Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151 results about "Designed equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for treatment by ionizing radiation

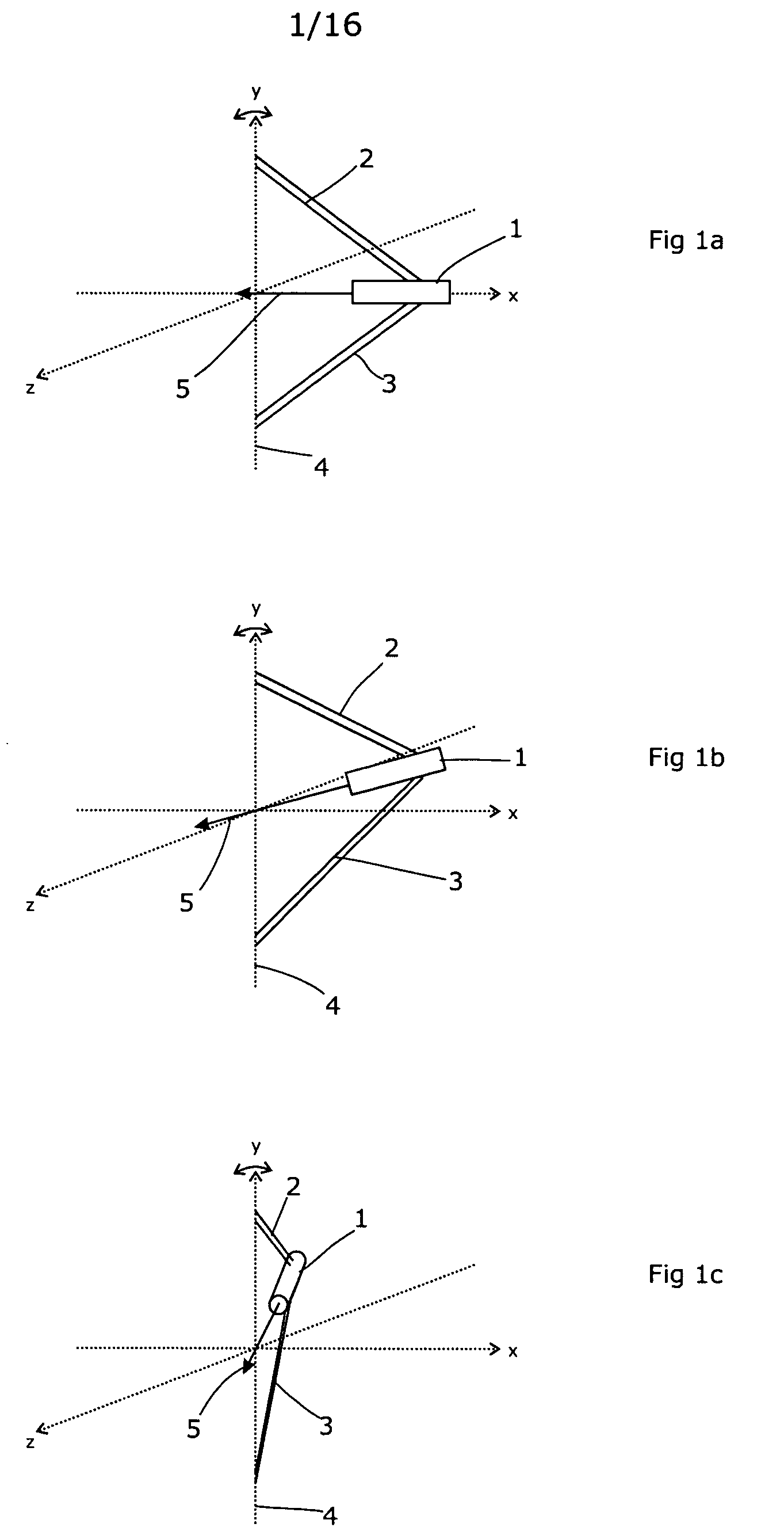

ActiveUS20050089141A1Improve accuracyEasy to operateMaterial analysis using wave/particle radiationRadiation/particle handlingBeam directionLight beam

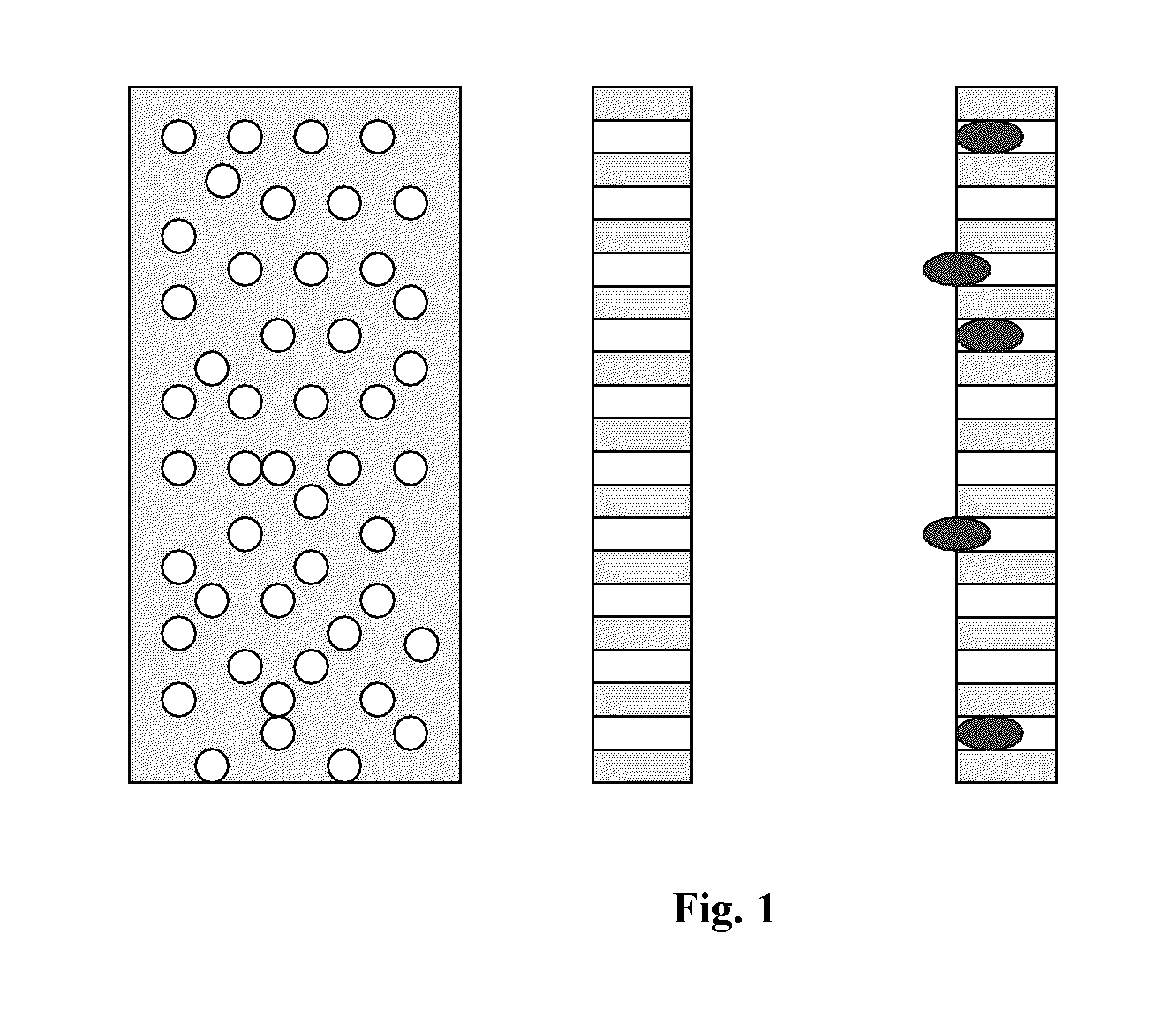

A radiation therapy / surgery device optimised to meet the needs of the Neurosurgeon is provided, i.e. one for the treatment of tumours in the brain. It combines the qualities of a good penumbra and accuracy, simple prescription and operation, together with high reliability and minimal technical support. The device comprises a rotateable support, on which is provided a mount extending from the support out of the plane of the circle, and a radiation source attached to the mount via a pivot, the pivot having an axis which passes through the axis of rotation of the support, the radiation source being aligned so as to produce a beam which passes through the co-incidence of the rotation axis and the pivot. It will generally be easier to engineer the apparatus if the rotateable support is planar, and more convenient if the rotateable support is disposed in an upright position. The rotation of the rotateable support will be eased if this part of the apparatus is circular. A particularly preferred orientation is one in which the radiation source is spaced from the rotateable support, to allow it to pivot without fouling the latter. It is thus preferred that the mount extends transverse to the support. In this way, the pivot axis is spaced from the rotateable support providing free space in which the radiation source can pivot. Another way of expressing this preference is to state that the pivot axis is located out of the plane of the rotateable support. To simplify the geometry of the device and the associated arithmetic, it is preferred both that the pivot axis is substantially perpendicular to the rotation axis, and that the beam direction is perpendicular to the pivot axis. It is preferred that the radiation source is a linear accelerator. The output of the radiation source is preferably collimated to conform to the shape of the area to be treated.

Owner:ELEKTA AB

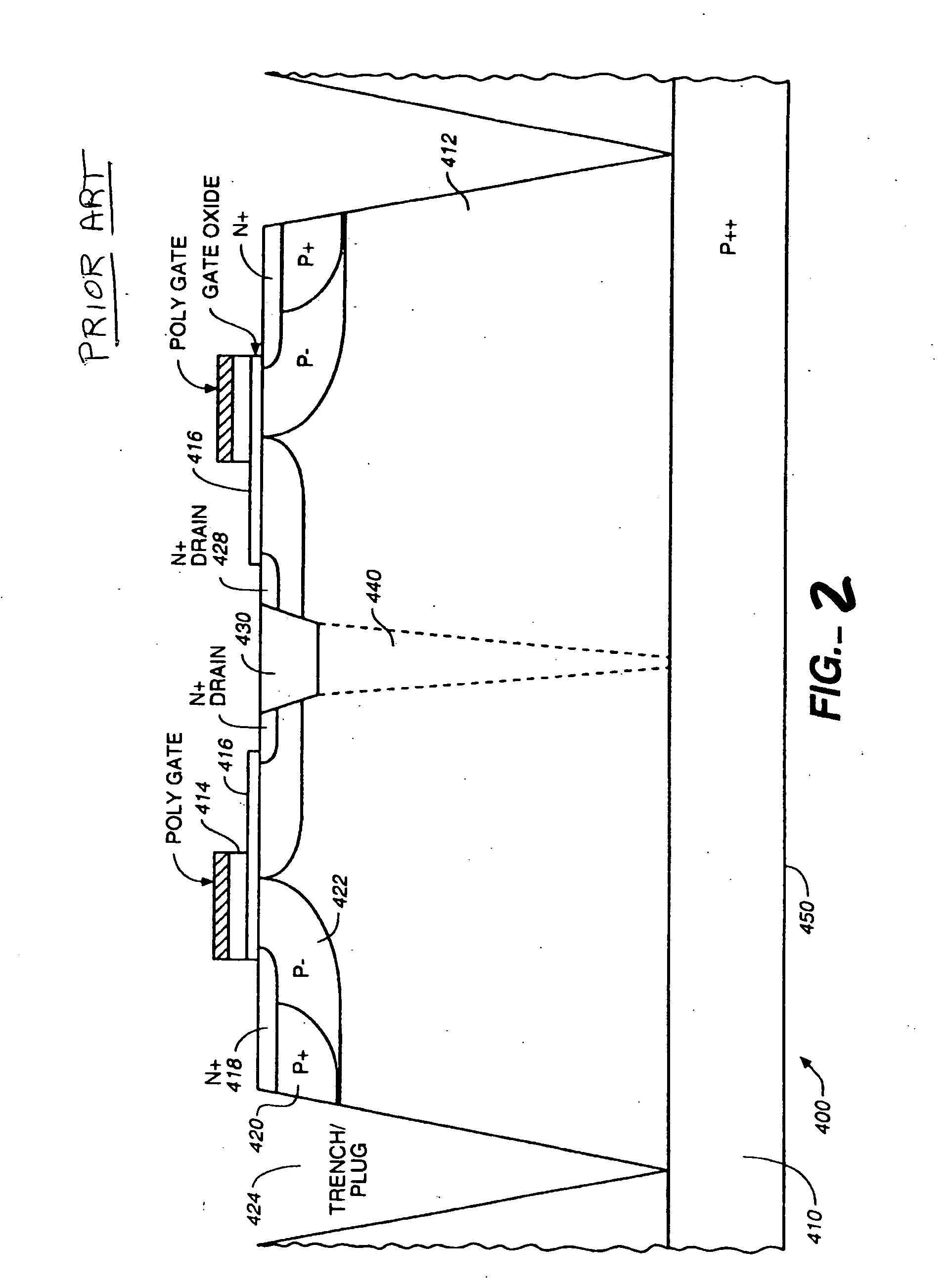

Lateral double-diffused metal oxide semiconductor (LDMOS) device with an enhanced drift region that has an improved Ron area product

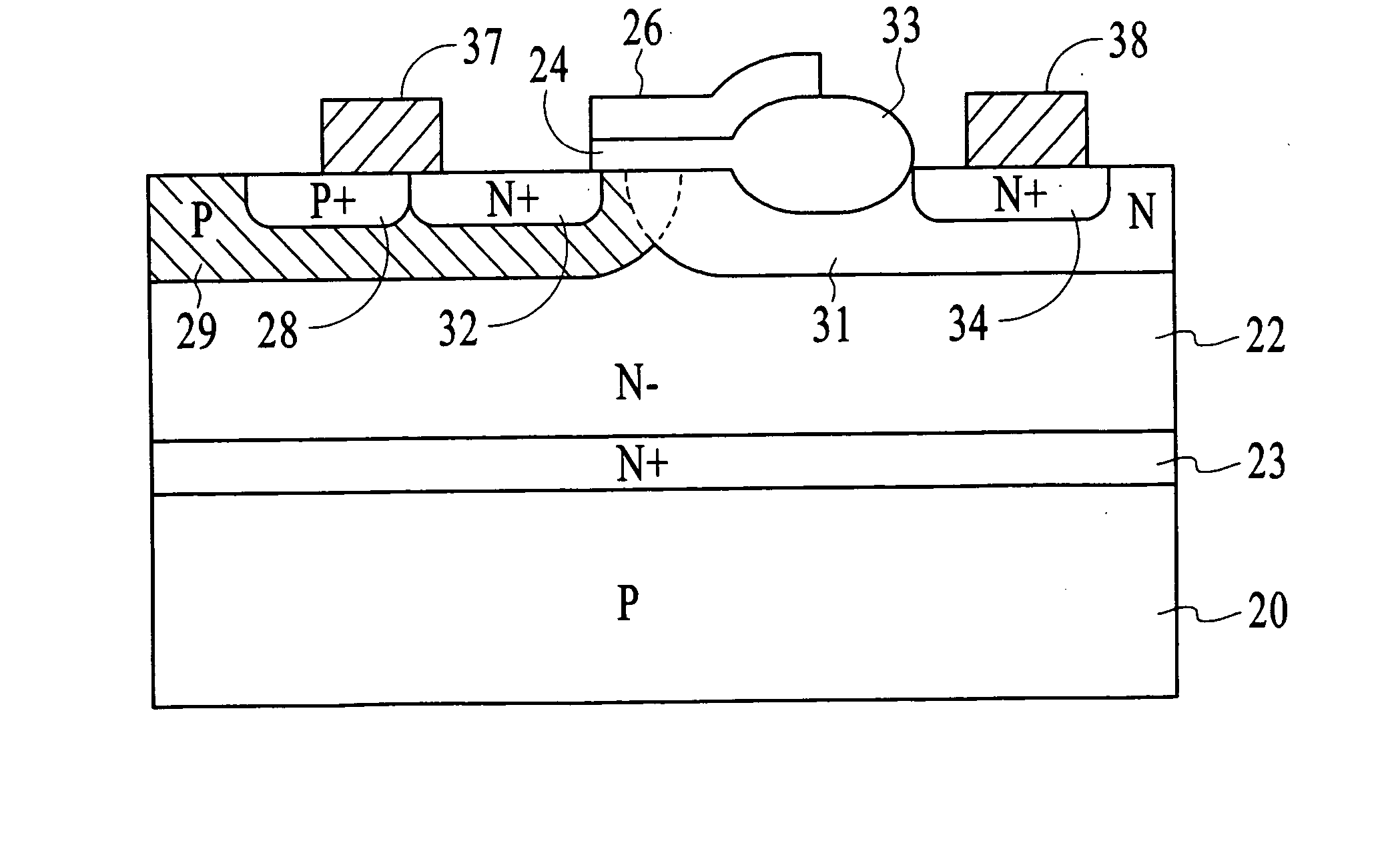

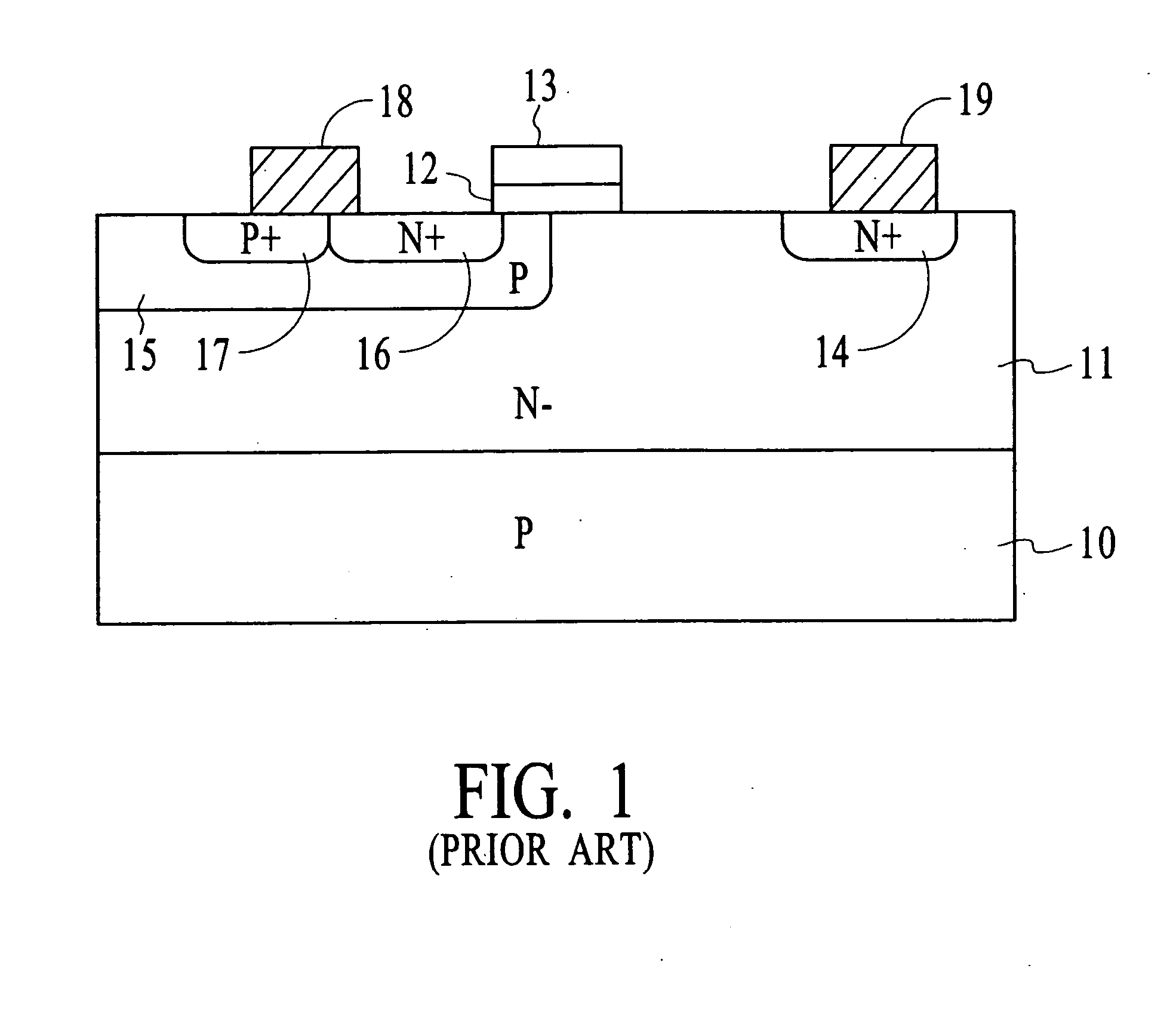

ActiveUS20070246771A1Reduce areaOn-resistance is significantly reducedSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSBody region

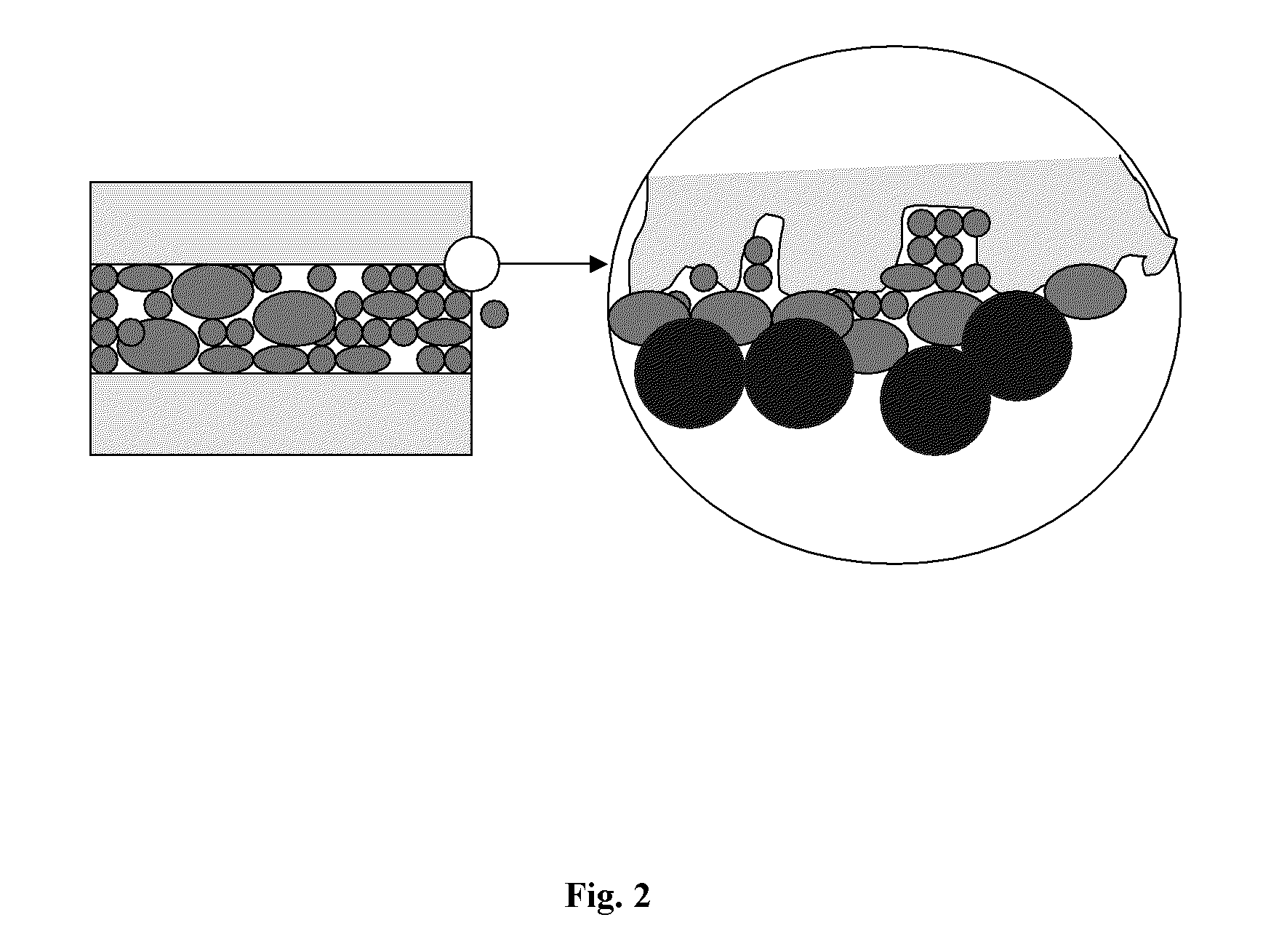

A lateral double-diffused metal oxide semiconductor (LDMOS) device is disclosed. The LDMOS device comprises a gate region and a body region under the gate region. The LDMOS device includes an enhanced drift region under the gate region. The enhanced drift region touches the body region. By designing the device such that the enhanced drift region overlaps and compensates the lateral tail of the body region of the LDMOS transistor, the Ron*area product is reduced. Accordingly, the on-resistance is significantly reduced while minimally affecting the breakdown voltage of the device.

