Process for the Preparation of Biodiesel from Vegetable Oils Containing High FFA

a technology of vegetable oils and biodiesel, which is applied in the direction of biofuels, fatty-oils/fat refining, fuels, etc., can solve the problem of uneconomical commercial production of direct transesterification of oils containing free fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

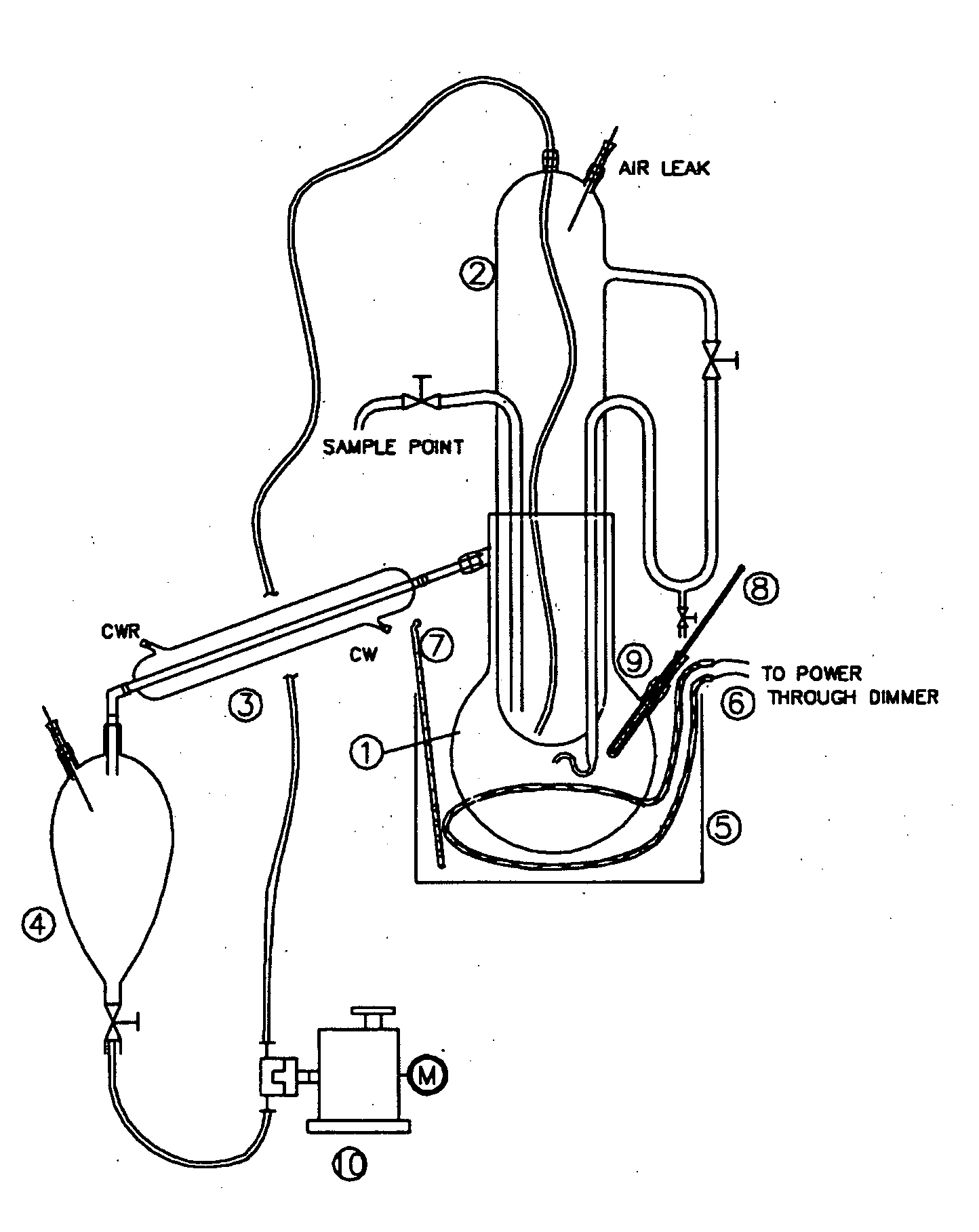

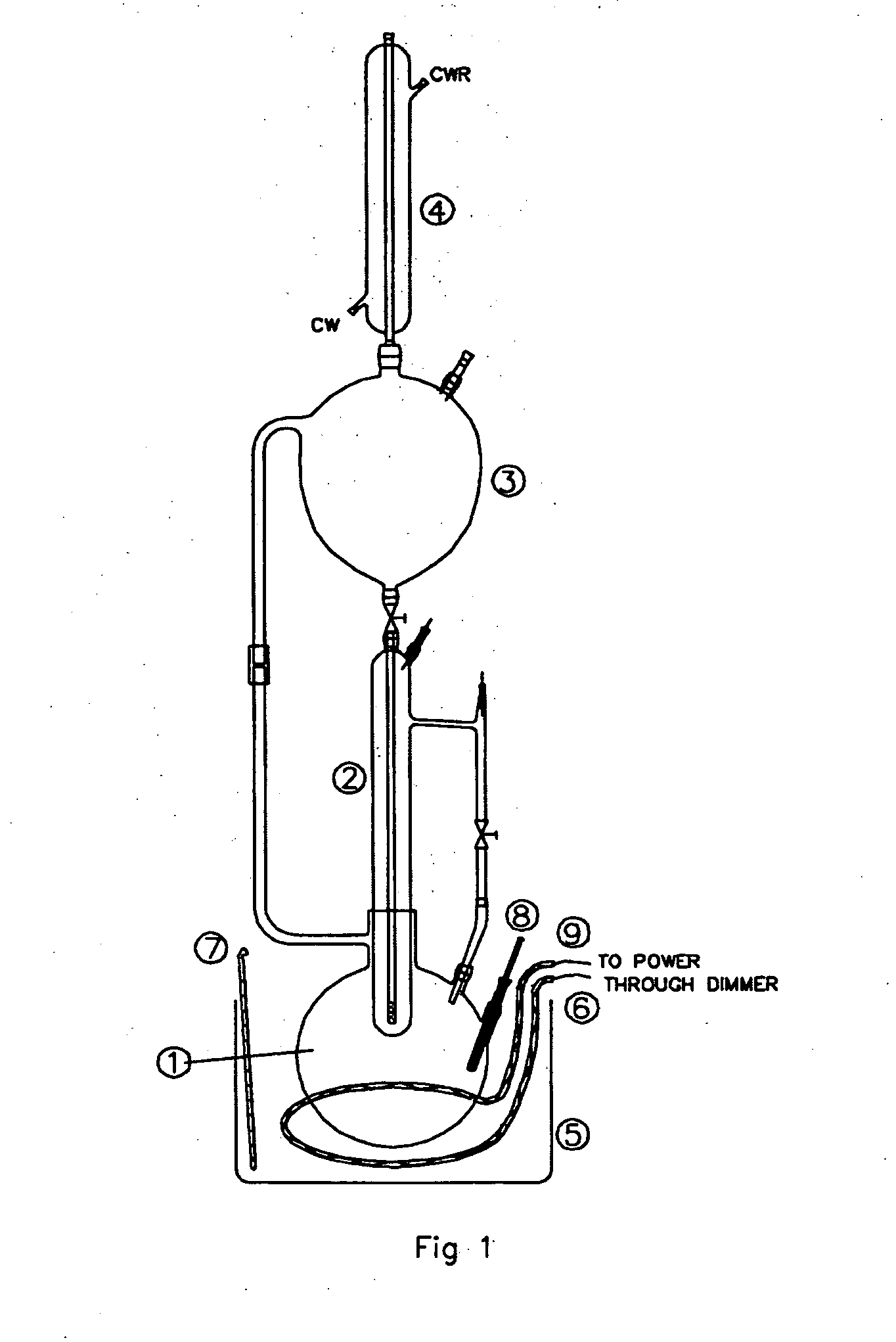

[0079]100 g of the synthetic mixture of the above mentioned mixture (feed) having an acid value of 8.6 is extracted (LLE) using IICT-RaoKVSA Liquid-Liquid Extractor-1 for a period of 5 hrs with continuous manual addition of the solvent. Raffinate samples were drawn at regular intervals and after solvent removal acid value was determined. The acid value was decreased to 0.7 after 5 hrs.

example 2

[0080]100 g of the synthetic mixture as above example 1, is extracted using IICT-RaoKVSA Liquid-Liquid Extractor-2 for a period of 4 hrs. with continuous controlled addition of the solvent with a metering pump. Raffinate is drawn using the sampler at regular intervals and after the solvent removal acid value is determined. The acid value is decreased to 0.2 after 4 hrs. extraction.

example 3

[0081]100 g of Crude Jatropha oil (feed) having an acid value of 8.9 is extracted by (LLE) using IICT-RaoKVSA Liquid-Liquid Extractor-1 for a period of 4 hrs. Raffinate samples are drawn at regular intervals and after the solvent removal it is analyzed for acid value. In another similar experiment after 4 hrs of extraction and after solvent removal raffinate obtained is 94 g having an acid value of 0.5 and the extract obtained after solvent removal is 6 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com