Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Chromium(III) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium(III) chloride (also called chromic chloride) describes any of several compounds of with the formula CrCl₃ • xH₂O, where x can be 0, 5, and 6. The anhydrous compound with the formula CrCl₃ is a violet solid. The most common form of the trichloride is the dark green hexahydrate, CrCl₃ • 6H₂O. Chromium chlorides find use as catalysts and as precursors to dyes for wool.

High anti-corrosion zinc coating trivalent chromium lue-white passivating agent and its preparing method

InactiveCN1858302AReduce concentrationReduce manufacturing costMetallic material coating processesAcetic acidMalonic acid

The present invention discloses anticorrosive trivalent chromium blue-white zinc coating passivator and its preparation process. The anticorrosive trivalent chromium blue-white zinc coating passivator includes Cr3+ 1-5 g / L, NaNO3 1-20 g / L, malonic acid 1-10 g / L, cobalt sulfate 5-20 g / L, acetic acid 1-10 g / L, phosphate 1-6 g / L, ammonium bifluoride 1-5 g / L and silicate 0.2-5 g / L. The preparation process includes dissolving the said materials in pure water successively through stirring to obtain transparent passivator. The present invention has the advantages of being practical and good use effect.

Owner:SUR PRECISION METAL TECH

Production method for health food rich in multiple trace elements and used for rehabilitation of coronary heart disease

InactiveCN103355607AOvercome absorbencyOvercome the disadvantages of side effects caused by direct administrationFood preparationChromium(III) chlorideBASIC COPPER SULFATE

The invention relates to a production method for health food rich in multiple trace elements and used for rehabilitation of a coronary heart disease. The production method comprises the following steps: filling 10 kg of grains into a square container and weighing 29 to 31 g of chromium chloride, 248 to 252 g of zinc chloride, 2.5 to 2.8 g of nickel chloride, 6 to 7 g of sodium selenite, 0.6 to 0.7 g of sodium metavanadate, 88 to 89 g of germanium tetrachloride, 155 to 160 g of copper sulphate, 140 to 145 g of manganese chloride, 288 to 292 g of iron chloride, 10 to 14 g of lithium chloride, 7 to 8 g of sodium molybdate, 0.6 to 0.7 g of cobalt chloride, 605 to 607 g of sodium silicate, 82 to 85 g of strontium sulfate and 65 to 68 g of sodium fluoride; mixing above-mentioned salts, adding water for dilution of the salts until 6 to 6.5 kg of a mixed salt solution is obtained and allowing the salt solution to be completely absorbed by the grains; and drying and crushing the grains so as to obtain the health food. The health food provided by the invention has a plurality of trace elements needed by a human body, and the trace elements and amino acids are compounded to form a plurality of amino acid salts which can be easily absorbed by the human body; the health food can maintain balance of trace elements in the human body, prevent and correct metabolic disorders of inorganic salts and trace elements, prevent and restore incomplete cells and regenerate new cells, enables blood vessels to be unblocked and rehabilitation of the coronary heart disease to be realized and has prevention and health care effects on the coronary heart disease.

Owner:买世禄 +1

Method for selectively recovering heavy metals in electroplating sludge by using chlorination roasting approach

InactiveCN109280777APromote resource utilizationSolving the Selective Extraction DilemmaProcess efficiency improvementSludgeSlag

The invention belongs to the technical field of solid waste treatment and discloses a method for selectively recovering heavy metals in electroplating sludge by using a chlorination roasting approach.The method comprises the followings steps that the electroplating sludge and a chlorinating agent are mixed and then roasted at 159-400 DEG C, volatile chromium chloride is collected through tail gasand absorbed by water to obtain a chromium chloride solution, water is added to dissolve residual solid materials, and solid-solution separation is carried out to obtain a metal chloride mixed solution and solid sludge slag. According to the method, the electroplating sludge is treated in combination with a chlorination roasting technology in industrial metallurgy, through using hydrochloric acidas the chlorinating agent, the recovery rate of chromium in the electroplating sludge can reach more than 85% or above, the recovery rate of nickel and the recovery rate of copper can reach more than90% or above, the process is simple, the recovery effect is good, and the method has relatively high environment and economic benefits, and is beneficial to resource utilization of the electroplatingsludge.

