Novel semi-dry flue gas desulphurization technology

A desulfurization process, semi-dry technology, applied in the field of flue gas desulfurization, can solve the problem of high sodium-alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The coal-fired flue gas enters the chimney through the bypass baffle door after electrostatic precipitator and is discharged. When desulfurization, open the inlet and outlet baffle door of the absorption tower. The flue gas is discharged into the chimney through the outlet damper door.

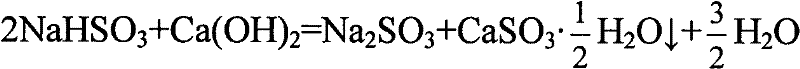

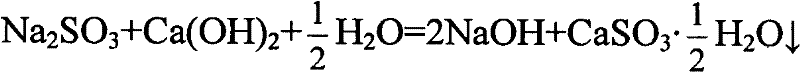

[0040] The desulfurized absorption liquid is sent to the neutralization regeneration tank by the discharge pump, mixed with the lime milk slurry pumped by the lime milk slurry pump, and regenerated by reaction. After regeneration, the regeneration solution is pumped into the inclined plate settler by the mixed liquid pump for clarification After separation, the supernatant overflows into the regenerated liquid tank, and the lye pumps into the added sodium lye to adjust the pH value of the absorbent liquid, and then is pumped into the bottom of the absorption tower by the regenerated liquid for cyclic absorption.

[0041] The underflow liquid of the inclined plate settler flows into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com