Treatment methods for silicon nitride thin films

A technology of silicon nitride layer and processing chamber, which is applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., and can solve the problems of unsuitable silicon nitride material processing, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

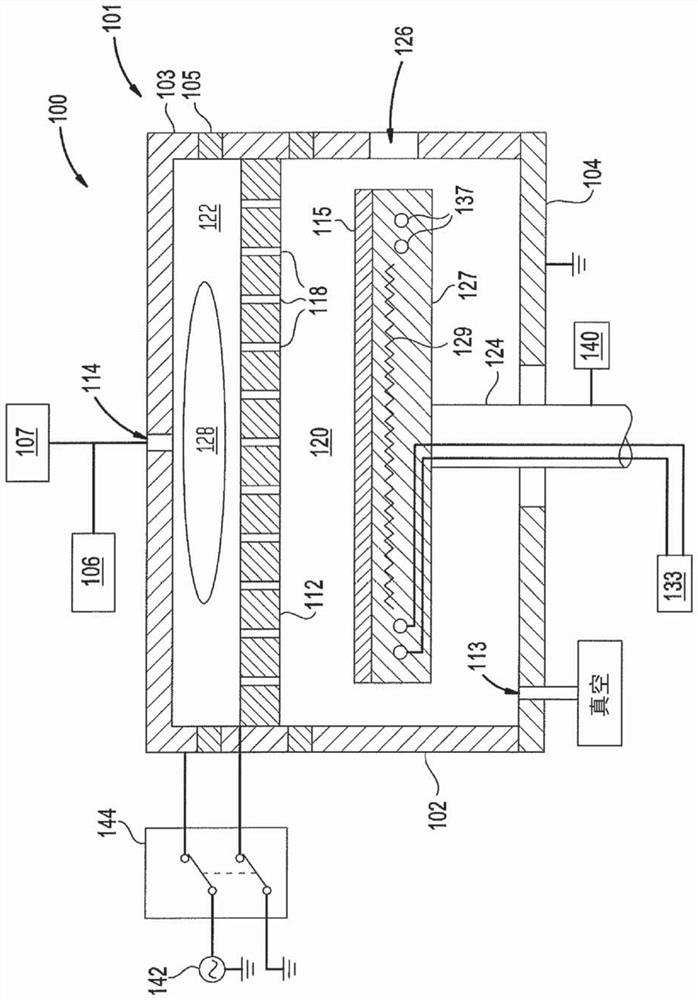

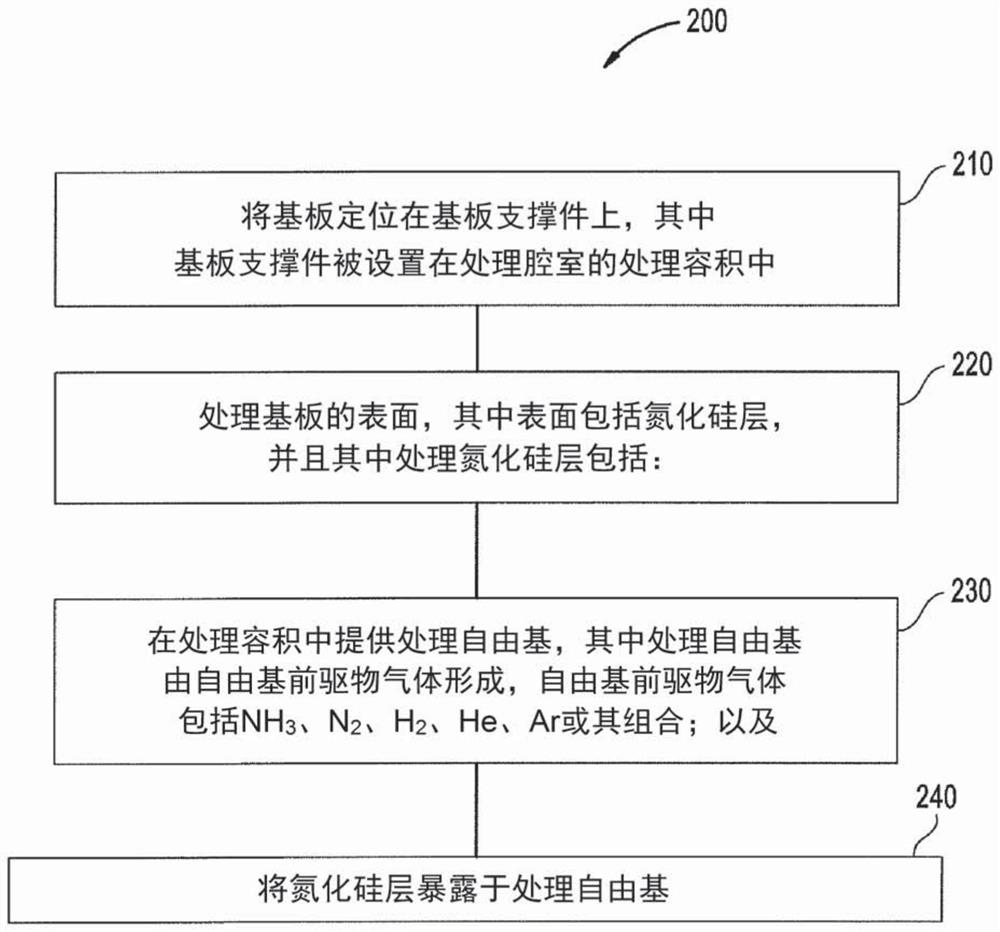

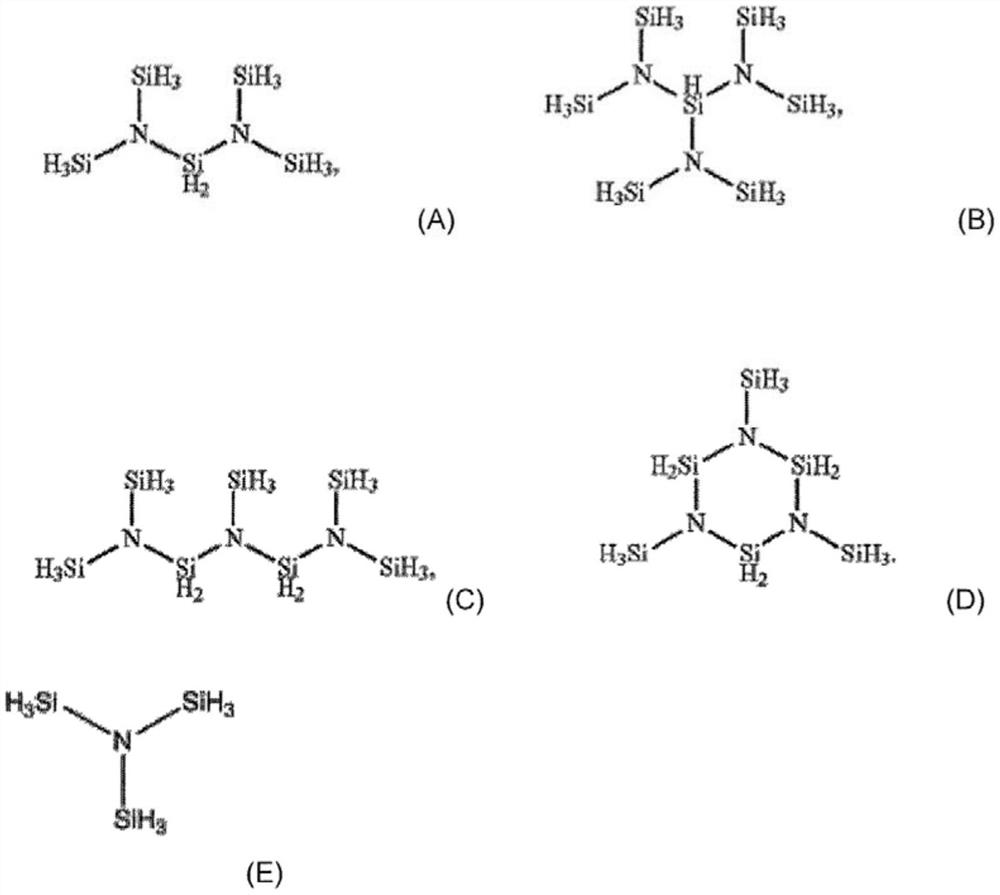

[0011] Embodiments described herein relate generally to methods for free radical-based treatment of silicon nitride layers disposed on substrate surfaces, and in particular, to methods for silicon nitride layers that have been deposited using a flowable chemical vapor deposition (FCVD) process. Method for radical-based treatment of silicon nitride layers. Flowable silicon nitride processes (eg, silicon nitride layers deposited using (FCVD) processes) generally provide improved gapfill performance of high aspect ratio features when compared to silicon nitride layers deposited using conventional methods. However, silicon nitride layers typically provided by FCVD processes can undesirably include complex networks of one or both of Si-H and Si-NH bonds, and, compared to conventionally deposited (non-flowable ) silicon nitride layer, which undesirably provides a lower film density of the silicon nitride layer. A conventional treatment method for improving the film quality of a sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com