Owner:SOUTH CHINA UNIV OF TECH

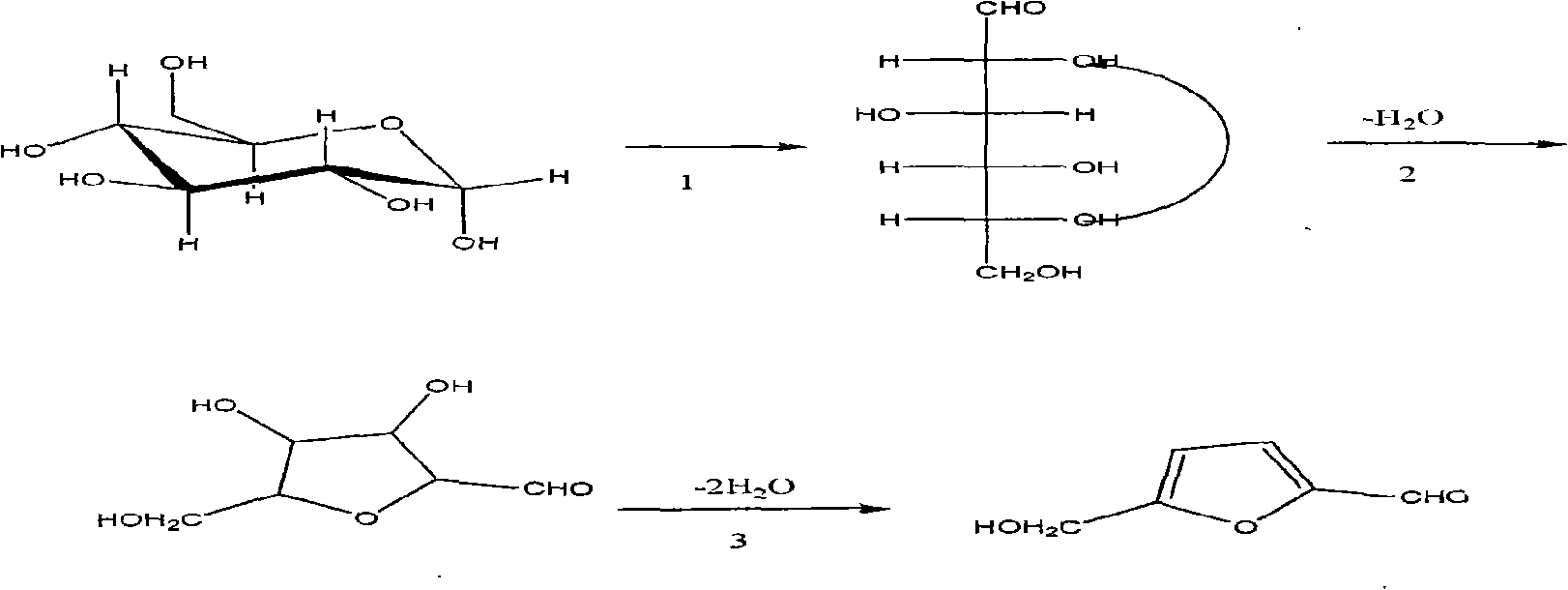

Method for synthesizing 5-hydroxymethyl-furfural

The invention relates to a synthesis method for 5-hydroxymethylfurfural and is characterized in that glucose is used as raw material and the 5-hydroxymethylfurfural is generated in the ionic liquid of chromium chloride through intramolecular mutarotation and dehydration; the reaction mixture firstly goes through flash evaporation to separate the product, by-product and the residual raw materials from the ionic liquid; the evaporated mixture is extracted and purified with supercritical fluid CO2 to obtain the 5-hydroxymethylfurfural; the ionic liquid is recycled. The synthesis technology has simple and fast courses and is energy-saving and environmentally-friendly; the obtained product has high quality and low cost, with the total mass yield reaching more than 58%.