Owner:MICREL

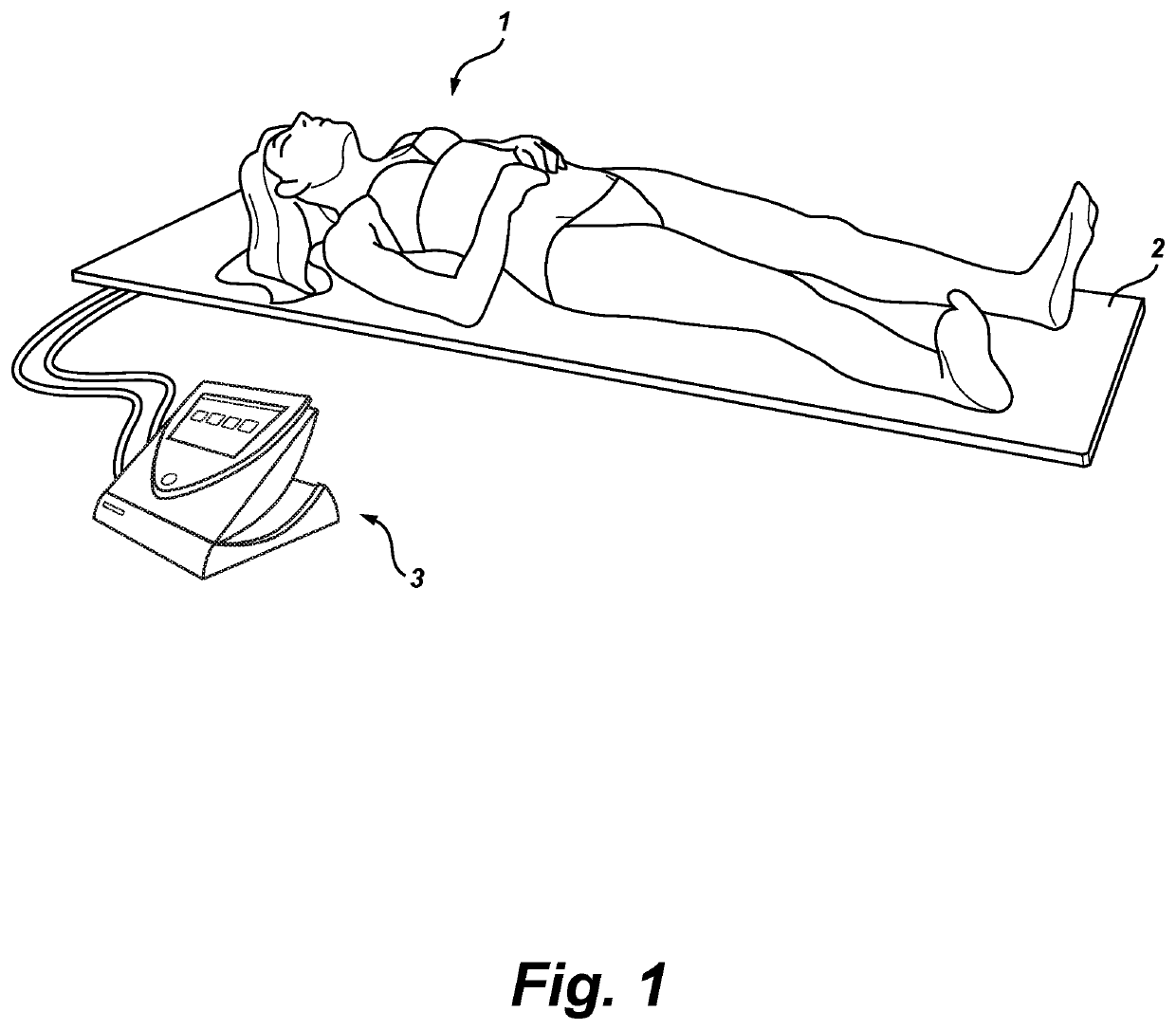

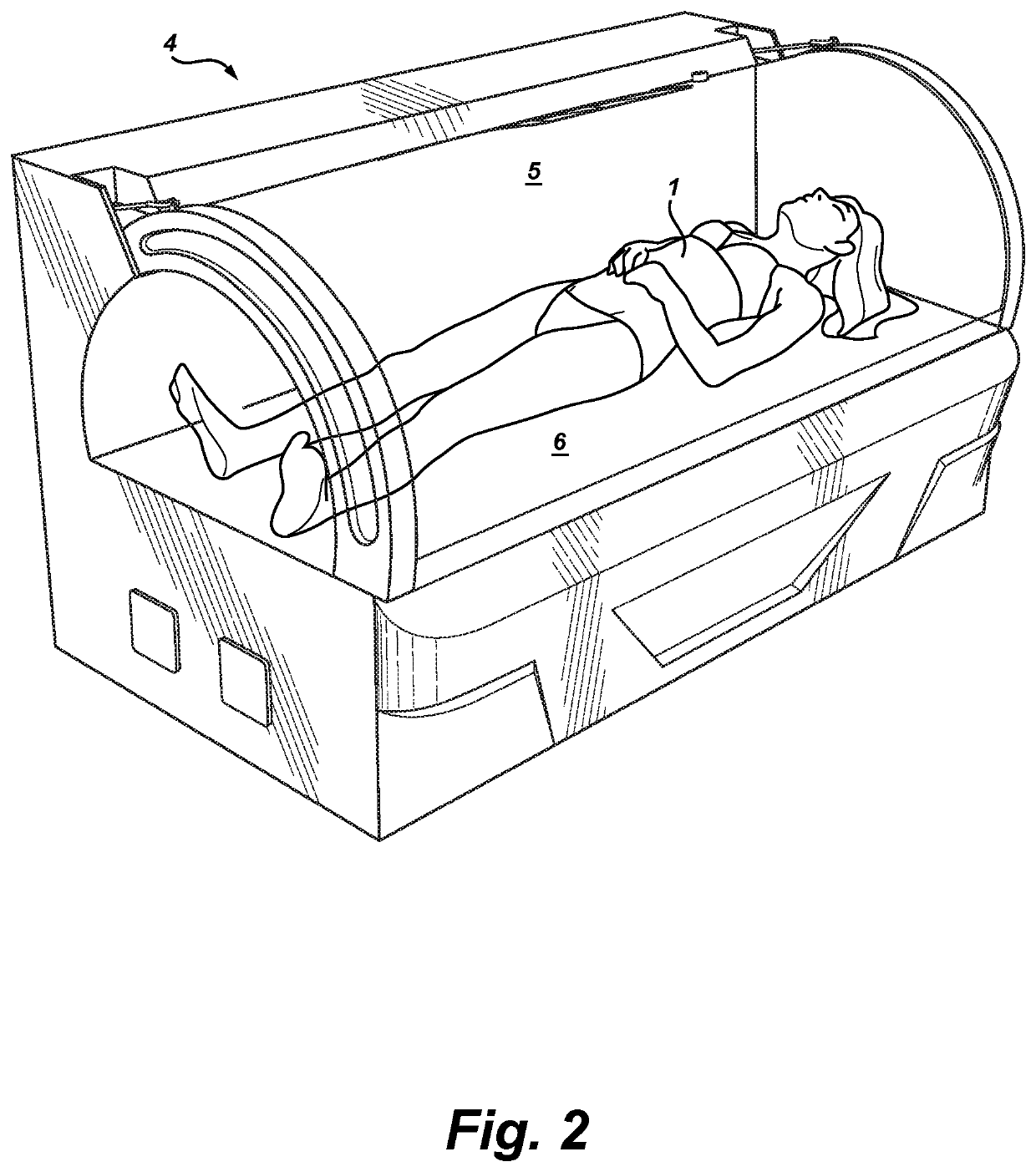

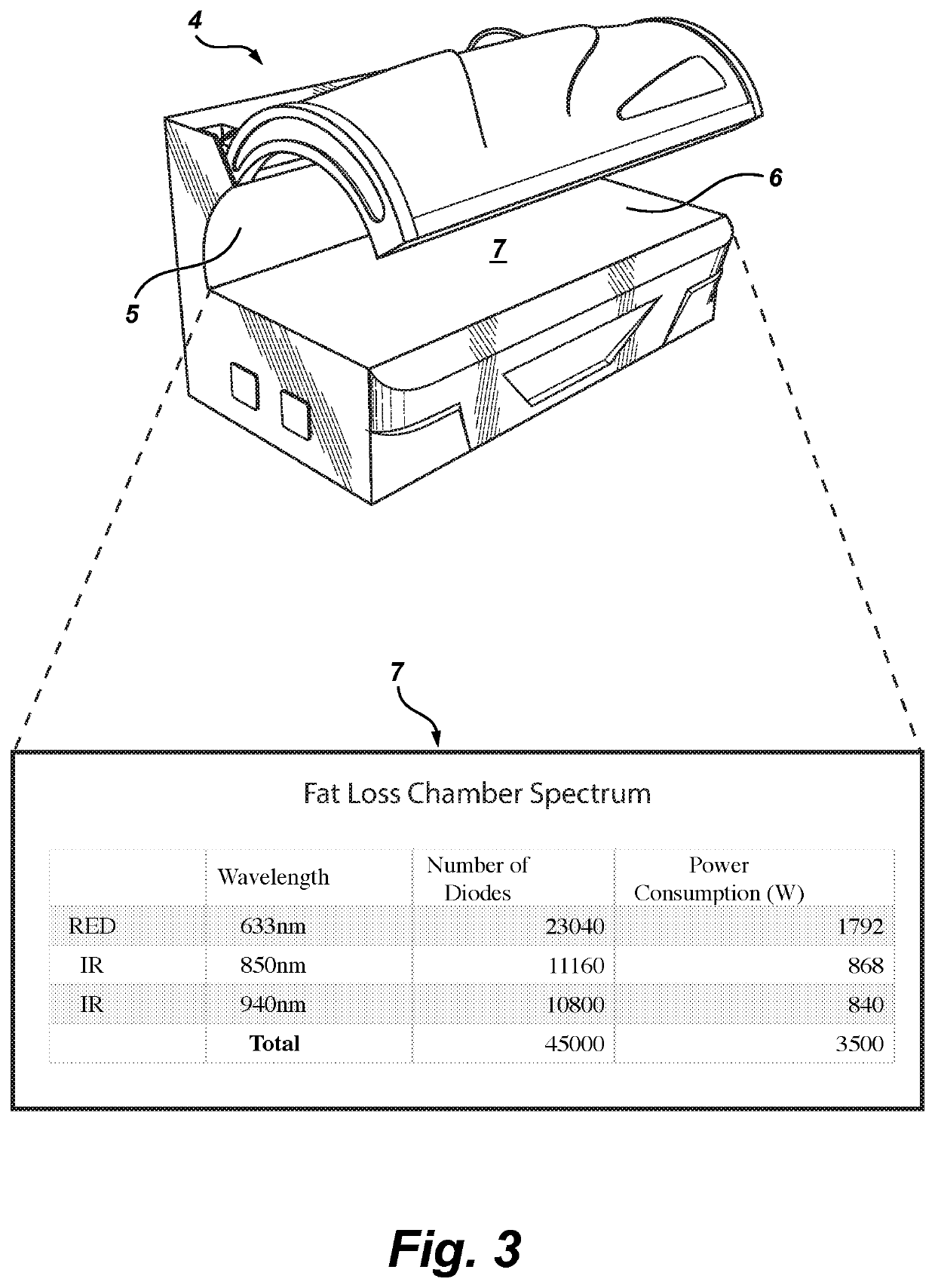

Method For Reducing Visceral Body Fat In Humans

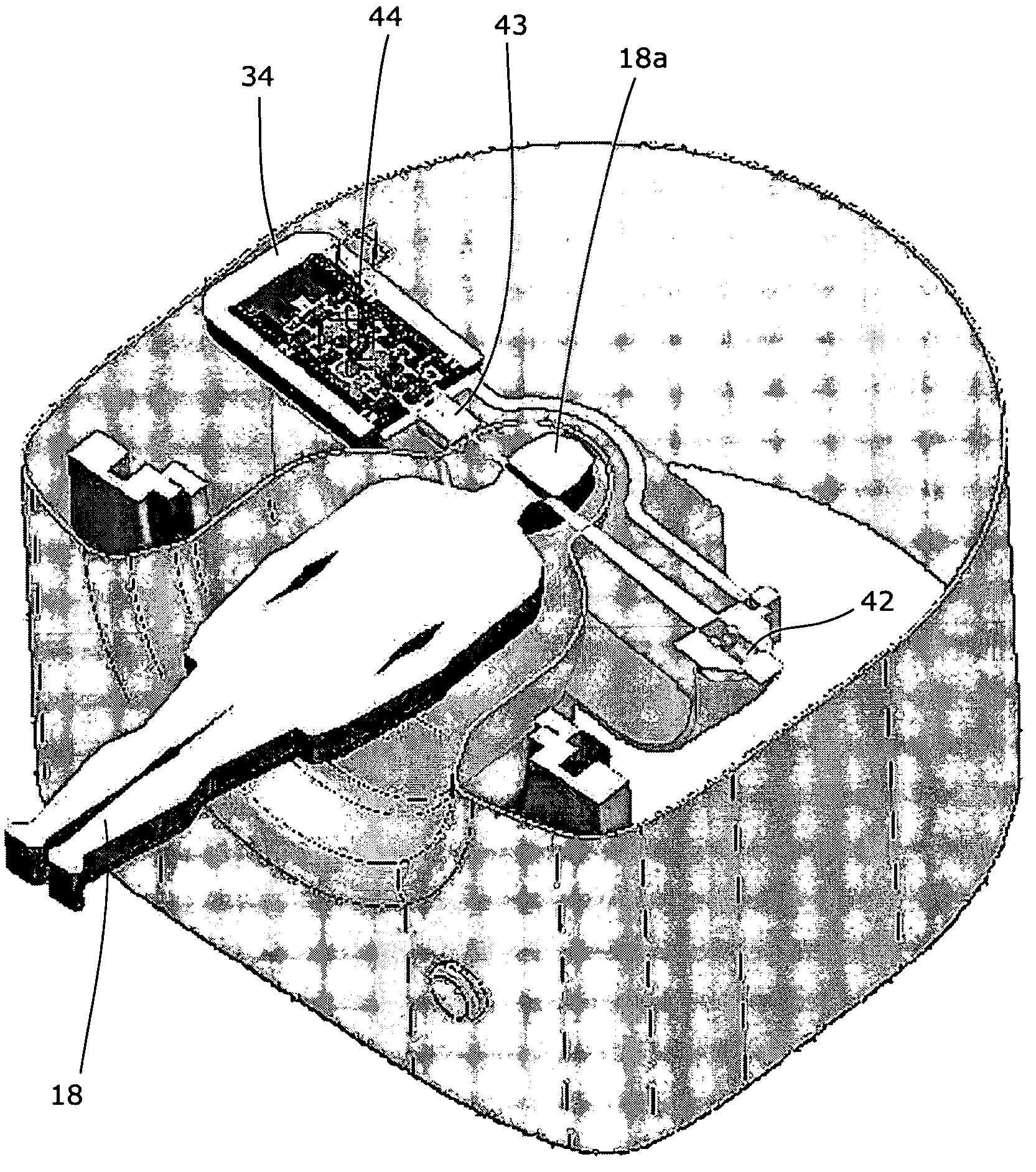

PendingUS20200353273A1Increase blood flowReduce decreaseElectrotherapyAnti-cellulite devicesHuman bodyLed array

A method for reducing visceral body fat in humans involving the steps of a user utilizing a pulsed electromagnetic field generating device for a recommended period of time; the user then laying in an LED therapy bed with a light chamber having an LED array configured to emit multiple wavelengths of light at differing output percentages, the LED array of the LED therapy bed producing a chamber spectrum combination of at least three different light wavelengths for a preferred length of time; and the user then utilizing a vibration platform for a preferred length of time. The method may be achieved through the use of custom designed equipment and methods.

Owner:ZUCCO DOUG

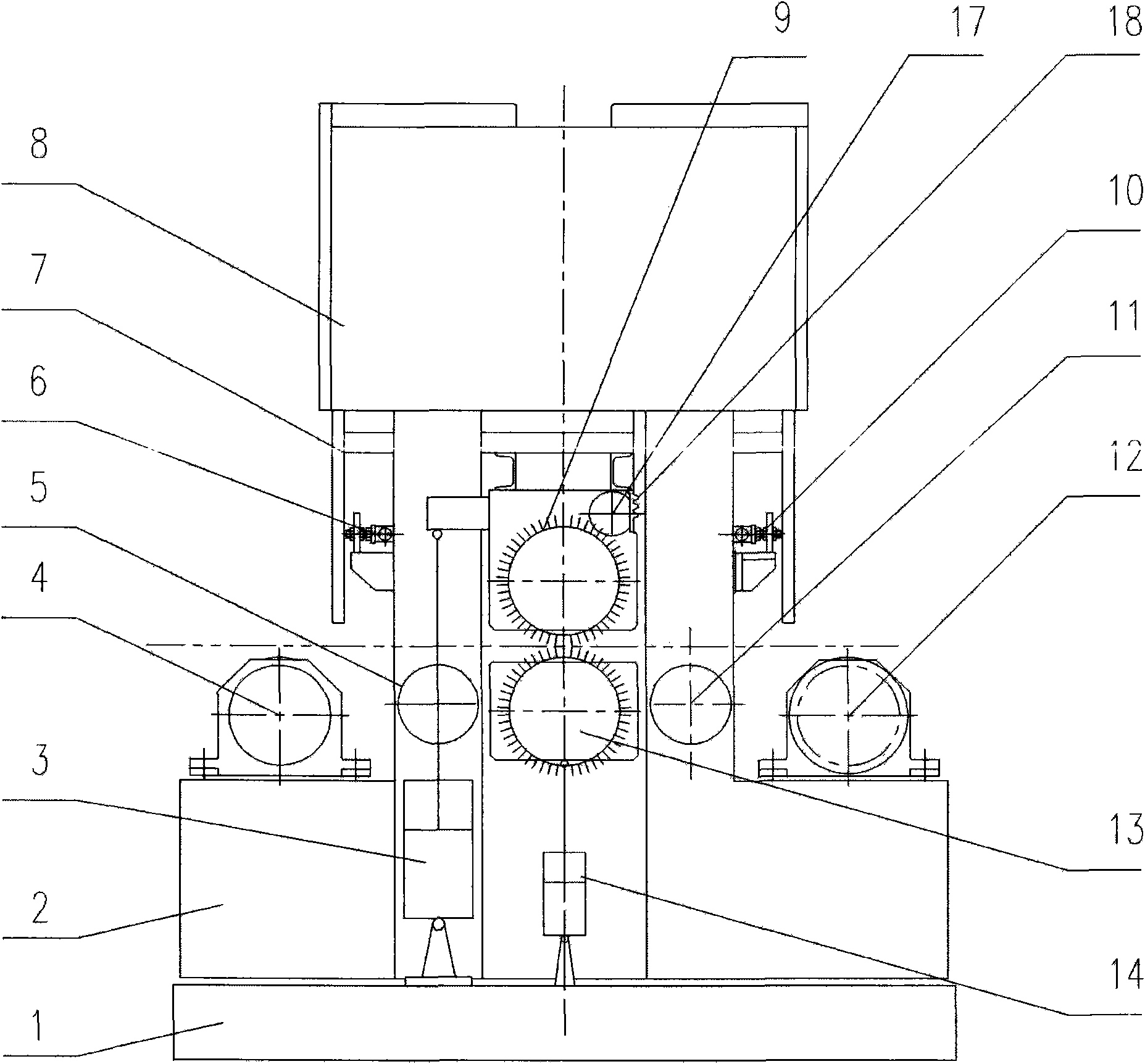

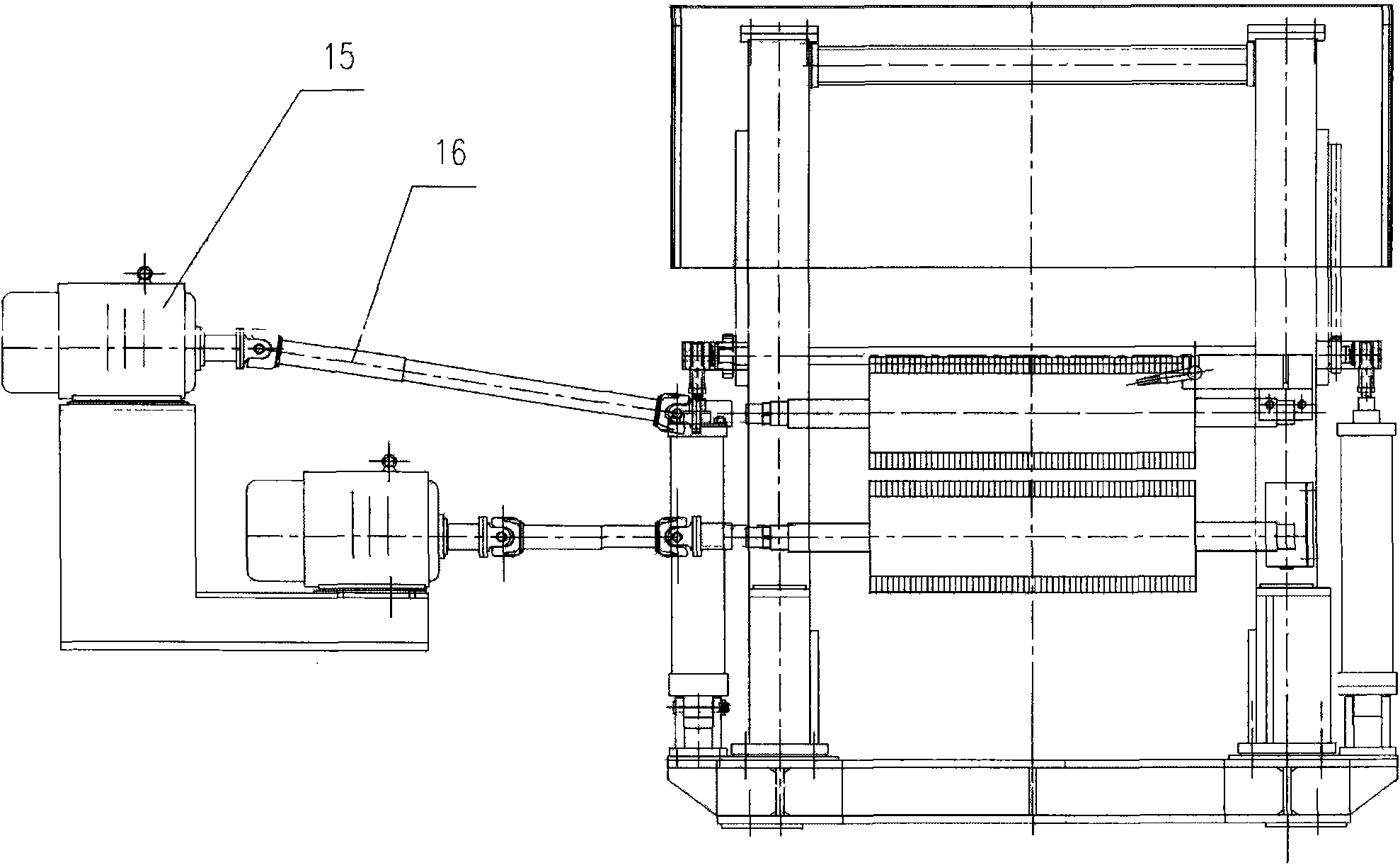

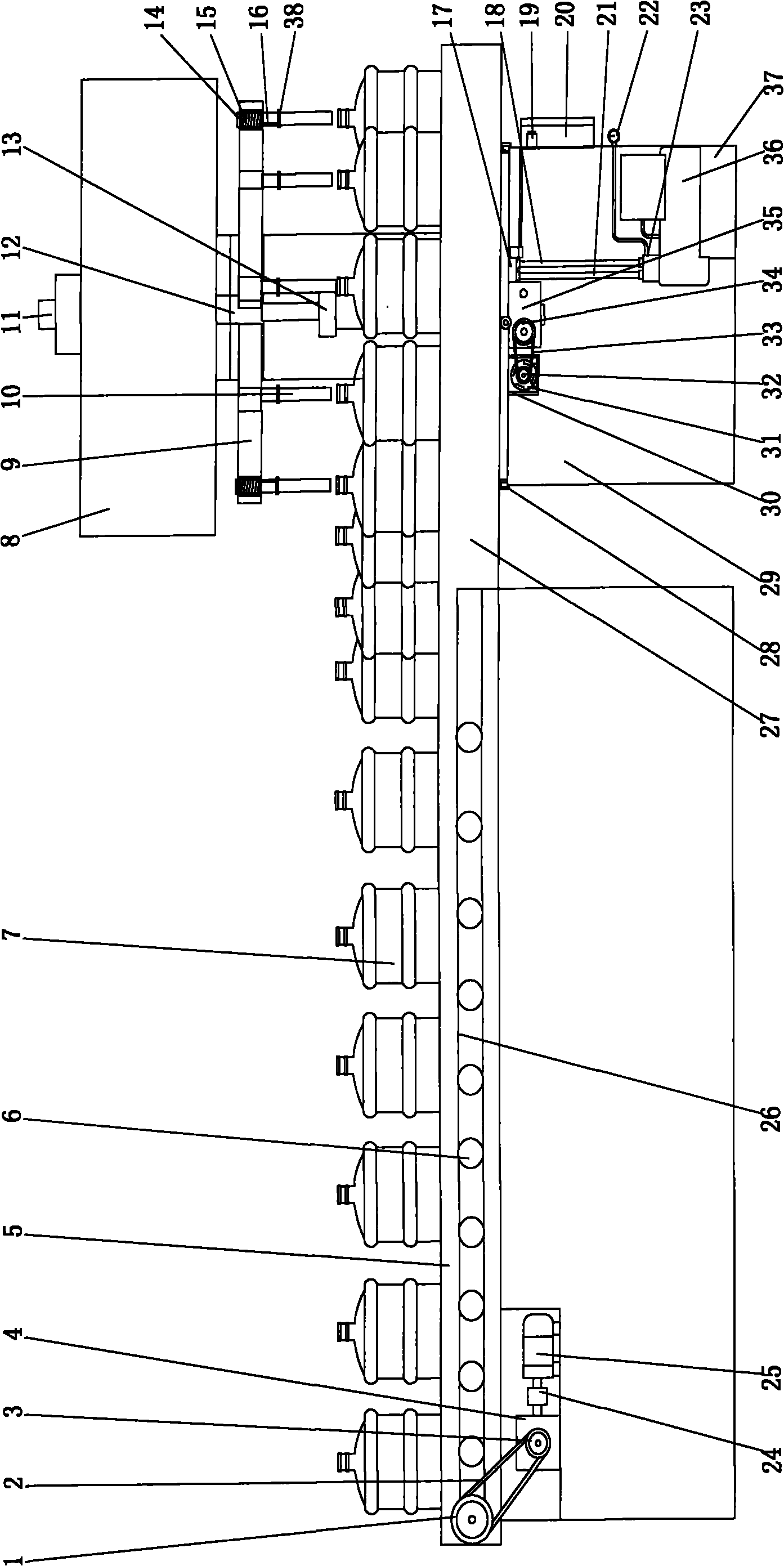

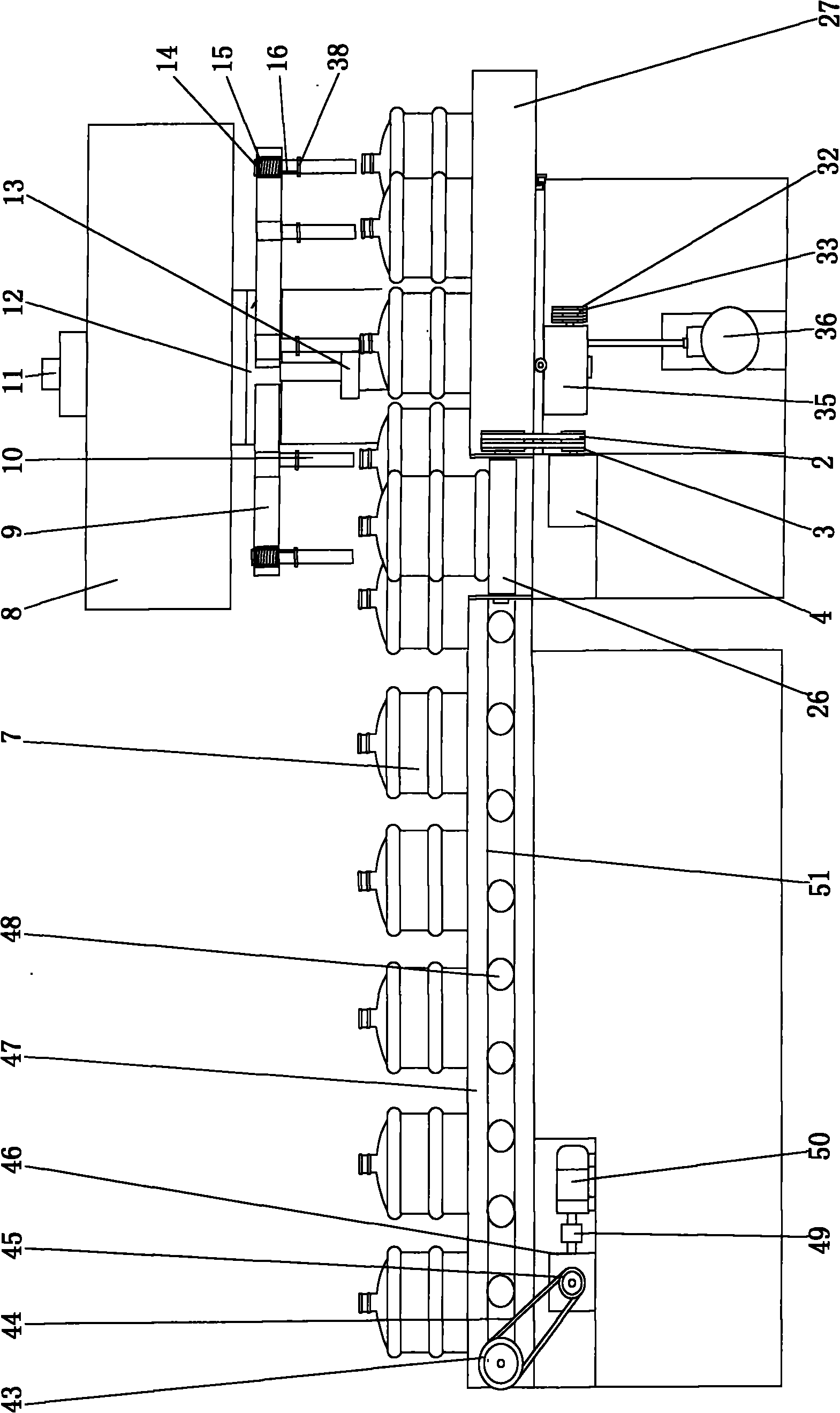

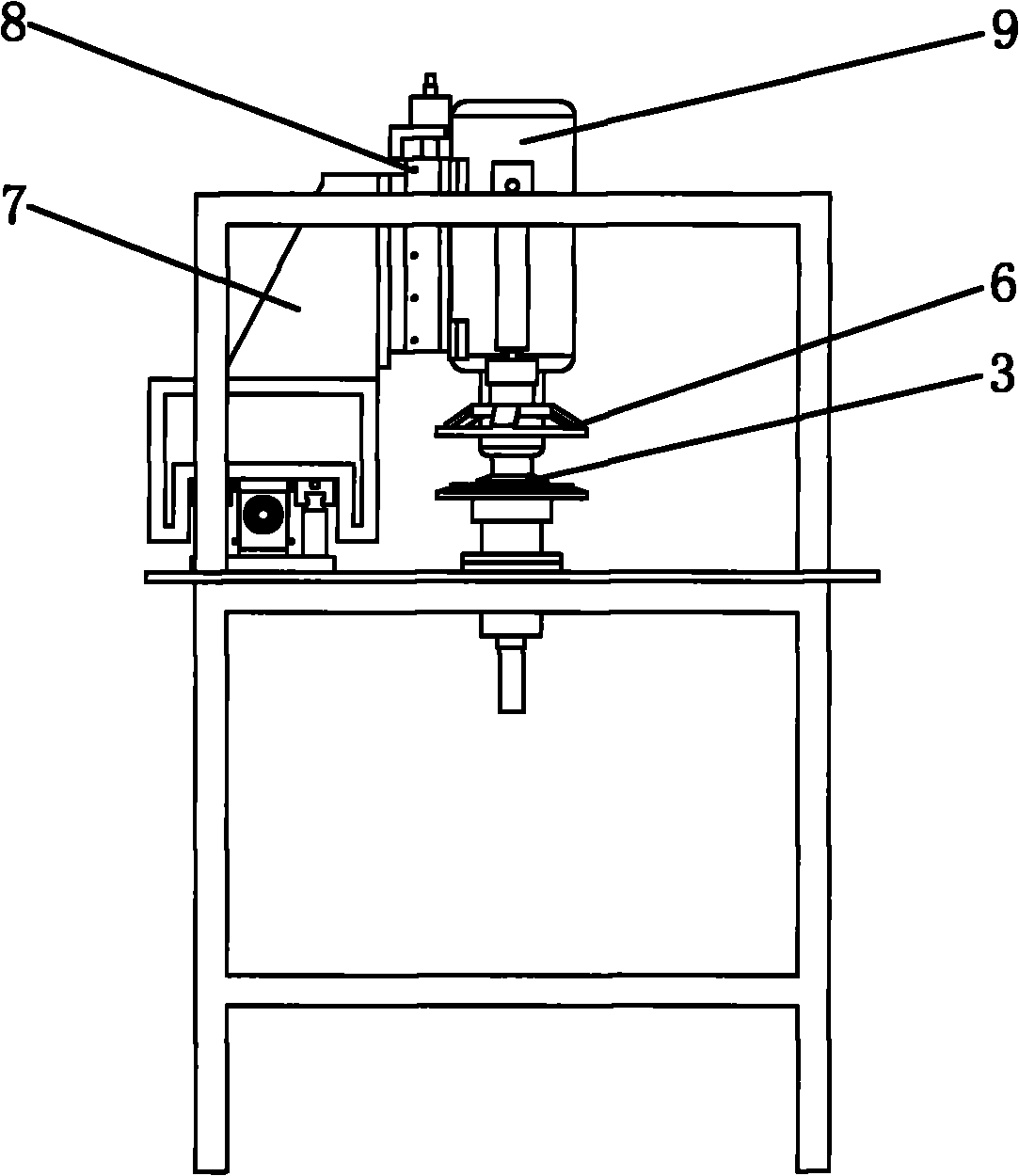

Method for designing equipment removing oxide skin on surface of slab band

InactiveCN101569896AImprove surface qualityHigh descaling efficiencyWork treatment devicesCleaning using toolsSurface oxidationDesigned equipment

