Electrical equipment foundation two-step type construction method

A technology of power equipment and construction methods, which is applied in infrastructure engineering, construction, etc., can solve problems such as difficult to meet the requirements of project quality and progress, tight construction period, and many bidding batches, so as to improve connection stability and reduce engineering costs. The cost and the effect of improving the technological level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

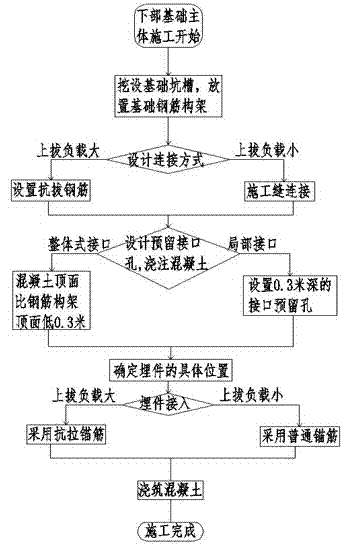

[0041] The construction process of the foundation embedded parts of the 500KVGIS outlet interval includes the following steps,

[0042] The construction of the main body of the lower part of the foundation includes the following steps,

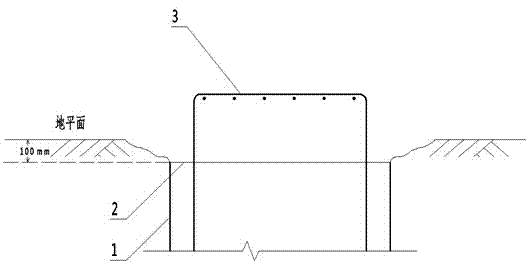

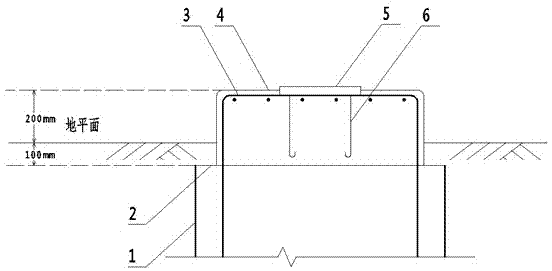

[0043] A1. According to the external dimensions of the 500KVGIS outgoing line interval in previous similar projects, the width of the 500KVGIS outgoing line interval can be determined to be about 2.7 meters. The foundation pit 1 of the electric equipment is excavated to be about 3 meters, and the foundation steel frame 3 is placed in the foundation pit 1;

[0044]A2. Design the connection method of the 500KVGIS outgoing line interval. The pull-up load of the 500KVGIS outgoing line interval is greater than 80% of the equipment's own weight, and the pull-out steel bars are set in the foundation pit 1;

[0045] A3. Concrete is poured for the first time in the foundation pit 1, and the reserved hole is designed for the interface: the cross-section...

Embodiment 2

[0051] The construction process of the foundation embedded parts of the 500KVGIS busbar interval includes the following steps,

[0052] The construction of the main body of the lower part of the foundation includes the following steps,

[0053] A1. The shape and size of the 500KVGIS busbar interval can be determined according to the external dimensions of the 500KVGIS outgoing line interval in similar projects in the past, and the foundation pit 1 of the power equipment is excavated, and the foundation steel frame 3 is placed in the foundation pit 1;

[0054] A2. Design the connection method of the 500KVGIS busbar interval. The uplift load of the 500KVGIS busbar interval is less than 80% of the weight of the equipment itself. No pullout steel bars are set in the foundation pit 1, and the ordinary connection method is adopted;

[0055] A3. Concrete is poured for the first time in the foundation pit 1, and the reserved hole is designed for the interface: the cross-sectional area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com