A kind of continuous ammoniation production process of 2,4-dinitroaniline

A technology of dinitroaniline and production process, which is applied in the field of continuous ammoniation production process of 2,4-dinitroaniline, can solve the problems of large pollution, high cost, low intermittent production efficiency and the like, and achieves low energy consumption and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

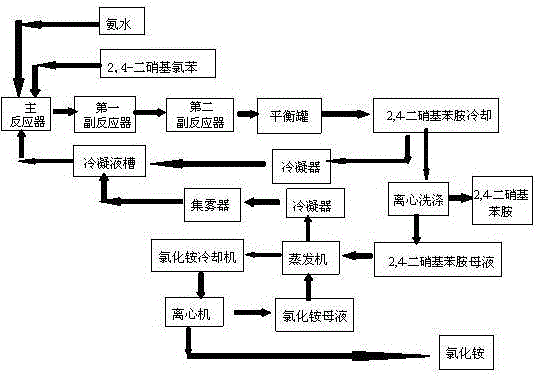

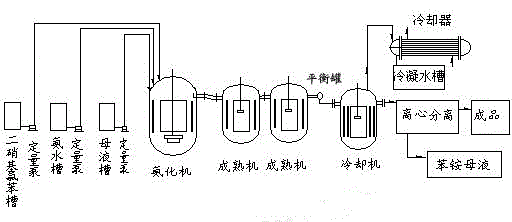

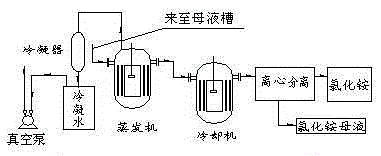

Method used

Image

Examples

Embodiment 1

[0043] The main reactor is stirred by a high-temperature, high-pressure self-priming turbine. The agitator is composed of a hollow shaft and a double-suction closed turbine stirring paddle. The upper and lower openings of the hollow shaft make the gas phase material above the reactor communicate with the stirring opening below. The structure of the double-suction closed turbine agitator is as follows: two ring-shaped cover plates are arranged on the upper and lower ends of the disc turbine agitator which is composed of 8 standard backward curved impellers and complies with HG / T3796.5-2005 , 10-20 round holes leading into the hollow shaft are opened on the shaft sleeve of the agitator, and a steady flow ring is installed at the lower end of the agitator, which is filled with the material first and then continues to produce after heating and increasing the pressure, saving the feeding time. The design of the main reactor is based on the characteristics of gas participating in the...

Embodiment 2

[0045] Use a hot water pump to add water to the coil in the main reactor, thereby cooling the main reactor, so that the temperature of the main reactor is controlled at 160°C to 170°C. The hot water comes out of the main reactor coil and becomes steam, and the steam is collected by the sub-cylinder for the evaporator in the evaporation and concentration section. The condensate after evaporation and condensation is collected and returned to the hot water pump to continue cooling the main reactor for use. The heat of ammoniation reaction of one kilogram of 2,4-dinitrochlorobenzene is 2685.6097KJ / Kg.

[0046] ⑴Required conditions

[0047] ①Reaction temperature 165℃

[0048] ②Pressure 10kg / cm3,

[0049] ⑵ Raw materials brought into heat

[0050] Table 1 Raw materials brought into heat

[0051]

[0052] ⑶ heat of reaction

[0053] Q=1145.75×2685.6097=3077037.31KJ / t

[0054] ⑷The heat taken away by the product

[0055] Table 2 The heat taken away by the product

[0056] ...

Embodiment 3

[0061] Dinitroaniline reacts with ammonia, the yield is 99%, and 1145.75kg of dinitrochlorobenzene is put into it. After the reaction, dinitroaniline is obtained: 105.48kg, and unreacted dinitrochlorobenzene is 5.73kg, which is produced by the reaction of the mature machine. 5.13kg of dinitroaniline, 5.13+1020.36=1025.49kg of dinitroaniline from the mature machine, 1025.48×0.985=1010.11kg of dinitroaniline after washing, 1010.11×0.99=1000.00kg of dinitroaniline after filtration. Put in ammonia water, the ammonia content is 17~18%, calculated according to 18%, the reaction input ammonia is 201.94kg, find the amount of ammonia water, 201.94÷0.18=1121.89kg / t, the specific gravity of ammonia water is 0.935, the volume is 1138.80kg / t, dinitro The ammonia used for aniline is 1145.75÷202.55×17=96.16kg / t, the HCl produced is 1145.75÷202.55×36.5=206.47kg / t, the ammonia reacted by HCl is 206.47÷36.5×17=96.16kg / t, and the remaining ammonia 201.94-96.16-96.16=9.62kg / t, the amount of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com