Small-flow pneumatic feeder for feeding gasification furnace

A feeder, small flow technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of uneven feeding, instability, easy blockage, etc., to achieve uniform feeding, continuous and stable flow, Low feed and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

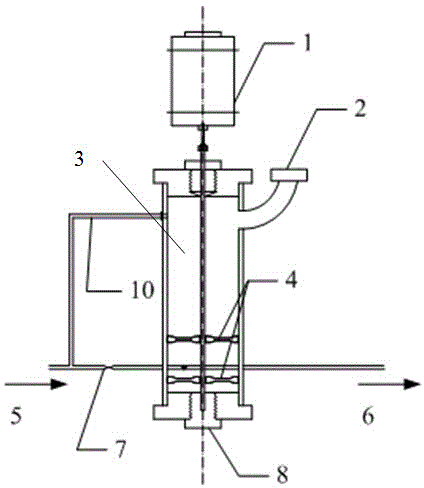

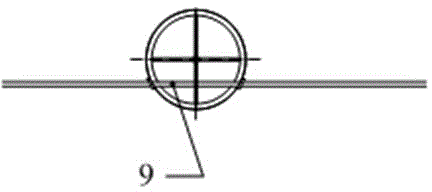

[0015] Such as figure 1 Shown, the present invention comprises motor 1, upper segment feed pipe 10, lower segment feed pipe 11 and stirring paddle 4, and the feeder inlet 2 that is used for solid particle loading is positioned at the upper side of feeder, feeder top A motor 1 is installed above, and the output shaft of the motor 1 is connected to the stirring paddle 4 of the feeder inner cavity 3; the carrier gas is blown in from the carrier gas inlet 5, and the carrier gas inlet 5 is connected to the upper feed pipe 10 and the lower feed pipe 11 , the upper feed pipe 10 directly communicates with the feeder inner chamber 3; the lower feed pipe 11 passes through the feeder inner chamber 3, and the outlet of the lower feed pipe 11 is used as the carrier gas outlet 6, as figure 2 As shown, the lower feeding pipe 11 is located in the inner cavity 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com