Pure water filling equipment

A filling equipment and pure water technology, applied in barrel/cask filling, liquid filling, etc., can solve the problems of slow waste of manpower and material resources, slow water filling speed, and filling can not be carried out, and achieve speed saving time and effort, Fast speed and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

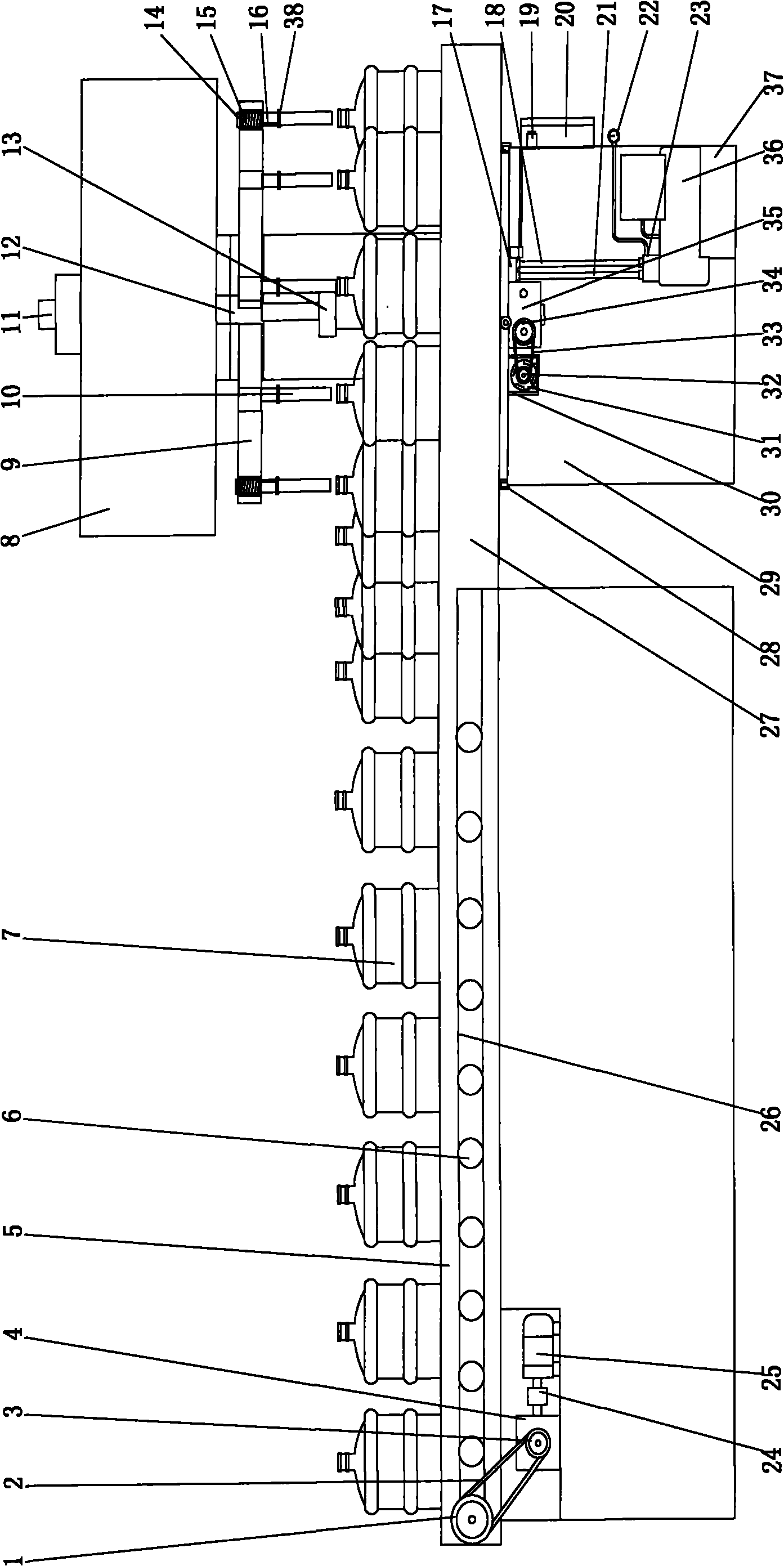

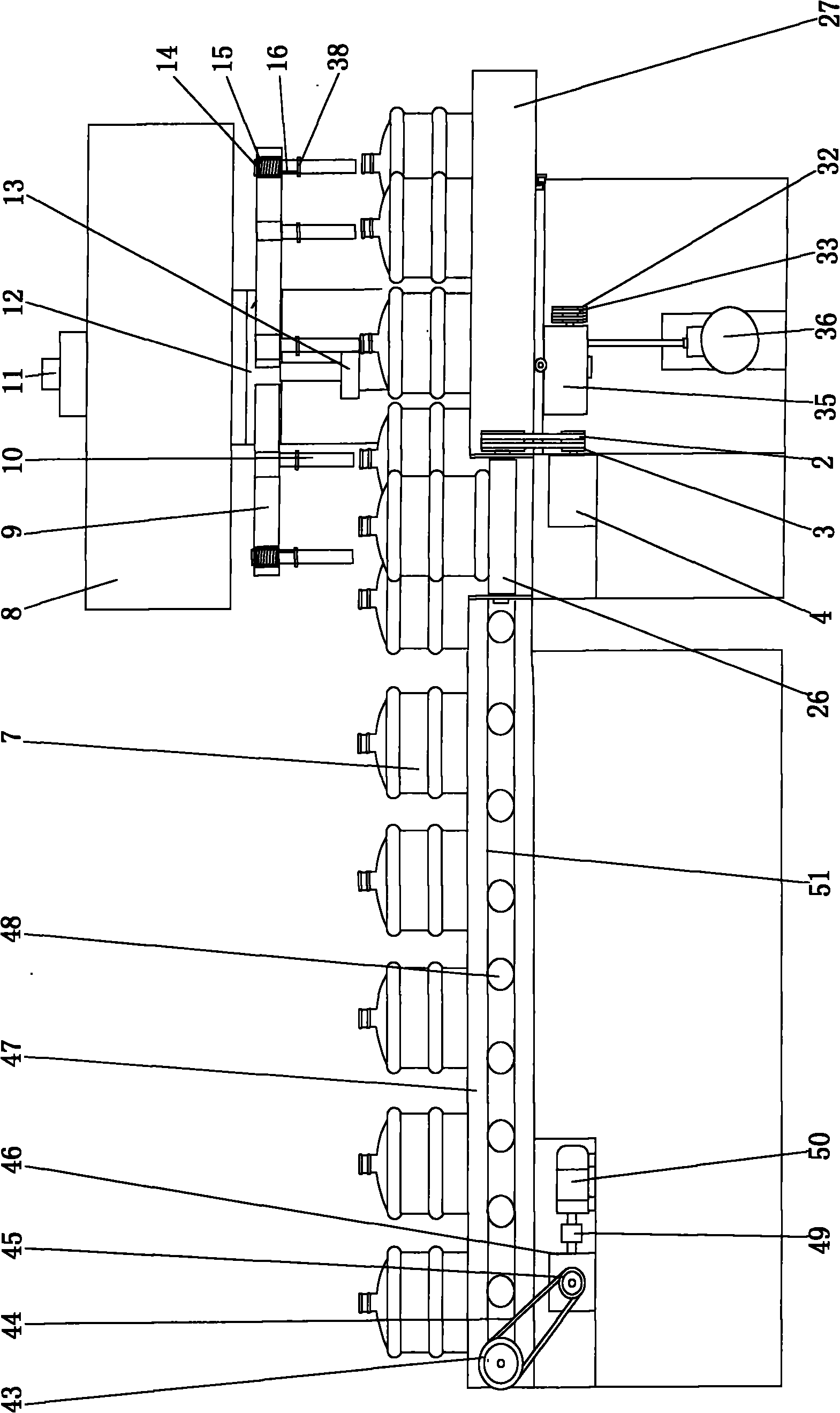

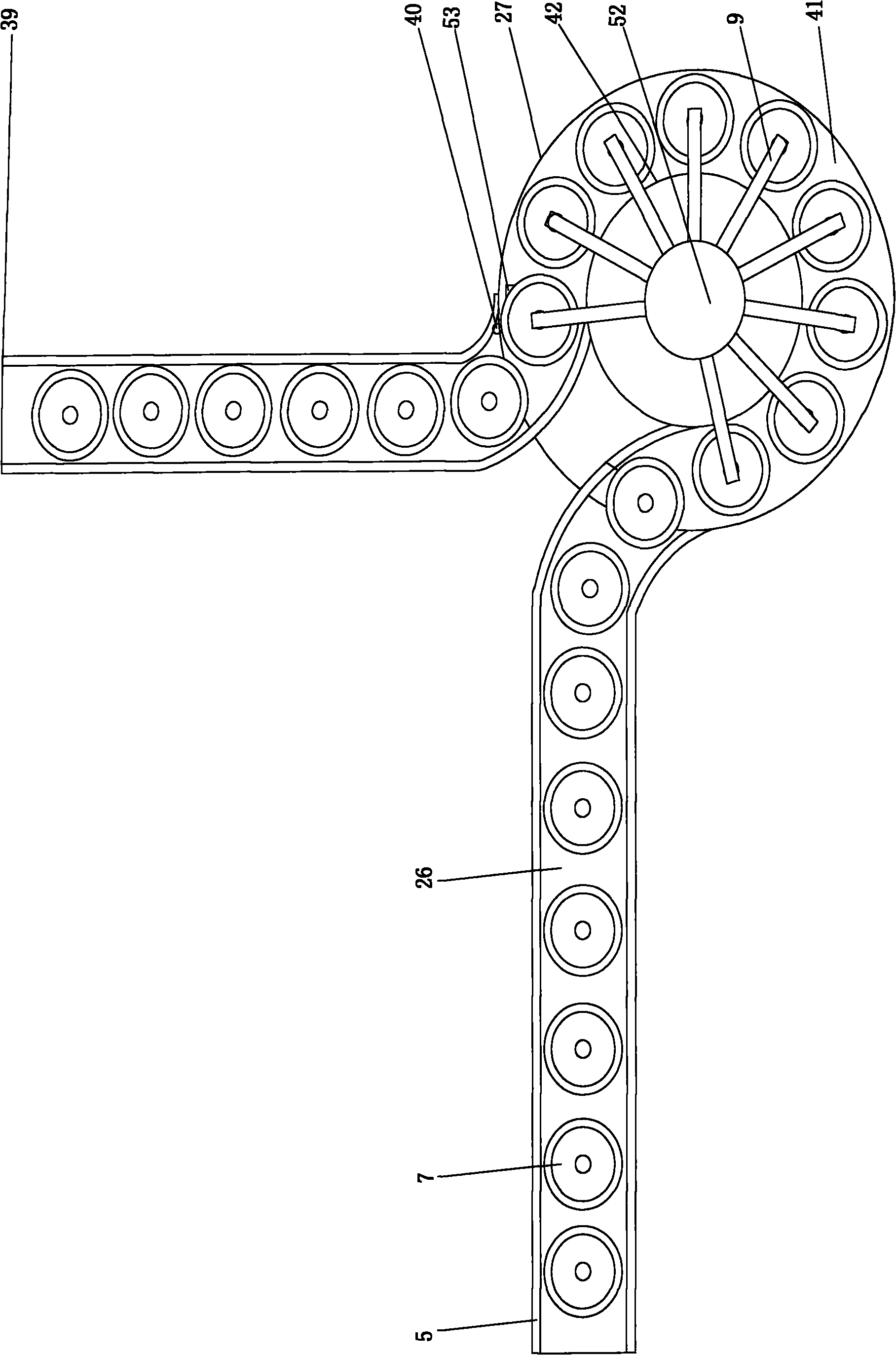

[0012] The pure water filling equipment is mainly composed of a turntable, a barrel conveyor belt, a water tank, a water injection rod, a water injection pipe, a cylinder, an air compressor, etc. It is characterized in that: press the main switch (19) located in the electrical box (20) Turn on the power supply of the whole machine, the rotation of the motor I (25) drives the rotation of the gearbox I (4) connected through the connection plate I (24), and the pulley I (3) on the gearbox I (4) rotates through the belt I (2) Drive main belt pulley I (1) to rotate, main belt pulley I (1) drives conveyor belt I (26) under the effect of roller shaft I (6) bucket (7) is moved to turntable baffle plate (27) along baffle plate I (5). ), when the bucket enters the turntable (41) connected by the turntable roller (28) above the turntable (29), the motor II (31) installed on the bracket (30) rotates to drive the front pulley II (32 ) to rotate, the belt pulley II (32) drives the main pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com