Device and method for laser shock forming super-hydrophobic micro-parts

A super-hydrophobic micro, laser shock technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor surface structure hydrophobic performance, durability and stability effects, complex processing, etc., to achieve mechanical properties Enhancement, increased durability, improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

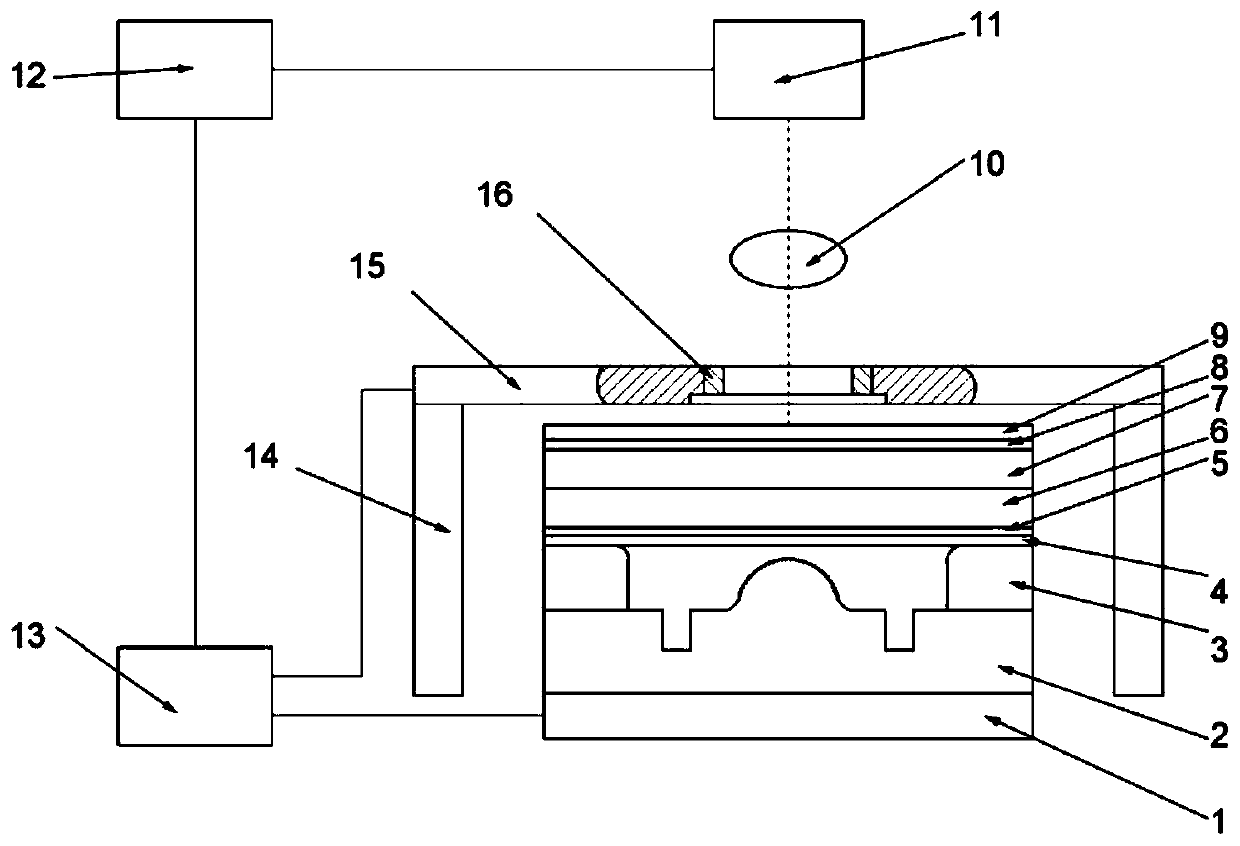

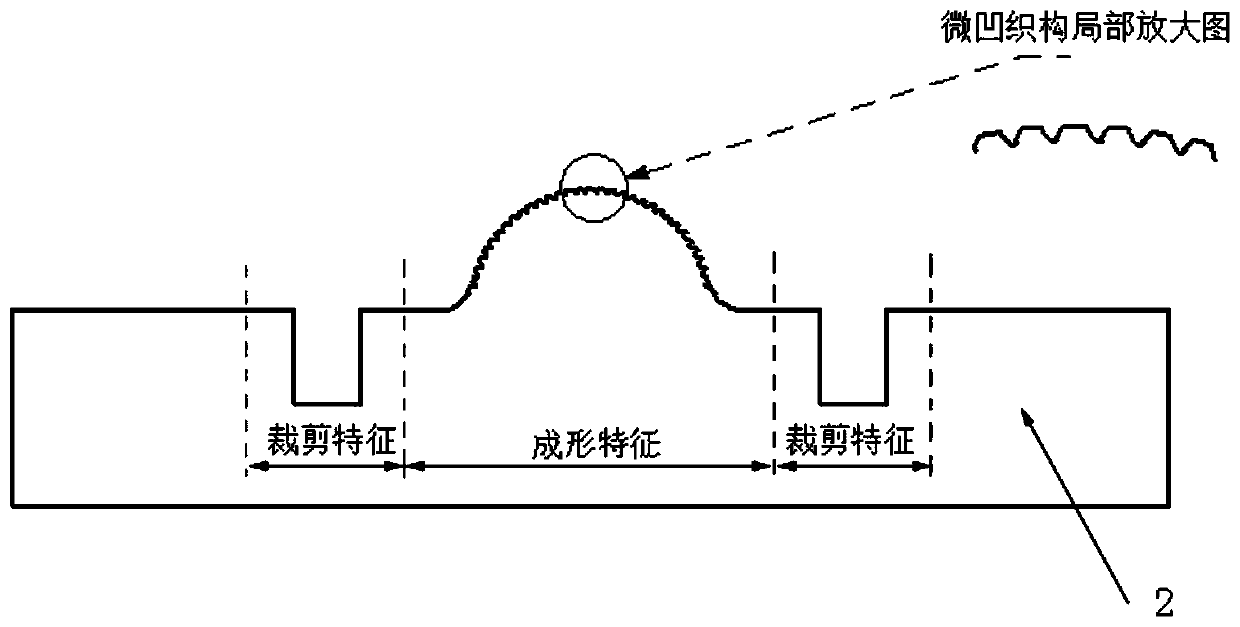

[0037] combined with figure 1 , 2, 3, and 4 show an embodiment of the device and method for realizing laser shock forming superhydrophobic micro parts according to the present invention, the device includes a laser loading system, a mask system, and a forming system;