Owner:ANHUI RUISAI BIOCHEM TECH

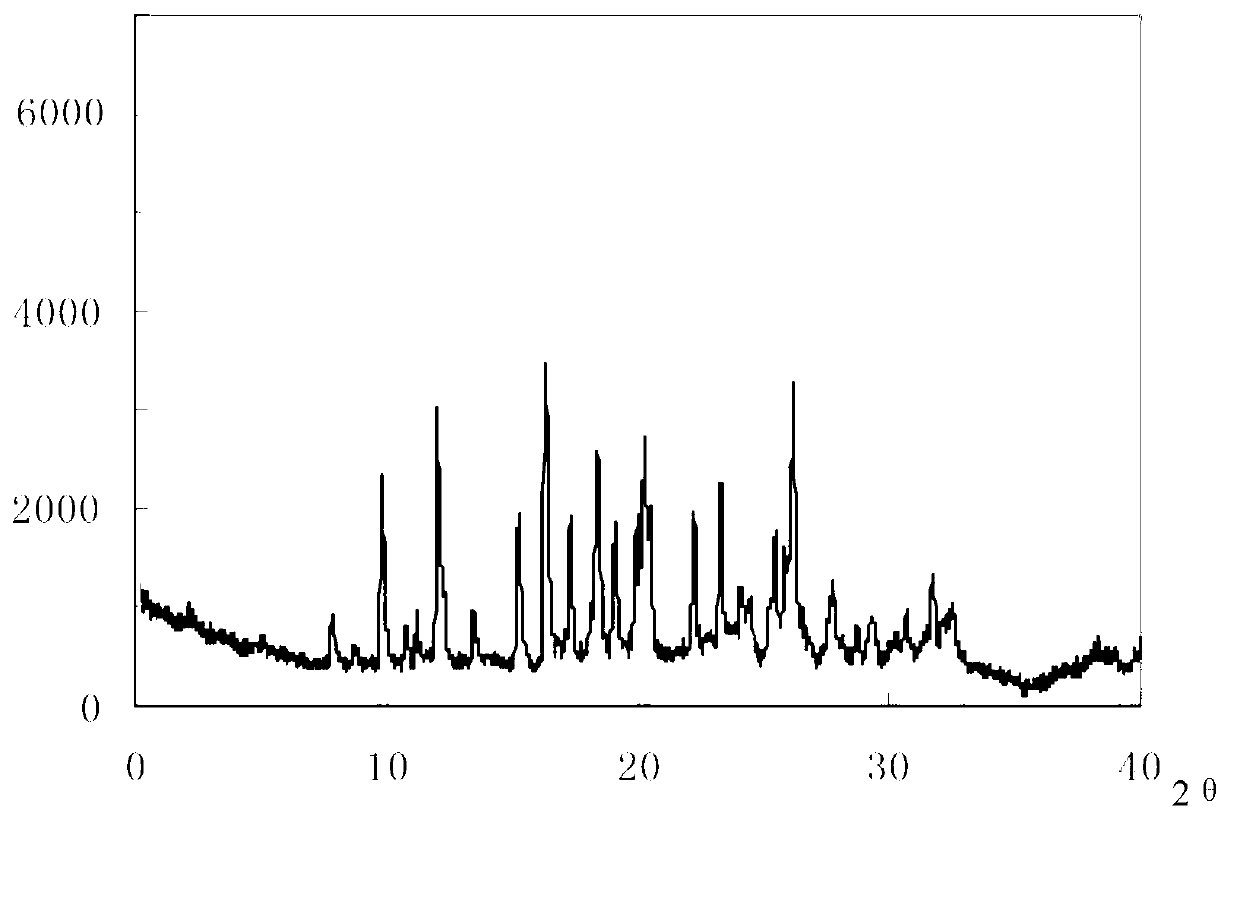

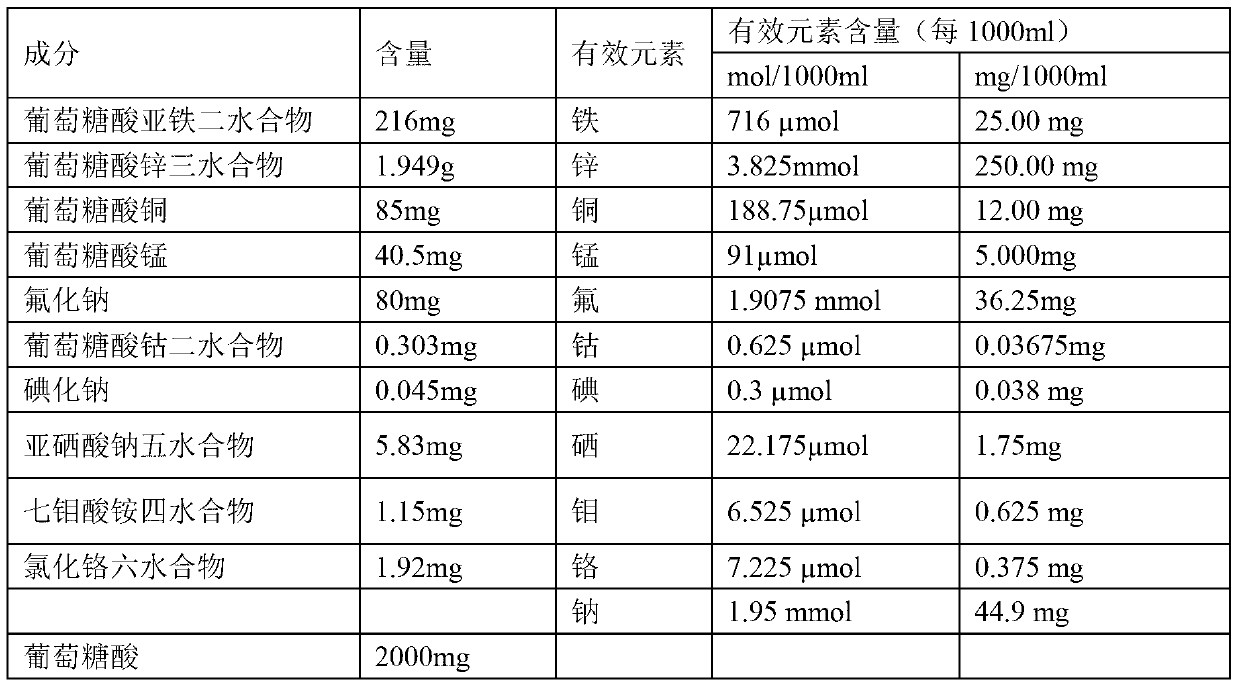

