Self-propelled feeding machine for aquaculture

A technology of aquaculture and feed machine, applied in application, fish farming, food science, etc., can solve problems such as poor force application effect, poor feeding effect, uneven feeding, etc., and achieve uniform feeding and change the effect of the area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

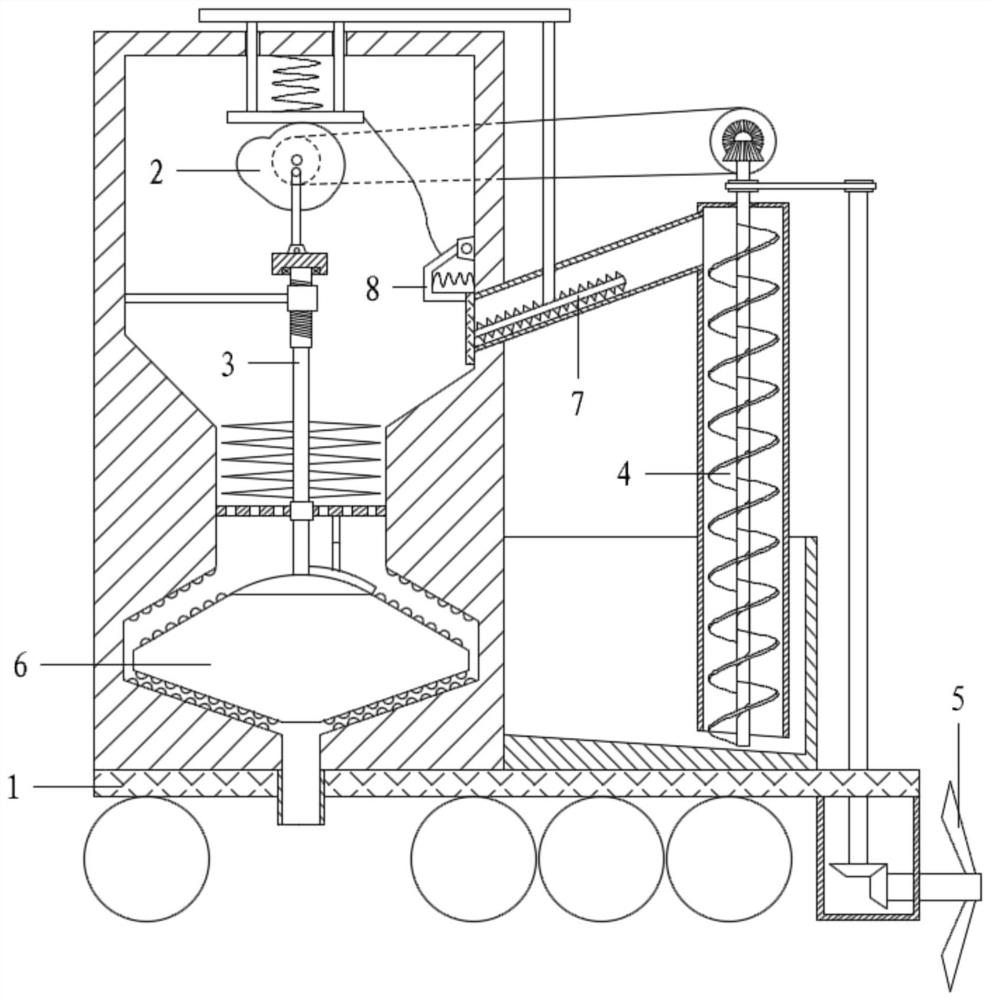

[0065] With reference to the accompanying drawings, a self-propelled feeding feed machine for aquaculture includes a hull assembly 1, a driving assembly 2, a crushing assembly 3, a feeding assembly 4 and a propulsion assembly 5;

[0066] The hull assembly 1 comprises a floating plate 101, an air bag 102, a housing 103, a sieve plate 104, a material storage tank 105 and a feed pipe 405; The interior of 103 is divided into an upper installation chamber 1031, a middle crushing chamber 1032 and a lower material receiving chamber 1033; the crushing chamber 1032 is equipped with a sieve plate 104; the bottom of the material receiving chamber 1033 is connected with a discharge pipe 1034, and the discharge pipe 1034 is downward Through the floating plate 101; the floating plate 101 is fixed with a storage tank 105 corresponding to the right side of the housing 103;

[0067] The installation chamber 1031 and the crushing chamber 1032 are provided with a crushing assembly 3; the storage...

