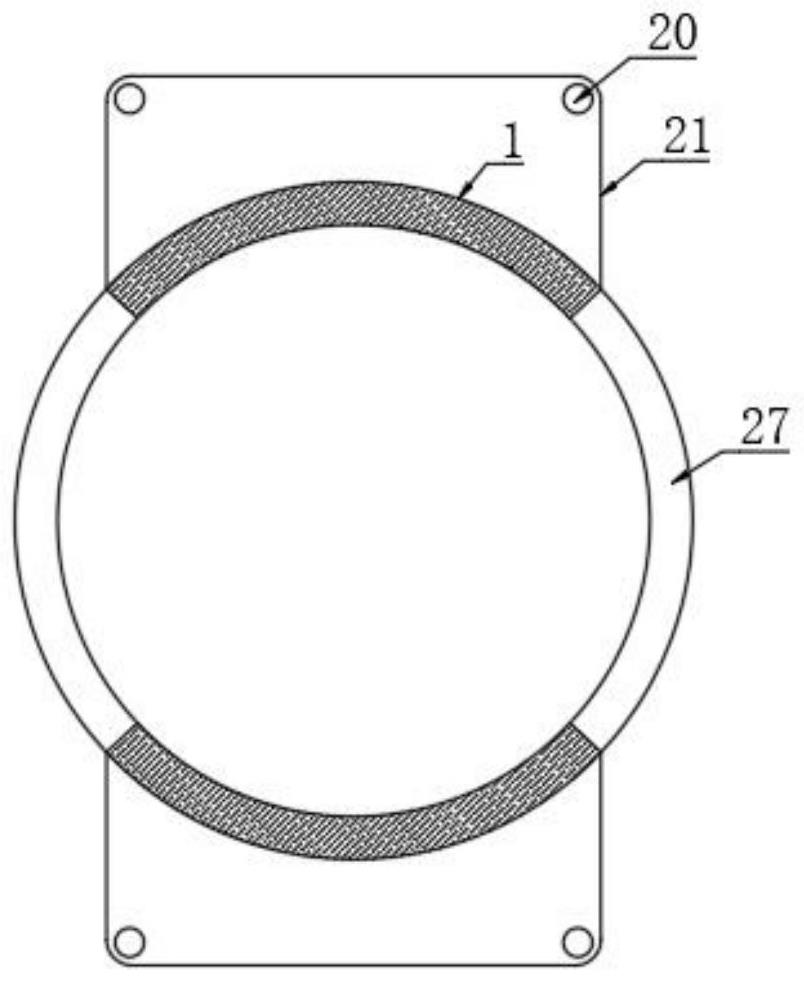

Chemical agent treatment equipment convenient for nursing

PendingCN113982472AReduce pollutionAchieve rotationDrilling rodsConstructionsDrill holeEnvironmental geology

The invention discloses chemical agent treatment equipment convenient for nursing. The chemical agent treatment equipment comprises a supporting table, two openings used for discharging soil are symmetrically formed in the outer side of the supporting table, two bases are fixedly connected to the outer side of the supporting table, and the two bases are symmetrically arranged; the lower end of each base is fixedly connected with two insertion rods used for improving the stability of the supporting table; and a liquid conveying rod is arranged at the upper end of the supporting table in a penetrating mode, the liquid conveying rod is rotationally connected with the supporting table, a connecting pipe is slidably connected into the liquid conveying rod, a drill rod for drilling holes to discharge chemical agents is fixedly connected to the lower end of the connecting pipe, and spiral blades are fixedly connected to the outer side of the drill rod. A hole is drilled to the specified depth through the drill rod and the spiral blade, then a chemical agent is injected into the liquid conveying cavity in the drill rod through a liquid pump and discharged, in this way, the chemical agent can be completely prevented from being attached to the hole wall, and environmental pollution is reduced.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

A kind of continuous ammoniation production process of 2,4-dinitroaniline

ActiveCN104130138BTo achieve the purpose of emissionIncrease productivityOrganic compound preparationAmino compound preparationReaction temperature2,4-Dinitrochlorobenzene

The invention relates to a 2,4-dinitraniline continuous ammonification production technology, which is characterized in that 2, ,4-dinitraniline and ammoniacal liquor are taken as raw materials, the raw materials are reacted at temperature of 160-170 DEG C and pressure of 0.5-1.0 MPa, and then continuously added in an ammonification reactor; when the raw materials exceeds a discharge hatch, and are successively flowed to two auxiliary reactors, wherein the reaction temperature is controlled at 160-170 DEG C, and the reaction pressure is controlled at 0.5-1.0 MPa, reaction time of an ammonification reactor is 42 minutes, and reaction time of each auxiliary reactor is 15 minutes. The production technology has the advantages of high production efficiency, low energy consumption, environmental protection, economy, low labor intensity and safety, waste heat during an ammonification reaction process can be fully used, by-product ammonium chloride can be simultaneously recovered, no waste water is generated, and the production technology has the advantages of green production and good economic benefit.

Owner:LIANYUNGANG DIPU CHEM

Dust collector

InactiveCN106563323ASimple structureLess investmentUsing liquid separation agentEngineeringDust collector

The invention relates to a dust collector, wherein a through pipe is designed, a plurality of separation layers are arranged in the through pipe through separation plates, each separation plate slightly and downwardly tilts, and each separation layer position is provided with a spraying faucet. The dust collector of the present invention has advantages of simple structure, less investment and significant dust removal effect, and is one of the ideal dust removal equipment.

Owner:黄树耿

A kind of apt production wastewater recycling method

ActiveCN106430787BAvoid churnIncrease added valueWater treatment parameter controlFatty/oily/floating substances removal devicesProduction lineAmmonium paratungstate

The invention discloses an APT (ammonium paratungstate) production wastewater recycling method. An APT production line which can realize zero emission of wastewater and is high in water recycling rate can be established, tungsten, molybdenum and other useful metals in a tail liquid can be recycled, loss of tungsten can be avoided, and the added output value can be increased, so that the economic benefit is increased; one part of the discharged tail liquid is recycled to be used for pulping, the other part is evaporated, steam condensate is recycled to be used for preparation of a back washing agent, and thus, zero emission of wastewater is realized. A conventional steam heating manner is changed in a caustification process, a good effect can also be realized through storage tank standing treatment, and the utilization rate of lime can reach 80%, so that steam is saved. Produced APT can meet the notational 0-level standard.