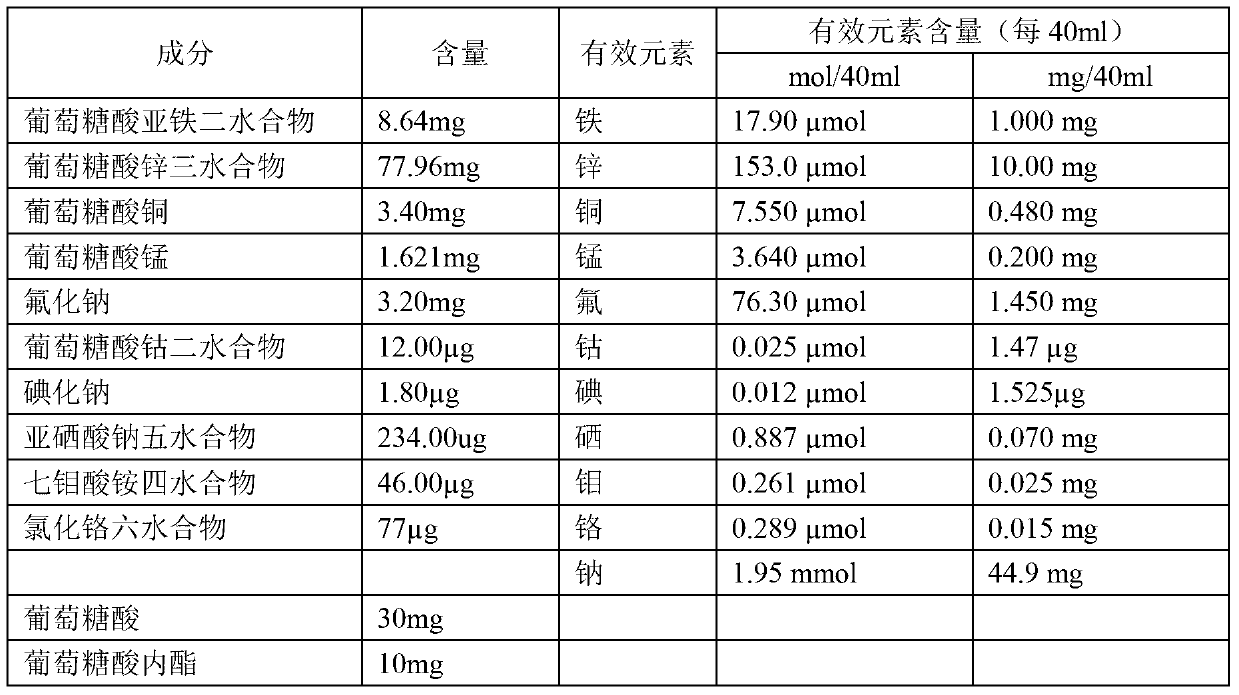

Composition containing various microelements, preparation and preparation method thereof

