Decoration waste treatment device for indoor design

A technology of interior design and processing equipment, applied in grain processing, recycling technology, mechanical material recycling, etc., can solve problems such as unevenness, incomplete melting, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

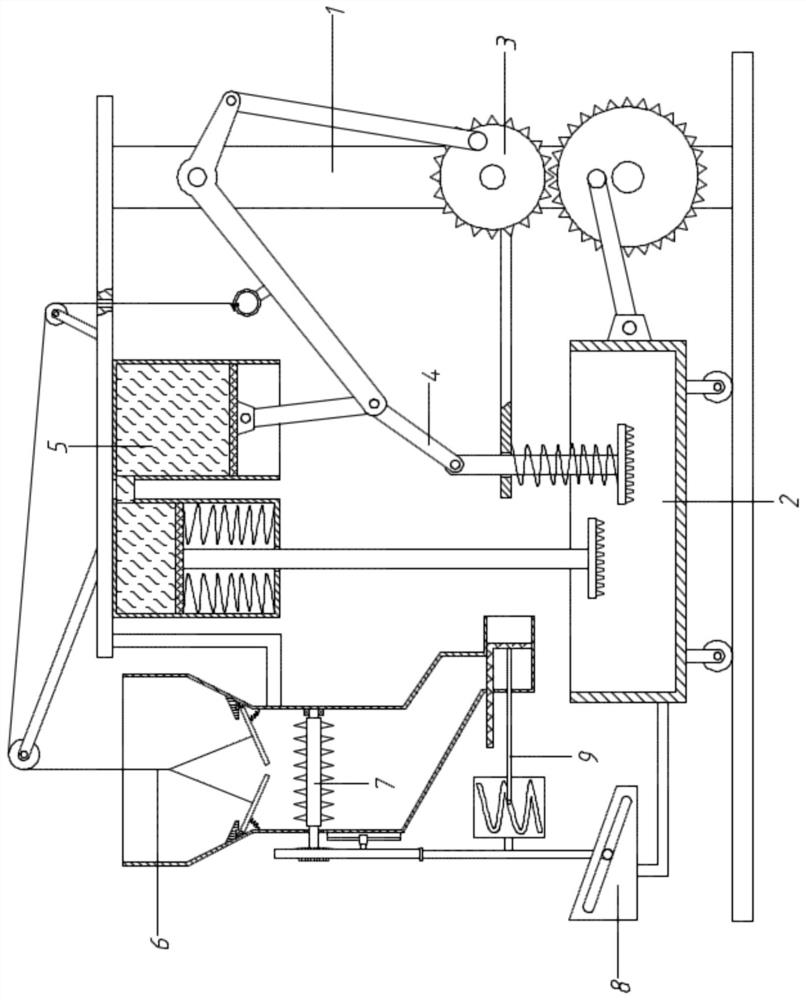

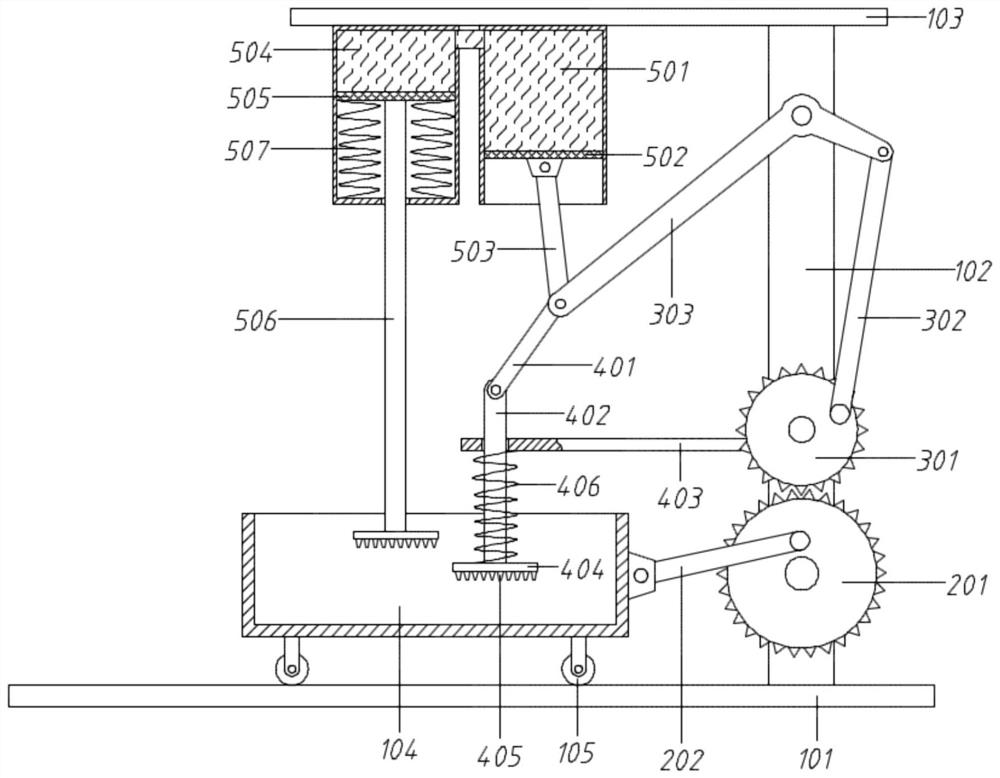

[0061] Referring to the accompanying drawings, the decorative waste disposal device for interior design includes a frame assembly 1, a reciprocating assembly 2, a driving assembly 3, a first-class crushing assembly 4 and a second-class crushing assembly 5;