Owner:HUNAN MAOTIAN SHIJIE NEW MATERIALS CO LTD

A treatment process for power plant flue gas desulfurization wastewater

ActiveCN104478141BOvercome the disadvantage of not being able to recycle and form waste solidsTo achieve the purpose of emissionTreatment involving filtrationWaste water treatment from gaseous effluentsFiltrationFlue gas

The invention relates to a wastewater treatment process, and in particular relates to a power plant flue gas desulfurization wastewater treatment process. The process comprises three steps as follows: I, carrying out plate frame filtration on desulfurated wastewater in a power plant, and implementing microporous filtration so as to obtain a clear filtrate without suspended solids; II, concentrating the clear filtrate by virtue of an electrodialysis membrane unit having a pH value regulating function, and recycling concentrated fresh water; and III, carrying out microporous filtration on a mixture in a concentrated water room, recovering filter residue, crystallizing the filtrate in a calcium sulfate crystal seed crystallizing device, and separating out calcium sulfate crystal. The wastewater treatment process disclosed by the invention is simple in process, and capable of effectively recovering heavy metals and achieving a purpose of zero discharge of desulfurized wastewater in a real sense.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

A kind of equipment used to clean the inner wall of the factory building for secondary treatment

ActiveCN109864672BEfficient collectionTo achieve the purpose of emissionCarpet cleanersFloor cleanersHydraulic cylinderHazardous substance

The invention discloses a device for cleaning the inner wall of a factory building for secondary treatment, which includes a sliding guide rail and a cleaning range adjusting device installed on the upper surface of the sliding guide rail. The sliding guide rail is fixedly connected to the inner wall of the factory building in the horizontal direction; The equipment used to clean the inner wall of the factory building for secondary treatment also includes an attachment cleaning device located above the sliding guide rail, and a harmful substance filtering device located at one end of the sliding guide rail; the attachment cleaning device drives the platform up and down through a hydraulic cylinder. Moving, the platform drives the cleaning brush to clean and adjust the cleaning brush to fit the inner wall of the factory building through the telescopic adjustment of the motor. The harmful substance cleaning device moves the harmful substance into the reaction box through the docking of the interface, and matches a certain proportion of chemical solvent through the adjustment of the regulating valve And react to harmful substances. The invention has the advantages of simple structure and strong practicability.