InactiveCN103340895AImprove stabilitySuitable for clinical applicationHeavy metal active ingredientsMetabolism disorderSodium iodideFreeze-drying

The invention relates to a pharmaceutical composition, and in particular relates to a composition containing various microelements, a preparation and a preparation method thereof. The composition comprises ferrous gluconate dihydrate, a zinc gluconate trihydrate compound, copper gluconate, manganese gluconate, sodium fluoride, cobalt gluconate dihydrate, sodium iodide, sodium iodide pentahydrate, ammonium heptamolybdate tetrahydrate, chromic chloride hexahydrate and a medicine auxiliary material. The form of the pharmaceutical composition can be injection or freeze-dried powder injection. According to the invention, organic iron, organic zinc, organic copper, organic manganese and organic cobalt are adopted to replace chloride, so that not only is the property of the composition more stable, but also the adverse reaction is reduced, and the bioavailability of the medicine is increased. Therefore, the preparation provided by the invention is better in safety and more suitable for clinical application.

Owner:江西博意特科技有限公司

Method for chroming by using trivalent chromium

The invention discloses a method for chroming by using trivalent chromium. A plating liquid is prepared from the following raw materials: 125-120 g / L of chromic chloride, 110-130 g / L of urea, 25-30 g / L of ammonium chloride, 9-10 g / L of boric acid, 8.5-9.5 g / L of methanoic acid, 200ml / L of carbinol, 25-35 g / L of sodium chloride and 0.05-0.2 g / L of thioformamide. The method comprises the steps of: during electroplating, electrolyzing for 24 hours by adopting the plating liquid, regulating the pH value to be 1.65-1.75, cleaning a part to be electroplated, then feeding into a plating groove in the electrifying state at the temperature of 20-40 DEG C, keeping constant potential of -3.5V to ensure that a cladding material reaches a specified thickness, fishing out, and drying by hot air. The invention has the advantages that complex ions formed by trivalent chromium and a ligand are completely depolymerized by using the thioformamide, the plating liquid is stable, the deposition speed is high, the generation of hydroxyl polymers can be inhibited when the pH value raises, and an electroplated chrome coating is in a stainless steel ground color and has better corrosion resistance and abrasive resistance.

Owner:ZHENGZHOU AIRCRAFT EQUIP

Trivalent chromium concentrated blue and white zinc passivant and passivation method by means of blue and white zinc passivant

InactiveCN103132068AWide process toleranceProcess tolerance is simpleMetallic material coating processesRare-earth elementNitrate

The invention belongs to the field of passivation treatment and discloses a trivalent chromium concentrated blue and white zinc passivant. The trivalent chromium concentrated blue and white zinc passivant is prepared from 8-50g / L of chromic chloride, 10-60g / L of aluminium potassium sulfate, 3-10g / L of aluminium potassium sulfate, 3-20g / L of cobalt nitrate, 8-15ml / L of coupling agent, and 0.5-5g / L of rare earth element. The invention further discloses a passivation method by means of the trivalent chromium concentrated blue and white zinc passivant. The passivation method includes a first step of galvanizing the surface of a product, washing the product with water, activating the product with concentrated hydrochloric acid, and washing the product with water, a second step of processing the product by means of the blue and white zinc passivant, washing the product with water, and sealing the product with hot water, and a third step of drying the product. The trivalent chromium concentrated blue and white zinc passivant and the passivation method by means of the trivalent chromium concentrated blue and white zinc passivant are environment-friendly, wide in technology tolerance, easy to operate, good in stability, firm in film formation, little in consumption, and low in cost.