The invention provides a method for designing equipment removing oxide skin on a surface of a slab band. The method comprises design of a brush roll transmission device, design of an upper brush roll synchronous device, design of an auxiliary transportation device, design of an oxide skin sweeping device, design of a dust collecting device and design of a matched frame, wherein the design of the brush roll transmission device is used for removing the oxide skin on two surfaces of the slab band; the design of the upper brush roll synchronous device is used for leading the axial lead of the upper brush roll not to incline when the upper brush roll is adjusted and displaced; the design of the auxiliary transportation device is used for transportation of the slab band in and out the brush roll; the design of the oxide skin sweeping device is used for sweeping the oxide skin on the surface of the slab band; the design of the dust collecting device is used for collecting oxide skin dust which is brushed by the brush roll or raised by sweeping; and the design of the matched frame is used for installing and fixing the device design. The method can effectively remove the oxide skin attached on the surface of the slab band under high temperature state and sweep the oxide skin cleanly, and also has the function of dust collection.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

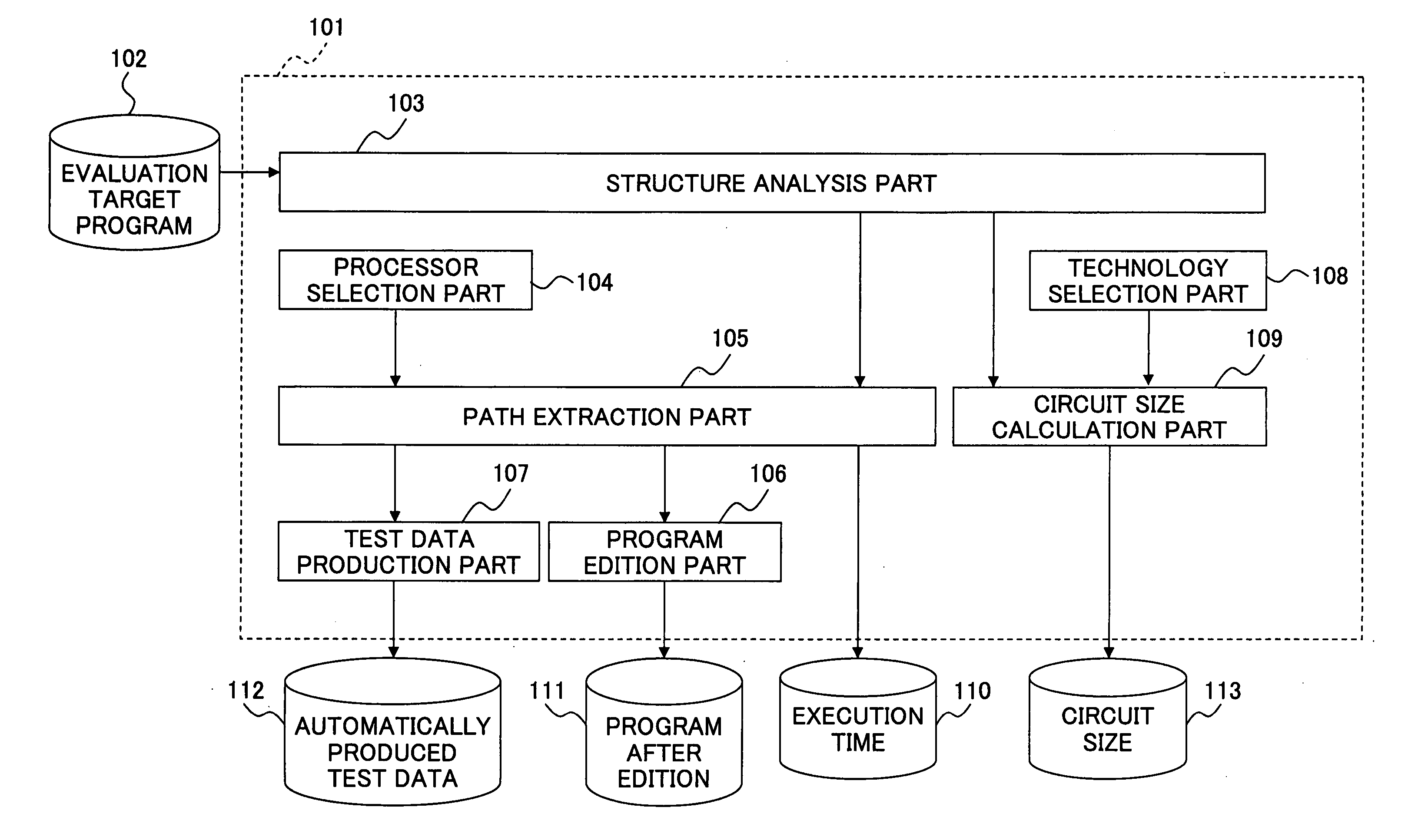

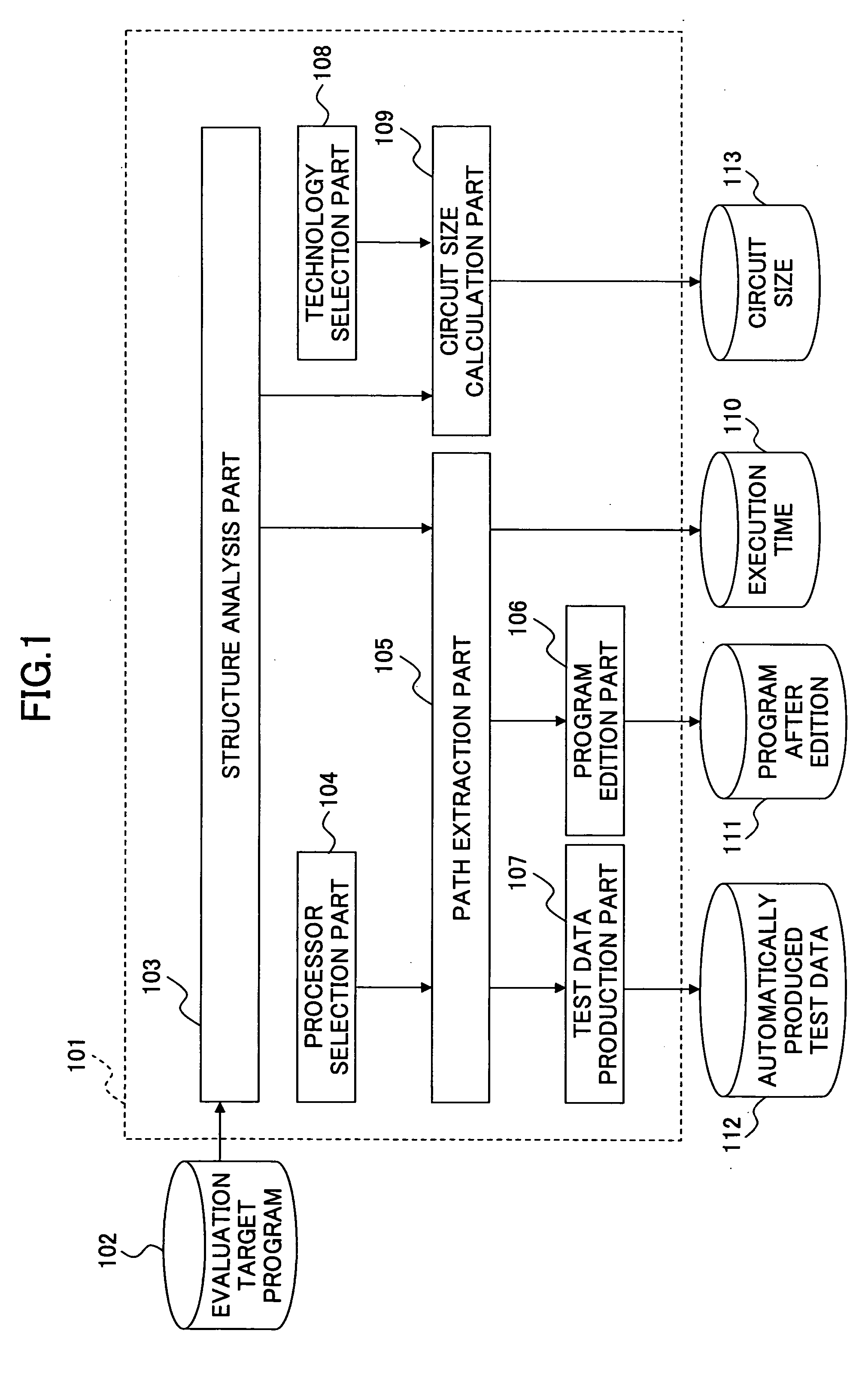

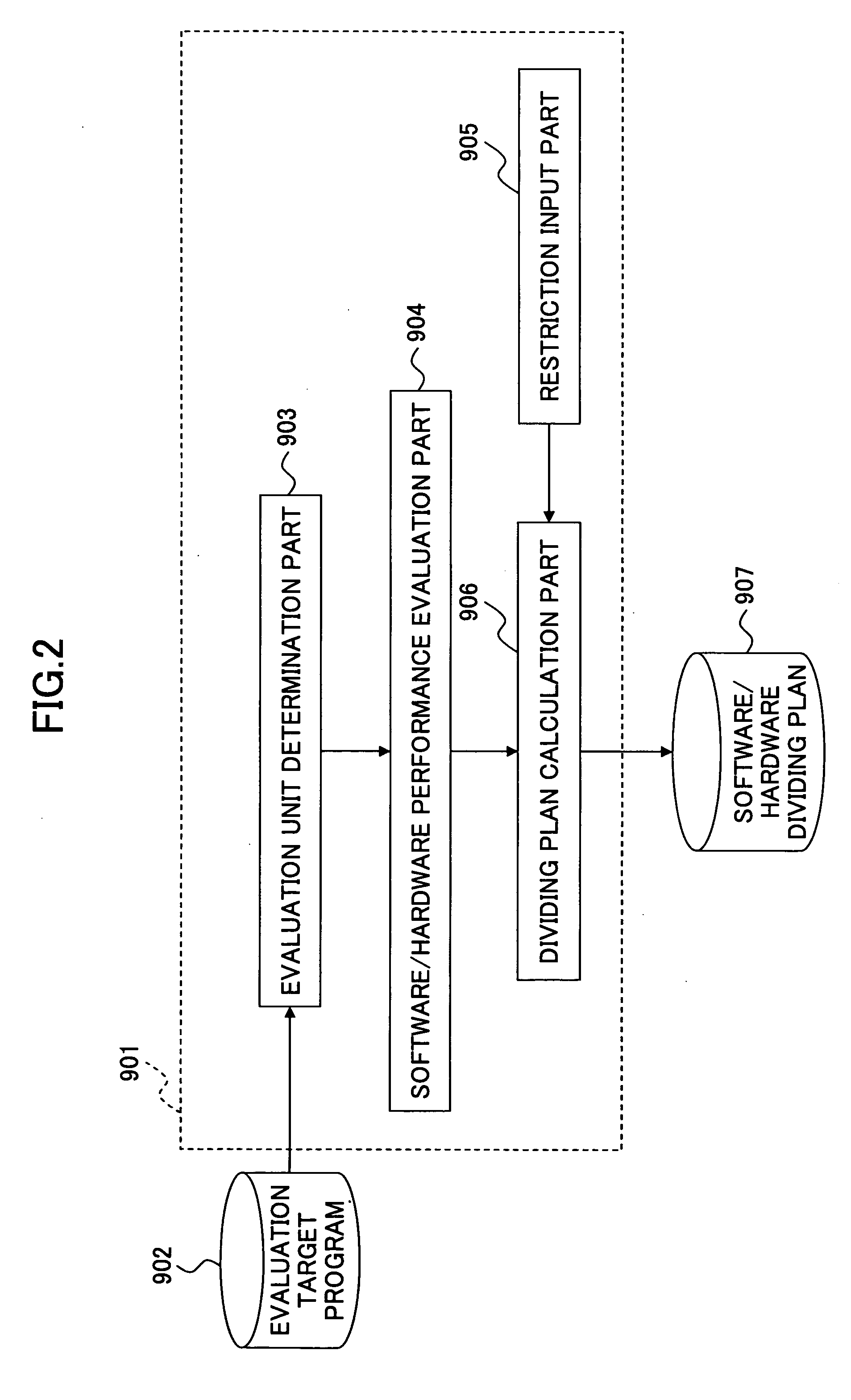

Data processing device designing method, data processing device designing apparatus, program and computer readable information recording medium

InactiveUS20050187750A1Easy to calculateMaximum required execution timeHardware monitoringCAD circuit designParallel computingDesign methods

A method includes steps of calculating, for each predetermined operation included in a program, an execution time required when the operation is executed by a predetermined processor, or calculating, for each predetermined operation included in the program, a circuit size required when the operation is realized in a form of hardware according to a predetermined technology; and calculating, for the entirety of the predetermined program or operations corresponding to a part the entirety of the predetermined program, a total execution time required when the entirety of the predetermined program is executed by the predetermined processor, as a result of applying in sequence the required execution time, or calculating, for the entirety of the predetermined program or operations corresponding to a part the entirety of the predetermined program, a total circuit size required when the entirety of the predetermined program or programs corresponding to a part of the entirety of the predetermined program, as a result of applying in sequence the required circuit size.

Owner:FUJITSU LTD

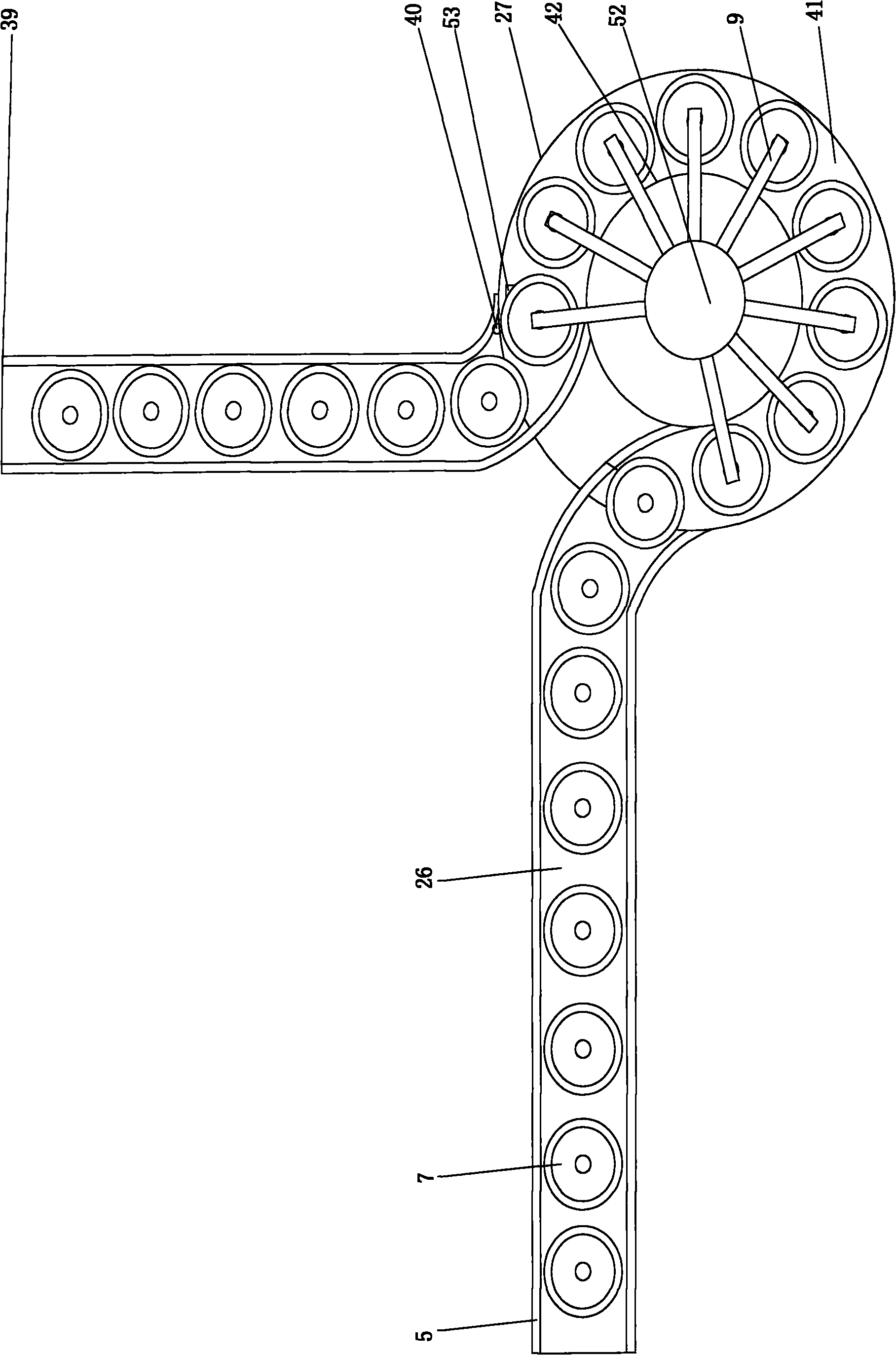

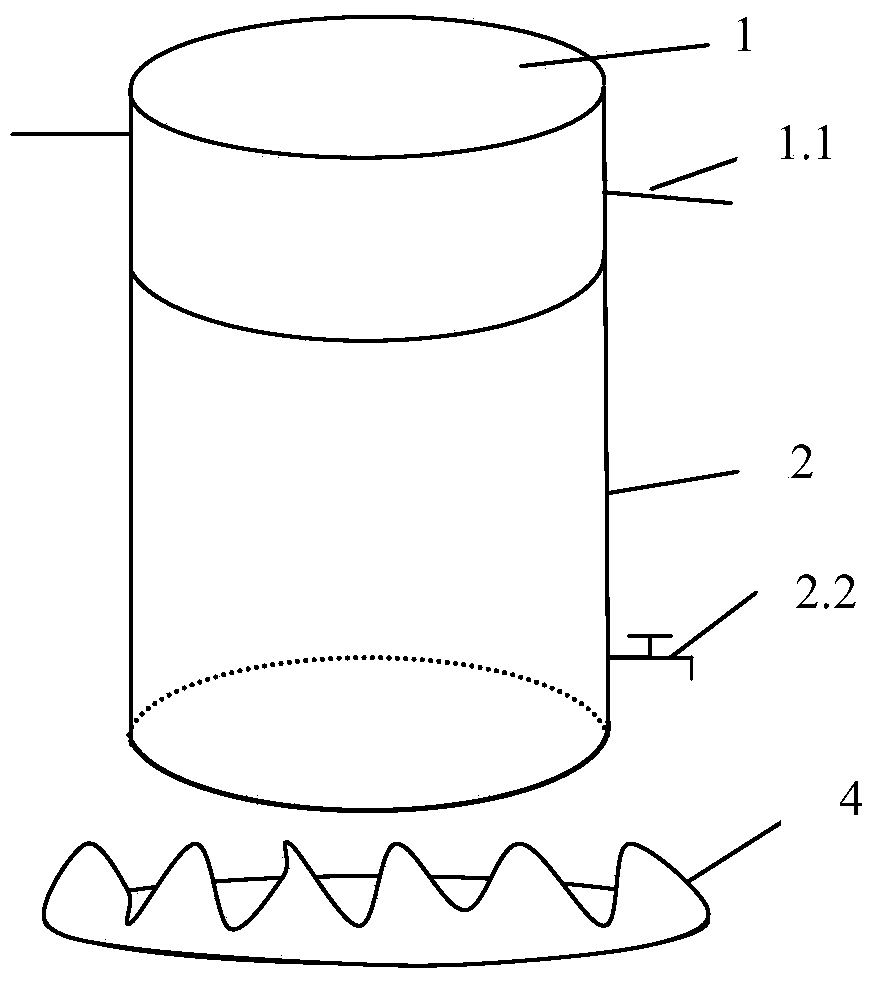

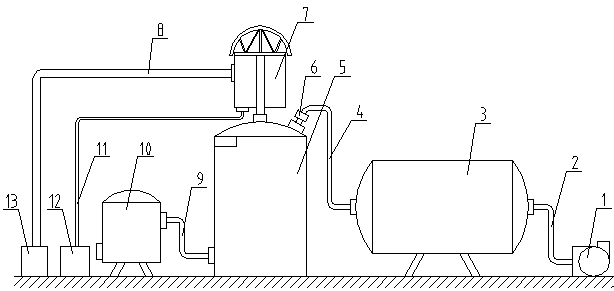

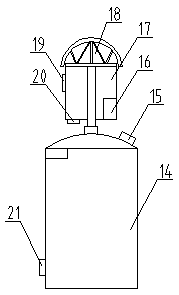

Pure water filling equipment

InactiveCN102060256ASolve the problem of fillingLabor savingBarrels/casks fillingMaterial resourcesAssembly line

The invention relates to pure water filling equipment and designs equipment for filling water in pure water buckets through full-automatic assembly line operation, in particular pure water filling equipment and aiming at solving the problems that in the prior art, pure water filling equipment used by a certain pure water plants at home have low filling speed by singly filling the buckets one by one and are tightly connected with bucket cleaning equipment and sealing equipment so that the complete set of equipment can not run if one link fails, and other pure water plants ask workers to hold a water injection pipe with hands to fill the buckets one by one so that the speed is low and manpower and material resources are wasted. For solving the problems in the prior art, the invention adopts the technical scheme that the pure water filling equipment comprises a rotary table, a bucket loading and conveying belt, a water tank, a water injection rod, a water injection pipe, an air cylinder, an air compressor, and the like. The equipment is favorable for not only saving labor, but also realizing the filling of 9 buckets once through the full-automatic assembly line operation and finishing the filling within 8s so as to achieve the purposes of high speed, time saving and labor saving.