Embodiment 2

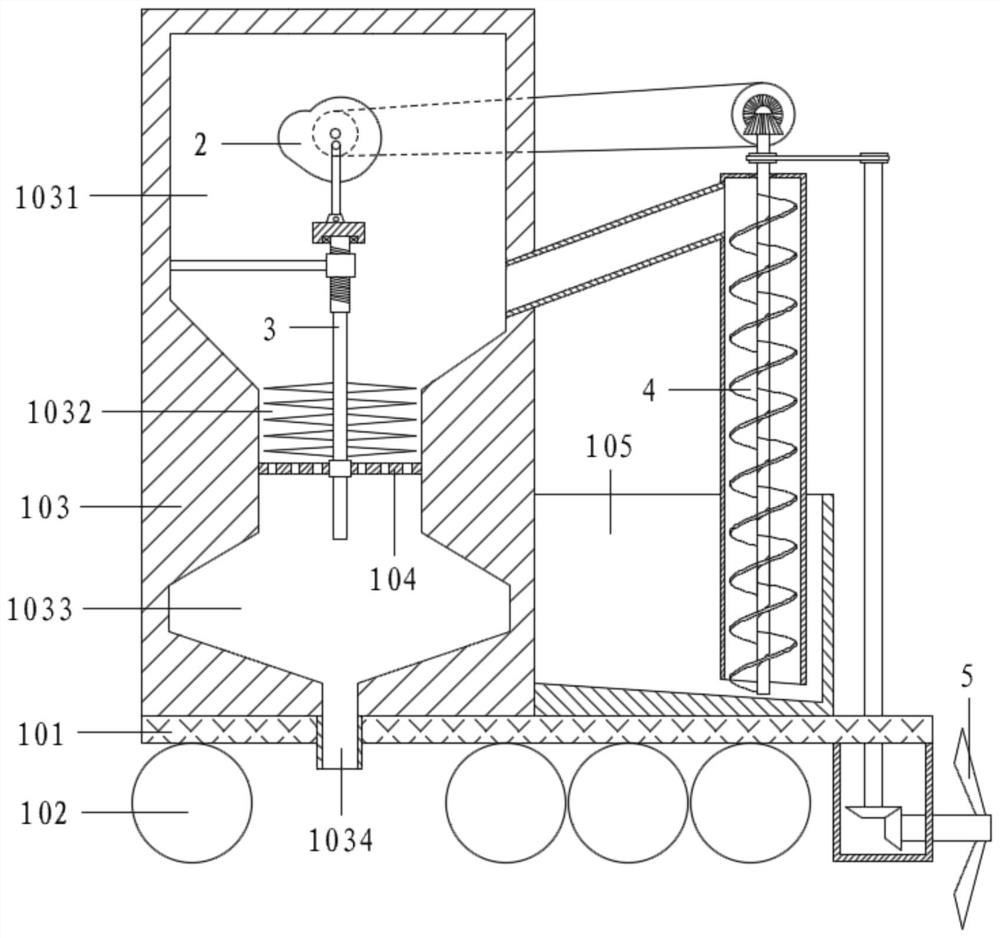

[0069] With reference to the accompanying drawings, a self-propelled feeding feed machine for aquaculture includes a hull assembly 1, a driving assembly 2, a crushing assembly 3, a feeding assembly 4 and a propulsion assembly 5;

[0070] The hull assembly 1 comprises a floating plate 101, an air bag 102, a housing 103, a sieve plate 104, a material storage tank 105 and a feed pipe 405; The interior of 103 is divided into an upper installation chamber 1031, a middle crushing chamber 1032 and a lower material receiving chamber 1033; the crushing chamber 1032 is equipped with a sieve plate 104; the bottom of the material receiving chamber 1033 is connected with a discharge pipe 1034, and the discharge pipe 1034 is downward Through the floating plate 101; the floating plate 101 is fixed with a storage tank 105 corresponding to the right side of the housing 103;

[0071] The installation chamber 1031 and the crushing chamber 1032 are provided with a crushing assembly 3; the storage...

