Method for constructing virtual-real combined digital twin simulation experiment platform

A technology of simulation experiment and combination of virtual and real, applied in instruments, control/regulation systems, simulators, etc., can solve the problems of insufficient realism in the simulation design stage and low efficiency in the debugging stage, so as to improve the debugging efficiency, reduce the debugging cycle, improve the Effects and Speed Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

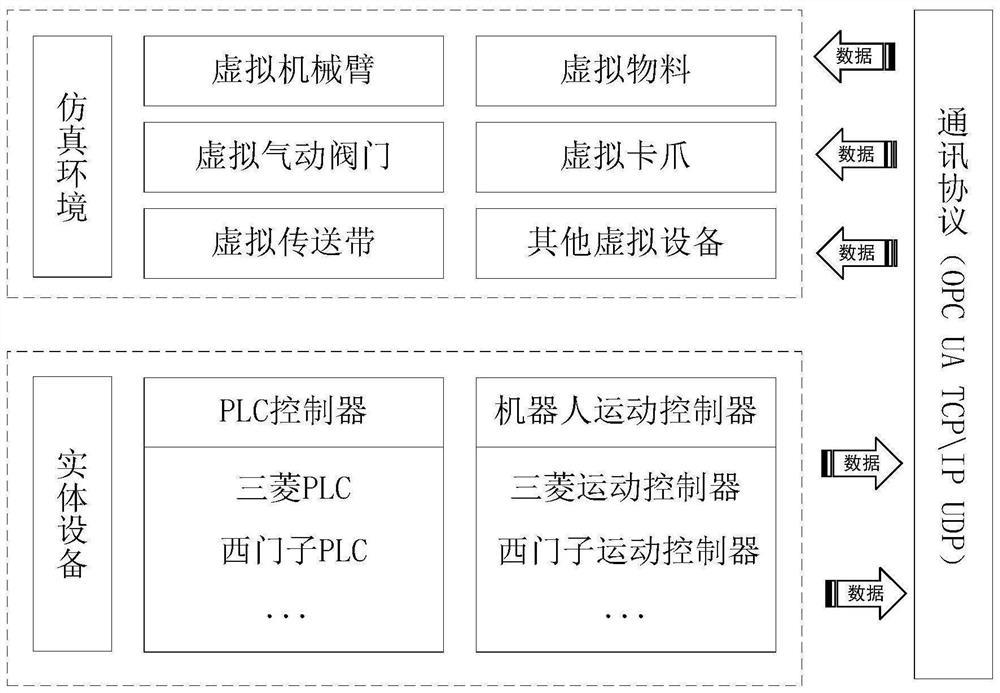

[0028] A virtual-real combined digital twin simulation experiment platform, comprising: a PLC controller, a motion controller, and a virtual simulation environment, wherein the PLC and the motion controller are respectively connected to a simulation PC through Ethernet.

[0029] Further, the PLC is a Mitsubishi PLC with a model number of FX5U-64M.