Owner:宋树建

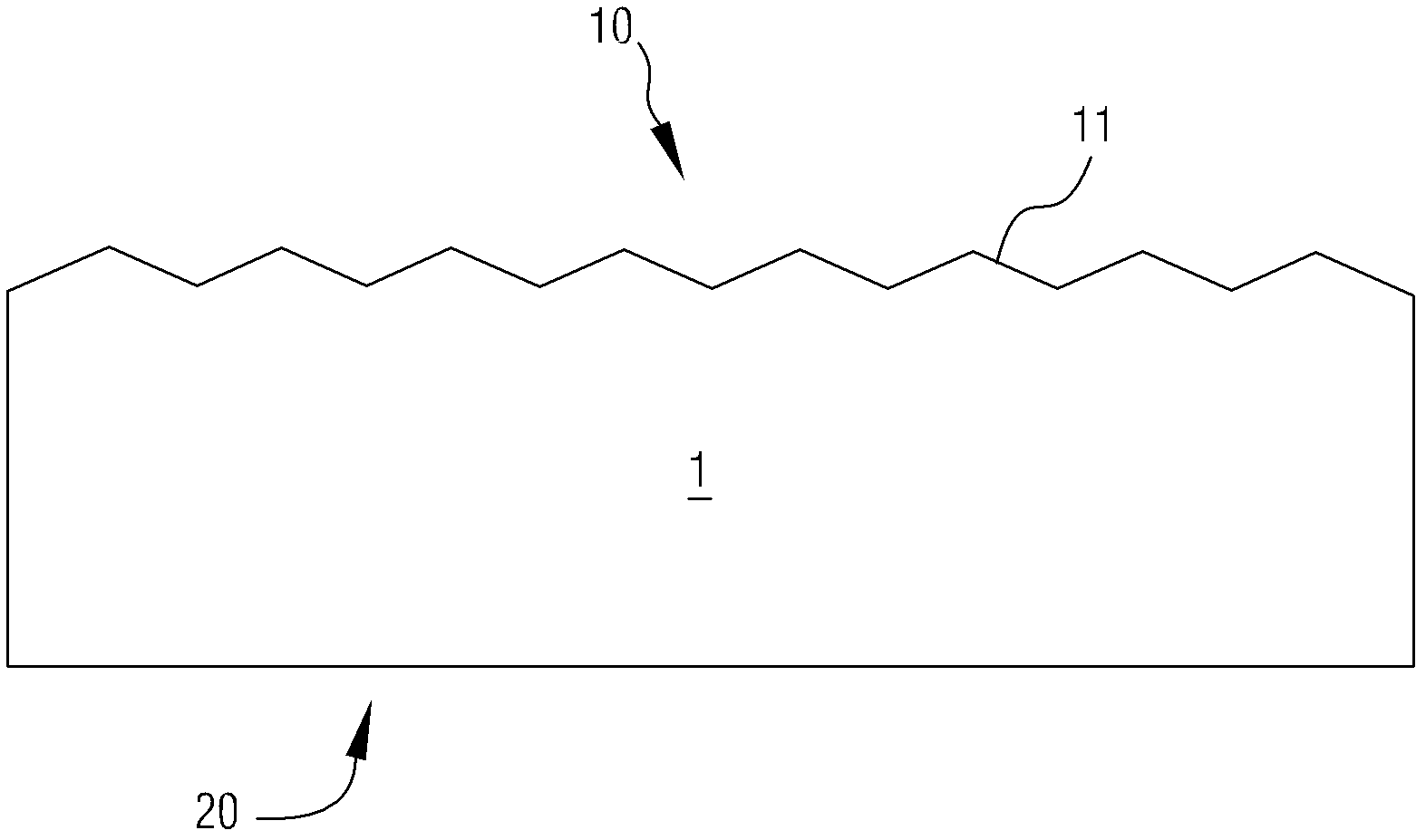

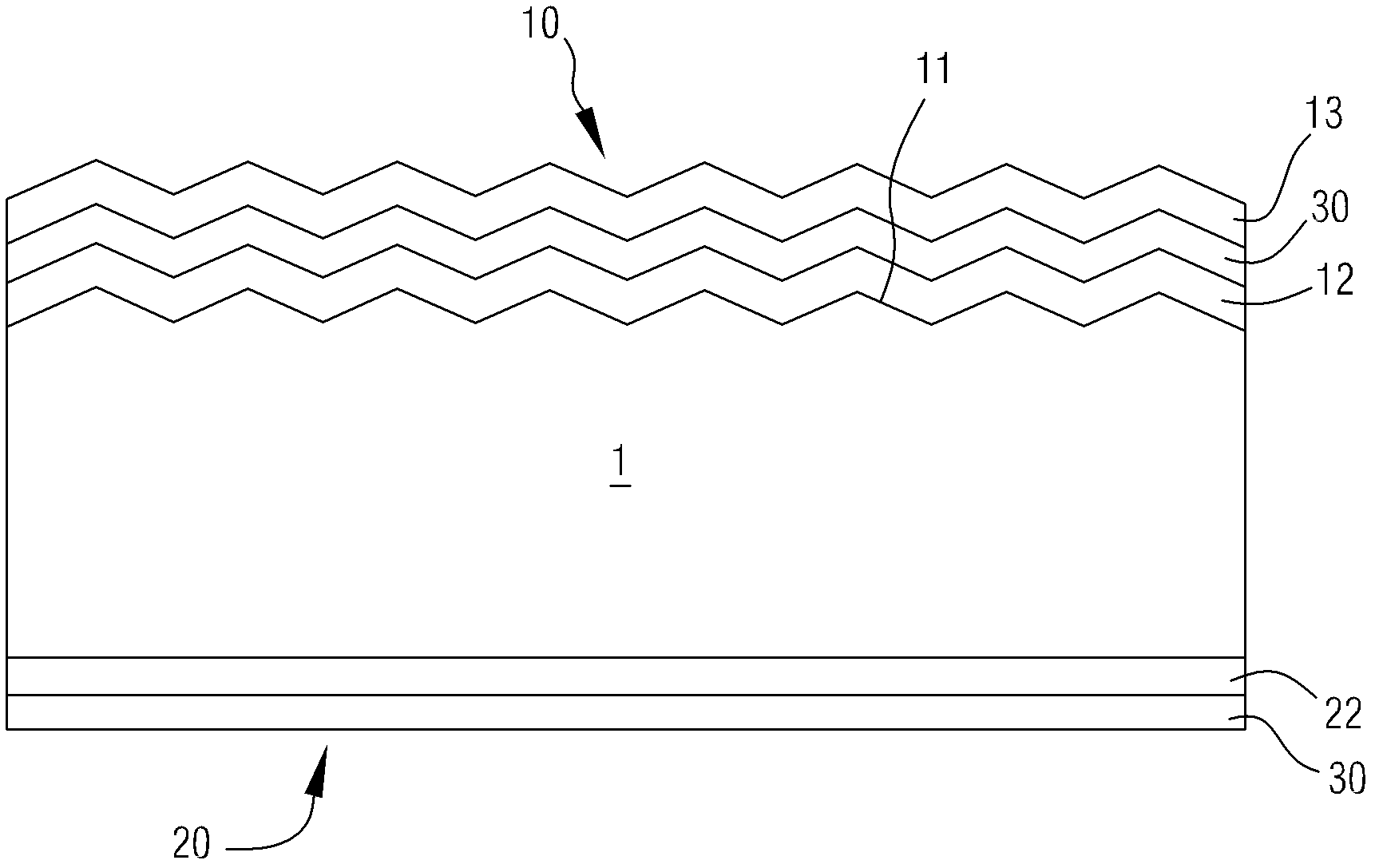

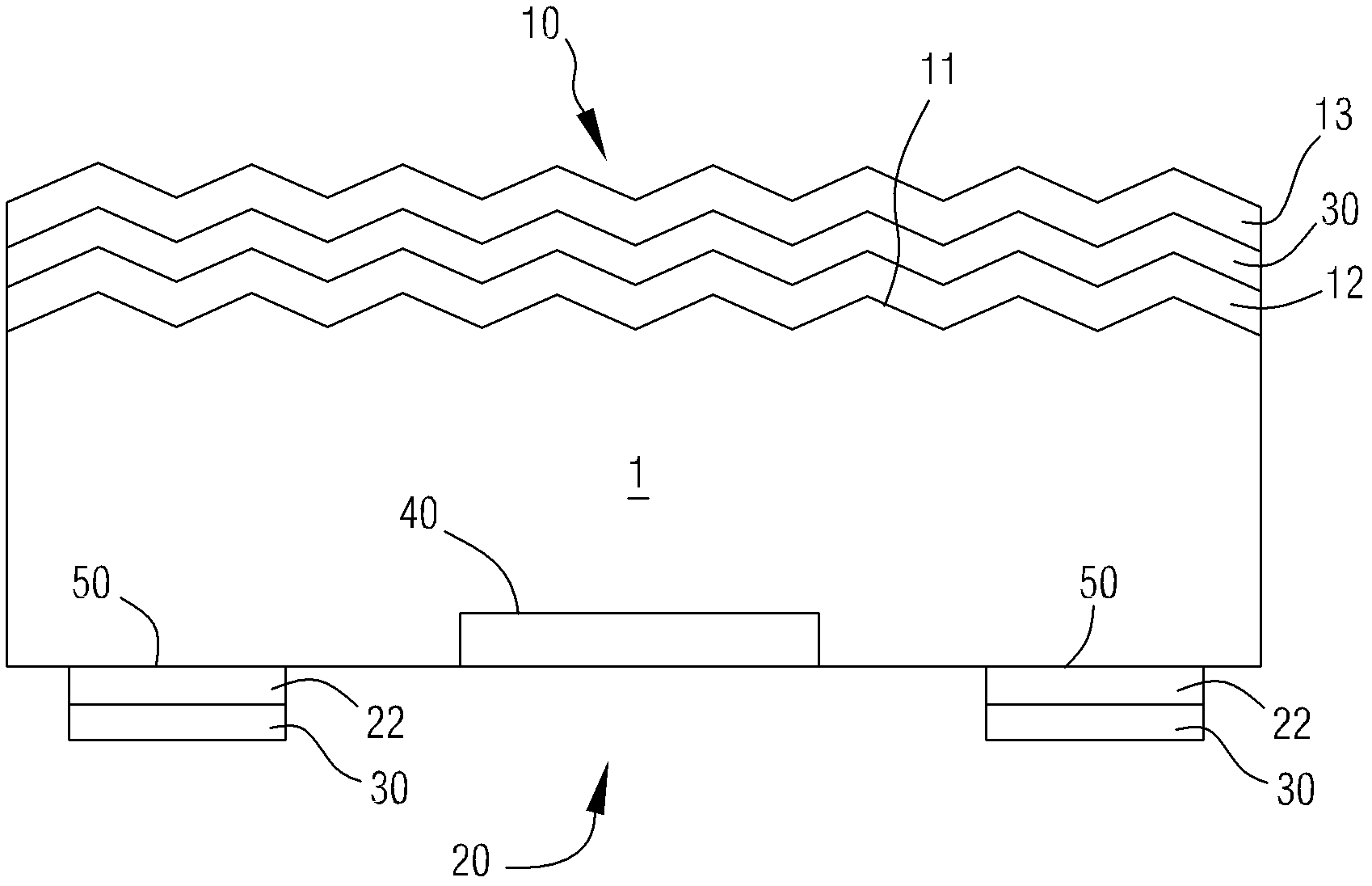

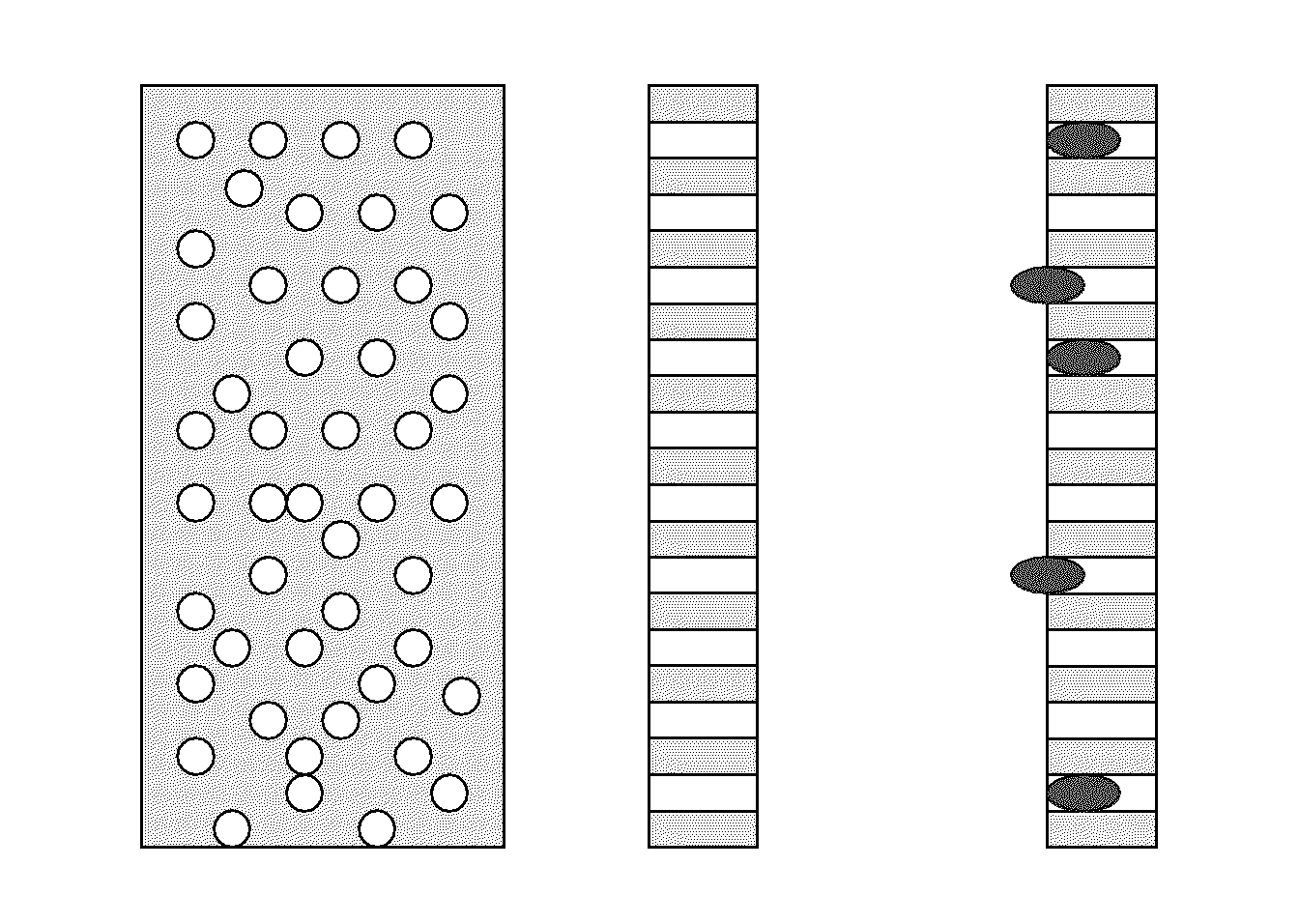

Manufacturing method of full back electrode solar cell

InactiveCN102208493ASimple processImprove battery efficiencyFinal product manufactureSemiconductor devicesHigh cellBack surface field

The invention relates to a manufacturing method of a full back electrode solar cell. According to the invention, after a damaged layer of a silicon chip is removed and a texturing process is carried out on a right side of the silicon chip, a phosphorus diffusion process is carried out on the silicon chip, and a right side filed and a back side field are formed. Oxide films are respectively formedon the right side and the back side of the silicon chip. And then, a part of the oxide film and a part of the back side field at the back of the silicon chip are removed, wherein the part of the oxide film and the part of the back side field are at a place where an electrode of an emitter electrode is needed to be formed; and meanwhile, another part of oxide film and another part of back side field are kept, wherein the another part of oxide film and the another part of back side field are at a place where a base electrode is needed to be formed. At last, by using the kept oxide film as a mask, a diffusion process is carried out on the back side of the silicon chip, wherein the processed area is where the oxide film and the back side field have been removed, so that the emitter electrode is formed. The full back electrode solar cell, which is produced by the method provided in the invention, has advantages of simple technology and high cell efficiency; besides, the assembly of the solar cell is easy to be welded. In addition, because the technology employed by the invention does not require especially-designed equipment, the cost is low, and produced production has good homogenization. Therefore, the manufacturing method of the full back electrode solar cell is suitable for large-scale industrialization production and application.

Owner:徐荣

Non-destructive method for testing content of formaldehyde in textile

ActiveCN103616340ASave resourcesPromote wettingColor/spectral properties measurementsNon destructiveEngineering

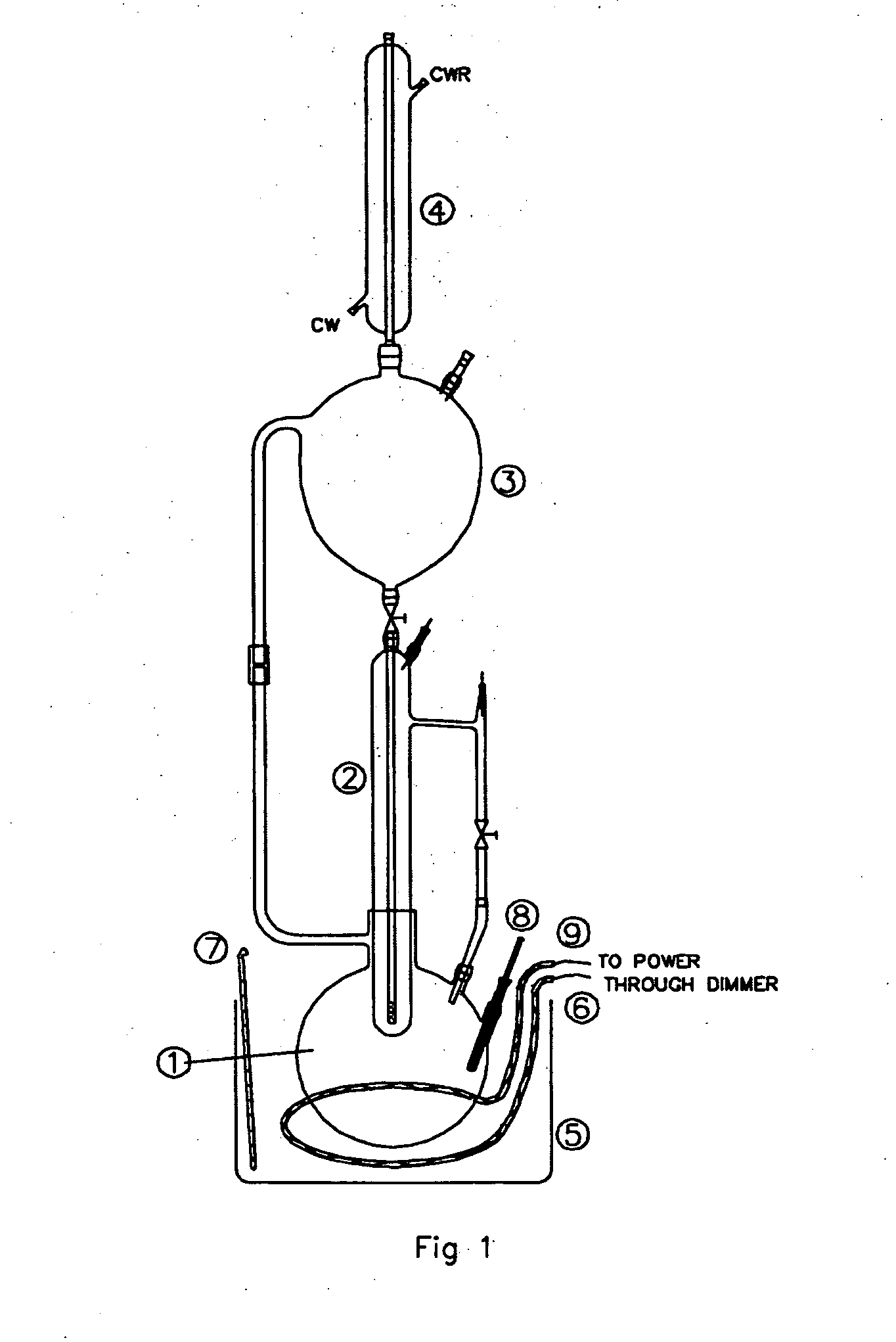

The invention discloses a non-destructive method for testing the content of formaldehyde in a textile. The method comprises the following steps: filling an absorption solution into equipment provided by the invention and fixing a textile to be detected on the equipment; then making the state of the absorption solution to be in a steam-liquid drop-steam ceaseless cycle from top to bottom by a condensing device and other outer equipment (such as a heating device) provided by the invention; eluting and absorbing released formaldehyde on the textile and determining an absorbance value by a spectrophotometer and through an acetylacetone developing process; and calculating the content of formaldehyde in the textile according to a standard formaldehyde working curve.

Owner:中纺协(北京)检验技术服务有限公司

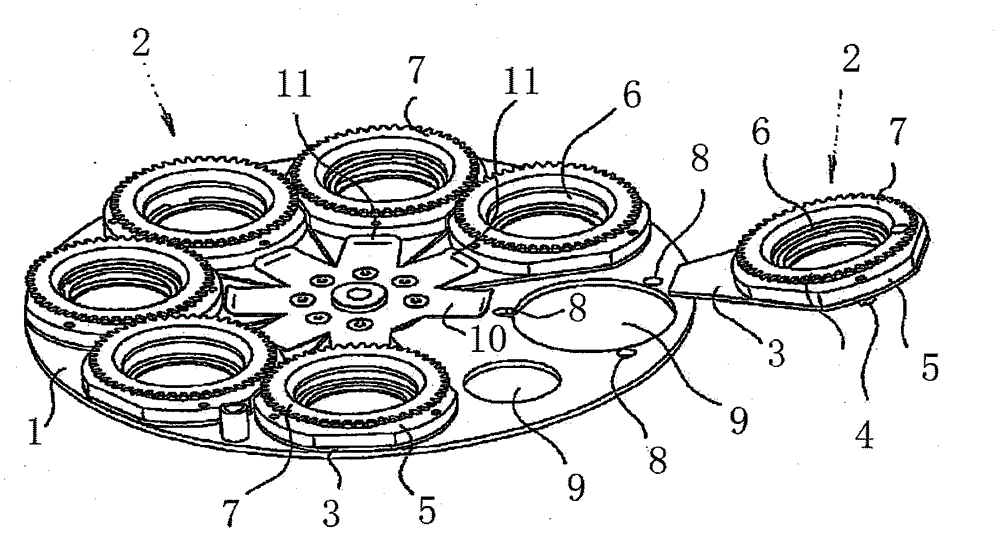

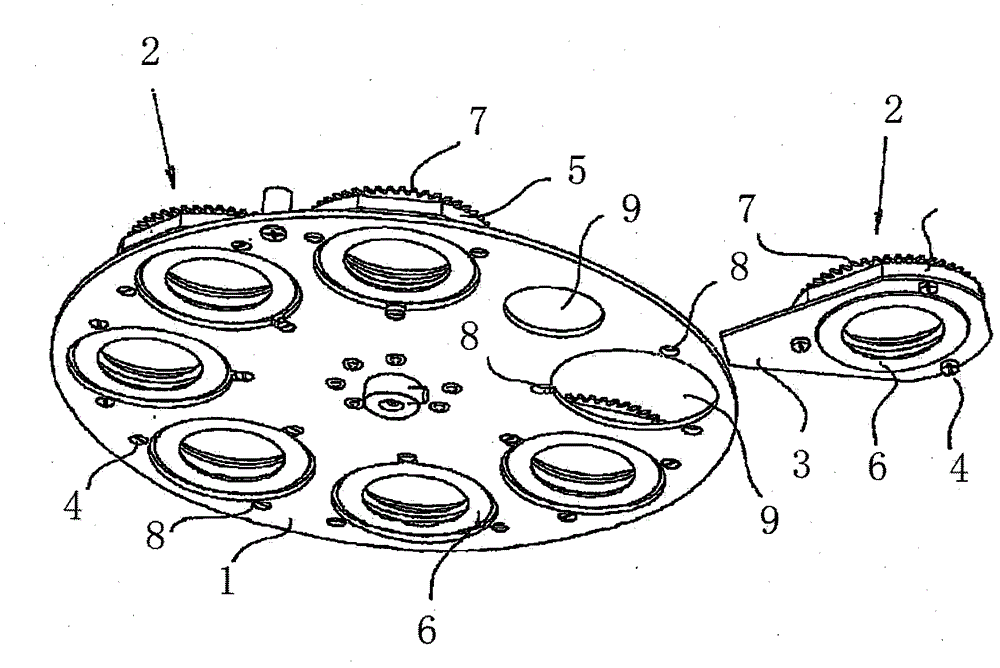

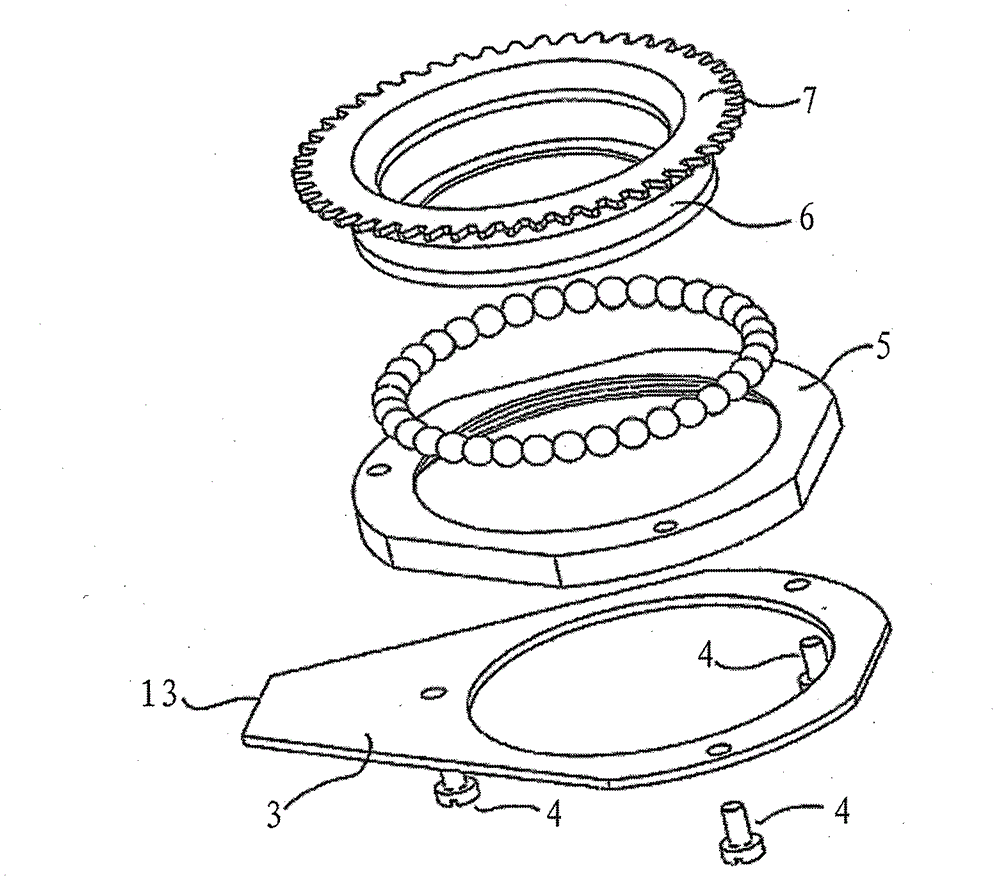

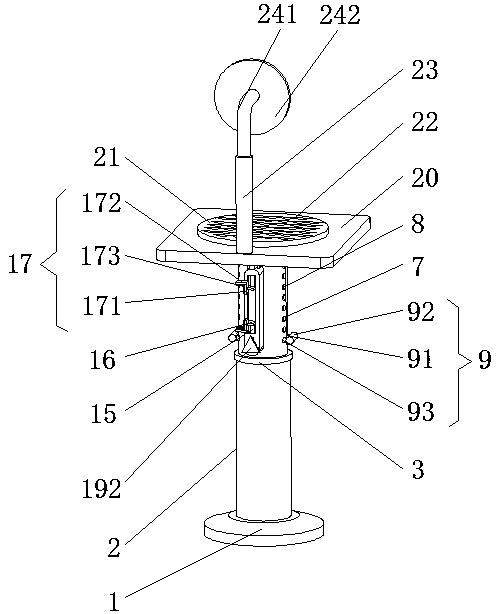

Spring slot&lock quick-change gobo changer system

InactiveUS20100246182A1Simple and easy procedureReduce manufacturing costLighting applicationsMechanical apparatusLight equipmentDesigned equipment

