High-salt iron phosphate liquid waste zero-emission treatment device and method

A technology of high-salt waste liquid and treatment device, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as iron phosphate high-salt waste liquid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

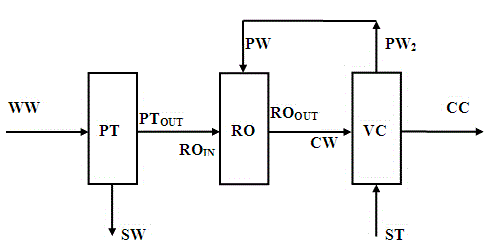

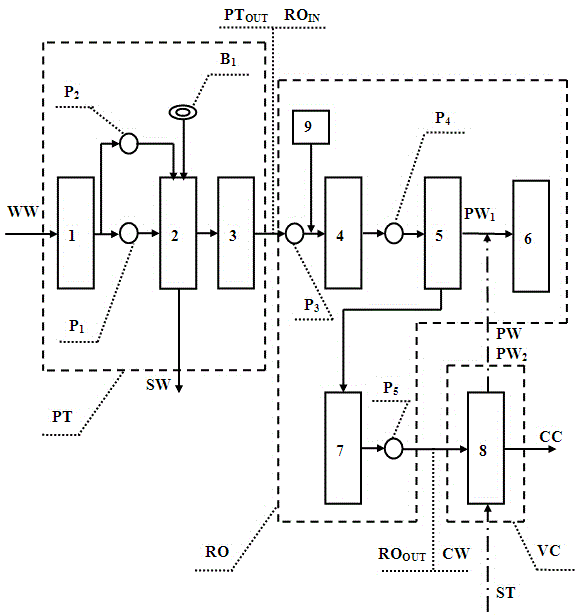

Method used

Image

Examples

Embodiment

[0027] A zero-emission treatment project of ferric phosphate high-salt waste liquid for a new energy company with an annual output of 30,000 tons of ferric phosphate. In the process of iron phosphate wastewater treatment, the remaining iron phosphate high-salt waste liquid after extracting fertilizer enters the system for zero liquid discharge treatment.

[0028] 1. Treat water quality and quantity

[0029] The main values of influent water quality and water quantity are as follows:

[0030]

[0031] 2. Water quality and quantity of reverse osmosis product water and reverse osmosis concentrate

[0032] The water quality and quantity of reverse osmosis product water and reverse osmosis concentrate are as follows:

[0033]

[0034] The reverse osmosis concentrate is then subjected to evaporation and crystallization.

[0035] 3. Process flow and water balance

[0036] The process flow and water balance diagram are attached Figure 4 .

[0037] 4. System main des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com