Owner:HANGZHOU FUYANG HEXIANG MOULD CO LTD

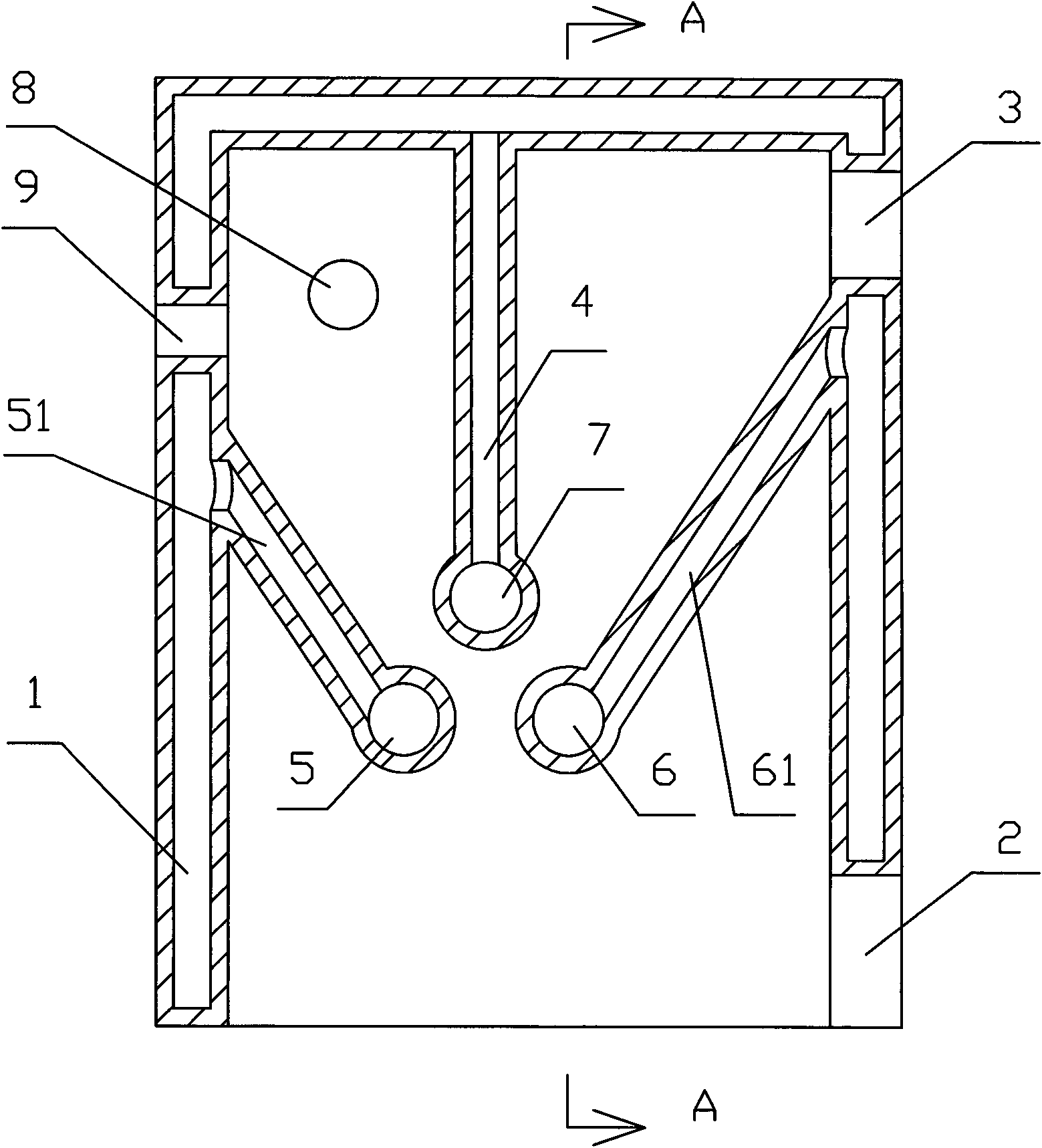

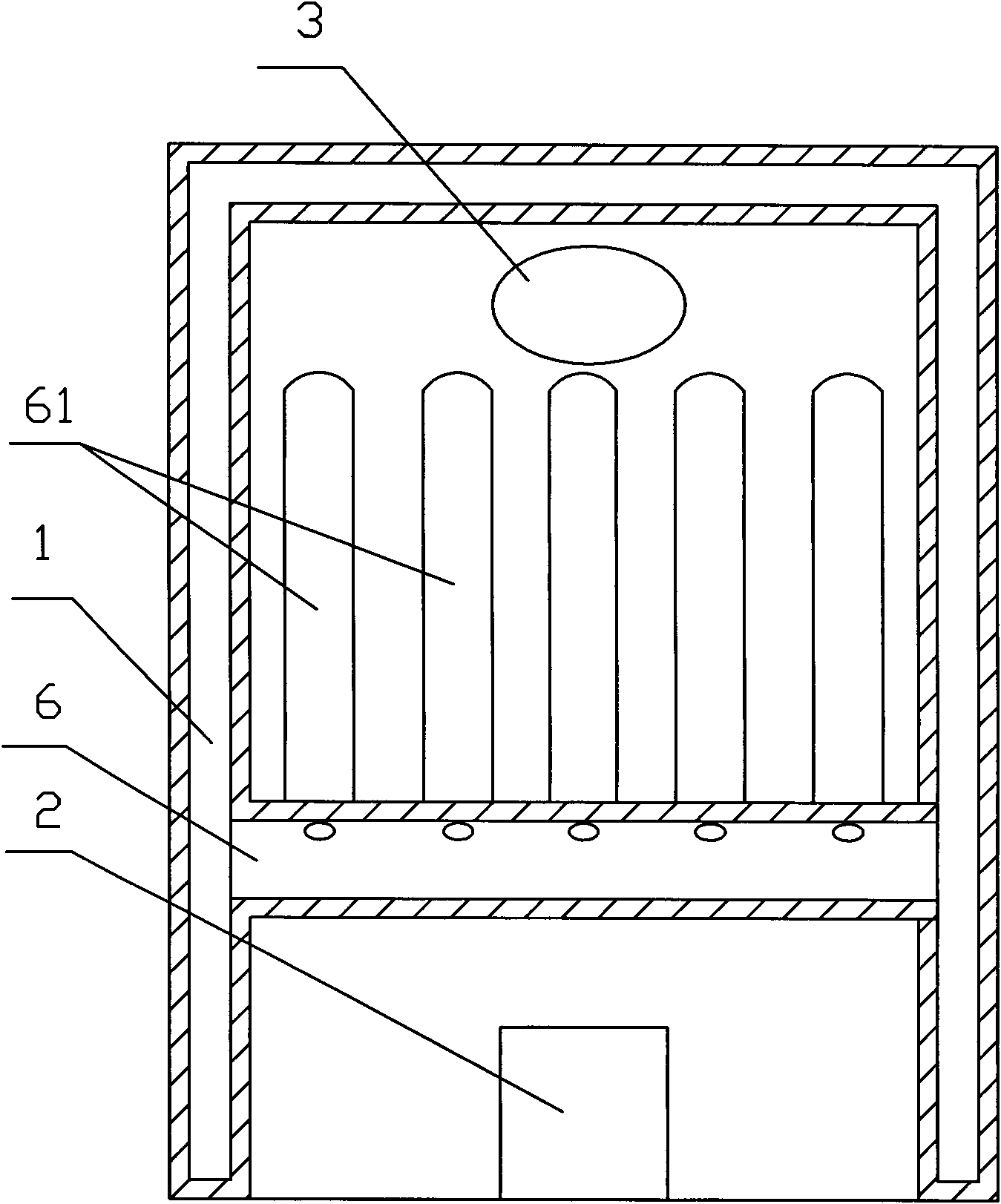

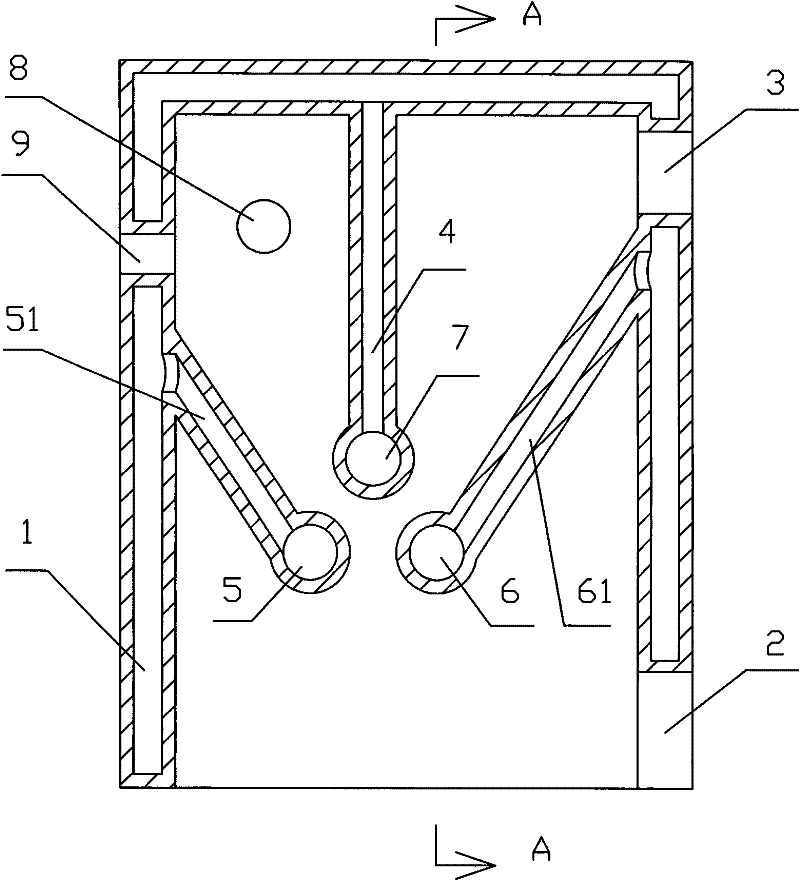

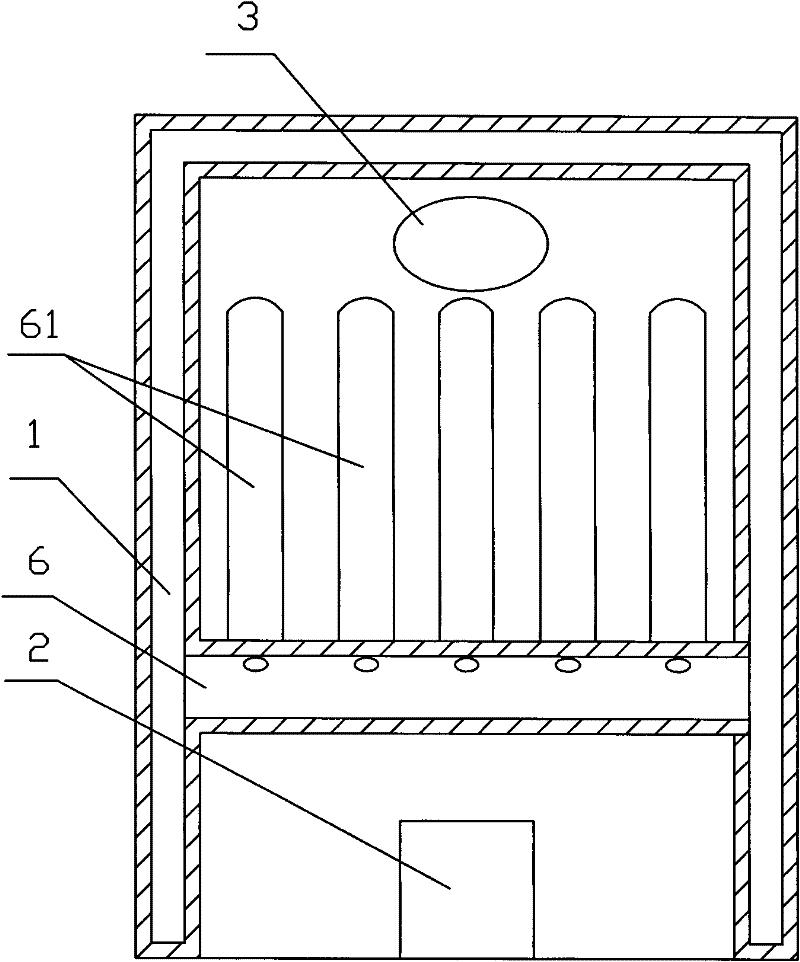

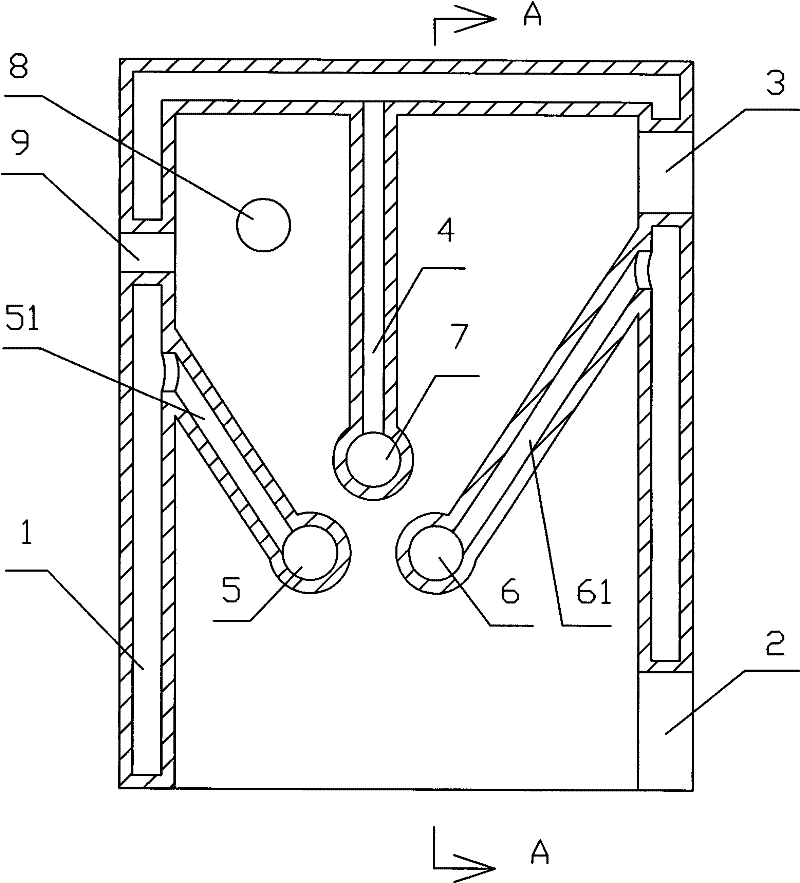

Fire grate free boiler

The invention relates to a boiler, in particular to a fire grate free boiler. A shell has a sandwich structure and is internally provided with a water jacket, and the cavity of the shell is internallyprovided with an upper partition board, a left horizontal pipe and a right horizontal pipe; two ends of the left horizontal pipe and the right horizontal pipe are all fixedly connected with the innerwall of the shell and communicated with the water jacket; the position of the lower end of the upper partition board is higher than the positions of the left horizontal pipe and the right horizontalpipe and the upper part of a hearth is divided into two combustion chambers by the upper partition board; the left horizontal pipe and the right horizontal pipe are respectively and fixedly connectedwith a left inclined pipe and a right inclined pipe, respectively extend towards the left side and the right side, are fixedly connected with the inner wall of the shell and communicated with the water jacket. The fire grate free boiler adopts the inclined pipes with special structures to support coal to replace the fire grate, and omits an independent fire grate, so the structure is simpler, thecoal is fully combusted, tail gas pollution is less and the aims of saving energy and protecting environment are achieved.