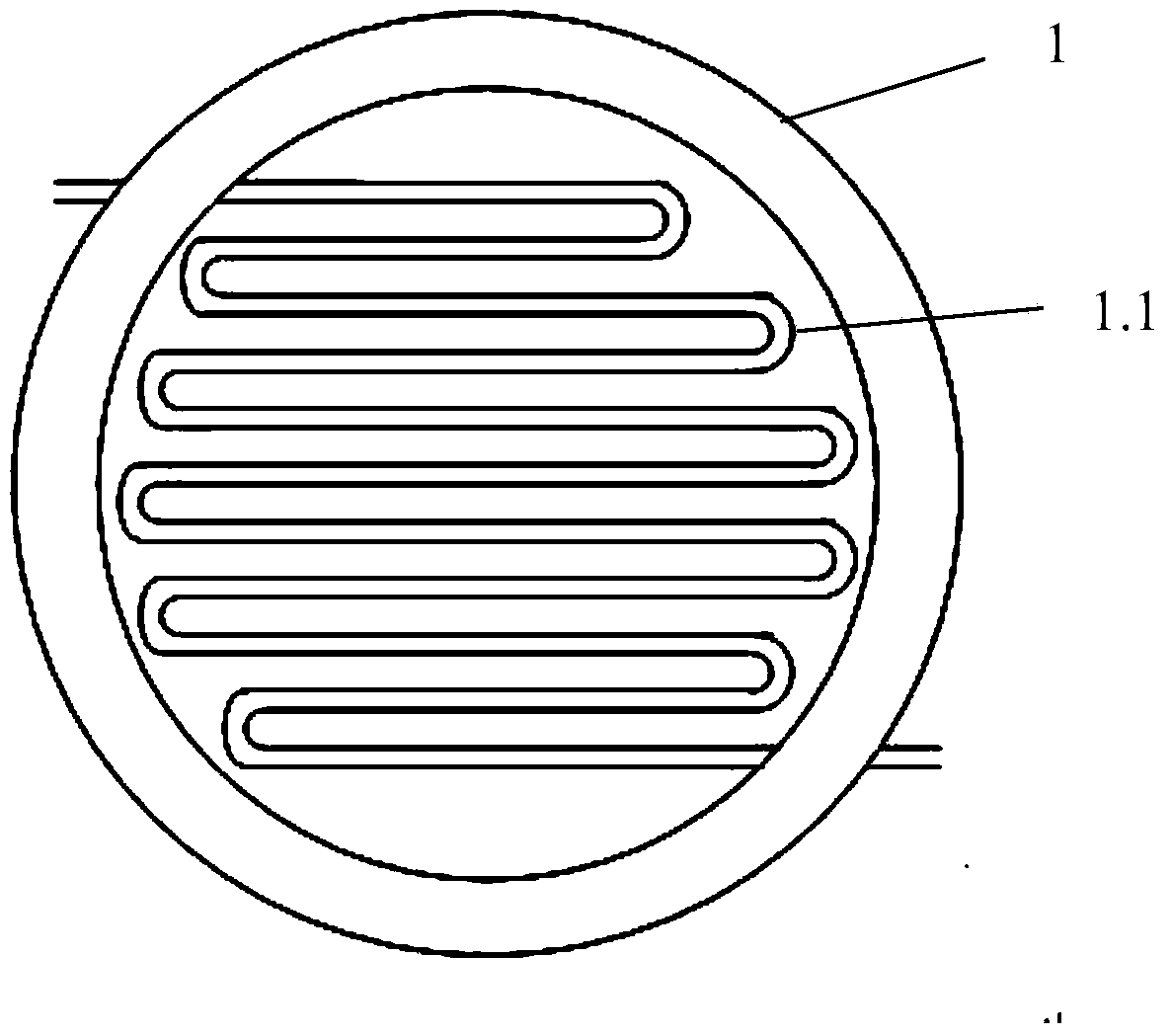

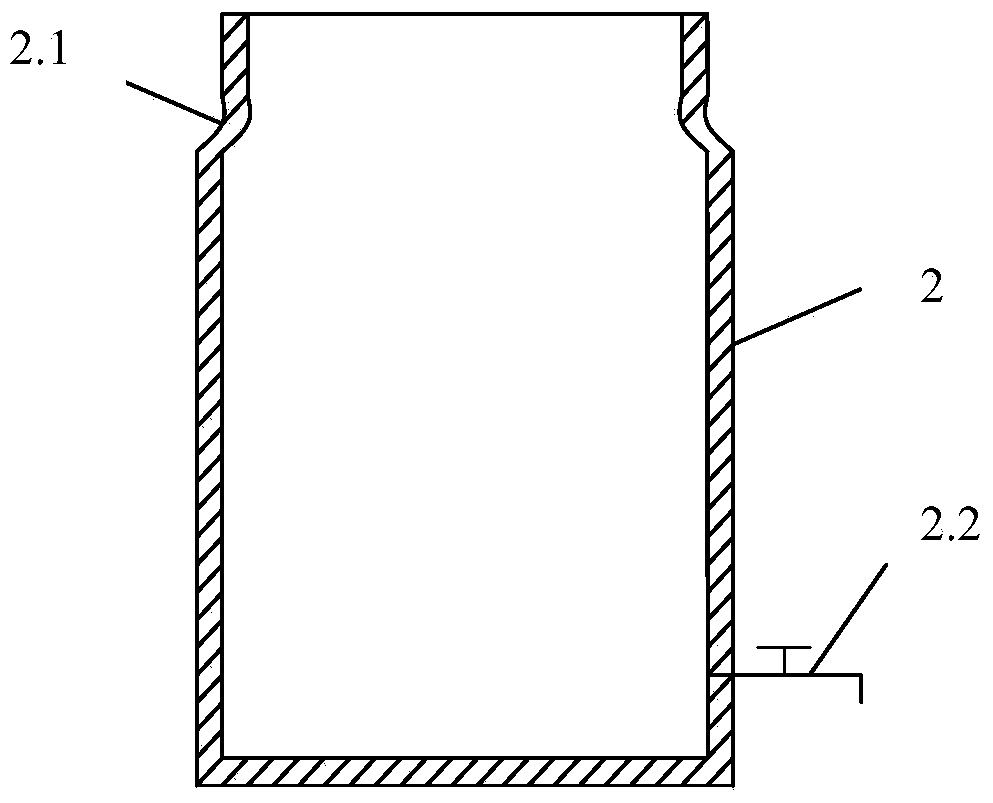

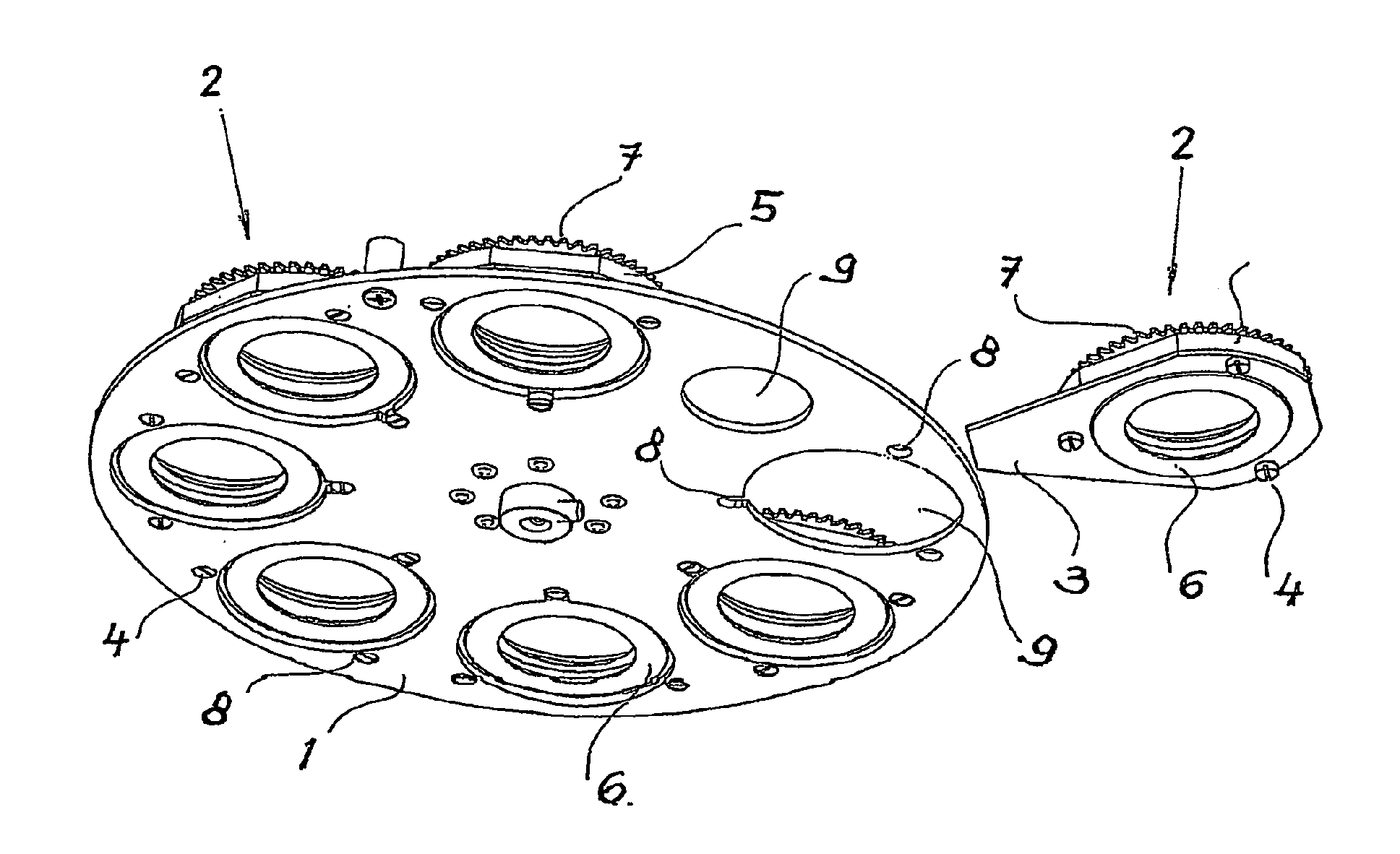

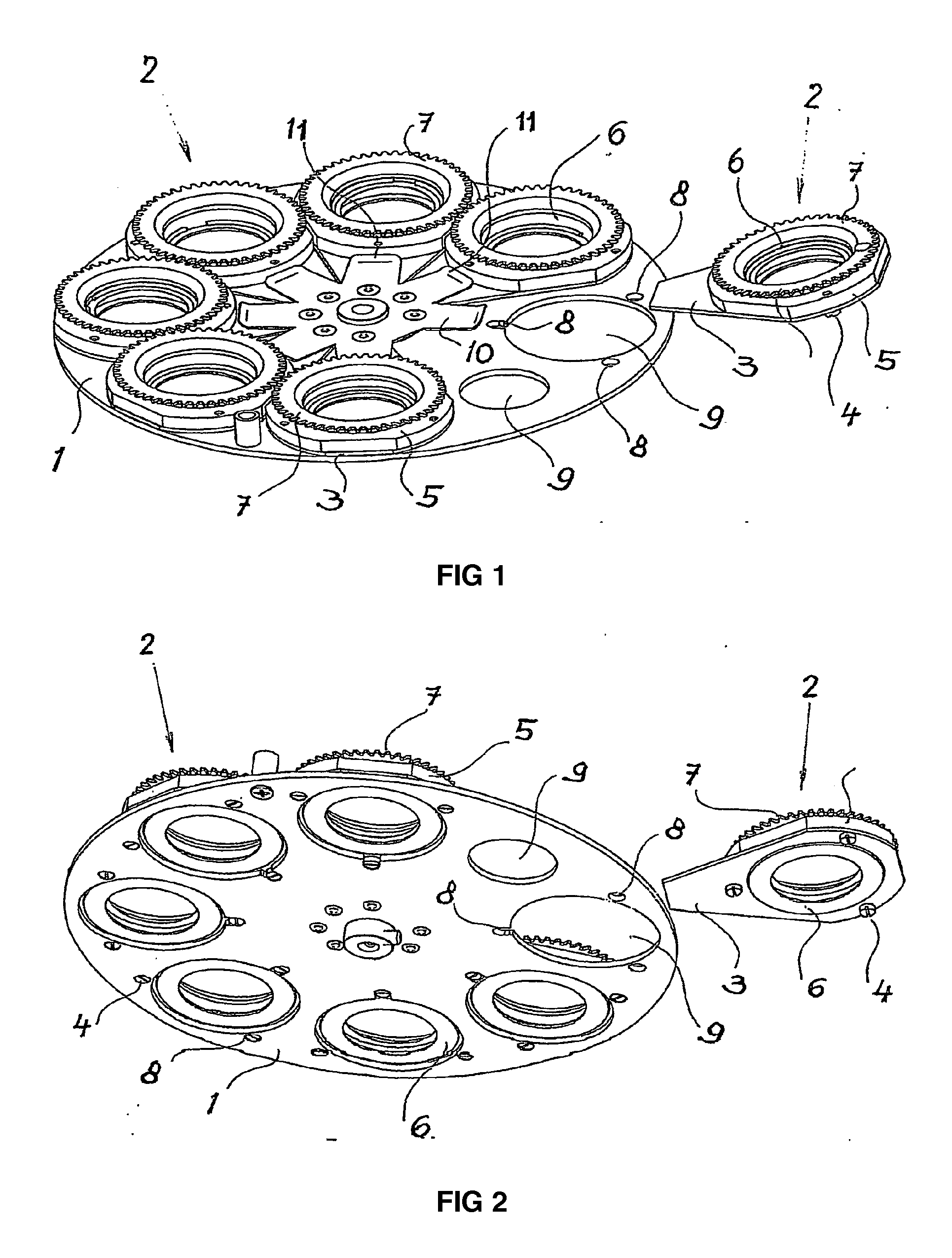

For lighting equipment for illumination of theatre and show stages and platforms there is designed equipment for quick change of rotary gobos comprising a carrier disc supporting interchangeable segments with the gobos. The individual segments are attached at the carrier disc by springs which register the position of the segment on the gobo carrier while at the same time holding the segment in place.

Owner:ROBE LIGHTING

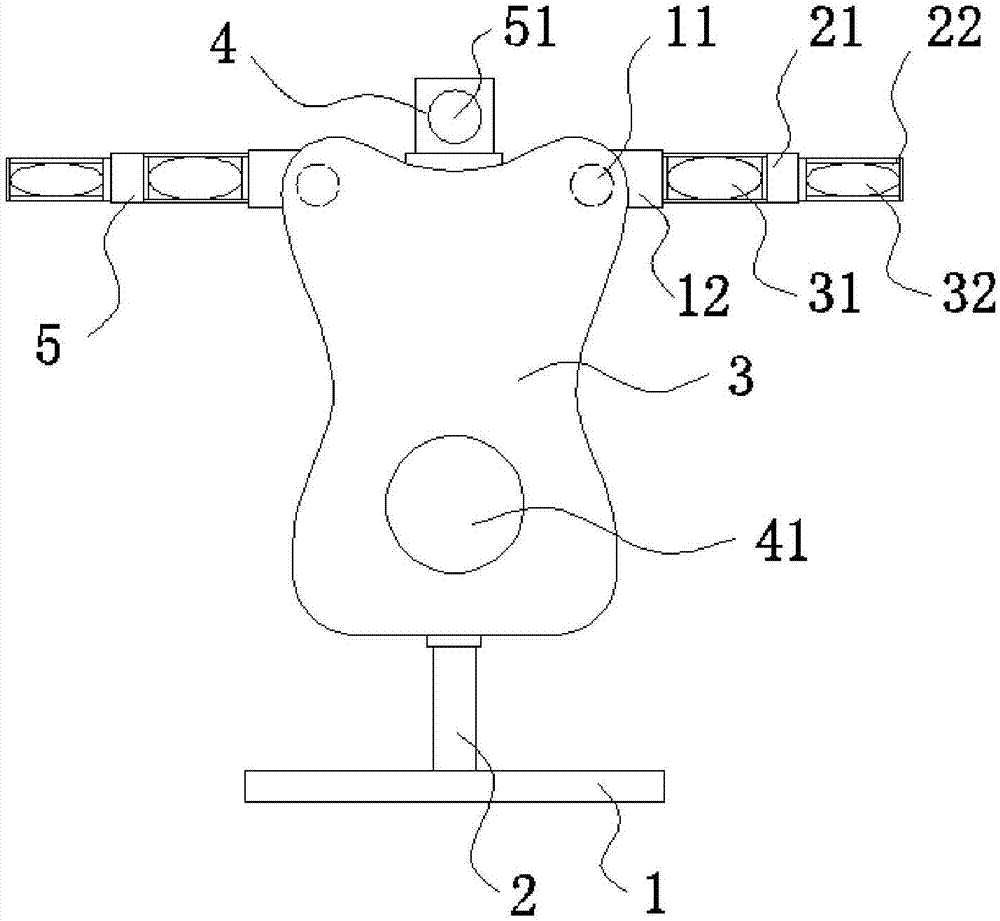

Support rack for upper outer garments of human bodies used for clothes design

The invention relates to a human body jacket support frame for clothing design, which belongs to the field of clothing design equipment. It includes a base plate, a support rod, a body module, a neck module and an arm module. The support rod is fixed on the base plate, the body module is installed on the support rod, the neck module and the arm module are respectively installed on the body module, and the number of arm modules is Two pieces, arranged symmetrically, and inflatable airbags are respectively provided on the stomach of the neck module, the body module, and the upper arm and forearm of the arm module; the present invention can help clothing designers design suitable tops.

Owner:安徽卡儿菲特服饰有限公司

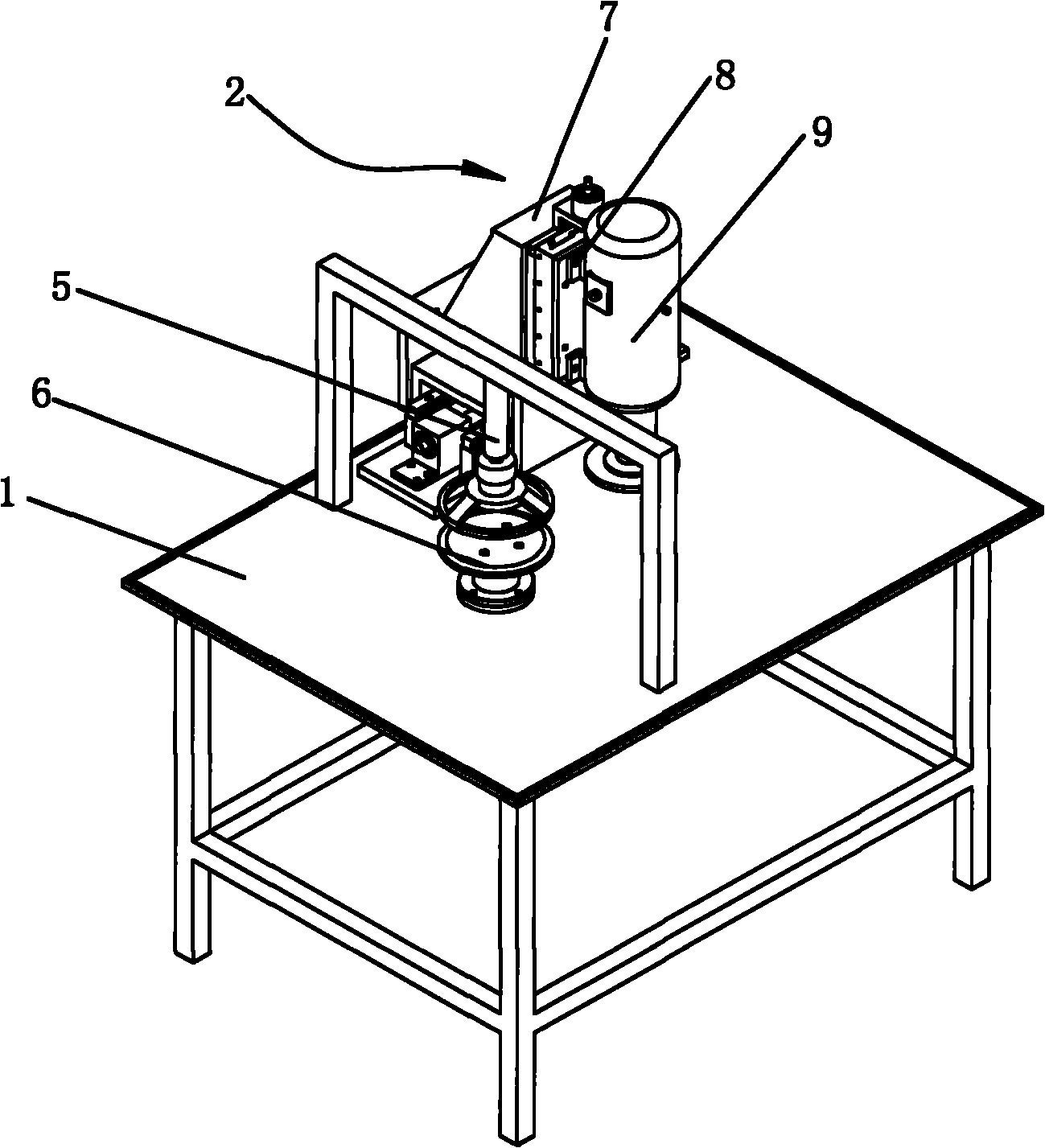

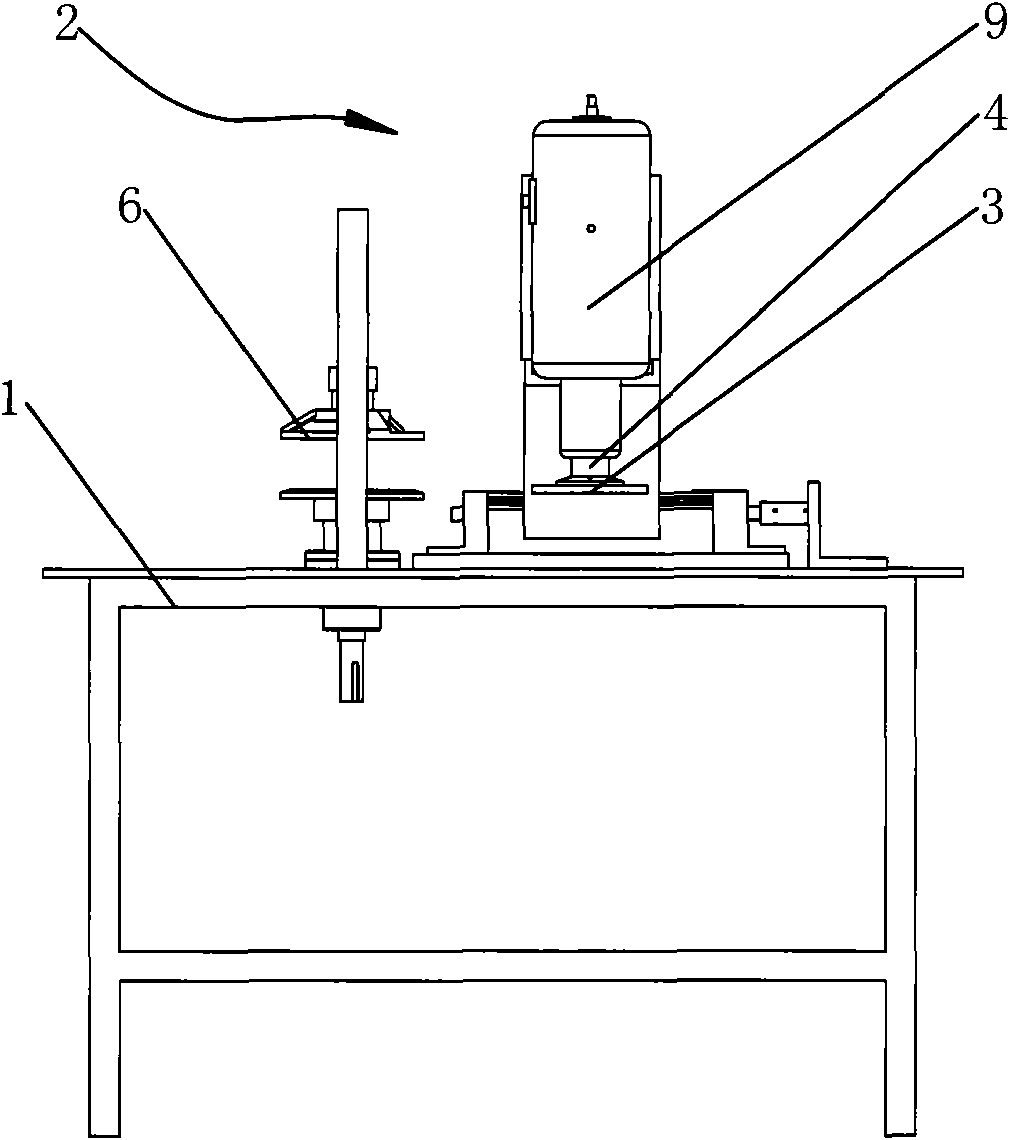

Circular glass numerical control edging machine

InactiveCN101879692AHigh precisionUniform roundnessEdge grinding machinesGrinding drivesNumerical controlBall screw

The invention relates to a circular glass numerical control edging machine. The machine comprises a work bench and a grinding mechanism arranged on the work bench. The grinding mechanism comprises an edging wheel, a main rotating shaft, a ball screw, a workpiece revolving shaft, a servo motor and a power unit, wherein the main rotating shaft is used for driving the edging wheel to rotate; the ball screw is used for driving the edging wheel to perform horizontal feed; the workpiece revolving shaft is used for driving glass to be edged to revolve; the servo motor is used for driving the ball screw to perform the horizontal feed; and the power unit is used for driving each shaft to rotate. The invention designs equipment special for edging circular glass. The tool setting and the edging of the edging wheel are controlled by adopting a numerical control operating system, so that mechanized glass has the characteristics of high precision, uniform roundness, high speed and low cost.

Owner:张家港市恒久玻璃机械有限公司

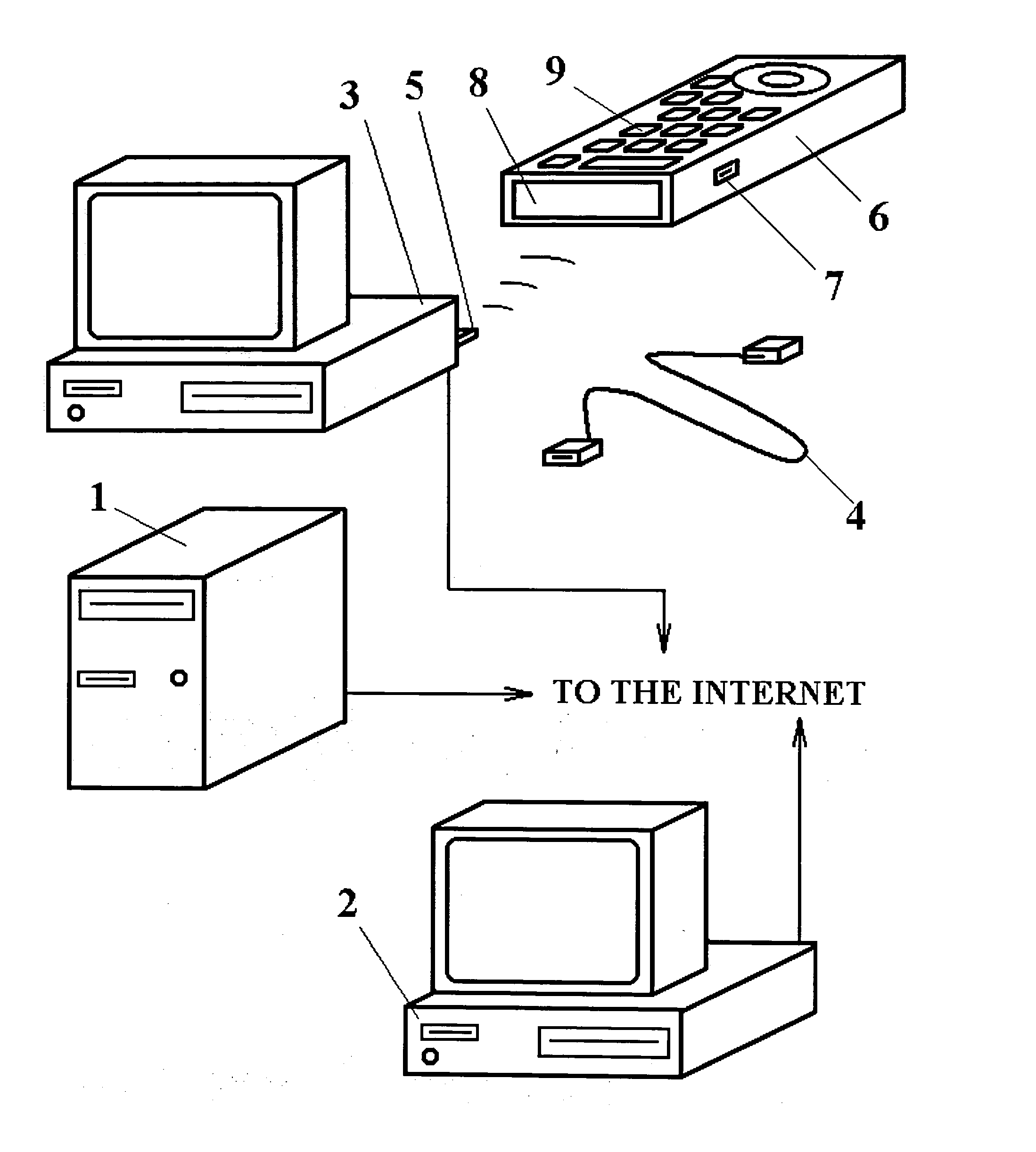

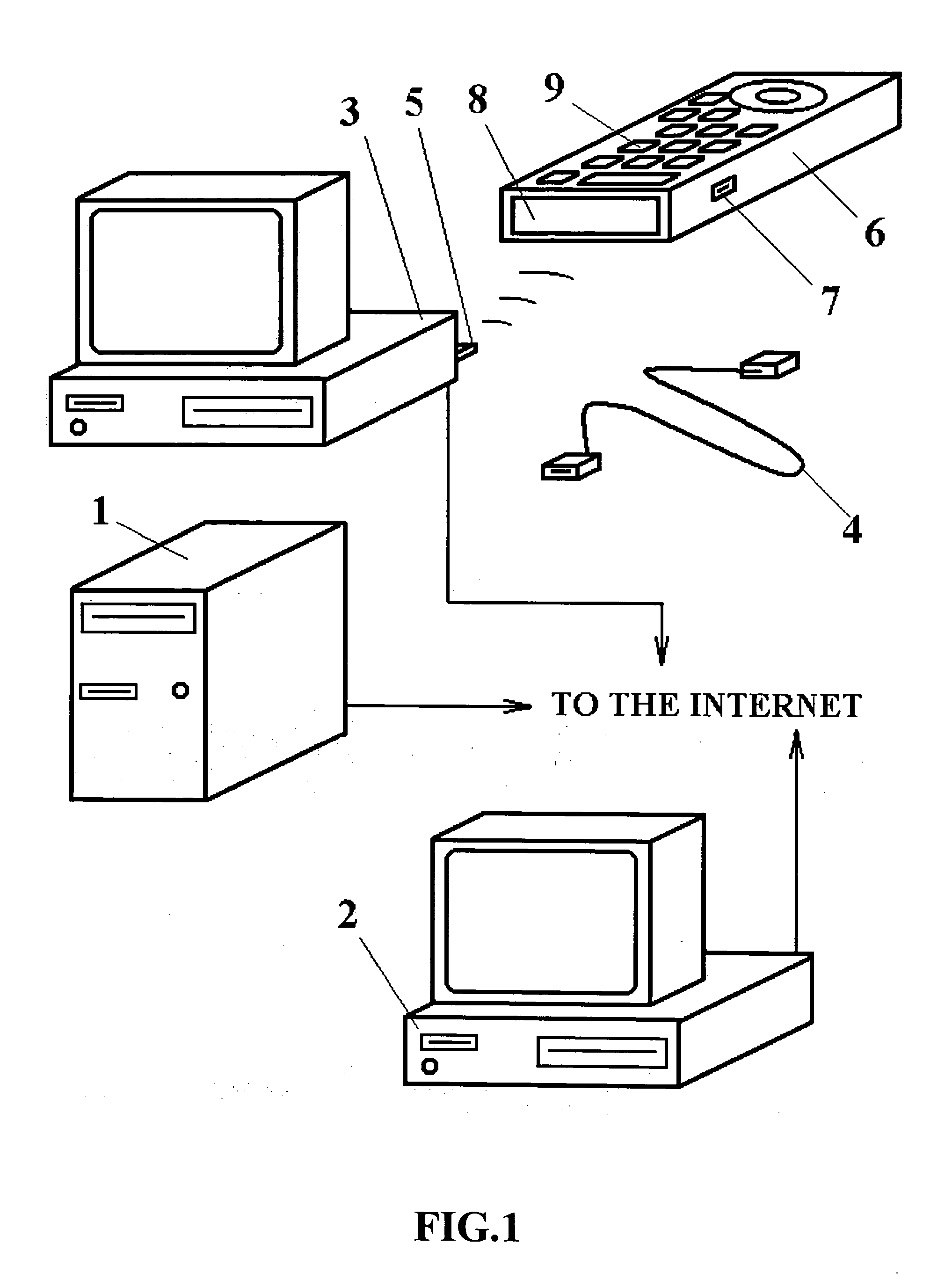

Programming system for remote control devices and method for operating said system

InactiveUS20060238369A1Improve versatilityLow costElectric signal transmission systemsComputer controlTransmission protocolGeneral purpose

The invention relates to a programming system for remote control devices (6) and a method for operating said system consisting in preparing and storing command code data and / or a command transmission protocol for controlling a remote electronic device on an information medium which is used for introducing said data into a device memory unit (6). The novelty of said invention lies in that the information medium is embodied in the form of the memory device of a telecommunication network server which is used for forming and storing database for different remotely controlled electronic equipments. The required data is obtainable from the memory device of said server (1) through the telecommunication network to a remote programmer (3) from which said data is introduces into the memory unit of the device (6), for example with the aid of a cable connection (4). The database can be created from a remote computer (2) through Internet network. Said invention makes it possible to increase a program generality since the server memory can simultaneously store data for controlling completely different electronic equipments in the form of different formats which are used by different producers and to reduce cost and simplify the structural design of reprogrammable general-purposed devices (6).

Owner:MAMONTOV VIKTOR ALEXANDROVICH

Cleaning method and system

InactiveUS20120055865A1Easy to cleanDetergent solventsLoose filtering material filtersChemical compositionMembrane surface

A method for removing particles or deposits from a surface having particles or deposits thereon. The method involves contacting a surface with a chemical composition sufficient to selectively dissolve and remove at least a portion of the particles or deposits from the surface. The chemical composition is compatible with the surface. This disclosure also relates to a system of specially designed equipment for removing particles or deposits from a surface having particles or deposits thereon. The disclosure is useful, for example, in cleaning porous surfaces, media for cartridge, pleated and membrane surfaces, and internal walls of tanks or filter housings.