Embodiment 3

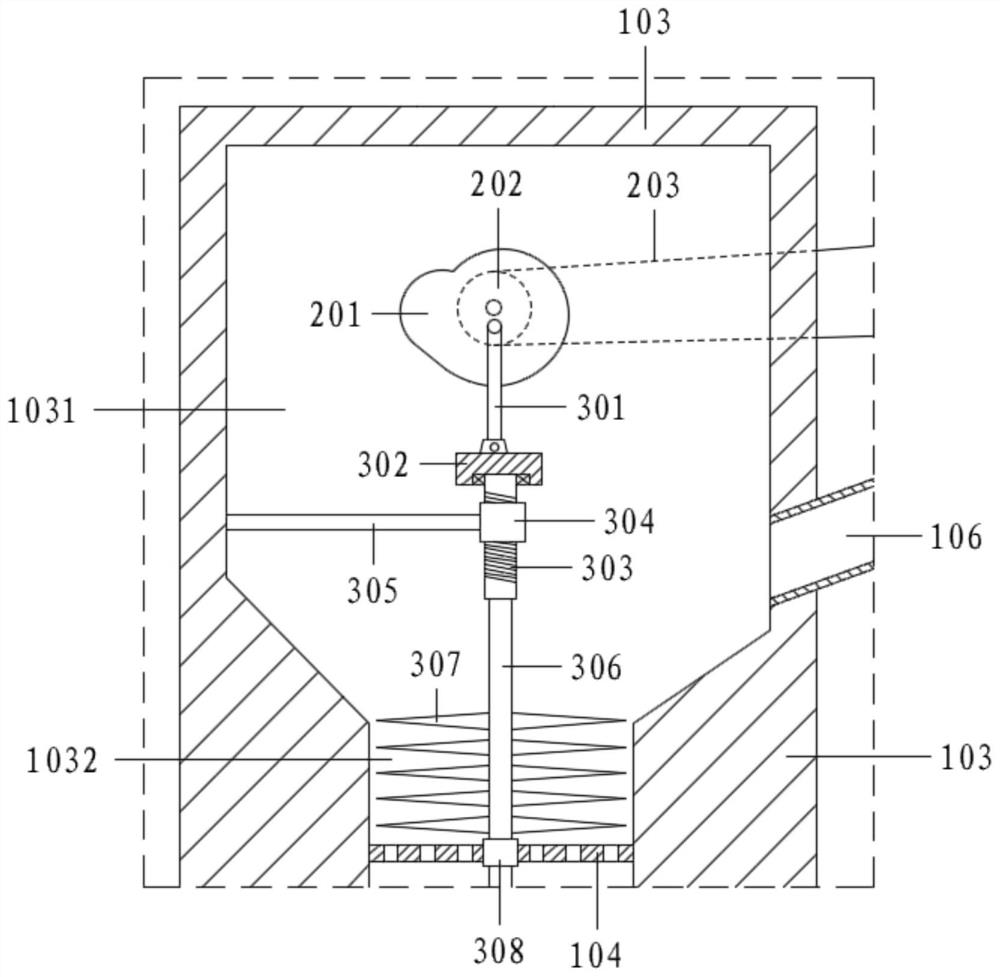

[0090] On the basis of embodiment 2,

[0091]It also includes a grinding assembly 6; the grinding assembly 6 is arranged in the material receiving cavity 1033, including a grinding head 601 and a grinding protrusion 602;

[0092] The upper part of the material receiving chamber 1033 is a flaring structure with a small upper part and a larger lower part, and the lower part of the material receiving chamber 1033 is a narrowing structure with a larger upper part and a smaller lower part; the bottom end of the installation shaft 306 extends into the material receiving chamber 1033, and is connected with a grinding Head 601; the upper part of the grinding head 601 is a circular platform structure with a small top and a large bottom, and the top of the circular platform structure is also processed with a spherical surface 605; the lower part of the grinding head 601 is a circular platform structure with a large top and a small bottom; the grinding head 601 and the material receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com