Tail gas recovery treatment and cyclic utilization device for zinc plating continuous annealing furnace and treatment technology thereof

A continuous annealing furnace and exhaust gas recovery technology, applied in waste heat treatment, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of wasting energy and unsafe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

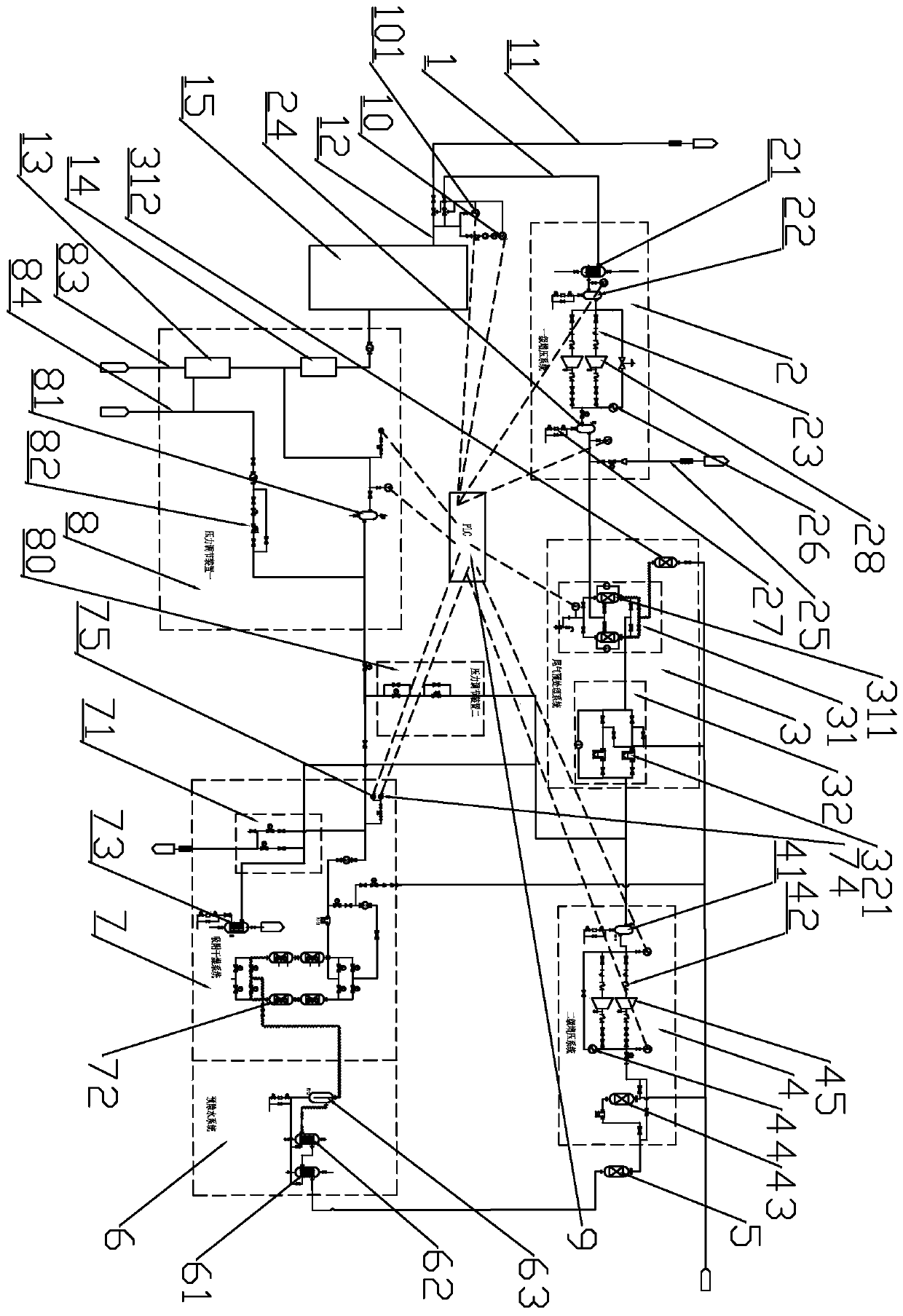

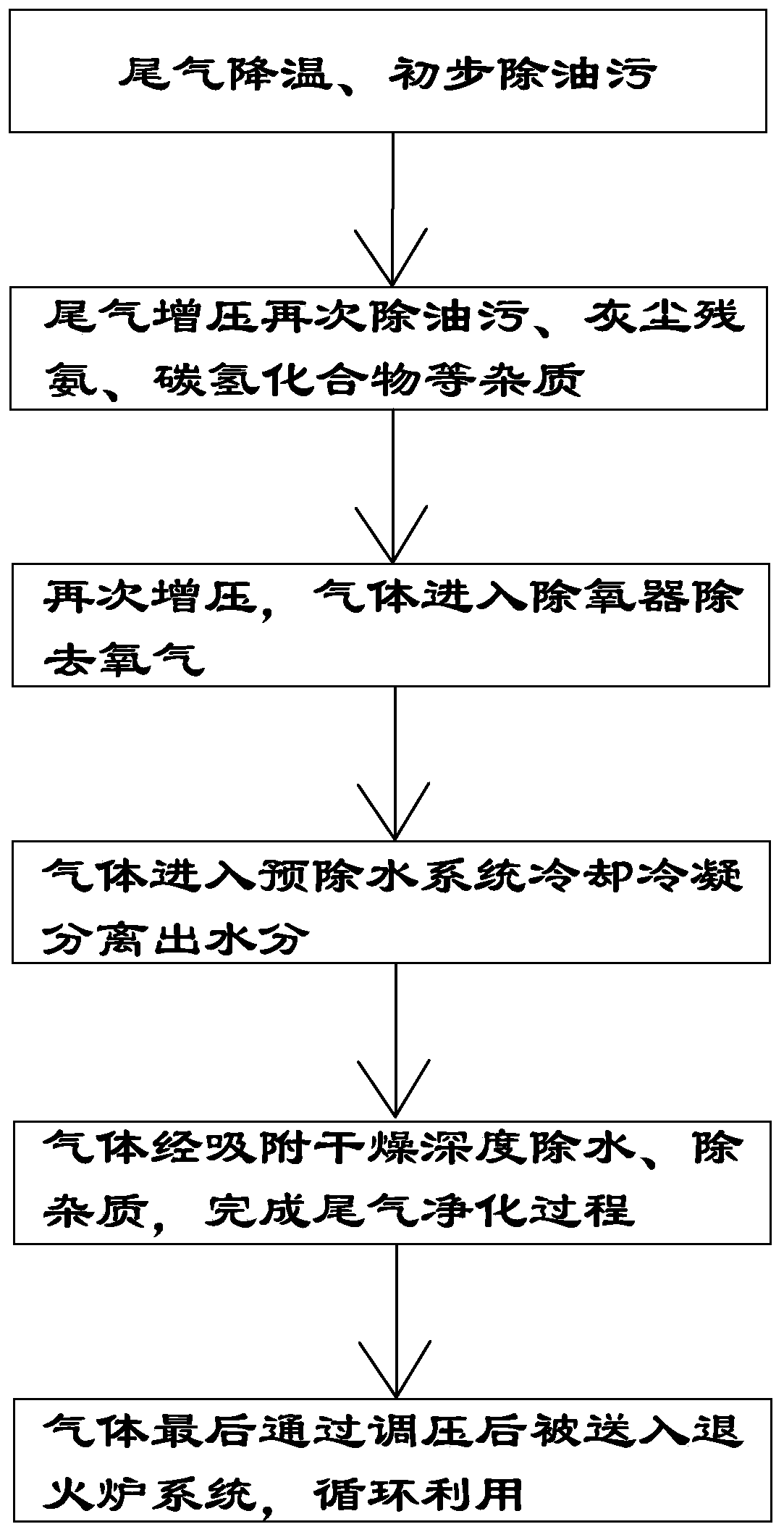

[0029] Such as figure 1As shown, a galvanized continuous annealing furnace tail gas recovery treatment recycling device, including tail gas recovery pipeline 1, a first-stage pressurization system 2, an exhaust gas pretreatment system 3, a second-stage pressurization system 4, a deaerator 5, a pre-treatment system Dewatering system 6, adsorption drying system 7, pressure regulator one 8 and PLC controller 9, described pre-dewatering system 6 includes the first cooler 61, condenser 62 and gas-water separator 63 that are connected with pipelines in the middle, The exhaust gas recovery pipeline 1 is connected in parallel with the exhaust gas discharge pipe 11 on the annealing furnace exhaust gas outlet main pipe 12, and the outlet of the exhaust gas recovery pipeline 1 is connected to the front end of the first-stage pressurization system 2, and the first-stage pressurization system 2. The rear end is connected to the front end of the exhaust gas pretreatment system 3. The rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com