Owner:FUJIFILM PLANAR SOLUTIONS

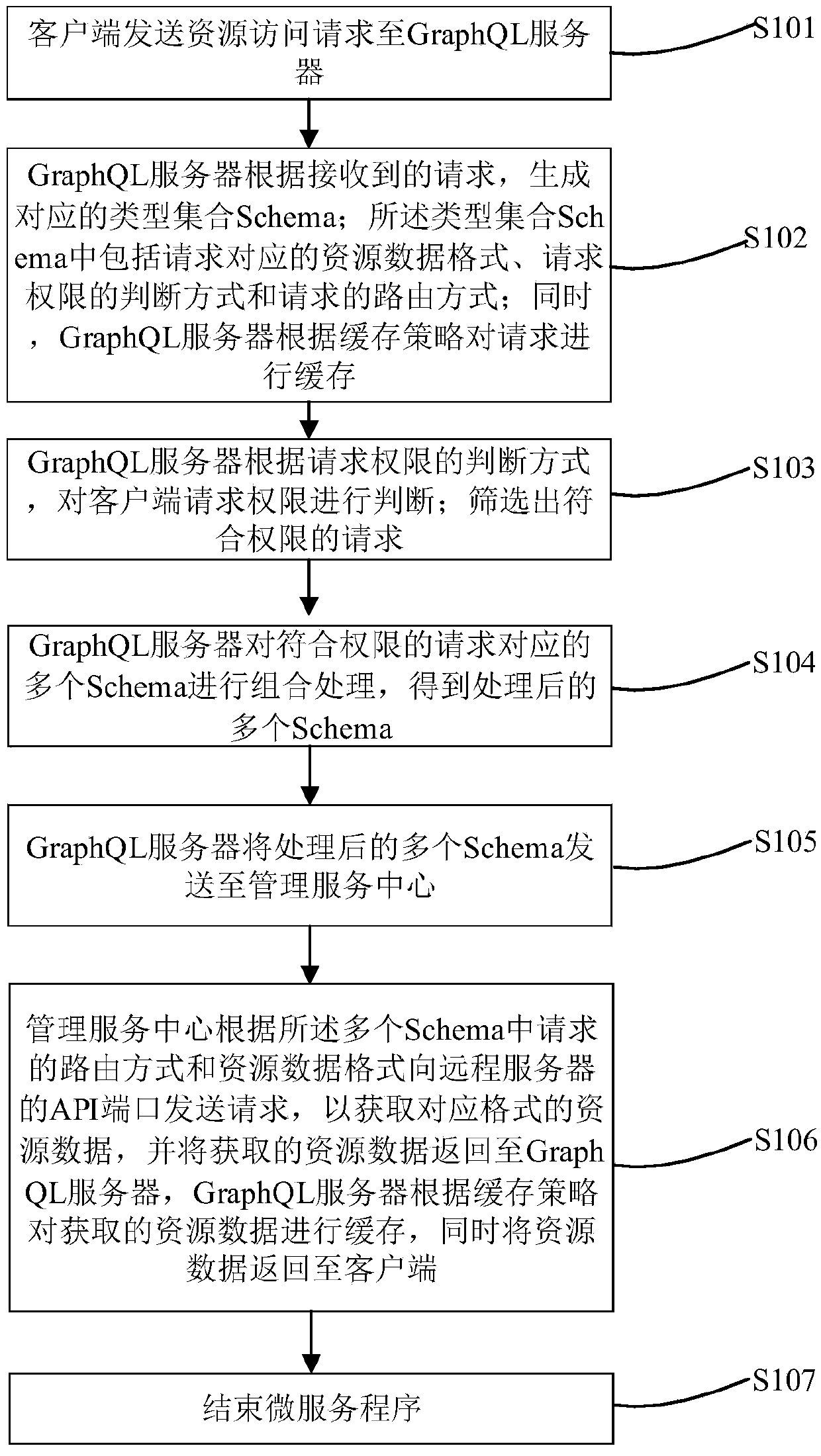

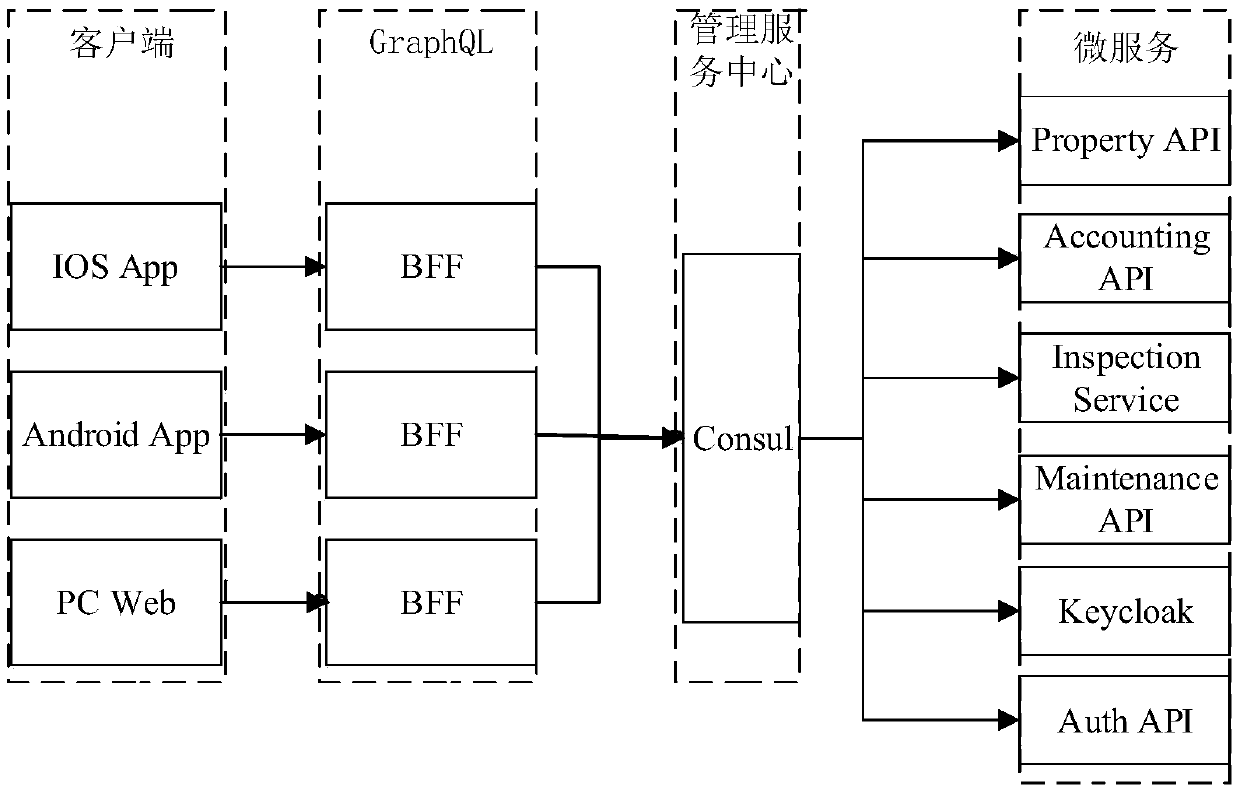

GraphQL based micro service configuration design method and device and storage equipment

The invention provides a GraphQL based micro service configuration design method and device and storage equipment. The method comprises that GraphQL is applied to micro service configuration, and userrequests are processed in a concentrated way by means of the GraphQL, and then sent to a management service center; and in a GraphQL server, a specific caching strategy is used to cache the user requests, and the burden of the server is alleviated. The problems of resource repetition and field conflict in the GraphQL server are solved by a bonding method, and resources in the GraphQL server are integrated in an RPC manner. The GraphQL based micro service configuration design device and storage equipment are used to realize the GraphQL based micro service configuration design method. Accordingto technical schemes of the invention, multiple requests of a client are gathered into one request, delay caused by multiple requests is reduced, and the caching strategy can be used to reduce the burden of the server.

Owner:武汉艺果互动科技股份有限公司

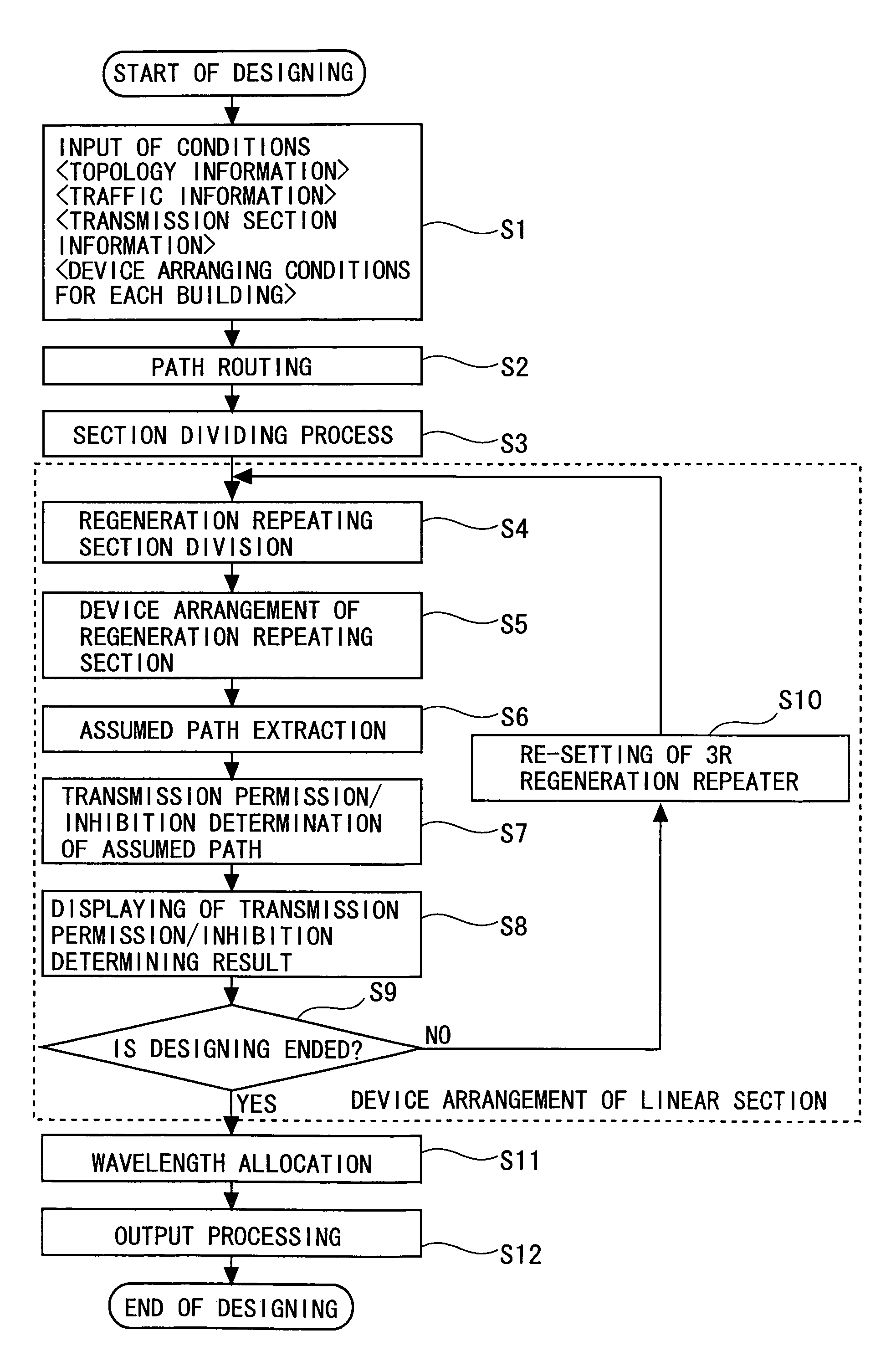

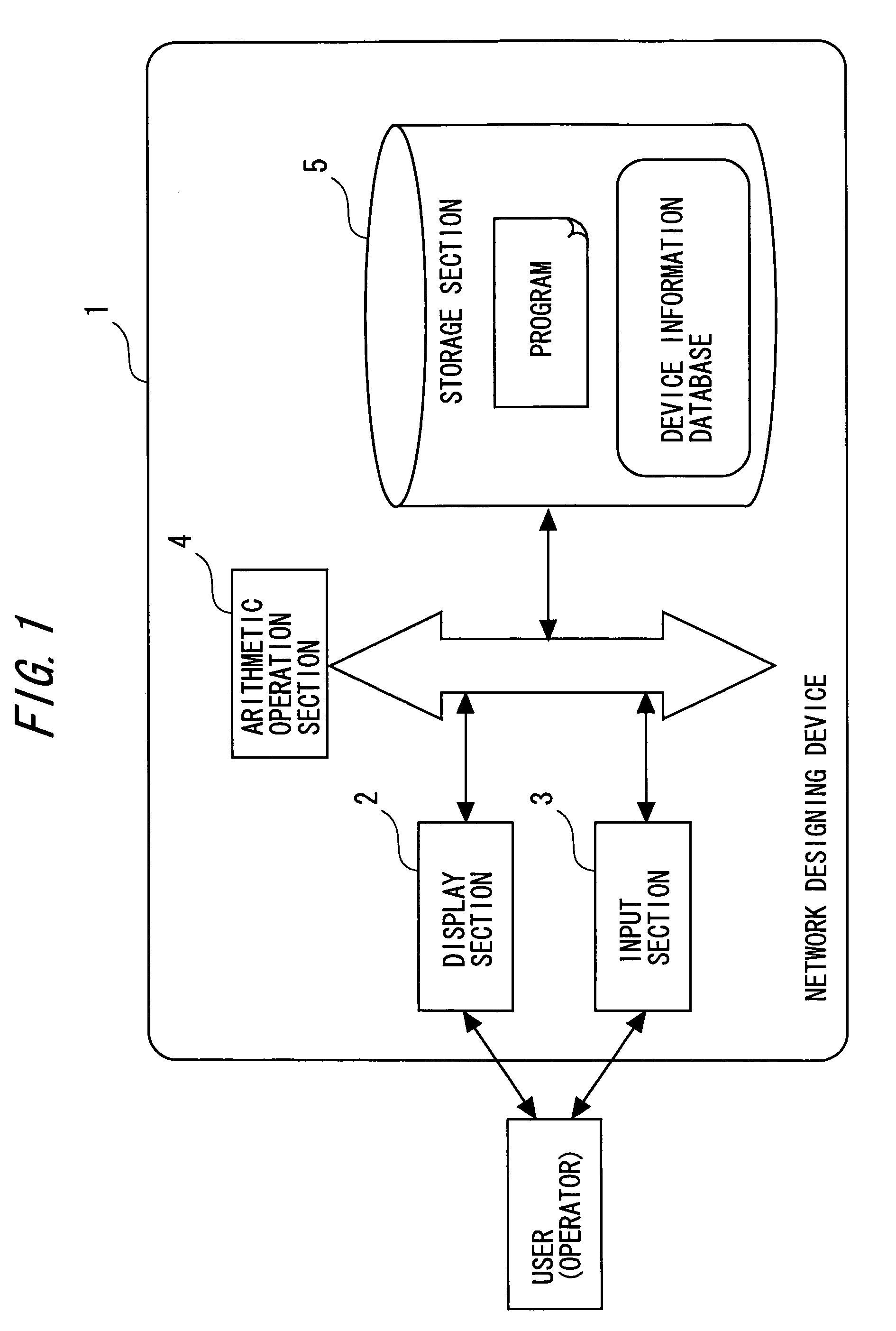

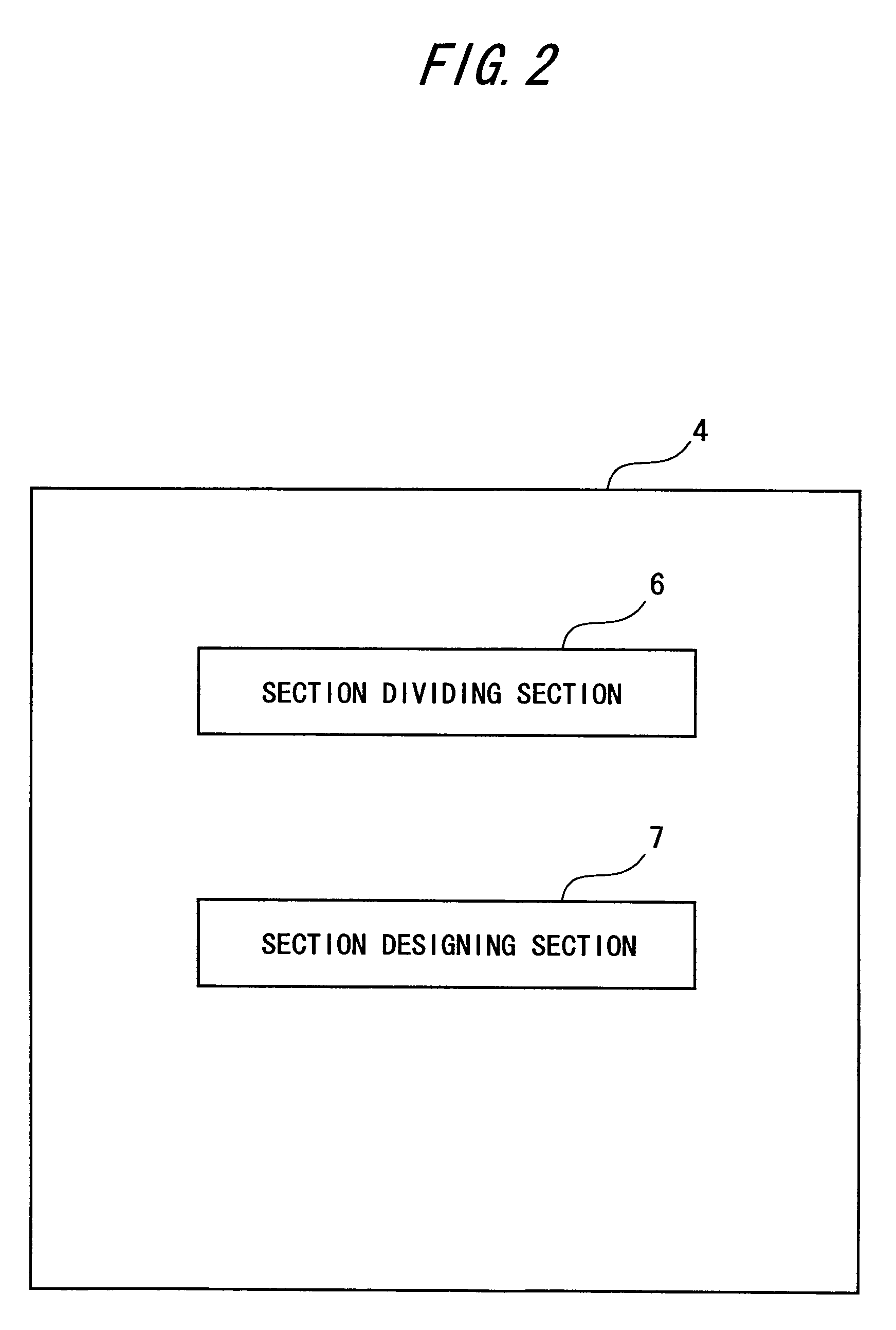

Network designing device and computer-readable medium

InactiveUS7505414B2Easy to installEasy to checkError preventionTransmission systemsEngineeringDesigned equipment

Owner:FUJITSU LTD

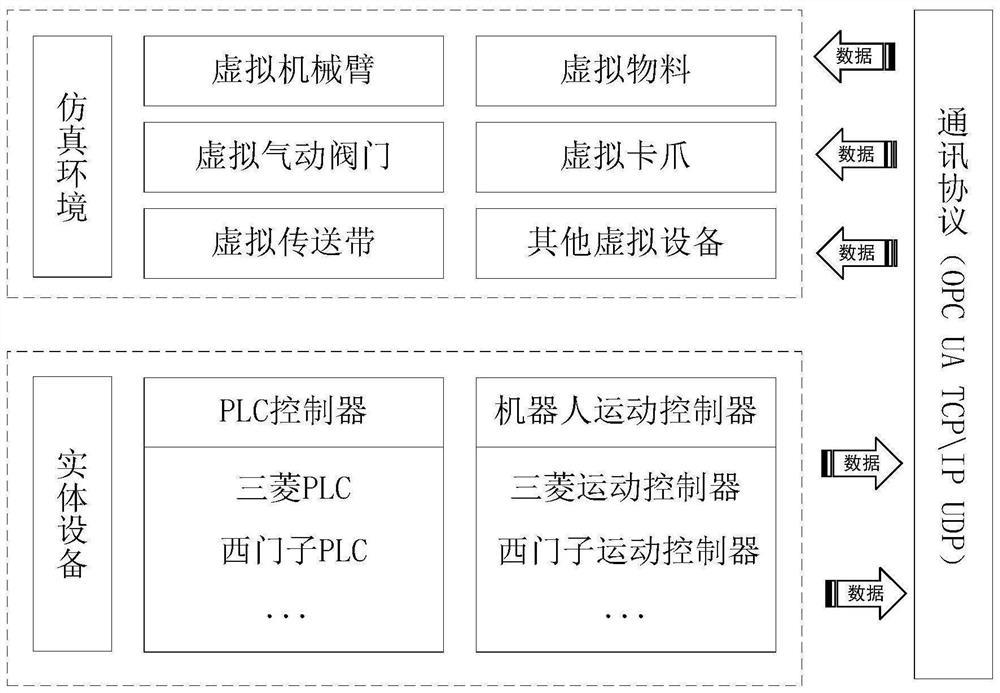

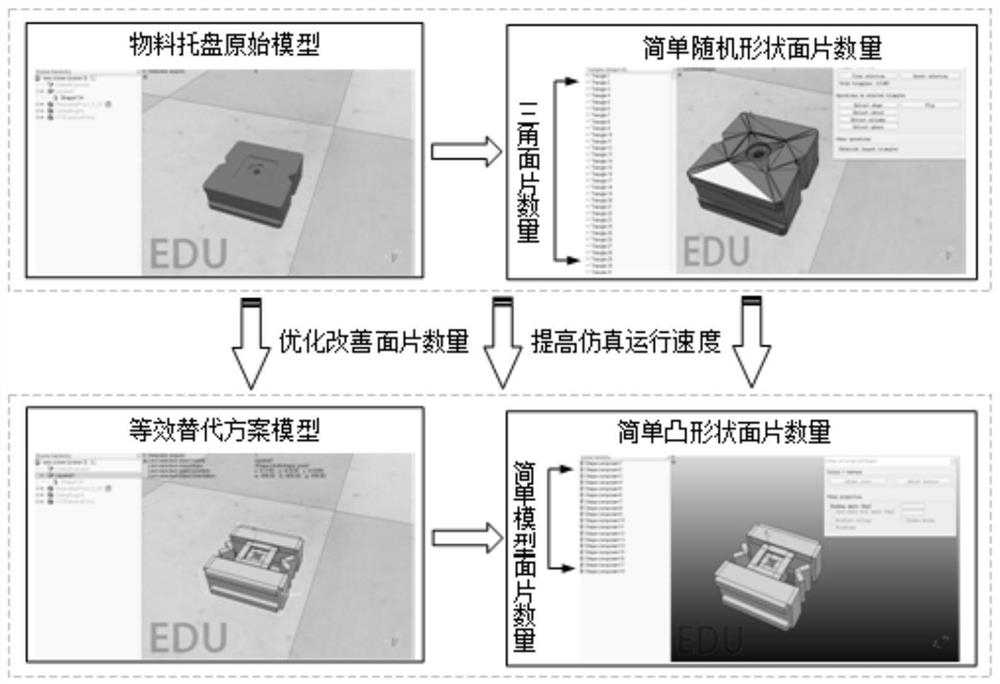

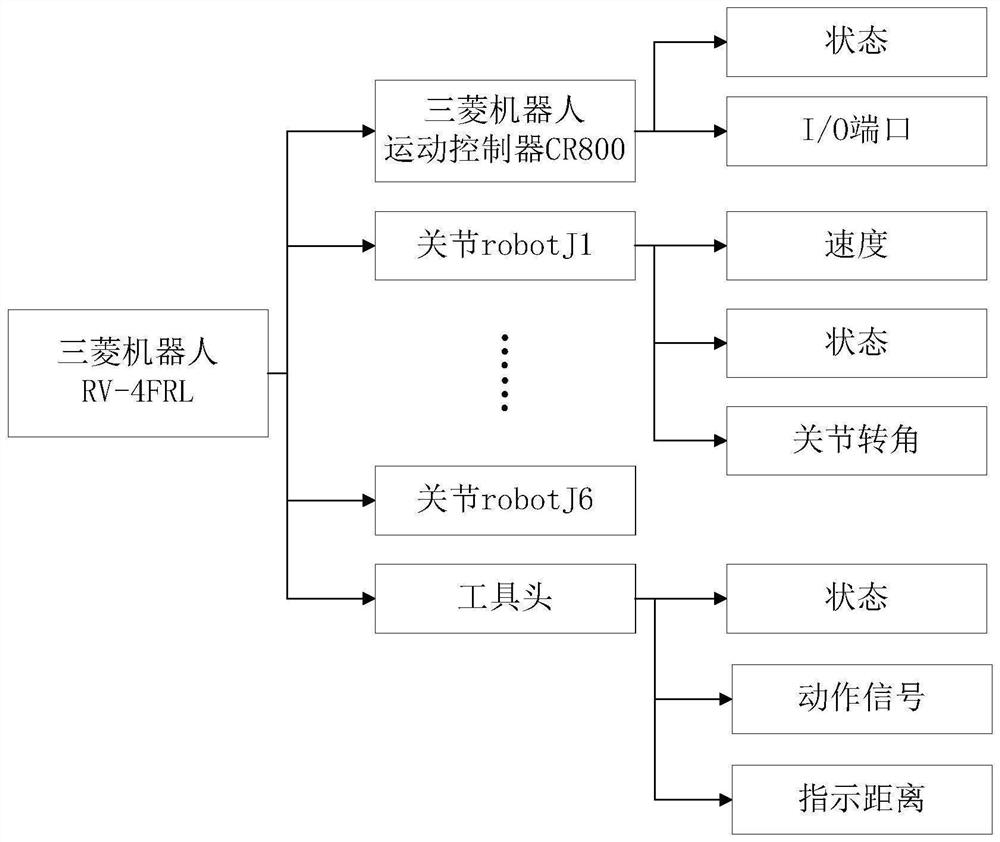

Method for constructing virtual-real combined digital twin simulation experiment platform

InactiveCN112684717AReflect programming effectsGuaranteed uptimeSimulator controlProduction lineSimulation

The invention discloses a method for constructing a virtual-real combined digital twin simulation experiment platform. The method comprises the following steps of: (1) designing an equipment three-dimensional model, and importing the equipment three-dimensional model into simulation software; (2) adding a motion control script and a data interface into simulation software; (3) compiling a control program of the PLC or a motion controller program of a robot, downloading the compiled control program or motion controller program to a corresponding controller for compiling and running, and running the program to obtain a data signal; (4) transmitting the data signal obtained in the step (3) to the simulation software in the step (1), performing data interaction, and driving virtual equipment in the simulation software to move; and (5) comparing the motion state of the virtual equipment with the actual programming effect of the controller to obtain a visual debugging result of the controller. According to the construction scheme provided by the invention, the development cost and the construction cost of the experiment platform can be remarkably reduced, the display effect is good, and the design debugging efficiency of a production workshop and a production line is improved.

Owner:NANJING UNIV OF SCI & TECH

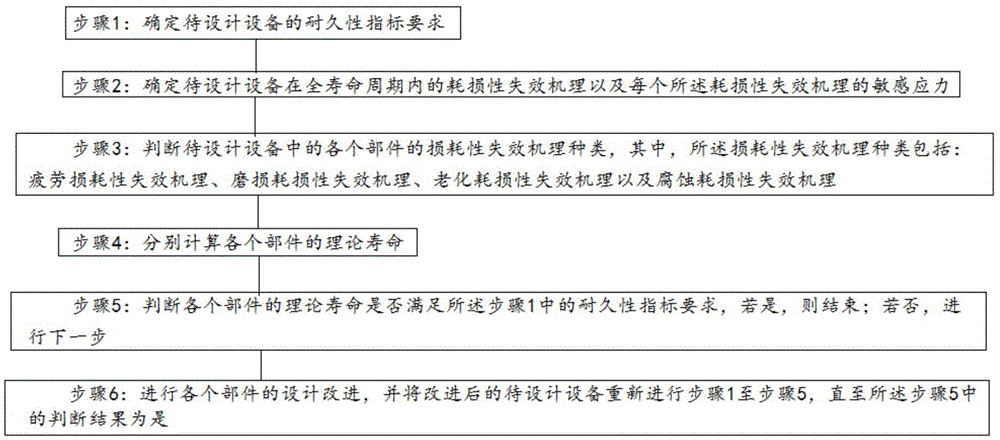

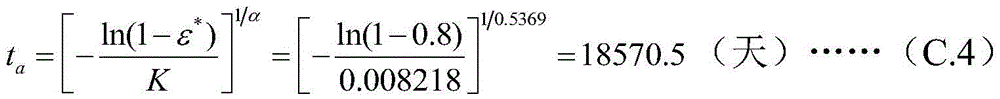

Aircraft equipment durability design method and aircraft equipment durability design system

InactiveCN105631091ADesign optimisation/simulationSpecial data processing applicationsModel NumberFailure mechanism

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

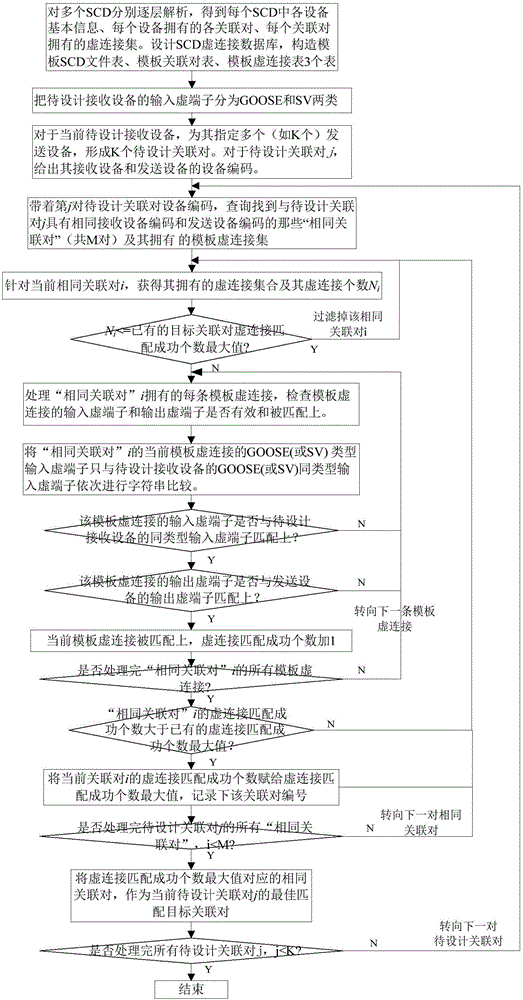

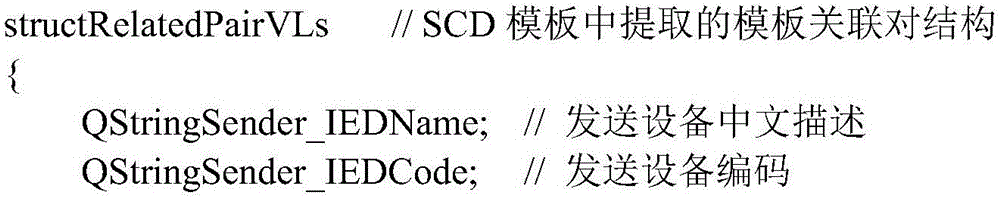

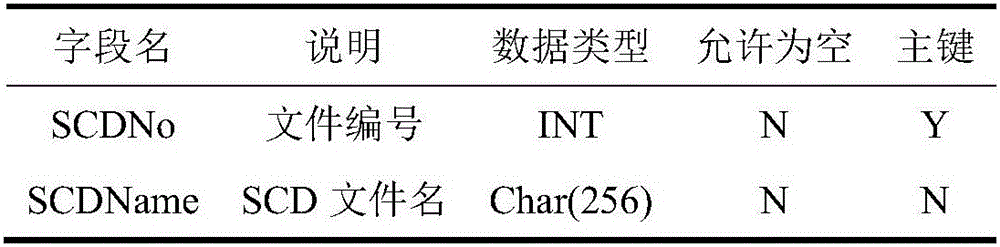

Multi-SCD-oriented method for rapidly searching and optimizing target associated pairs of intelligent substations

ActiveCN105956276ANarrow searchImprove search speedSpecial data processing applicationsVirtual terminalSmart substation

The invention discloses a Multi-SCD-oriented method for rapidly searching and optimizing target associated pairs of intelligent substations. The method comprises the following steps: respectively analyzing a plurality of existing SCD files layer by layer, and forming to-be-designed associated pair codes by utilizing each equipment code; aiming at a historical SCD database, filtering the same associated pairs which do not need to be processed and virtual connections thereof by adopting a filtering strategy; comparing input virtual terminal description of the current template virtual connection of the same associated pairs with the same type of input virtual description in to-be-designed equipment, checking the matching condition of each template virtual connection, and optimizing and rapidly searching the target associated pairs with the maximum matching number and the virtual connection thereof. According to the method disclosed in the invention, technical problem that the conventional virtual terminal design method is high in workload, low in efficiency and easy to cause errors and does not fully utilize the existing SCD design achievement is solved, the auxiliary automatic design of the virtual terminals of the intelligent substations is realized, the workload is greatly decreased, the intelligence, correctness and working efficiency are improved, and the reusability of the virtual terminal design achievement in the existing SCD is improved.