[0062] Frame assembly 1 comprises base plate 101, vertical bar 102, top plate 103, crushing box 104 and roller 105, and top plate 103 and bottom plate 101 right end are connected by vertical bar 102; It is in rolling contact with the bottom plate 101; the vertical rod 102 is provided with a drive assembly 3, and the bottom of the drive assembly 3 is connected to the right side of the crushing box 104 through the reciprocating assembly 2; the bottom of the left end of the drive assembly 3 is connected with a first-class crushing assembly 4, and the bottom of the first-class crushing assembly 4 The end corresponds to the crushing box 104;

Embodiment 2

[0064] Referring to the accompanying drawings, the decorative waste disposal device for interior design includes a frame assembly 1, a reciprocating assembly 2, a driving assembly 3, a first-class crushing assembly 4 and a second-class crushing assembly 5;

[0065] Frame assembly 1 comprises base plate 101, vertical bar 102, top plate 103, crushing box 104 and roller 105, and top plate 103 and bottom plate 101 right end are connected by vertical bar 102; It is in rolling contact with the bottom plate 101; the vertical rod 102 is provided with a drive assembly 3, and the bottom of the drive assembly 3 is connected to the right side of the crushing box 104 through the reciprocating assembly 2; the bottom of the left end of the drive assembly 3 is connected with a first-class crushing assembly 4, and the bottom of the first-class crushing assembly 4 The end corresponds to the crushing box 104;

[0066] Wherein, the driving assembly 3 includes a No. 1 gear 301, a No. 1 connecting ...

Embodiment 3

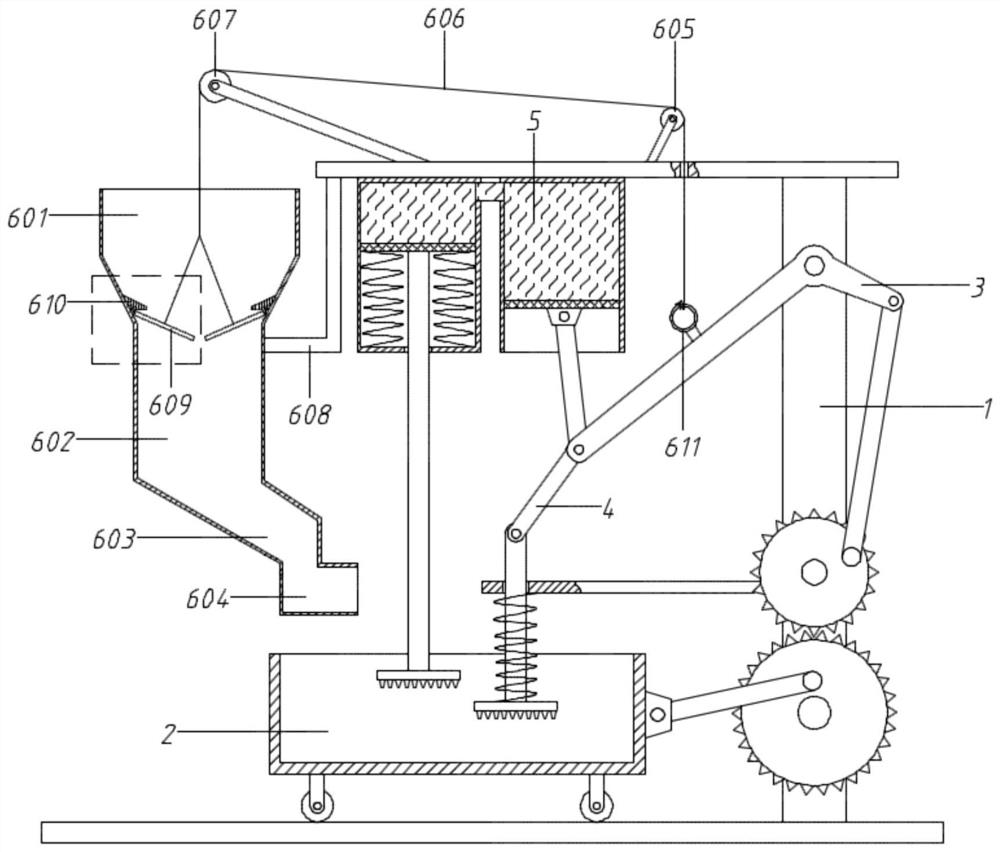

[0078] On the basis of embodiment 2,

[0079] It also includes a blanking assembly 6; the blanking assembly 6 includes a material storage cylinder 601, a blanking tube 602, a material guide tube 603, a discharge tube 604, a No. 1 guide wheel 605, a stay rope 606, a No. 2 guide wheel 607, and a fixed rod 608, blocking plate 609, limit block 610 and tether ring 611;

[0080] The left side of the top plate 103 is connected with the material storage tube 601 through the fixed rod 608, and the bottom of the material storage tube 601 is connected with the discharge pipe 602, and the bottom end of the discharge tube 602 is connected with the discharge pipe 604 through the feed pipe 603, and the discharge pipe 604 exits To the crushing box 104;

[0081] The bottom of the storage tank 601 is symmetrically provided with a blocking plate 609, and one end of the blocking plate 609 is hinged to the inner wall of the storage tank 601; The left section is connected with a tether ring 611, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com