Fermenting method utilizing soy sauce and grains fully

A technology for soy sauce and grain is applied in the field of full utilization of soy sauce grain and brewing, which can solve the problems of landfill soil salinization, high salt content, environmental pollution, etc., and achieve the effect of improving crude protein and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

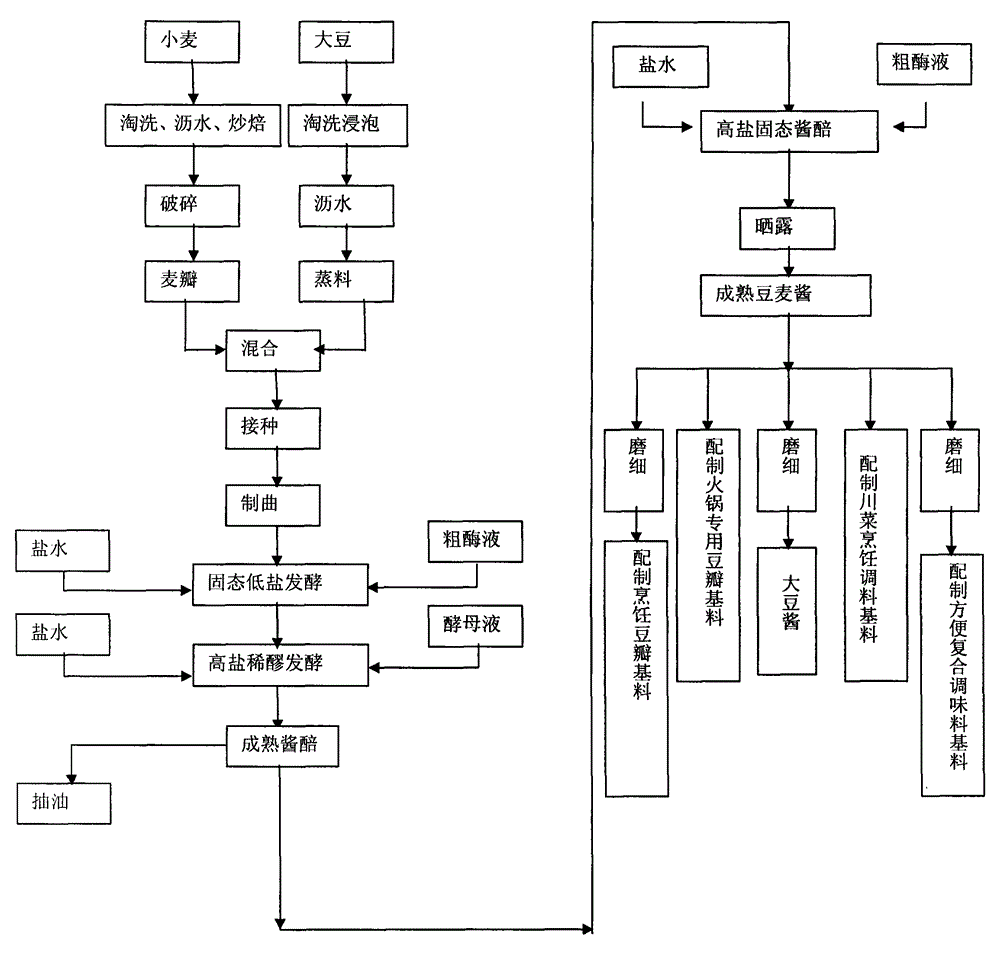

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

[0019] 1, raw material preparation: soybean and wheat, its weight ratio is 2: 1, soak soybean: soak 5-16 hour (according to seasonal regulation), finally make the water content after soybean soak between 40%-65%; After cleaning, drain the remaining water, fry and roast, and break into fried wheat flaps.

[0020] 2. Loading and steaming: Drain the soaked and washed soybeans and transfer them to a steaming tank, steam them under a pressure of 0.10-0.30Mpa for 20-70 minutes, and then suffocate them for another 20-50 minutes.

[0021] 3. Mixing: Cool the steamed soybeans quickly and mix them evenly with the fried wheat flaps.

[0022] 4. Inoculation into koji: The clinker is delivered to the inoculation machine through the air cooler for inoculation. The weight percentage of seed koji inoculum is 0.2-0.6%. Weigh the fried wheat flour whose volume is 2-3 times that of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com