Oiler

A technology for oiling machines and oil tanks, which is applied to mechanical equipment, gear lubrication/cooling, belts/chains/gears, etc., and can solve problems such as oil stains being coated in keyways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

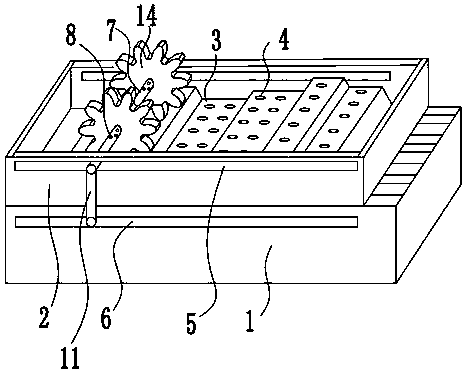

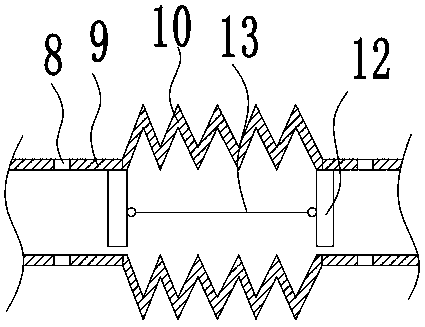

[0029] The reference signs in the drawings of the description include: fuel tank 1, oil pool 2, pool bottom 3, leakage hole 4, first slideway 5, second slideway 6, rotating shaft 7, spray hole 8, straight pipe 9, corrugated Pipe 10, oil delivery pipe 11, baffle plate 12, connecting rod 13, gear 14.

[0030] Such as figure 1 and figure 2 As shown, the oiler includes an oil tank 1, an oil pool 2 and an oil delivery pipe 11 connecting the oil tank 1 and the oil pool 2; The oil pool 2 is supported by the support net without affecting the passage of the oil leaked from the oil leakage hole.

[0031] The oil pool 2 is provided with an ups and downs pool bottom 3 that can be touched by the gear 14. The pool bottom 3 is provided with a plurality of leakage holes 4 for oil leakage; the pool walls on both sides of the pool bottom 3 are provided with 3 first slideways 5 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com