Low nitrogen oxide heat accumulating type flat burner

A low-NOx, flat-flame burner technology, applied in the direction of indirect carbon dioxide emission reduction, burners, combustion methods, etc., can solve the problems of difficult precise control of combustion-supporting air, affecting combustion efficiency and emission performance, and insufficient mixing. Achieve good energy saving effect, less nitrogen oxide emissions, and reduce flame combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

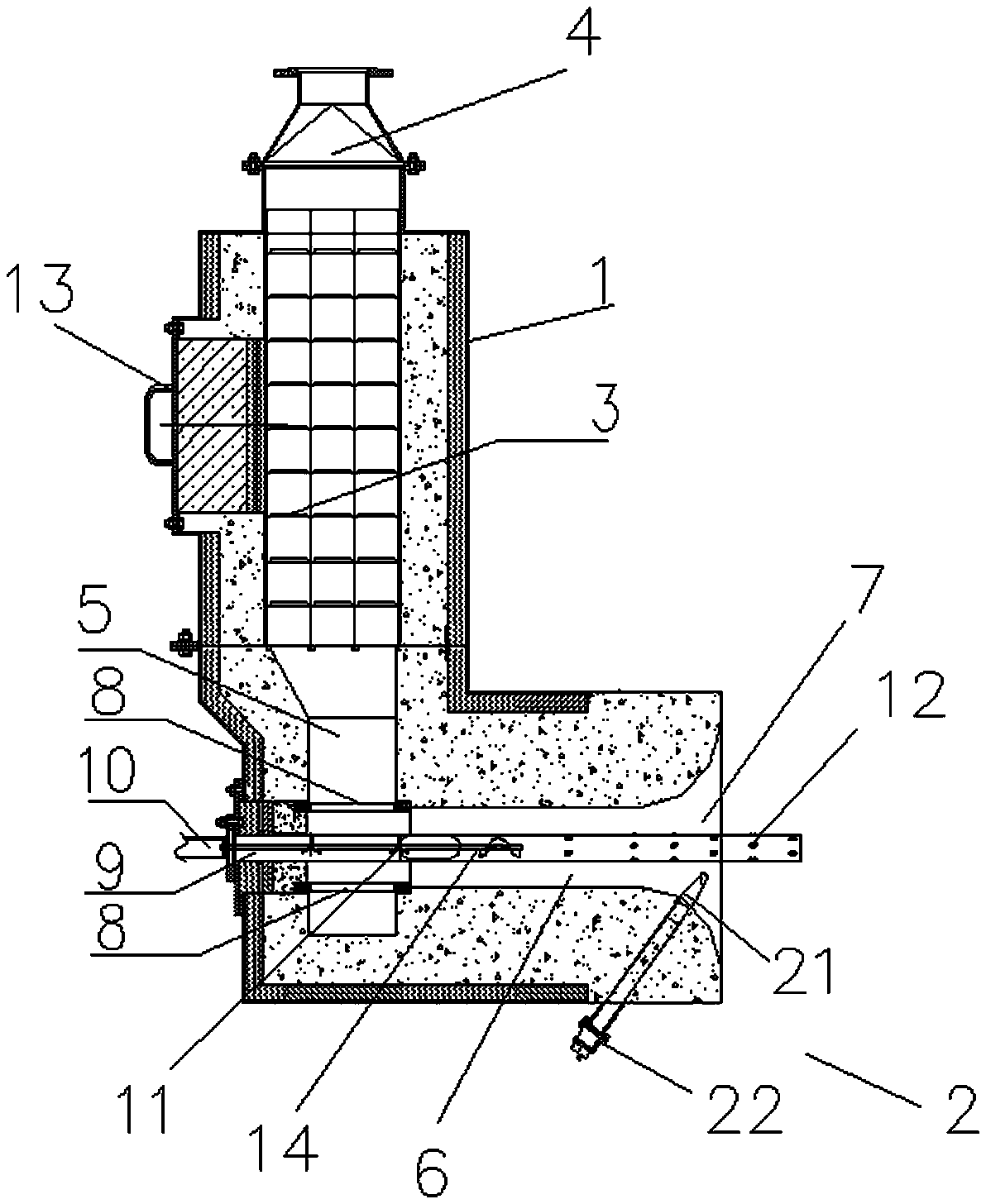

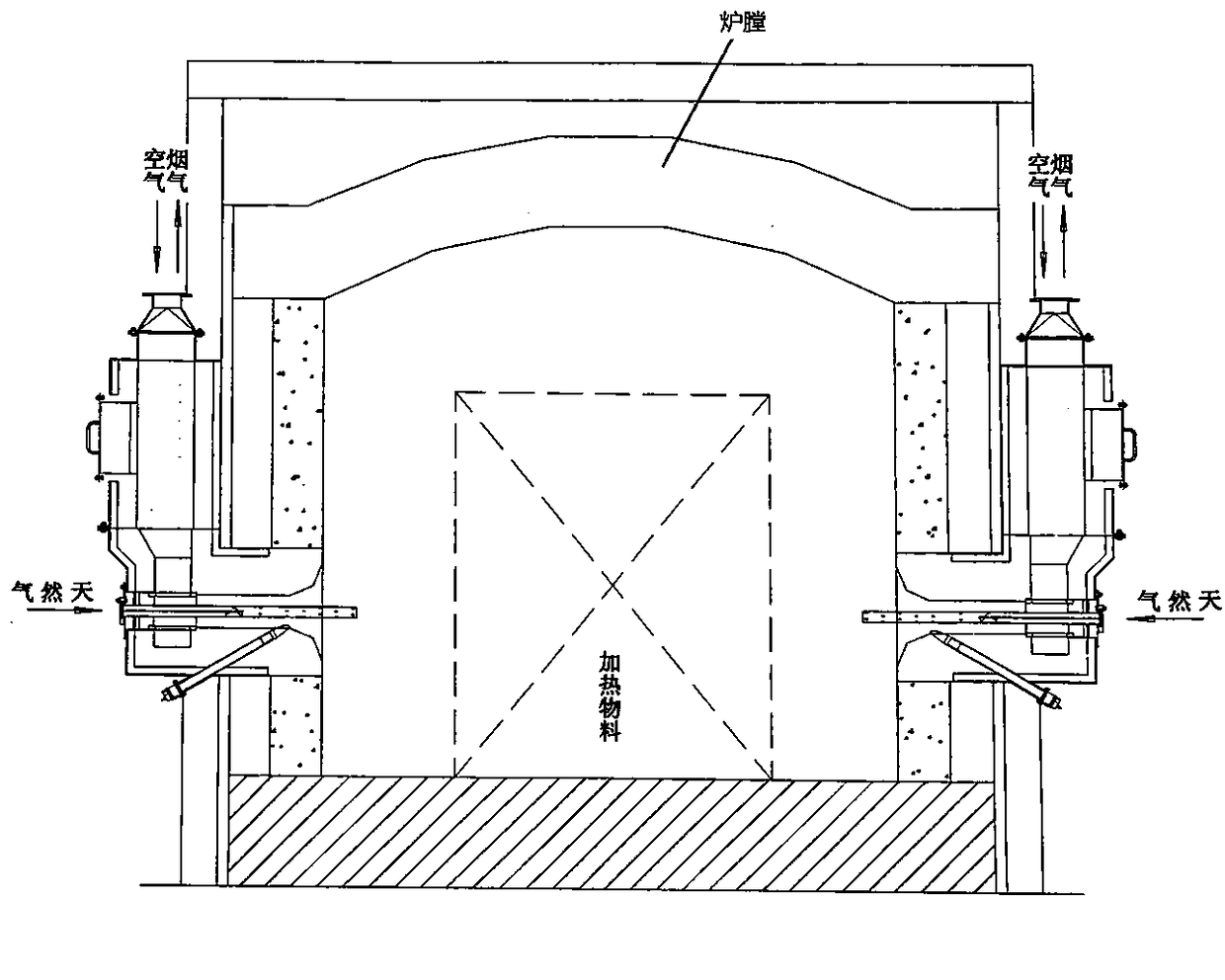

[0015] Such as figure 1 As shown, a low nitrogen oxide regenerative flat flame burner includes a hollow L-shaped shell 1, a combustion safety control assembly 2, a heat storage body 3 installed in a vertical shell, and the adjacent side of the heat storage body 3 There is an installation port 13 on the shell, the internal hole of the heat storage body 3 is honeycomb type, the air inlet 4 is placed on the top of the heat storage body, the vertical ventilation hole 5 below the heat storage body is connected to the horizontal ventilation hole 6, and the end of the vertical ventilation hole 5 passes through Through the horizontal ventilation hole 6, the other end of the horizontal ventilation hole 6 is a nozzle 7 with a trumpet-shaped gradually widening structure, and an air cyclone 8 is installed at the junction of the vertical ventilation hole 5 and the horizontal ventilation hole 6, and the cyclone of the air cyclone 8 The orifices are distributed in a circular shape. The natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com