Owner:SOUTHWEST JIAOTONG UNIV

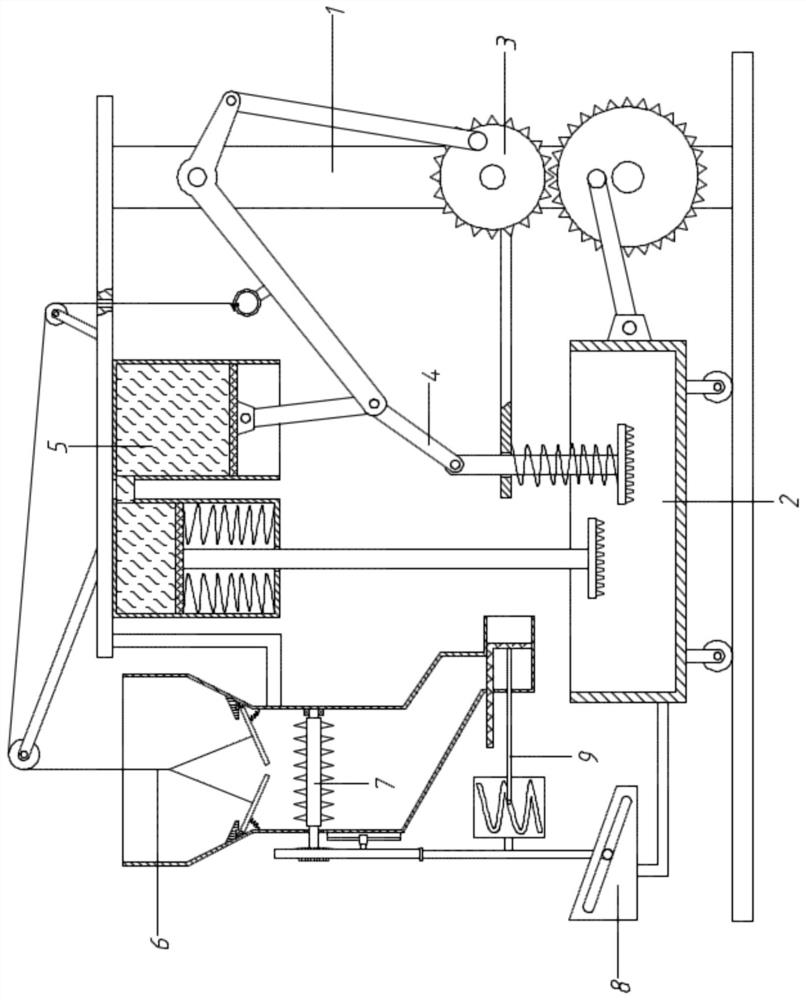

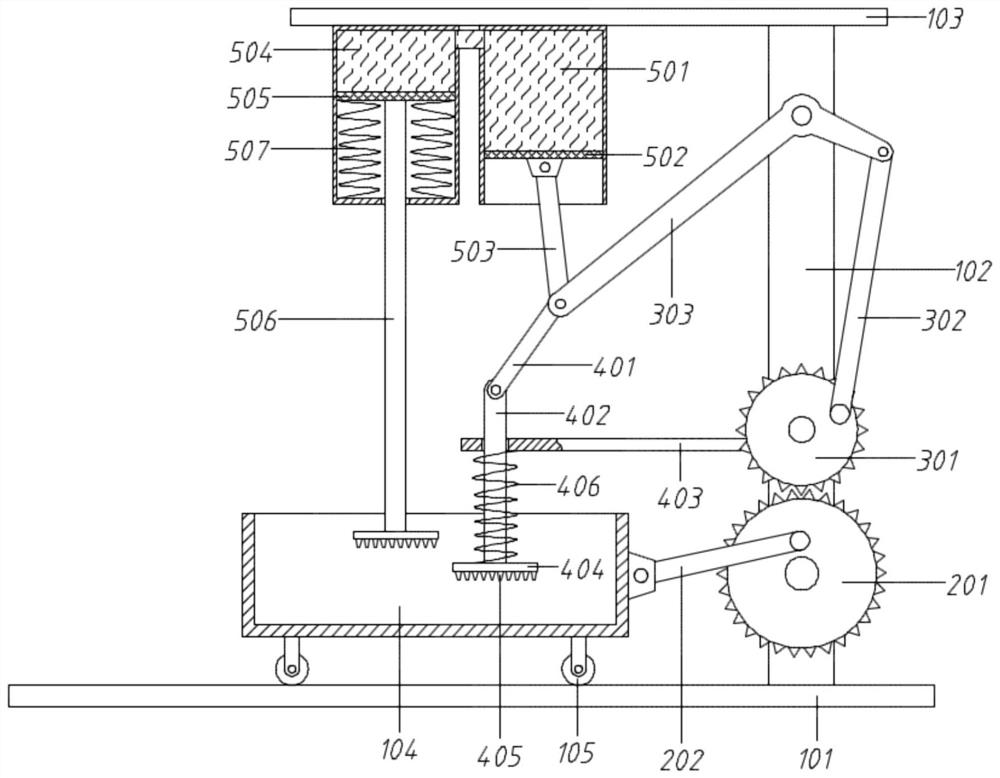

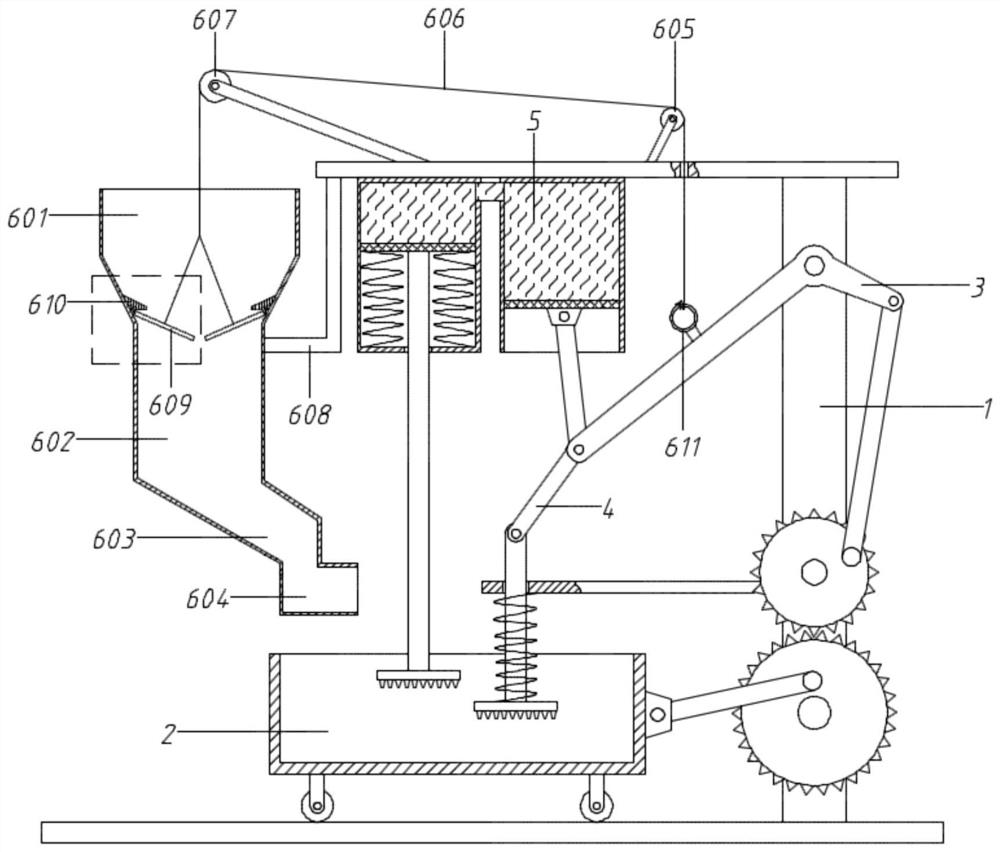

Decoration waste treatment device for indoor design

PendingCN111805804AChange the area of effectIncrease in sizePlastic recyclingGrain treatmentsGear wheelPlastic waste

The invention relates to the technical field of indoor design equipment, in particular to a decoration waste treatment device for indoor design. A servo motor is adopted for driving a first gear to rotate, on one hand, a first connecting rod acts on the right end of an L rocker arm, the L rocker arm does swing with the bending end hinge point as the circle center, the left end of the L rocker armswings up and down, a third connecting rod acts on a first lifting rod, in cooperation with a first kind of spring, the first lifting rod drives a breaking end on the bottom end to move up and down, the plastic waste in a smashing box can be crushed, on the other hand, a second gear is driven to rotate, a second connecting rod drives the smashing box to do left and right reciprocating moving, theaction area of the breaking end can be changed, the left end of the L rocker arm swings up and down, meanwhile, a fourth connecting rod drives a first piston plate to move up and down, a second pistonplate moves in a following manner, a second lifting rod is driven to lift, and the breaking end on the bottom end can crush the plastic waste in the smashing box.

Owner:河北能源职业技术学院

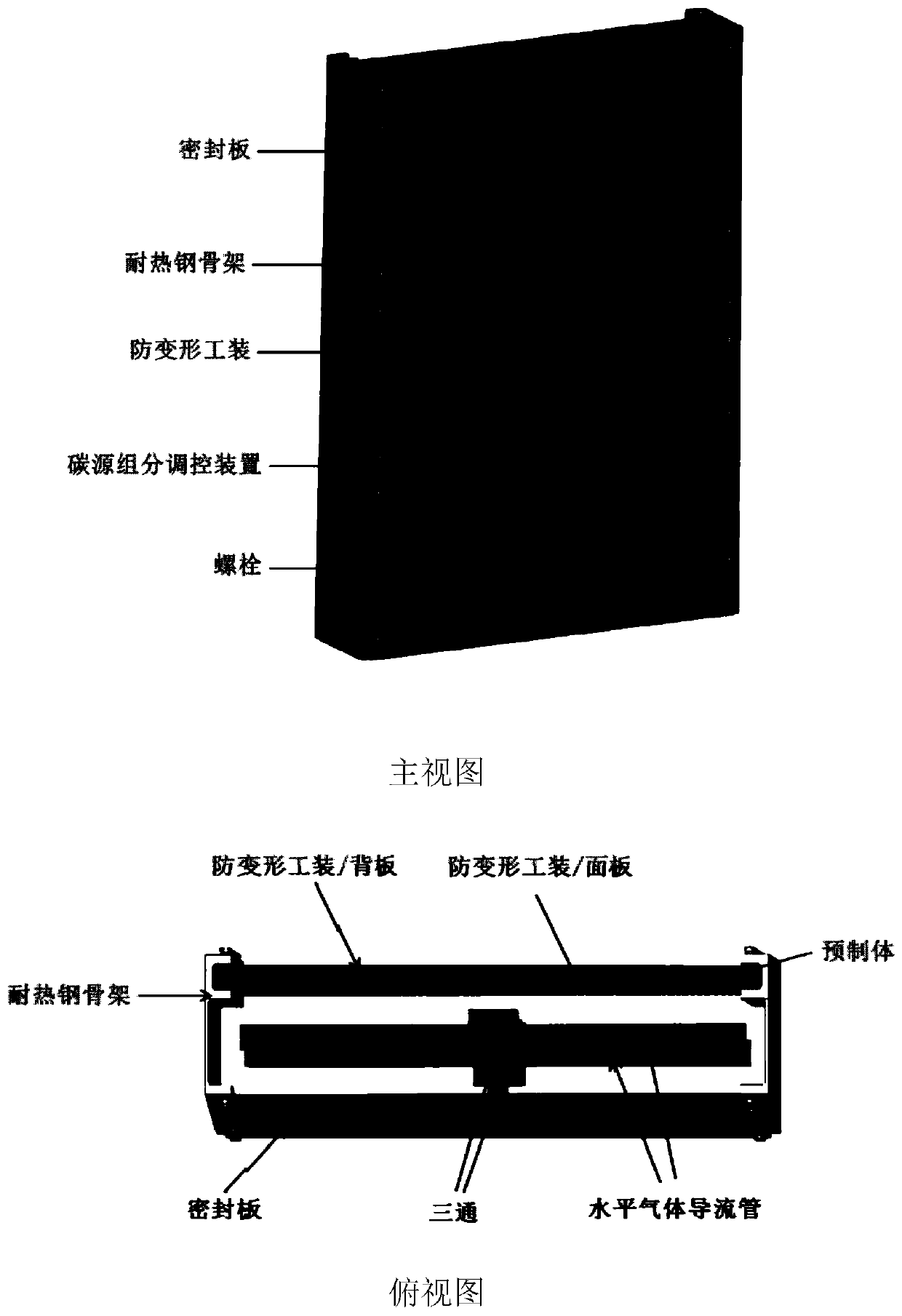

Ultra-large-size carbon/carbon composite material sheet and equipment for preparing the same

PendingCN111574237AReduce distortionAchieve near net shapeChemical vapor deposition coatingCarbon compositesCarbon fibers

The invention discloses a super-large-size carbon / carbon composite material sheet and equipment for preparing the same. The invention discloses a super-large-size carbon / carbon composite material sheet. A preparation method of the super-large-size carbon / carbon composite material sheet comprises the following steps: (1) designing and constructing a reactor; (2) clamping and loading a carbon fiberpreform; (3) performing carbon source component regulation and flow field control setting; (4) performing chemical vapor deposition densification; and (5) discharging and dismounting the tool. The invention further designs equipment matched with the process, the super-large-size carbon / carbon composite sheet with high straightness, uniform densification and small deformation can be obtained through cooperation of the equipment and the process, and a feasible method is provided for near-net forming preparation of the super-large-size carbon / carbon composite sheet.

Owner:CENT SOUTH UNIV

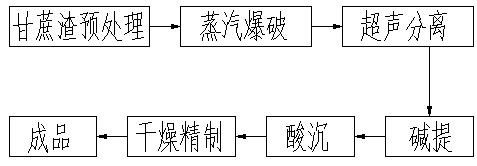

Method for separating lignin from bagasse, and special equipment thereof

The invention discloses a method for separating lignin from bagasse, and special equipment thereof. The method mainly comprises: (1) bagasse pretreatment; (2) steam explosion; (3) ultrasonic separation; 4) alkali extraction; (5) acid precipitation; and (6) drying refining. The present invention further provides the special equipment used by the method. According to the present invention, by adopting the synergetic treatment method of steam explosion and ultrasonic separation, the effective wall breaking on the bagasse is ensured, and the separation efficiency of the lignin is significantly improved so as to substantially improve the separation purity of the lignin in the bagasse; and the organic solvent is not used, and the designed equipment can ensure the smooth recovery of the waste liquid generated in the preparation process, such that the method is environmentally friendly.

Owner:广西洋荣科技有限公司

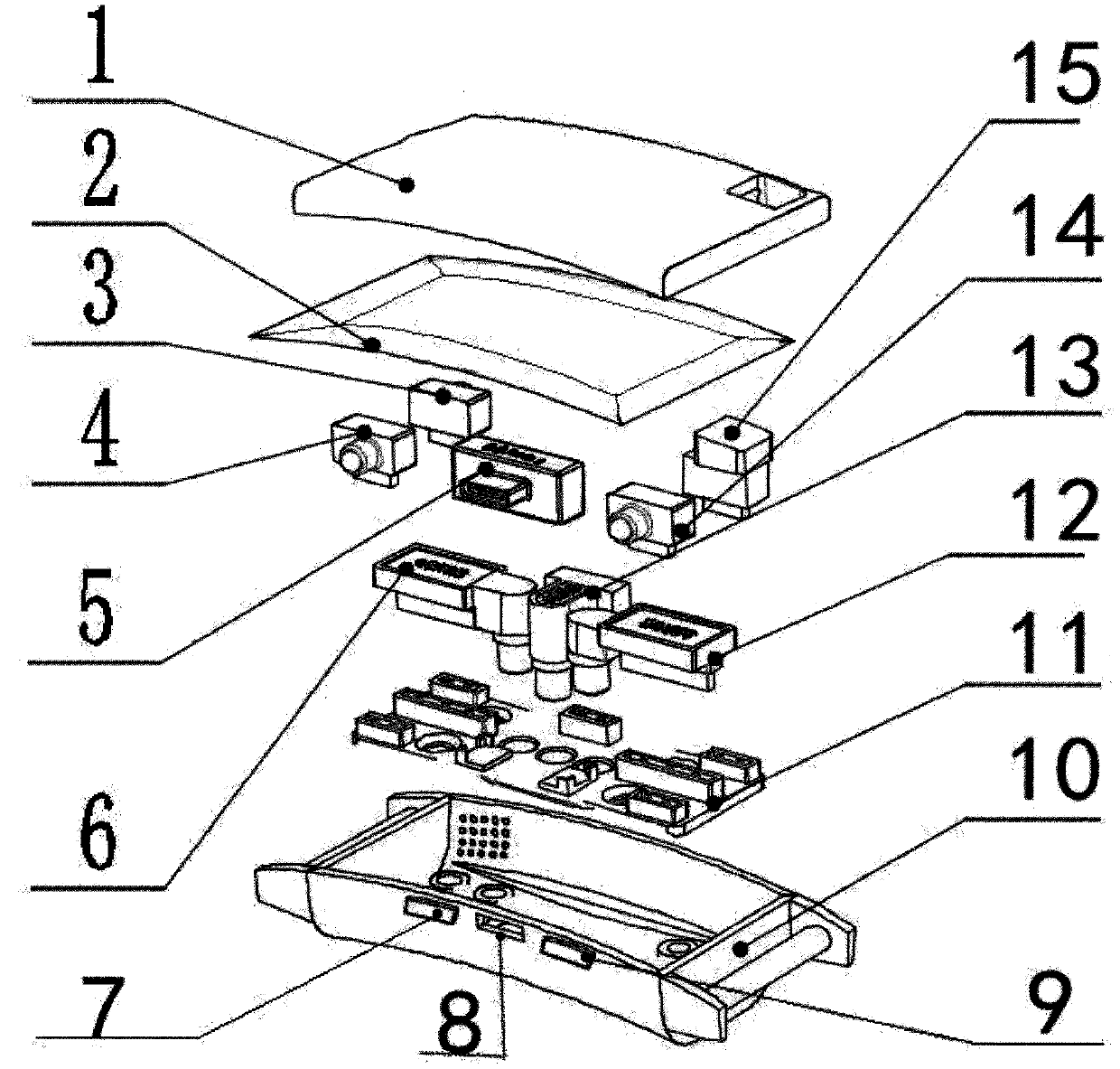

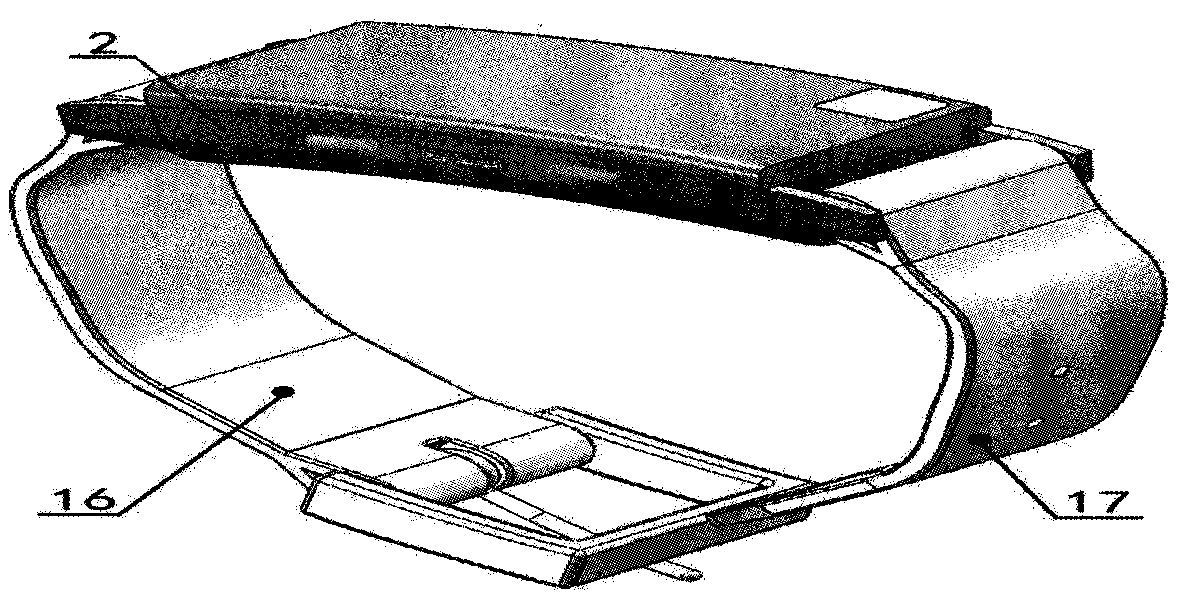

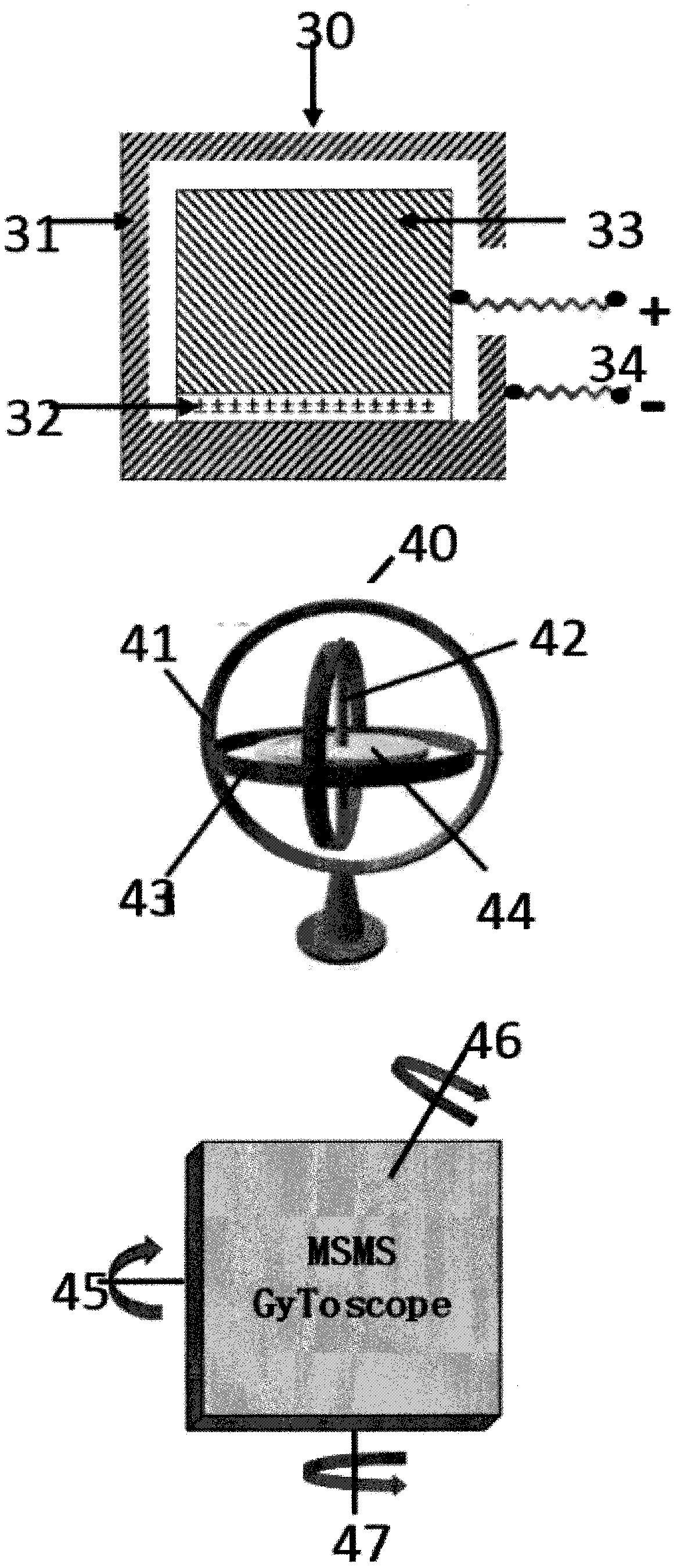

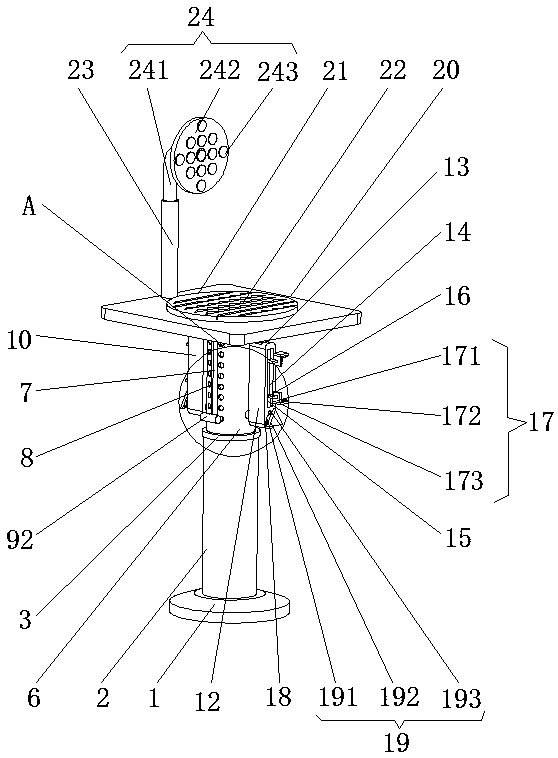

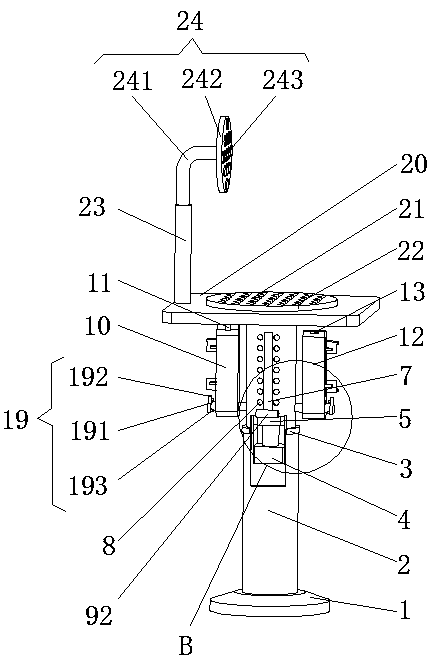

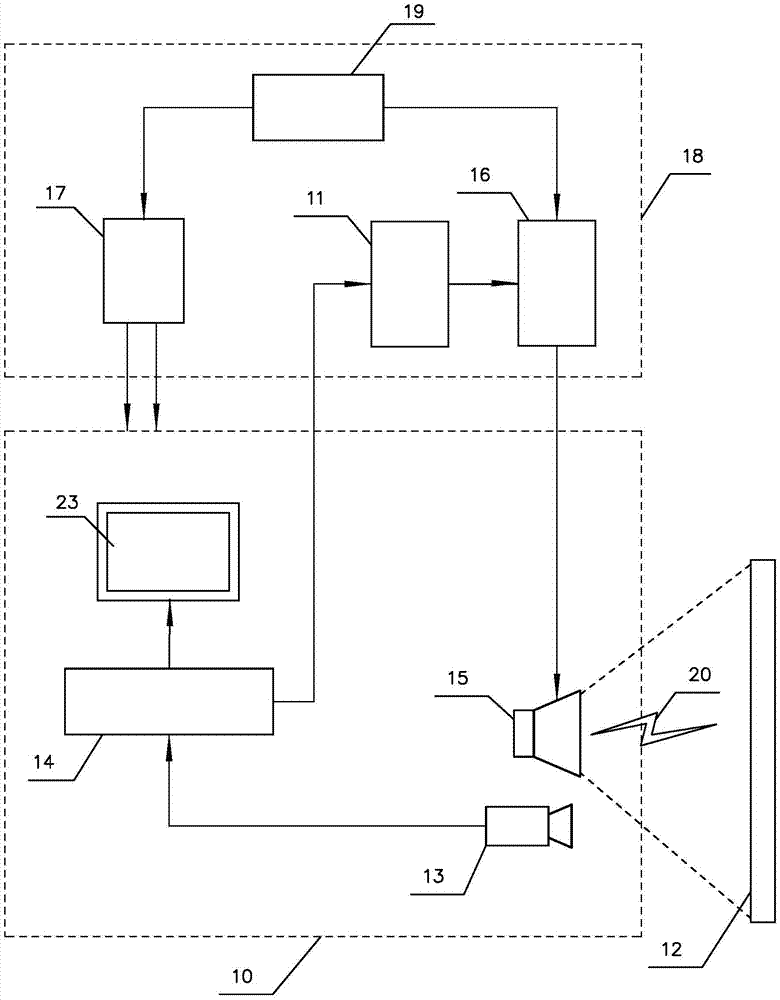

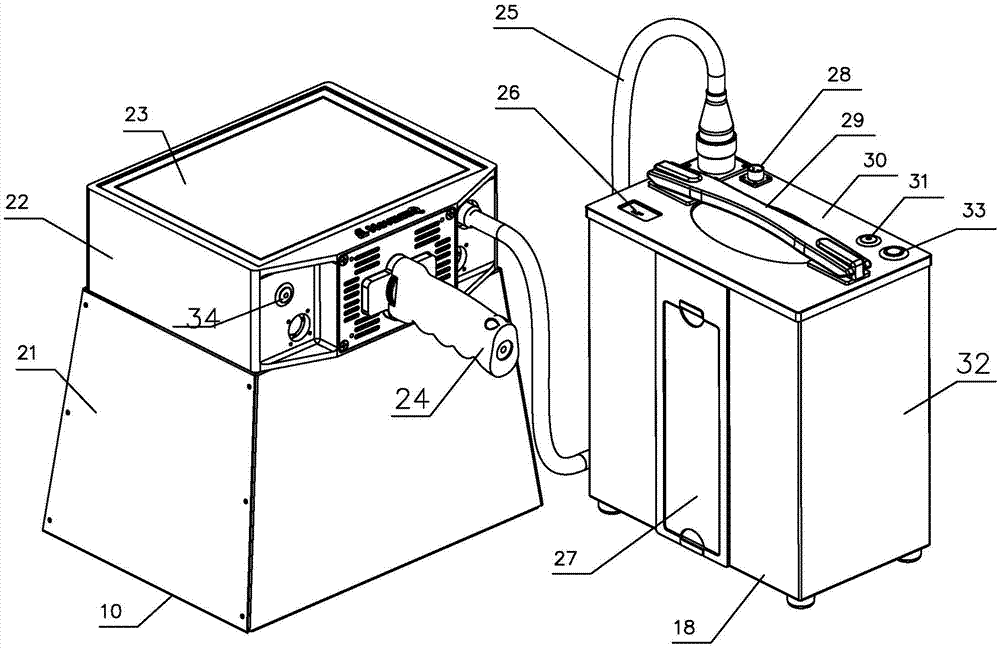

Home equipment for stroke monitoring and early detection and early warning

The invention designs equipment that can be used for early detection and early warning of the occurrence of stroke in non-medical environments such as home. The equipment comprises a main control module 11, a physiological data module 12, a walking habit module 14, a detection start button 9, a display module and touch screen 1, a camera 15, and a communication module 6, wherein the main control module 11 comprises a storage module, an activation module, a detection module and a data analysis module, the detection module of the equipment can be triggered by a user through the detection start button 9 to start the detection; or the detection is started after the comparison operation of data fed back to the activation module by the walking habit module 14 and the physiological data module 12, and corresponding data in the storage module. The equipment can also be provided with a pressure deformation band 2 and a pressure sensor 3 below the display module and the touch screen 1, and if there is no response and a pressure is not released after a certain period of time, the communication module 6 is triggered to contact an emergency contact or medical institution stored in the communication module.

