Manufacturing method of full back electrode solar cell

A technology for solar cells and manufacturing methods, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as high manufacturing costs and prices, difficult doping and diffusion control, and difficult alignment of graphics. Large-scale industrial production and application, good product uniformity, and high battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0031] Based on the description of the relevant prior art in the background art, in the following embodiments of the present invention, the structure and principle of the all-back electrode solar cell will not be described in detail to save space.

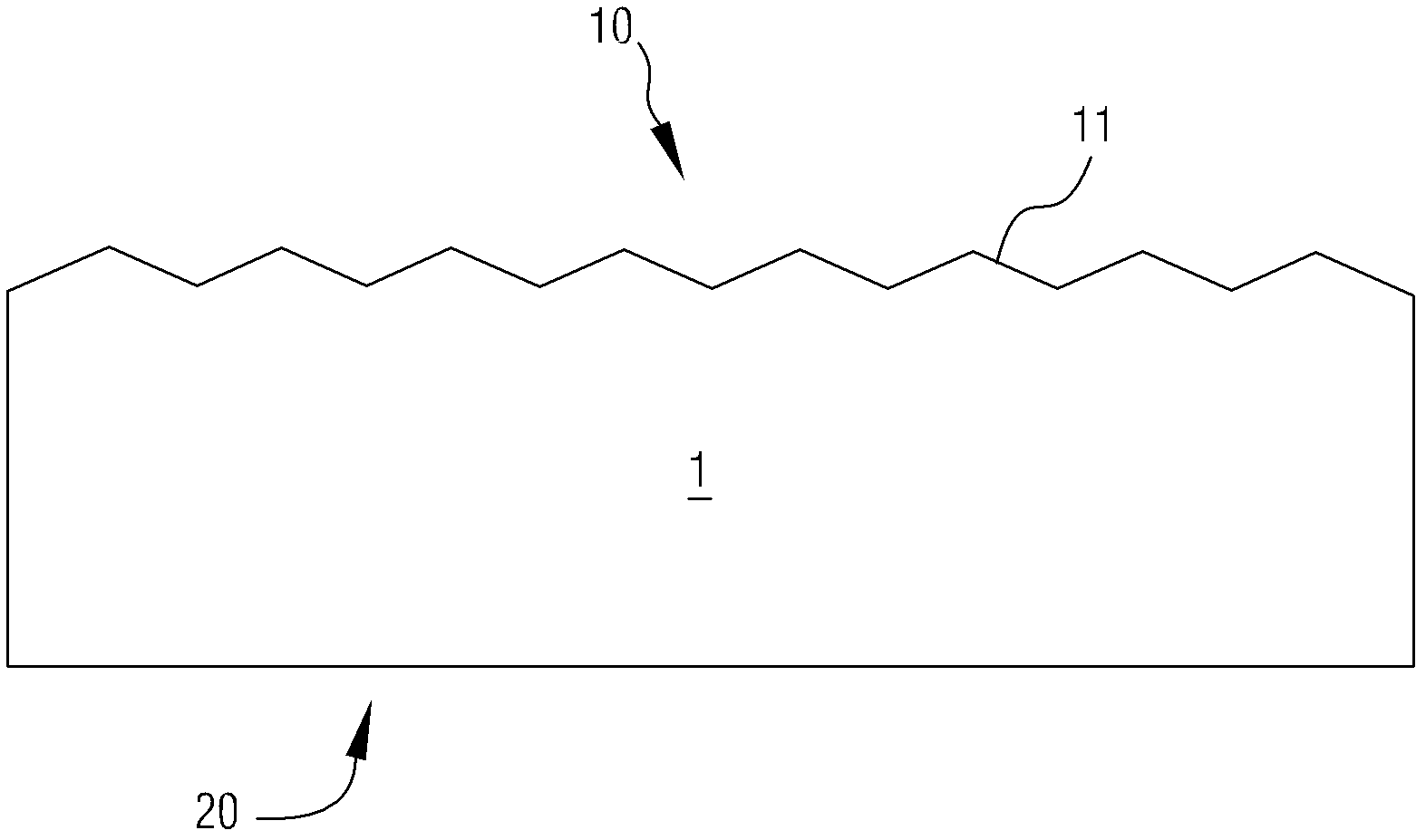

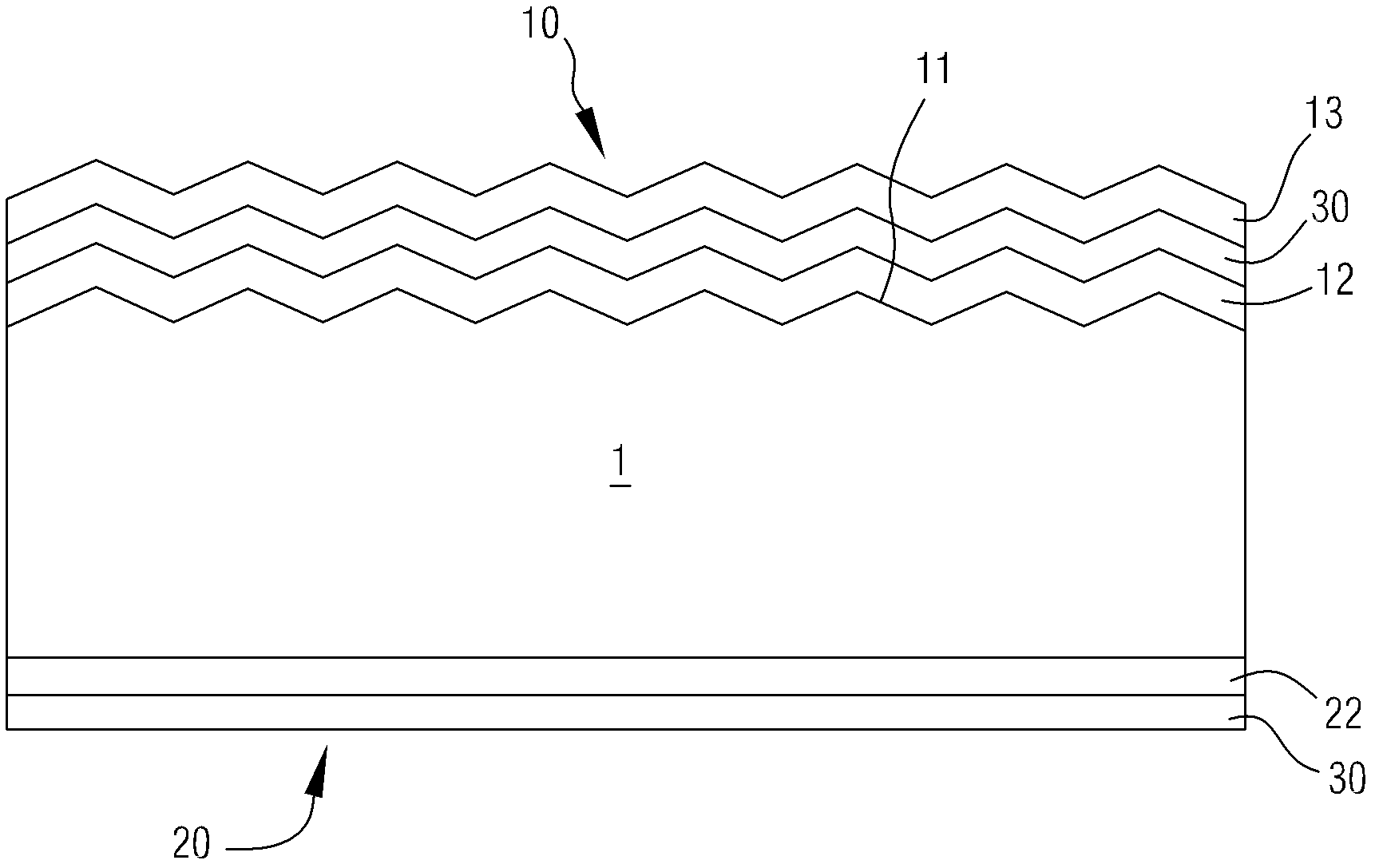

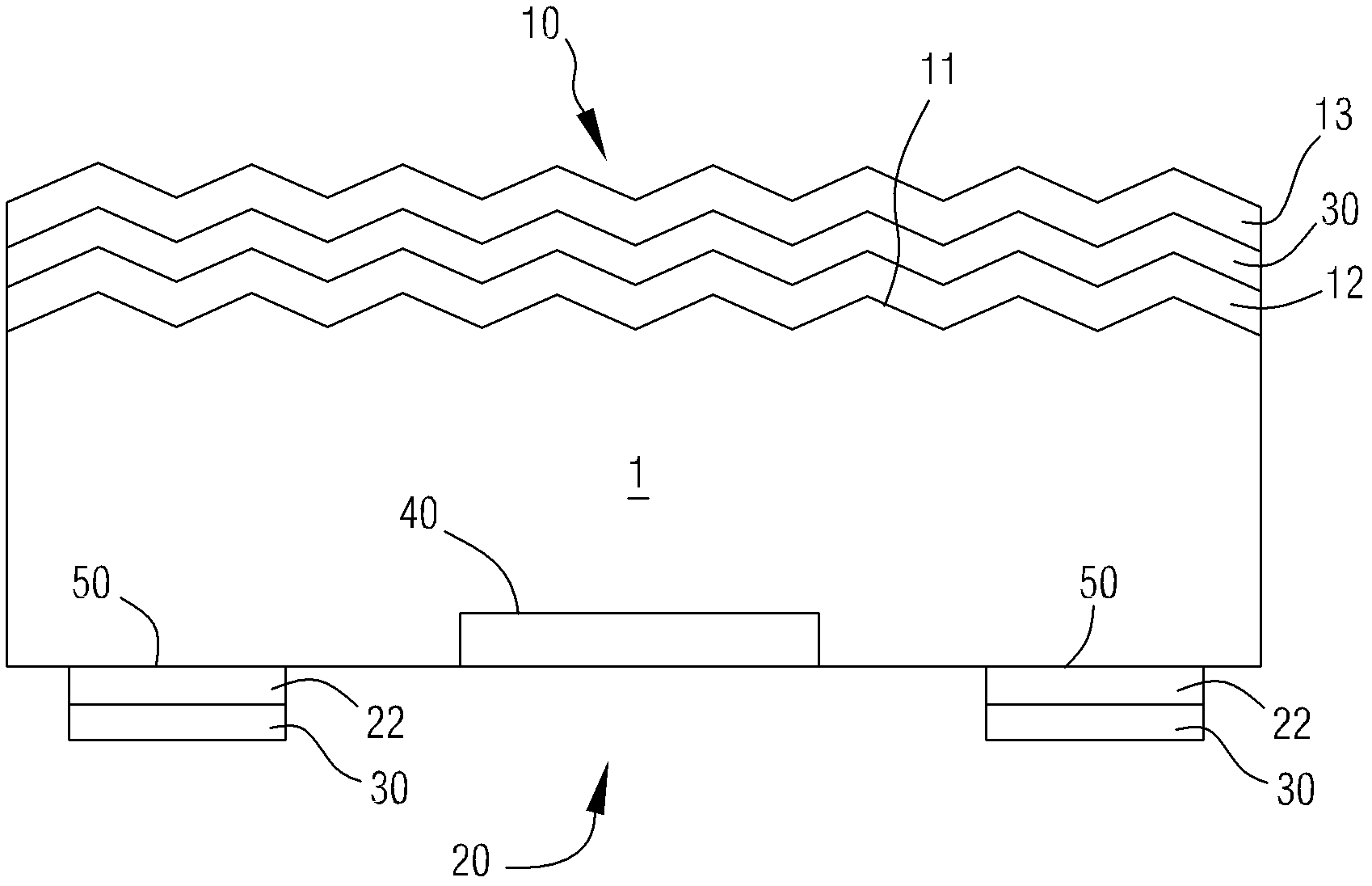

[0032] According to a specific embodiment of the present invention, a method for making a full-back electrode solar cell can refer to Figure 1-5 The process flow is described in detail, as shown in the figure, in the manufacturing method of the full back electrode solar cell of the present invention, the solar cell includes a silicon wafer 1, in this embodiment, the silicon wafer 1 is an N-type silicon wafer, The silicon chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com