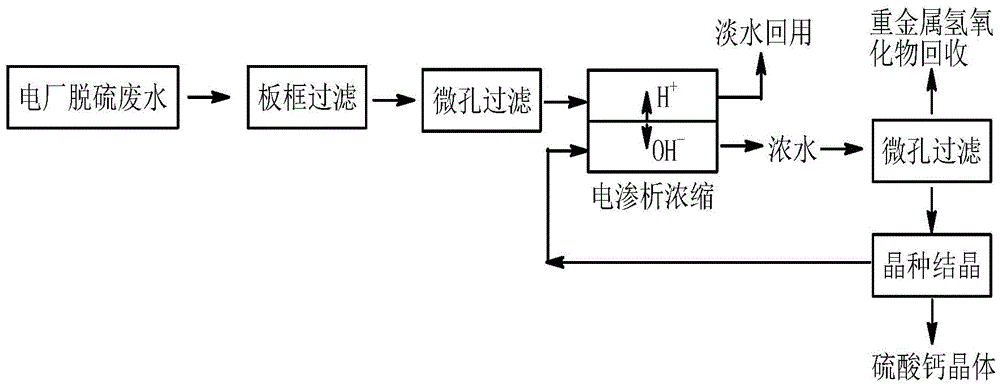

Power plant flue gas desulfurization wastewater treatment process

A technology for desulfurization wastewater and treatment process, applied in the field of water treatment, can solve the problems of complex treatment procedures and the formation of waste solids from heavy metals, and achieves the effect of simple process and overcoming complex treatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For the desulfurization wastewater of a power plant, the calcium sulfate content is 2000mg / L, the heavy metal content is 20mg / L, and the pH is 5.3.

[0032] After the desulfurization wastewater is filtered through the plate and frame, the sintered microporous filter rod is filtered to obtain a clear filtrate without suspended matter. Wherein the sintered microporous filter rod is cleaned by air blowback, the filter aperture is 0.45 microns, and the air blowback pressure is 0.2MPa.

[0033] The clarified liquid is concentrated by an electrodialysis membrane unit with a pH adjustment function, and the concentration ratio is 40 times. The fresh water is reused, and the concentrated water enters the calcium sulfate seed crystal crystallization device. The pH adjustment function of the electrodialysis membrane unit comes from the bipolar membrane. In the electrodialysis membrane unit, part of the negative membrane is replaced by a bipolar membrane. Two sets of JED-5000, 200 ...

Embodiment 2

[0037] For desulfurization wastewater from a power plant, its calcium sulfate content is 2200mg / L, heavy metal content is 30mg / L, and pH is 6.5.

[0038]After the desulfurization wastewater is filtered through the plate and frame, the sintered microporous filter rod is filtered to obtain a clear filtrate without suspended matter. Wherein the sintered microporous filter rod is cleaned by air blowback, the filter aperture is 1.0 micron, and the air blowback pressure is 0.3MPa.

[0039] The clarified liquid is concentrated by an electrodialysis membrane unit with a pH adjustment function, and the concentration ratio is 40 times. The fresh water is reused, and the concentrated water enters the calcium sulfate seed crystal crystallization device. The pH value adjustment function of the electrodialysis membrane unit comes from the bipolar membrane. In the electrodialysis membrane unit, part of the negative membrane is replaced by a bipolar membrane, and a set of JED-5000, 200 is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com