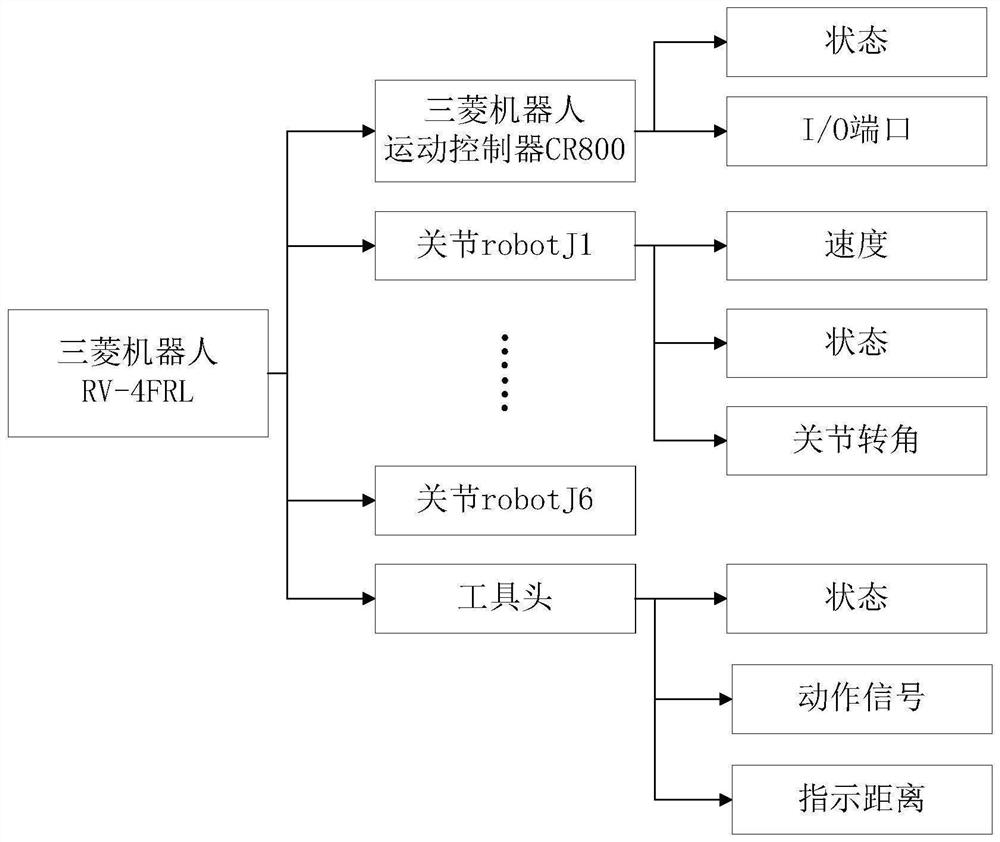

[0030] Further, the motion controller is a Mitsubishi motion controller, model CR800.

[0031] Further, the simulation environment is simulation software CoppeliaSim.

[0032] Further, the above-mentioned physical device is connected to the PC by using a network cable.

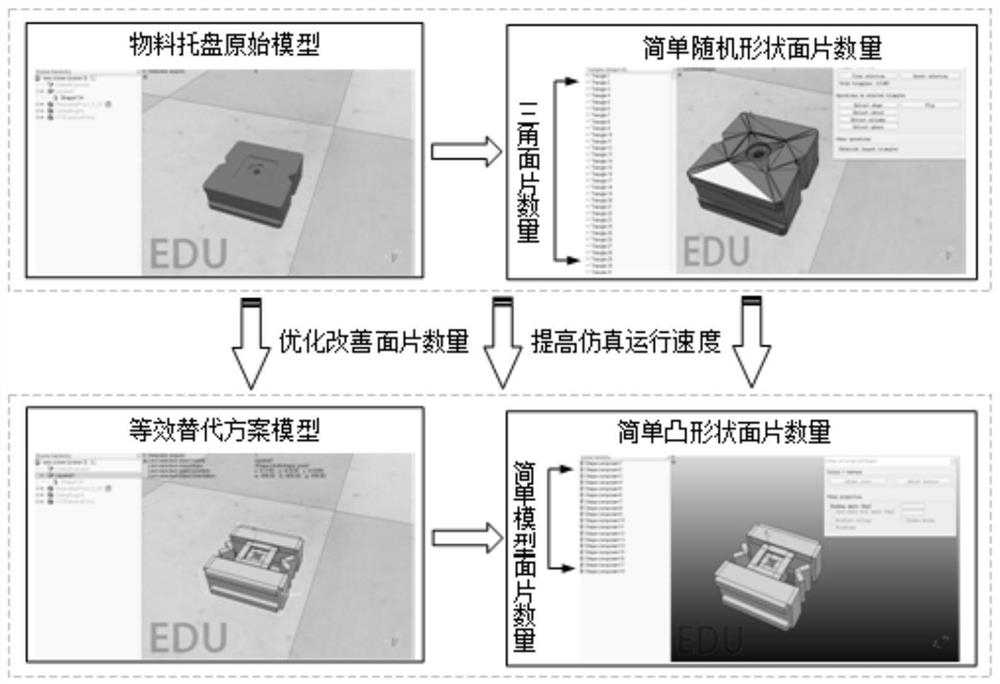

[0033] Furthermore, the PC side establishes a specific three-dimensional model of the controlled equipment and performs lightweight processing.

[0034] Further, the 3D model is imported into the virtual environment, and logic modeling and data interface scripting are performed.

[0035] Further, write the PLC control program and the robot motion control program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com