Owner:CHONGQING DIANSHI METAL SURFACE TREATMENT

Chromium-rich specialized foliar fertilizer

InactiveCN104692857APromote growthHigh content of major elementsFertilizer mixturesNutritionPhosphate

The invention belongs to the technical field of a fertilizer, and in particular relates to a chromium-rich specialized foliar fertilizer characterized by comprising the following raw materials by weight: 25-35 parts of chromium (III) trichloride, 15-25 parts of urea, 5-15 parts of potassium dihydrogen phosphate, 10-20 parts of potassium oxide, 10-12 parts of boron, 8-10 parts of zinc, 3-5 parts of manganese, 0.5-1.5 parts of copper, 1-2 parts of iron and 0.1-0.3 part of molybdenum. Compared with the prior art, the chromium-rich specialized foliar fertilizer has the fertilizer-medicine double effect, is full in nutrition components, high in concentration, low in cost, non-toxic, remarkable in disease and disaster prevention effect, convenient to use, great in yield increasing extent, and suitable for a variety of soil and crops for application and the like. The content of the main elements of nitrogen, phosphorus, potassium, chromium and the like in the chromium-rich specialized foliar fertilizer is high, after application of the crops, the chromium content is greatly improved, and the chromium-rich specialized foliar fertilizer plays a good role to promote crop growth and increase stress resistance.

Owner:烟台鑫海耐磨胶业有限公司

Trivalent chromium electrolytic solution, preparation method and application thereof in electroplating stainless steel work piece

The invention relates to trivalent chromium electrolytic solution. The raw material comprises the following components by concentration: 15-20g / L of chromic chloride hexahydrate, 40-60g / L of ammonium formate, 70-80g / L of potassium chloride, 40-50g / L of potassium sulphate, 90-100g / L of ammonium chloride, 8-12g / L of ammonium bromide, 40-70g / L of boric acid, 2ml / L of polyoxyethylene actyl phenolic ether, 2ml / L of glycerine, and appropriate sulphuric acid capable of regulating pH to be 4-5. The preparation method includes that: (1) ammonium chloride solution is added into chromic chloride solution, full stirring is carried out for dissolution; (2) ammonium formate, boric acid, polyoxyethylene actyl phenolic ether and glycerine are added in ratio; (3) then low temperature heating in water bath at 40 DEG C is carried out to dissolve undissolved substance in confecting process; (4) leaching and aging are carried out after confecting is finished, thus obtaining the trivalent chromium electrolytic solution. Nickel plated and aluminium plated work piece is firstly washed by acid, trivalent chromium electrolytic solution is used for electroplating, the conditions include that: working temperature is room temperature, current density is 15-30A / dm2, appropriate sulphuric acid is used for regulating pH of electrolytic solution to be 4-5, electroplating time is 10-40min, and anode electrode is high-purity graphite electrode; and water is used for cleaning work piece after electroplating, and drying is carried out. The electrolytic solution prepared by the invention is easy to prepare and has low toxicity.

Owner:JIANGSU UNIV

Preparation method and application of manganese-chromium binary metal oxide energy storage material

ActiveCN108242539ARich reservesLow toxicityCell electrodesSecondary cellsChromium(III) chlorideRetention ratio

The invention relates to a preparation method of a manganese-chromium binary metal oxide energy storage material. The preparation method comprises the following steps: dropwise adding mixed solution of sodium hydroxide and sodium carbonate into mixed solution of manganese chloride and chromium chloride by adopting a coprecipitation method until the mixed solution is alkaline, and then stirring for0.5-2 hours; then ageing for 6-48 hours at the temperature of 25-100 DEG C; washing precipitates, drying and grinding; and then heating and calcining in an aerobic atmosphere, milling, and sieving, thus obtaining the manganese-chromium binary metal oxide energy storage material. The obtained manganese-chromium binary metal oxide energy storage material product is of a nano sheet structure and canalleviate volume expansion effect, inhibit single phase crystal grain agglomeration and shorten a migration path of lithium ions in charging and discharging processes, so that the rate capability ofthe material product is improved, under the condition of 1A / g, from a third cycle, efficiency is higher than 97%, discharge specific capacity after 300 cycles is 913mAh / g, capacity retention ratio is112.0% compared with that of a second circle, and the material product has good application prospect in the aspect of negative electrode materials of a lithium ion battery.