Owner:岳秀宇

Fire grate free boiler

The invention relates to a boiler, in particular to a fire grate free boiler. A shell has a sandwich structure and is internally provided with a water jacket, and the cavity of the shell is internally provided with an upper partition board, a left horizontal pipe and a right horizontal pipe; two ends of the left horizontal pipe and the right horizontal pipe are all fixedly connected with the inner wall of the shell and communicated with the water jacket; the position of the lower end of the upper partition board is higher than the positions of the left horizontal pipe and the right horizontalpipe and the upper part of a hearth is divided into two combustion chambers by the upper partition board; the left horizontal pipe and the right horizontal pipe are respectively and fixedly connectedwith a left inclined pipe and a right inclined pipe, respectively extend towards the left side and the right side, are fixedly connected with the inner wall of the shell and communicated with the water jacket. The fire grate free boiler adopts the inclined pipes with special structures to support coal to replace the fire grate, and omits an independent fire grate, so the structure is simpler, thecoal is fully combusted, tail gas pollution is less and the aims of saving energy and protecting environment are achieved.

Owner:岳秀宇

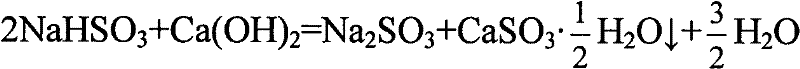

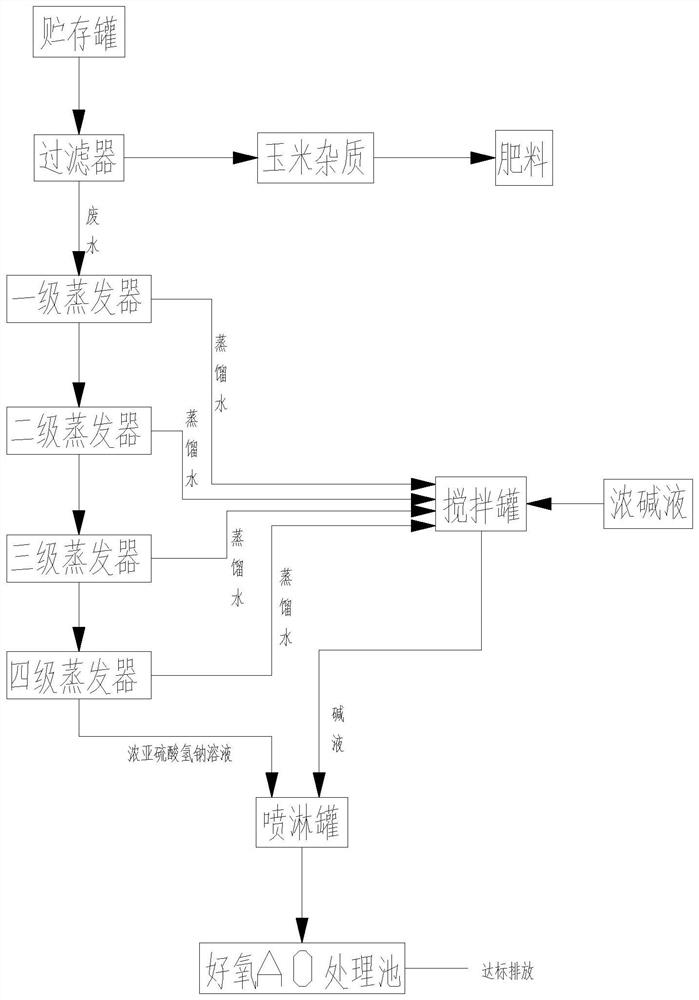

Water treatment process for corn starch processing wastewater

InactiveCN112759179ALow costTo achieve the purpose of emissionWater contaminantsTreatment involving filtrationDistillationTreatment pond

The invention discloses a water treatment process for corn starch processing wastewater. Wastewater with sodium hydrogen sulfite generated after corn soaking is filtered, impurities are separated out, the wastewater sequentially enters a first-stage evaporator, a second-stage evaporator, a third-stage evaporator and a fourth-stage evaporator, and water evaporation treatment is conducted, so that sodium hydrogen sulfite is separated from the water and a condensed sodium hydrogen sulfite solution is obtained; condensed water obtained by distillation is mixed with concentrated alkali liquor in a stirring tank, and then is mixed with the concentrated sodium hydrogen sulfite solution in a spraying tank for neutralization through spraying, finally treatment is conducted in an aerobic AO treatment pond and discharging is conducted after the standard is met. The technology separates out sodium hydrogen sulfite from water through a physical way, and then the separated water is mixed with alkali liquor for neutralization with sodium hydrogen sulfite, so that not only is the cost of wastewater treatment reduced, but also the wastewater can be used for purification treatment, and the purpose of discharging is achieved.

Owner:肇庆焕发生物科技有限公司

Fermenting method utilizing soy sauce and grains fully

ActiveCN102715490BAchieve energy saving and emission reductionTo achieve the purpose of emissionFood processingAnimal feeding stuffProcess engineeringSoya sauce

The invention discloses a method for brewing soy sauce and grains, which comprises the following steps: A1, preparation of raw materials; A2, charging and steaming; A3, mixing: cooling the steamed soybeans rapidly, and mixing them evenly with fried wheat flaps; A4, inoculation into koji; A5, koji making; A6, solid-state low-salt "double mold" fermentation; A7, thin mash fermentation; A8, soy sauce sterilization; A9, clarification, inspection; A10, solid-state sauce fermentation. In addition to producing the required soy sauce, the fermented soy sauce is combined with the crude enzyme solution to carry out the traditional process of drying and fermenting to further decompose the active ingredients in the raw materials, so as to obtain a rich sauce with a special taste and aroma of traditional soybean paste and sweet noodle sauce The finished soybean paste is used as a base for preparing soybean paste and compound seasoning. So as to achieve the purpose of no waste residue discharge in the production of soy sauce, and realize the purpose of energy saving, emission reduction and full utilization of food in the food manufacturing industry.