[0038] combined with figure 1As shown, the laser loading system includes a laser controller 12, a nanosecond laser 11 and a focusing lens 10, and the laser beam emitted by the nanosecond laser 11 enters the mask system after passing through the focusing lens 10; the forming system includes an annular optical medium 9. Absorbing layer film 8, polyurethane soft film 7, plasticine 6, isolation layer film 5, workpiece raw material 4, isolation gasket 3, micro mold 2 and three-dimensional mobile platform 1.

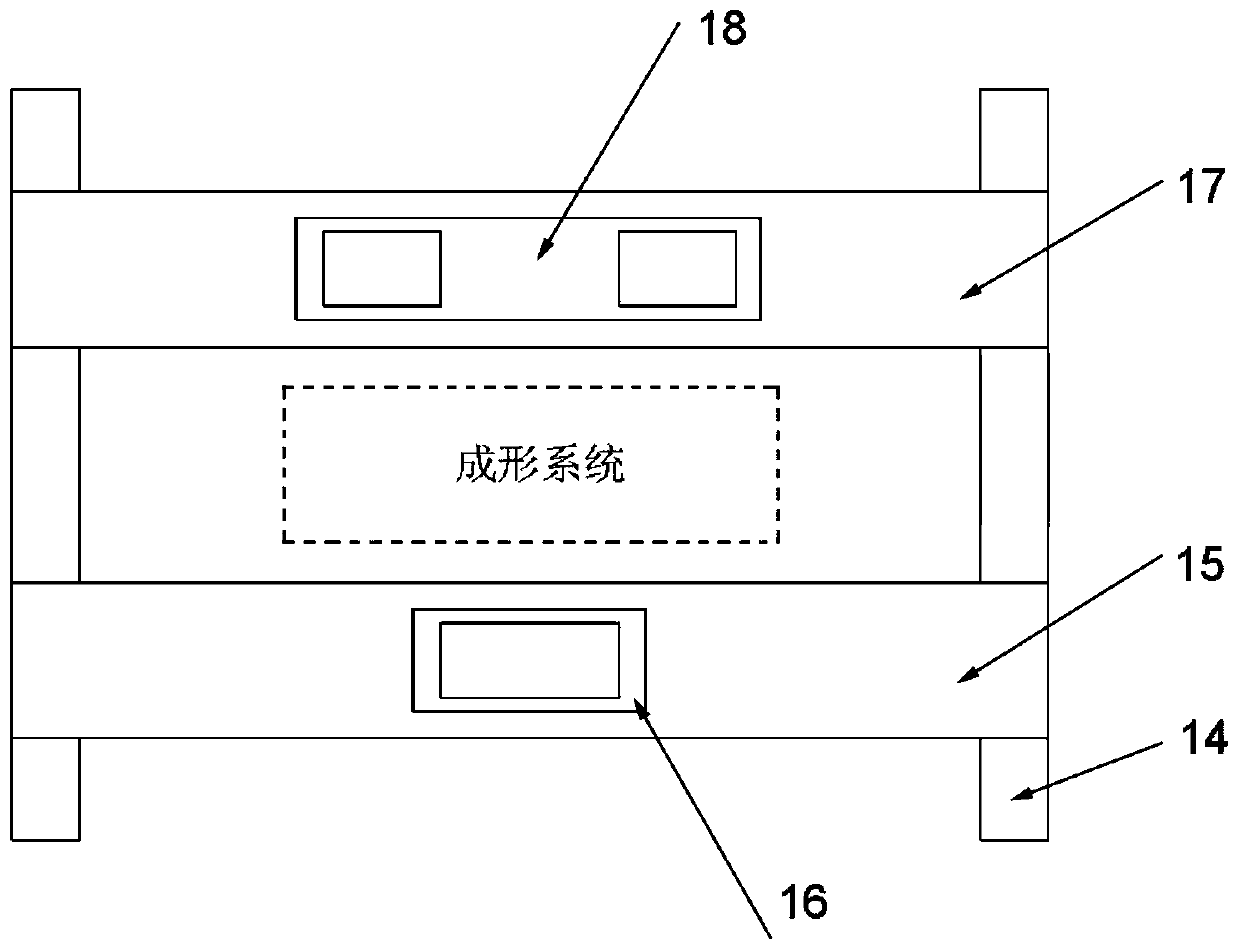

[0039] combined with image 3 As shown, the mask system includes a mask holder 14, a first mask tray 15, a first mask plate 16, a second mask tray 17 and a second mask plate 18; the first mask tray 15 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com