Owner:董思羽 +1

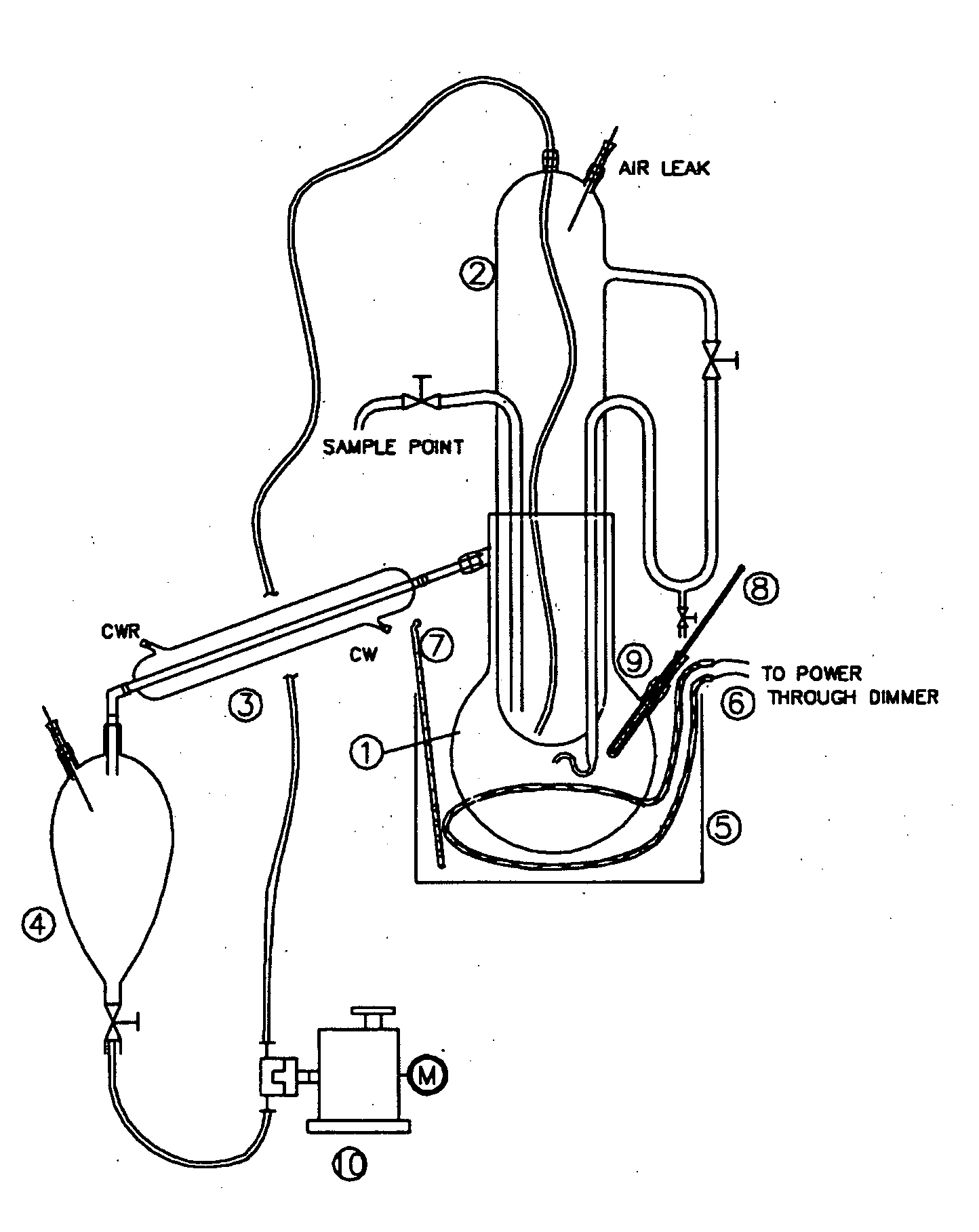

Process for the Preparation of Biodiesel from Vegetable Oils Containing High FFA

The present invention provides an improved process for the preparation of biodiesel from crude vegetable oils especially Jatropha (Jatropha curcas) and Karanja (Pongamia pinnata). In the preset invention the bio-active constituents, fatty acids and polar materials are selectively removed from the crude oils by liquid-liquid extraction with a polar solvent into the solvent phase in a non-destructive manner in specially designed equipment either in a batch mode or continuous mode and the oil left as residue is amenable for direct transesterification. After transesterification, the glycerol phase is separated and the crude biodiesel is neutralized, purified by adsorption of undesirable constituents like the residual glycerol, gums, soap, salts etc over a bed of adsorbent like Celite thereby circumventing the conventional water washing step. An alternative to the adsorbent method, the crude ester obtained after transesterification is purified using partition with aqueous solvent to biodiesel which meets the International specifications.

Owner:COUNCIL OF SCI & IND RES

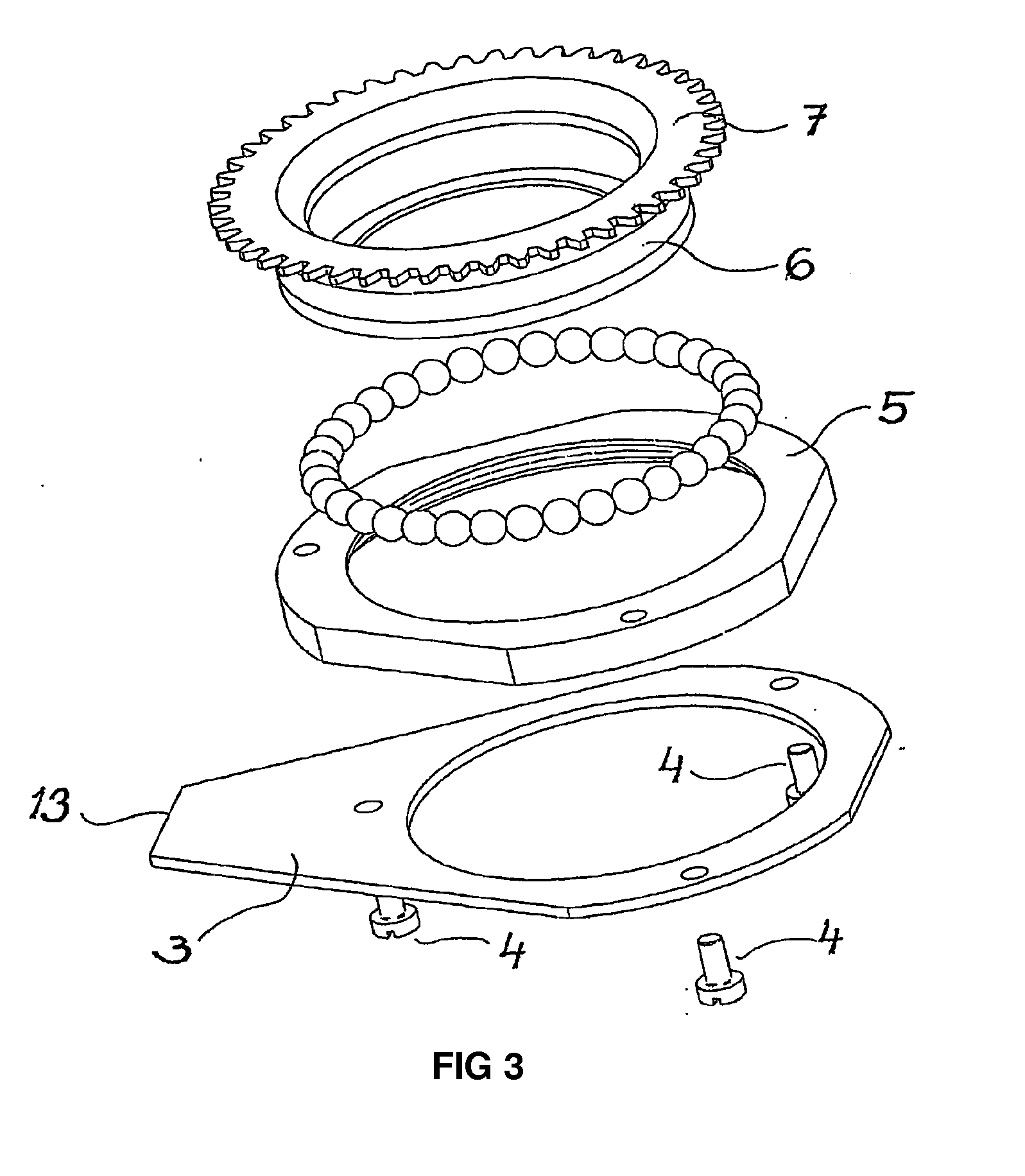

A spring slot & lock quick-change gobo changer system

InactiveCN102803830AEasy to placeSimple technologyLighting applicationsMechanical apparatusLight equipmentDesigned equipment

For lighting equipment for illumination of theatre and show stages and platforms there is designed equipment for quick change of rotary gobos (302) comprising a carrier disc (301) supporting interchangeable segments with the gobos. The individual segments are attached at the carrier disc by springs (303) which register the position of the segment on the gobo carrier while at the same time holding the segment in place.

Owner:ROBE LIGHTING

Power grid engineering material purchasing demand declaration method based on big data

InactiveCN110276665ASpeed up declarationSolve data source inconsistenciesBuying/selling/leasing transactionsInformation technology support systemData sourcePower grid

The invention discloses a power grid material declaration method. The method comprises the following steps: (1) creating an asset management system; (2) enabling the material application module to acquire required engineering information and create a material plan album; (3) enabling the material application module to acquire resource data online and compile the resource data into a material plan and technical information; (4) transmitting the material plan and the technical information to a technical specification book compiling module to generate a technical specification book; (5) forming a material plan album according to the technical specification; and (6) carrying out identity verification on the material plan album online and then exporting the material plan album, or directly exporting the material plan album offline, and taking the exported material plan album as the basis of the material demand plan. According to the invention, the power grid material declaration speed is accelerated, and the material declaration work is completed in a material inventory import mode; the problem of inconsistency of material data sources in a material list and a material list of design equipment is solved, the design list is rapidly converted into the material list, and the generation efficiency of the material list is improved.

Owner:南方电网能源发展研究院有限责任公司

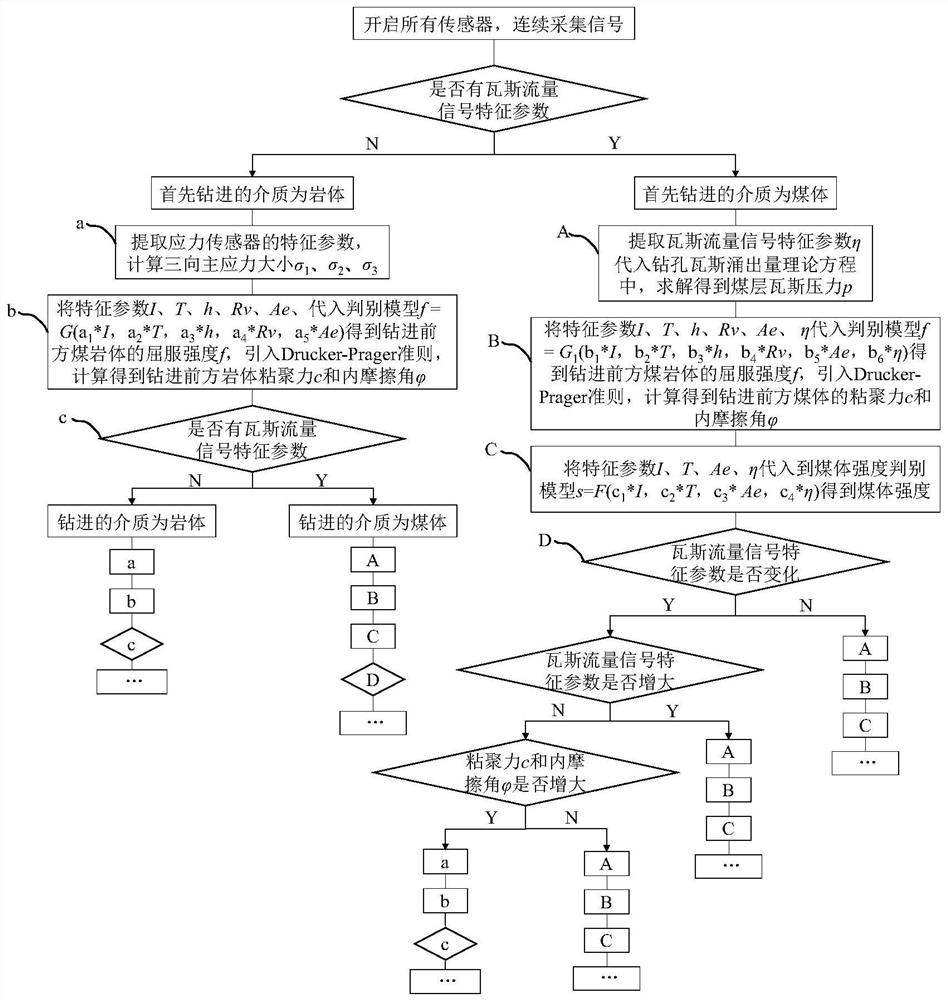

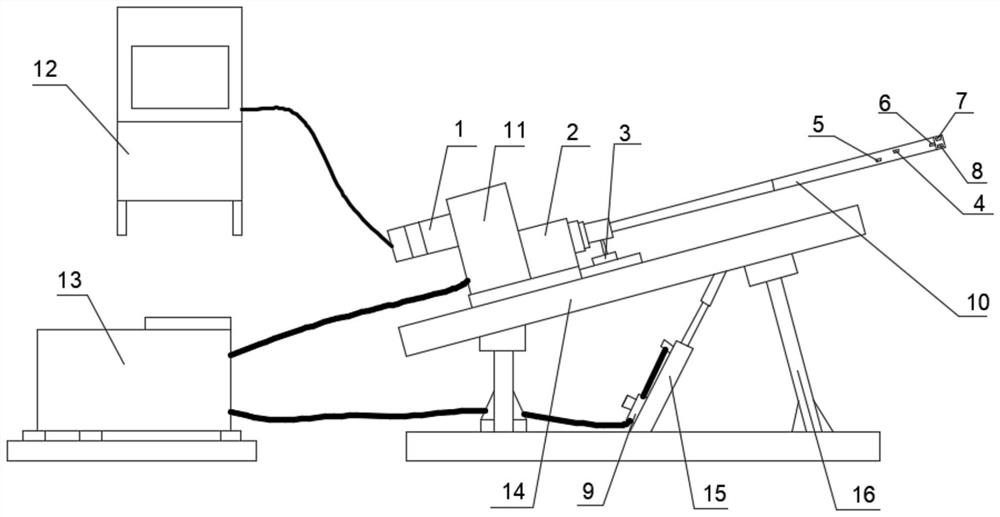

Method for measuring physical and mechanical parameters and stress state of underground coal and rock mass of coal mine while drilling

PendingCN114370263AAccurate pressureAccurate identificationSurveyMining devicesEarly warning systemMathematical model

The invention provides a method for measuring physical and mechanical parameters and stress states of coal and rock masses under a coal mine while drilling, which comprises the following steps of: acquiring parameters such as stress, drilling thrust, torque, rotating speed, acoustic emission, gas flow and the like in real time; a mathematical model is used for analyzing the parameters to obtain the three-dimensional stress state of the coal and rock mass in front of the drill hole, the cohesive force and the internal friction angle of the coal and rock mass and the hardness degree of the coal body, and therefore the purpose of rapidly and accurately obtaining the physical and mechanical properties and the stress state of the coal and rock mass in front of the drill hole in the drilling process is achieved. The invention further designs equipment capable of monitoring, transmitting and analyzing multiple parameters obtained in the drilling process in real time, and by means of the equipment, the coal rock mass property and the coal seam gas pressure in front of drilling can be rapidly and accurately obtained and transmitted to a ground early warning system in real time, so that a basis is provided for outburst prediction and early warning.

Owner:CCTEG CHINA COAL RES INST

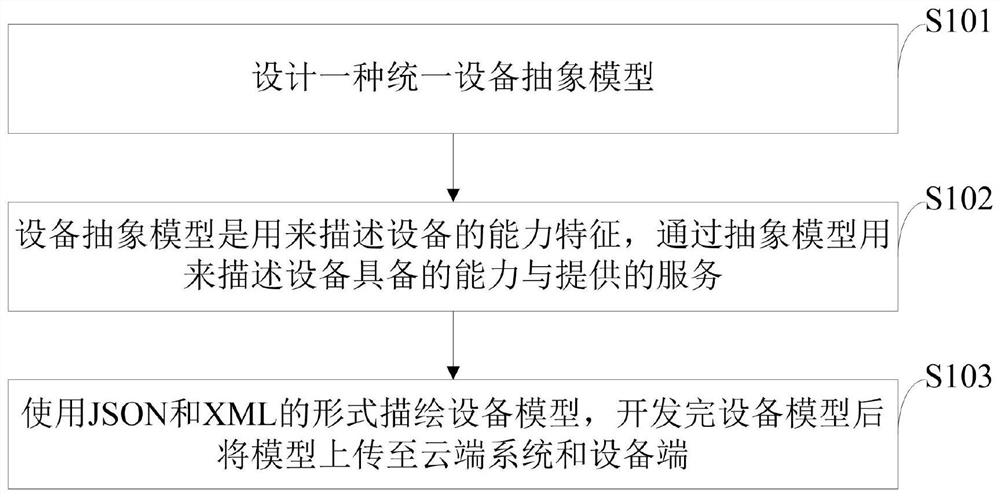

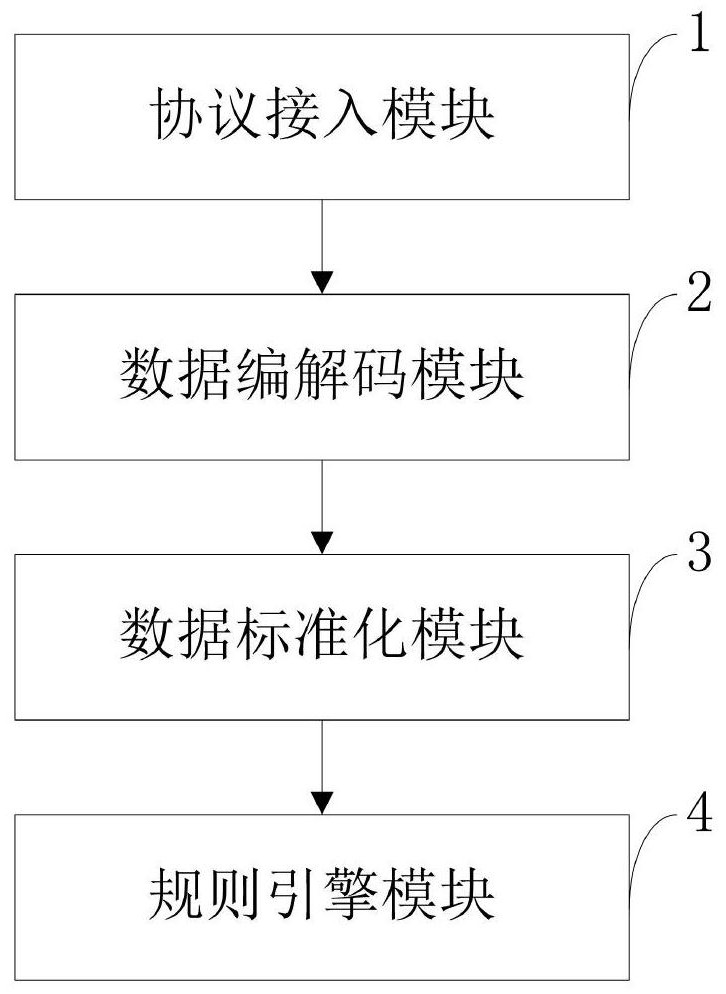

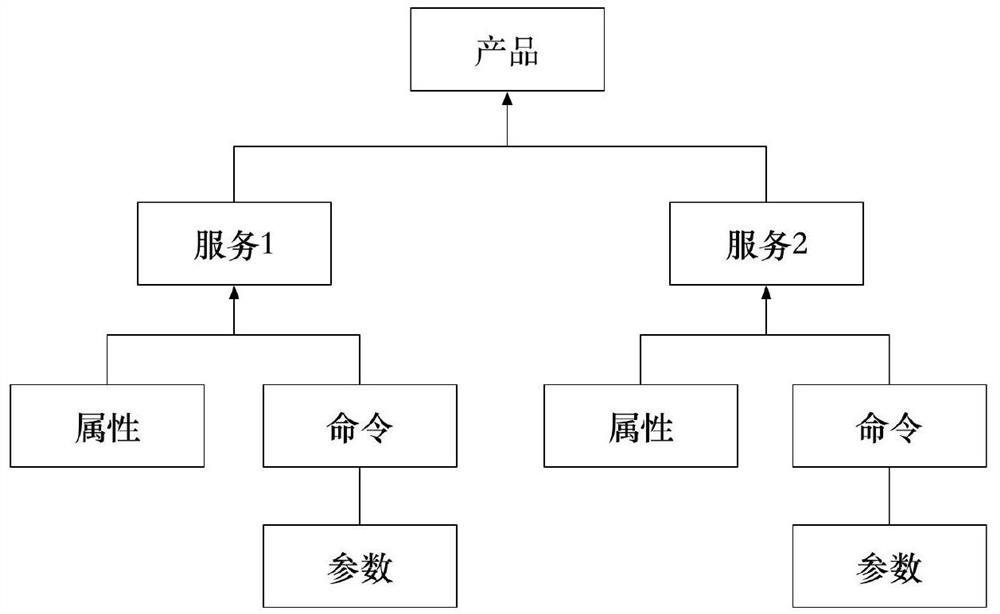

Method for accessing and managing massive Internet of Things devices

InactiveCN113132192ASolve access difficultiesSolve the costInstrumentsWide area networksDevice typeAccess technology

The invention belongs to the technical field of Internet of Things, discloses a mass Internet of Things equipment access and management method, and designs a unified equipment abstract model. The equipment abstract model is used for describing the capability characteristics of the equipment, and the abstract model is used for describing the capability of the equipment and the provided service; and the equipment model is described in the forms of JSON and XML, and the model is uploaded to a cloud system and an equipment end after the equipment model is developed. And the capability characteristics of the equipment are equipment model identification attributes: equipment type, manufacturer, model, protocol type, service supported by the equipment, attribute and control command. According to the method, the steps are simple and clear, the massive heterogeneous equipment is subjected to standardization processing by designing the equipment unified description model, and a very good effect can be achieved. Compared with the existing Internet of Things access technology, the mass Internet of Things equipment access and management method provided by the invention fundamentally solves the problems of difficulty in Internet of Things equipment access, high cost, poor safety and difficulty in interaction.

Owner:XIDIAN UNIV

Heightening frame with adjustable height, for graphic design

ActiveCN108561687AHeight adjustableEffective and stable workStands/trestlesDrawing desksEngineeringLantern

The invention relates to the technical field of graphic design equipment, and discloses a heightening frame with an adjustable height, for graphic design. The heightening frame with the adjustable height, for graphic design comprises a fixed base, wherein the middle part of the upper surface of the fixed base is fixedly connected with the bottom ends of support legs; a fixed lantern ring fixedly sleeves outside the top end of each support leg; an electric push rod is fixedly installed in an inner cavity in the top end of each support leg; the bottom of a housing of each electric push rod is fixedly connected with the bottom of the inner cavity in the top end of the corresponding support leg; and a push shaft of each electric push rod is fixedly connected with the bottom end of a push rod.According to the heightening frame with the adjustable height, for graphic design, efficient adjustment is carried out on the height of the heightening frame through the action of the electric push rods and according to the need of the height in graphic design working; and meanwhile, efficient stabilization working is carried out on the heightening frame after the height adjustment through the action of a limit device, so that the stability of the heightening frame is greatly improved while the heightening frame is enabled to have an efficient height adjustment function.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

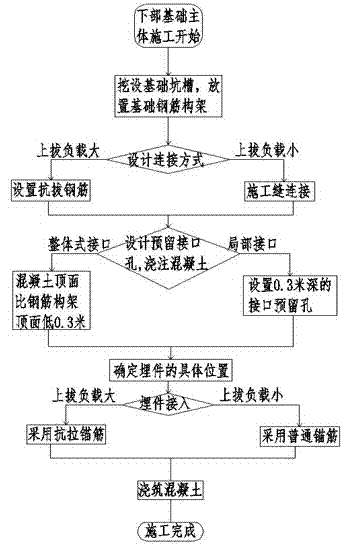

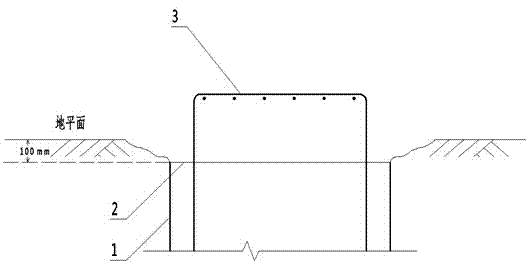

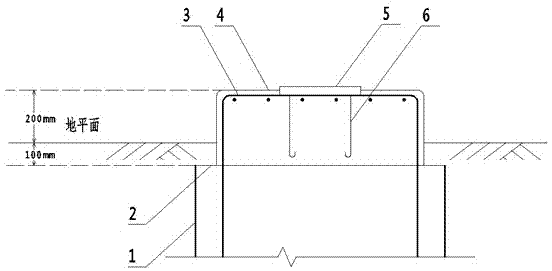

Electrical equipment foundation two-step type construction method

The invention discloses an electrical equipment foundation two-step type construction method used for construction of an electrical equipment foundation. The method includes the processes of foundation lower body construction and embedded part foundation construction. The foundation lower body construction includes the following steps that A1, a foundation pit slot of electrical equipment is dug, and a foundation reinforcement frame is placed in the foundation pit slot; A2, the connecting mode of the equipment is designed, and anti-drawing connection or common connection is designed according to actual requirements. The embedded part foundation construction includes the following steps that A3, concrete is poured into the foundation pit slot for the first time, and joint preformed holes are reserved; B1, the specific positions of embedded parts are determined; B2, embedded part anchor bars are arranged according to actual requirements; B3, concrete is poured for the second time. The accuracy and the flatness technological level of main electrical equipment embedded parts of a transformer substation can be improved, the degree of dependence of construction on manufacturer data is reduced, and the construction time of the equipment foundation embedded parts is shortened.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Portable nondestructive testing system for flashlight excitation heat waves

The invention discloses a portable nondestructive testing system for flashlight excitation heat waves. The system comprises a high-power flashlight, an infrared imager, a data processing and displaying system, a touch screen displayer, a flashlight control unit and a flashlight power source. The portable nondestructive testing system has the advantages that the designed equipment structure is compact and portable, the infrared imager, the high-power flashlight, a data processing unit and the touch screen displayer are integrated in a portable detection module, the flashlight control unit and a power source supply unit are integrated in a power source control system module, and other external power sources are not needed during use; operators can hold a detection unit by one hand to generate heat waves on sample surfaces through high-energy pulse thermal excitation and test the heat waves; the equipment is operated and controlled by a touch screen, and a man-machine interface is simple and convenient.

Owner:NANJING NOVEL PHOTOELECTRIC SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com