Owner:重庆天厨天雁食品有限责任公司

Oil-fog purifier set

This invention is an oil mist clearing machine group, it belongs to separating technique field. It is mainly consisted by air intake section, cleaner section and air outtake section. The cleaner section is consisted by liquor resisted section and catching section, the resisted section is consisted by stainless steel compaction, and liquor resisted module combined by flexed liquor resist board and frame. The catching section is combined by catching net and frame of multi-layer stainless steel, catching module formed by batten compacted. Steam clean comb is set in machine group and the comb is connected to steam pipe, valve group is set on the pipe and blow-off pipe is set at bottom of the group. The product in this invention is easy to tinertoy, detach, detect and transmit, it can online spray steam for cleaning. It is produced as technique quick rhythm, its cleaning is auto, replacing is convenient, cleaning efficiency is high. It can be widely used to clear oil mist and gas with wet dust, especially to large emulsion oil mist when cold-rolling mill is working to reach the goal of clean exhaust gas.

Owner:CISDI ENG CO LTD

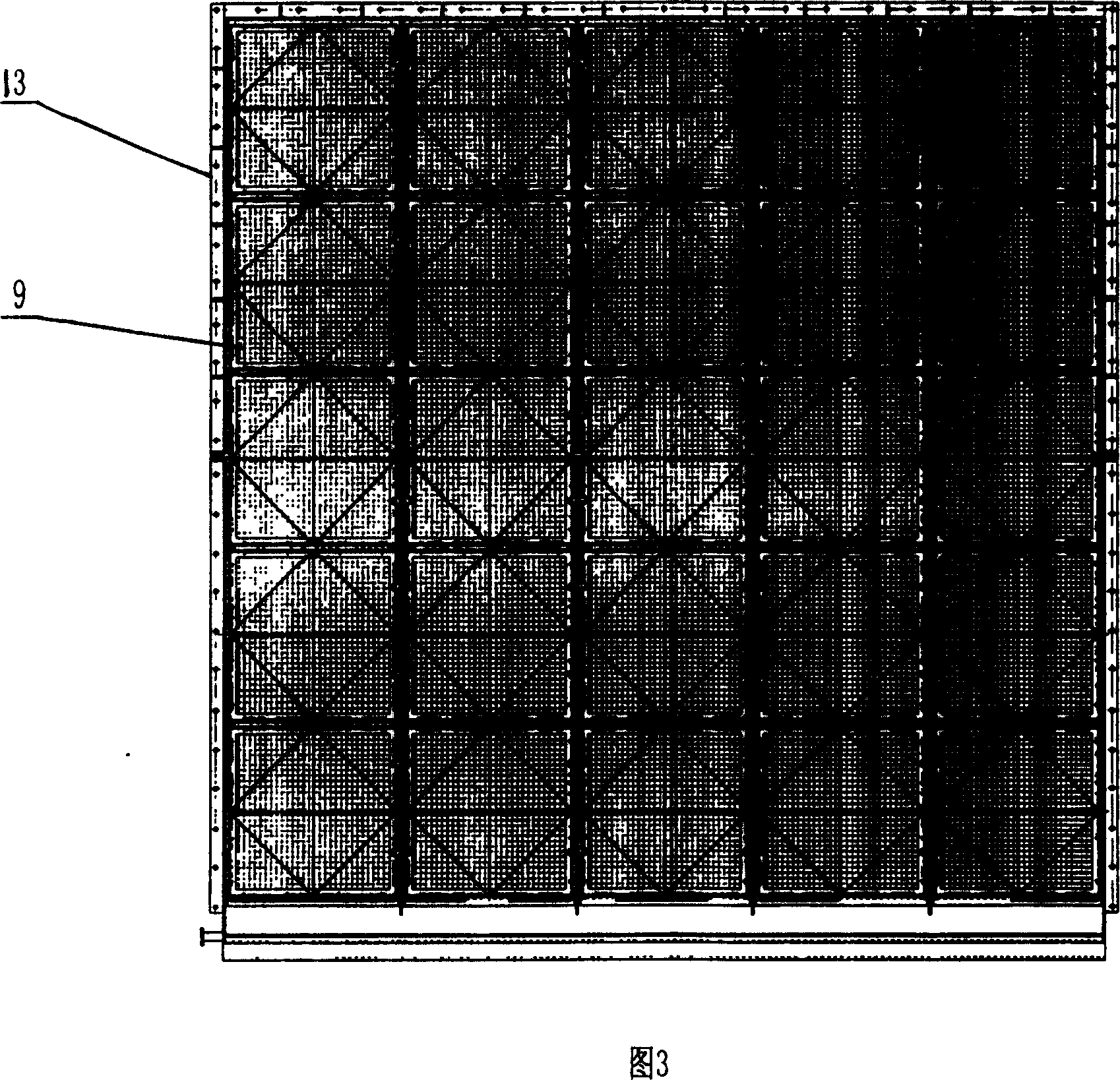

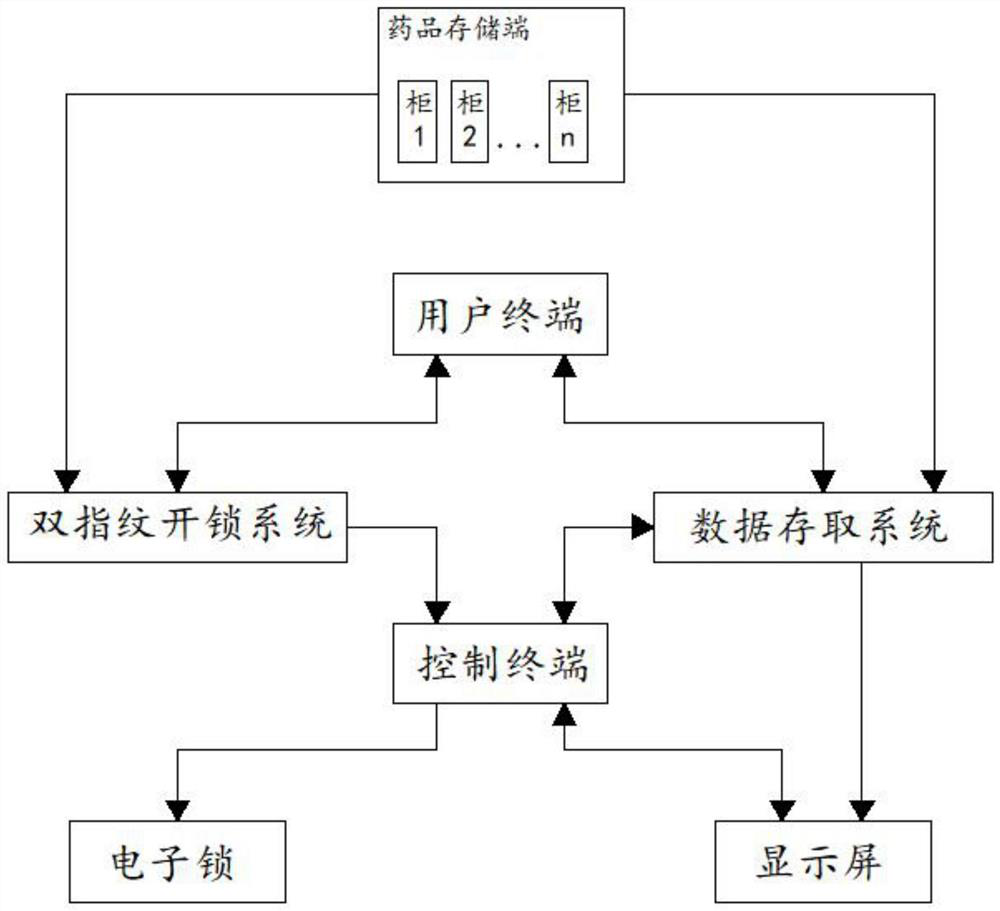

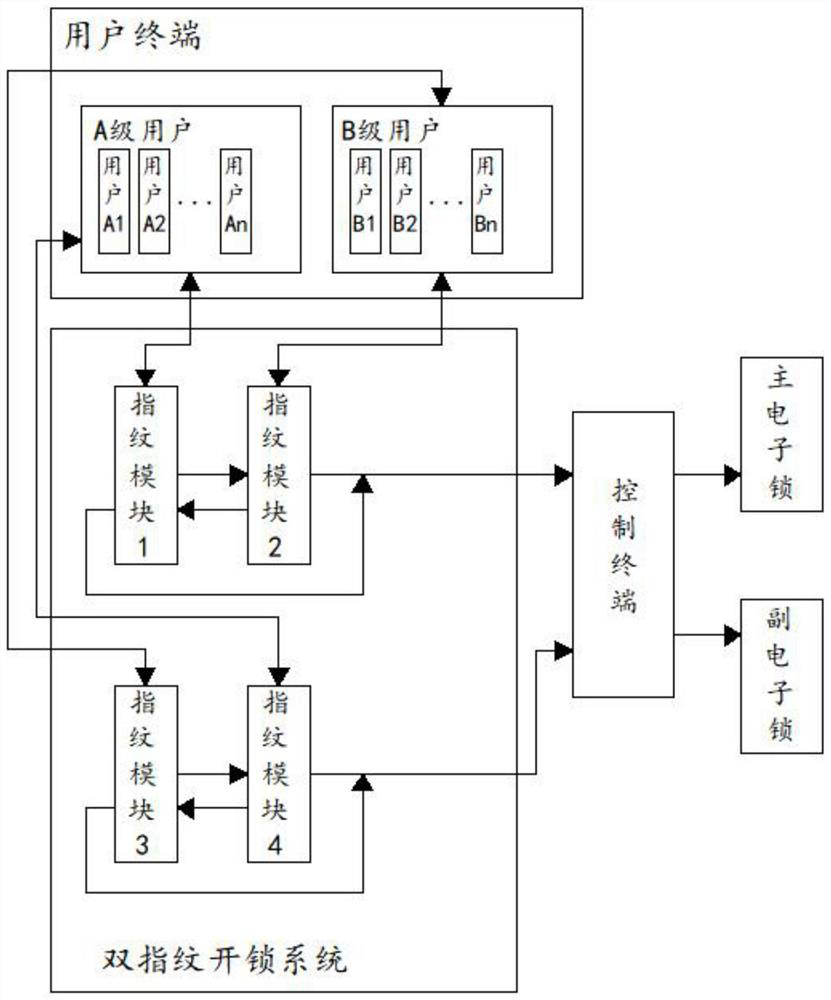

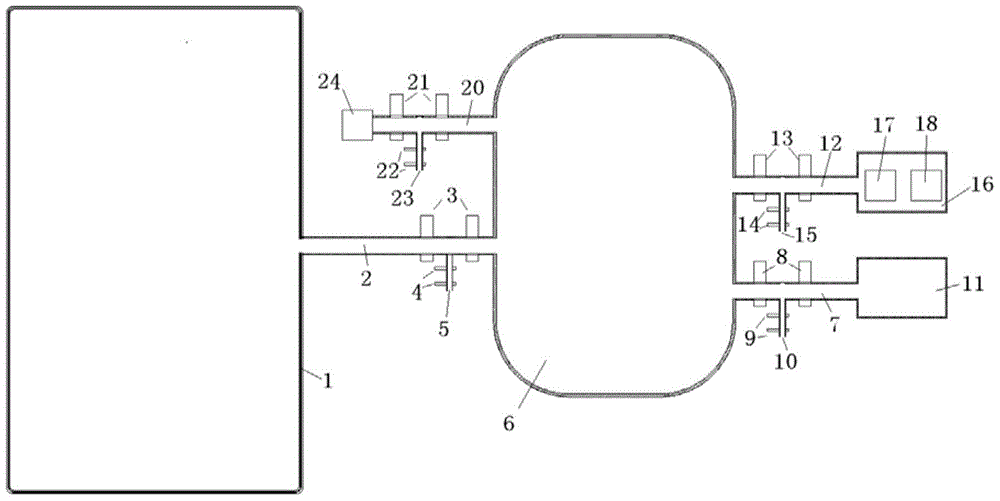

Electronic double-fingerprint-lock poison and anesthesia medicine management cabinet and system

