Method for measuring physical and mechanical parameters and stress state of underground coal and rock mass of coal mine while drilling

A technology of stress state and mechanical parameters, applied in measurement, mining equipment, mining equipment, etc., can solve problems such as lack of equipment and methods for coal property changes, and failure to consider the impact of high-energy and high-pressure gas discrimination results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

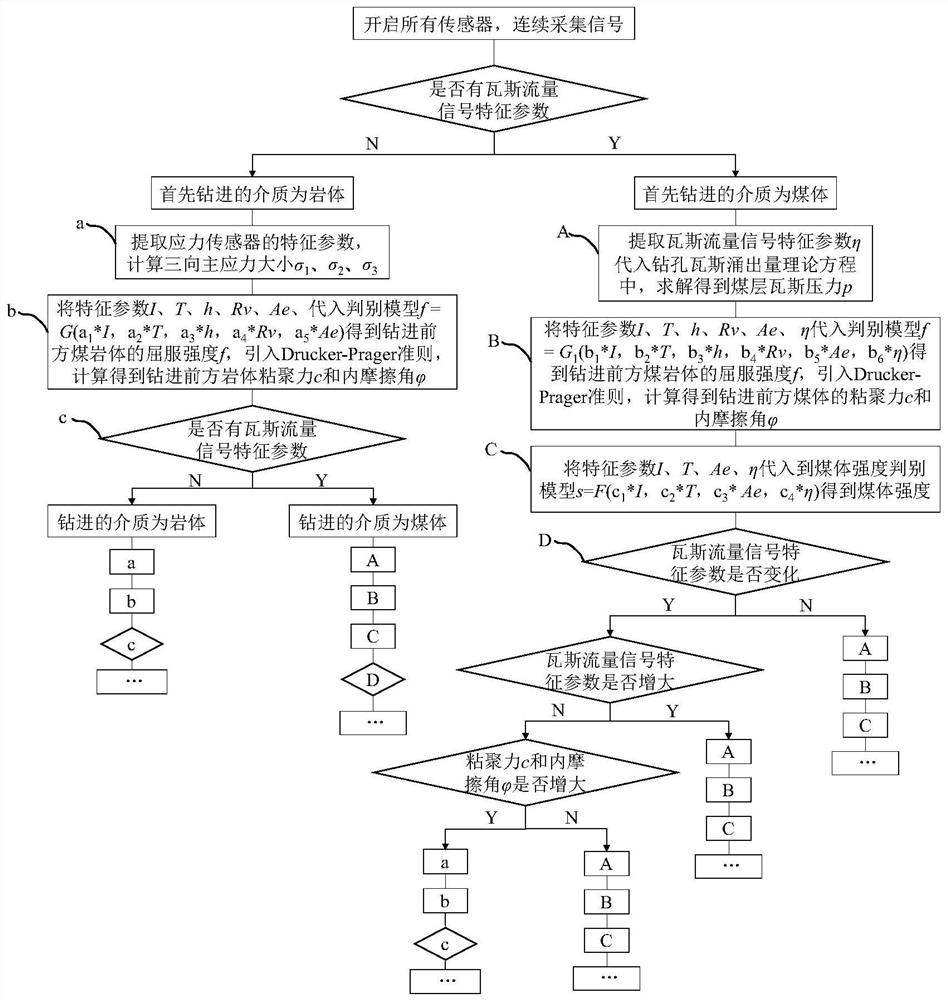

[0035] The method for measuring the physical and mechanical parameters and stress state of coal and rock mass in underground coal mines while drilling is described below with reference to the accompanying drawings.

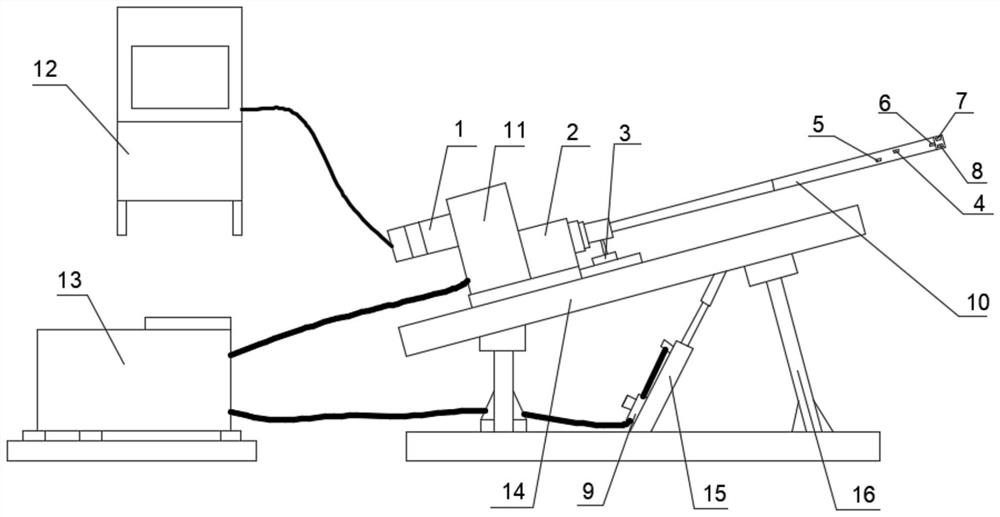

[0036] Such as figure 1 As shown, an embodiment of the present application proposes a device for measuring the physical and mechanical parameters and stress state of coal and rock mass in a coal mine while drilling, which mainly includes a drilling rig main body 11, a detection drill pipe 10, a data transmission and analysis substation 12, and a pumping station with console 13. The drill body 11 provides power for the survey drill pipe 10 . The dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com