A filling method for the thick coal seam layered mining working face to pass through the old roadway of the lower layer

A layered mining and working face technology, which is applied in the direction of filling, mining equipment, earth cube drilling, etc., can solve the problems of threatening the safety production of coal mines, unreal filling of the old roadway of the lower layer, and the influence of the old roadway of the lower layer, etc. Achieve the effects of promoting sustainable and healthy development, good weathering resistance, and saving underground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

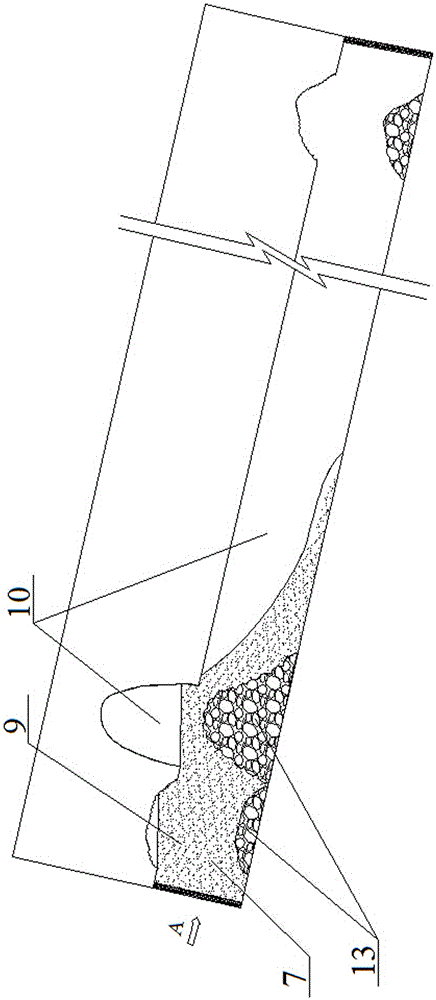

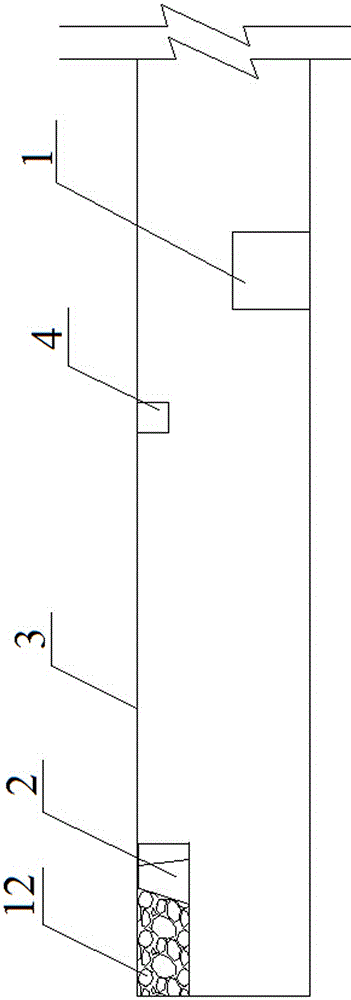

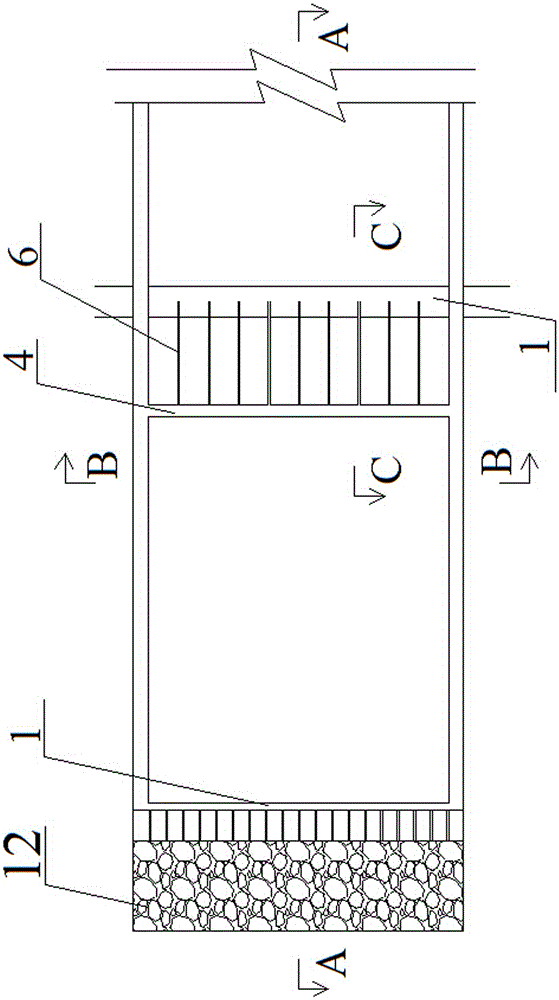

[0034] Such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the filling method of the thick coal seam layered mining face in this embodiment through the lower layered old roadway includes the following steps:

[0035] (1) Draw the layout diagram of the layer relationship between the old lane 1 of the lower stratum and the working face 2 of the upper stratum, mark in detail the position of the old lane of the lower stratum and the positional relationship between the old lane of the lower stratum and the working face of the upper stratum, and mark at the same time Out of goaf 12;

[0036] (2) Arrangement of filling roadway: Excavate a coal roadway parallel to the long axis of the old roadway of the lower layer along the roof 3 of the working face of the upper layer, as the filling roadway 4, and the horizontal distance between the filling roadway and the old roadway of the lower layer is 5m, the section size of the filling roadway is height: 1.8m, wi...

Embodiment 2

[0039] Such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the filling method of the thick coal seam layered mining face in this embodiment through the lower layered old roadway includes the following steps:

[0040] (1) Draw the layout diagram of the layer relationship between the old lane 1 of the lower stratum and the working face 2 of the upper stratum, mark in detail the position of the old lane of the lower stratum and the positional relationship between the old lane of the lower stratum and the working face of the upper stratum, and mark at the same time Out of goaf 12;

[0041] (2) Arrangement of filling roadway: Excavate a coal roadway parallel to the long axis of the old roadway of the lower layer along the roof 3 of the working face of the upper layer, as the filling roadway 4, and the horizontal distance between the filling roadway and the old roadway of the lower layer is 8m, the cross-sectional size of the filling roadway is height: ...

Embodiment 3

[0046] Such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the filling method of the thick coal seam layered mining face in this embodiment through the lower layered old roadway includes the following steps:

[0047] (1) Draw the layout diagram of the layer relationship between the old lane 1 of the lower stratum and the working face 2 of the upper stratum, mark in detail the position of the old lane of the lower stratum and the positional relationship between the old lane of the lower stratum and the working face of the upper stratum, and mark at the same time Out of goaf 12;

[0048] (2) Arrangement of filling roadway: Excavate a coal roadway parallel to the long axis of the old roadway of the lower layer along the roof 3 of the working face of the upper layer, as the filling roadway 4, and the horizontal distance between the filling roadway and the old roadway of the lower layer is 10m, the cross-sectional size of the filling roadway is height:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com