InactiveCN112674502ATo achieve the purpose of emissionEasy to sort and storeChestsBuilding locksEngineeringSurgery

The invention discloses an electronic double-fingerprint-lock poison and anesthesia medicine management cabinet. The cabinet comprises a shell, a top box is fixedly installed at the top of the shell, a containing groove is formed in the shell, a protective door is movably installed on the front face of the shell, a main fingerprint lock and an auxiliary fingerprint lock which are used for being locked with the shell are fixedly installed on the front face of the protective door, the main fingerprint lock and the auxiliary fingerprint lock each comprise two fingerprint modules and an electronic lock, handles are fixedly installed on the front faces of the main fingerprint lock and the auxiliary fingerprint lock, buttons are fixedly installed on the front faces of the handles, a control panel is fixedly installed on the front face of the shell, a draught fan located in the top box is fixedly installed on the top of the shell, an air inlet pipe extending into the containing groove is fixedly installed at the air inlet end of the draught fan. According to the electronic double-fingerprint-lock poison and anesthesia medicine management cabinet and system, a user can perform classified storage more conveniently, management of the user is facilitated, safety and protection performance are better, and the cabinet and the system are more convenient for the user to use.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

A high yield neutron generator helium processing device

InactiveCN104093261BHigh outputExtended service lifeDirect voltage acceleratorsNuclear targetsProduct gasAlloy

The invention discloses a helium processing device of a high yield neutron generator. The helium processing device is connected to a large-volume helium processing vacuum container through a vacuum pipeline outside a neutron generator main vacuum chamber. In the helium processing container, hydrogen absorption alloy which has large adsorbing capacity and high absorbing speed to deuterium and tritium gas, has low absorbing speed to non-hydrogen impurity gas, and does not have the absorbing effect on helium is used for absorbing the deuterium and tritium gas in a system, and remaining helium and non-hydrogen impurity gas are pumped by an ionic pump. Then, the hydrogen absorption alloy is appropriately heated, the absorbed deuterium and tritium gas is released to the inside of the vacuum container again, and the purposes that in the totally-sealed container, the deuterium and tritium gas is basically not consumed and meanwhile the helium and other impurity gas are dynamically eliminated are achieved. The helium processing device is particularly suitable for being used in totally-sealed deuterium and tritium neutron generators which has long service life and high yields.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

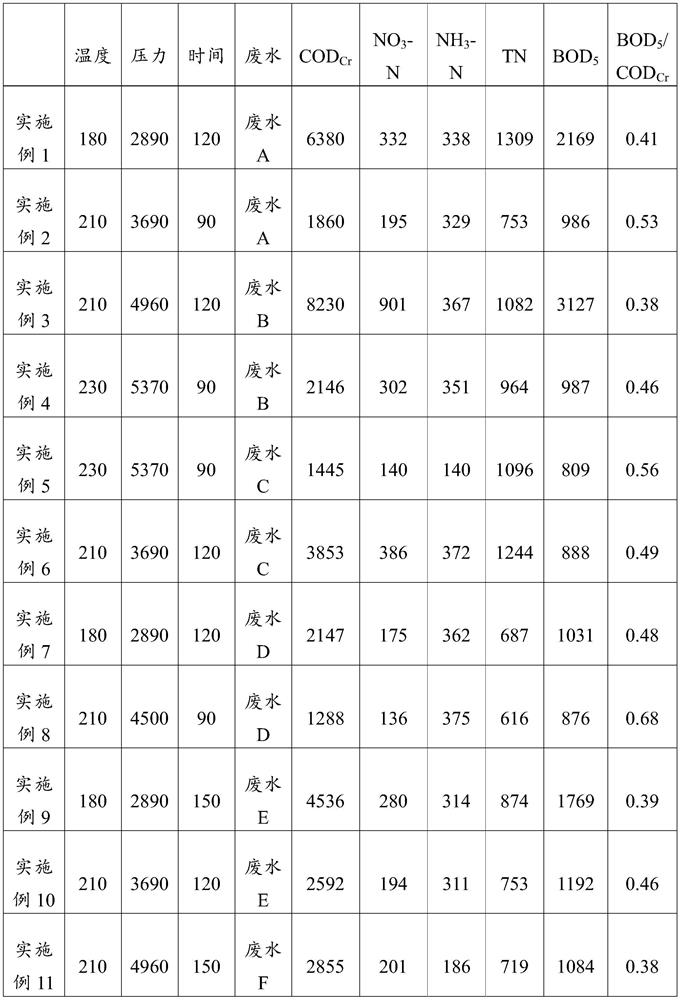

Treatment method for improving biodegradability of refractory organic wastewater

PendingCN113830971ATo achieve the purpose of degrading CODImprove biodegradabilityWater treatment parameter controlWater contaminantsNitrate nitrogenWastewater

The invention provides a treatment method for improving biodegradability of refractory organic wastewater, and belongs to the field of environmental protection. The method comprises the following steps: putting the organic wastewater into a reactor, adding an oxidizing agent, and reacting at the temperature of 150-300 DEG C and the pressure of 2-6 MPa to obtain the treated organic wastewater. Nitrate nitrogen and other organic pollutants in the organic wastewater can be efficiently degraded through heating and pressurizing, various pollutants can be deeply removed from the treated organic wastewater through common biochemical treatment, the purpose of discharging is achieved, and the method has the advantages of being efficient, energy-saving, economical and reliable.

Owner:FIRST RARE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com