Owner:湖南烯顺新材料有限公司

Aqueous solution of chromium salt and method for producing same

Disclosed is an aqueous solution of a chromium salt which is characterized in that the oxalic acid content is not more than 8 weight% relative to chromium. In this aqueous solution of a chromium salt, the total organic carbon is not more than 4 weight% relative to chromium. The chromium salt may preferably be a chromium chloride, a chromium phosphate or a chromium nitrate. The chromium chloride may preferably contain a basic chromium chloride represented by the following composition formula: Cr(OH)xCly (wherein 0 < x <= 2, 1 <= y < 3, and x + y = 3). The chromium phosphate may preferably be one represented by the following composition formula: Cr(H3-3 / nPO4)n (wherein n is a number satisfying 2 <= n <= 3). The chromium nitrate may preferably be a basic chromium nitrate represented by the following composition formula: Cr(OH)x(NO3)y (wherein 0 < x <= 2, 1 <= y < 3, and x + y = 3).

Owner:NIPPON CHECMICAL IND CO LTD

Method for preparing iron-chromium redox battery electrolyte

ActiveCN112234238AGuaranteed purityRegenerative fuel cellsAcid electrolytesElectrolytic agentElectrical battery

The invention provides a method for preparing an iron-chromium redox battery electrolyte, and the method comprises the following steps: 1) dissolving an iron-containing material into hydrochloric acidwith the concentration of 0.1-0.5 mol / L, inserting an electrode into the solution, setting the electrode as a negative electrode, and introducing current for electrolysis; 2) adding chromium chlorideand hydrochloric acid into the reaction container under the condition of isolating air, and starting stirring in the process of adding chromium chloride; and 3) after the chromium chloride is completely dissolved, mixing the negative electrode solution obtained by electrolysis in the step 1) with the solution obtained in the step 2). According to the preparation method of the iron-chromium redoxbattery electrolyte, provided by the invention, industrial wastes, such as red mud and the like, can be used as electrolysis raw materials, and impurities which cannot be dissolved in the electrolytein the red mud are discarded through constant-current electrolysis, so that the industrial wastes are digested, and the cheap electrolyte is obtained.

Owner:中海储能科技(北京)有限公司

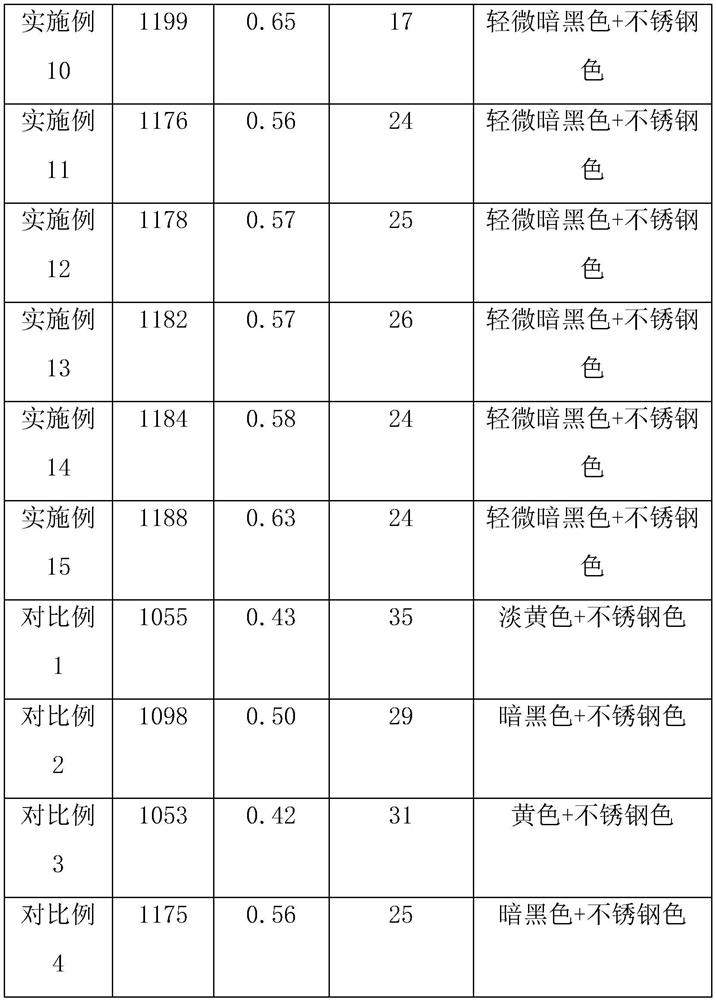

Trivalent chromium plating solution, preparation method thereof and trivalent chromium plating method

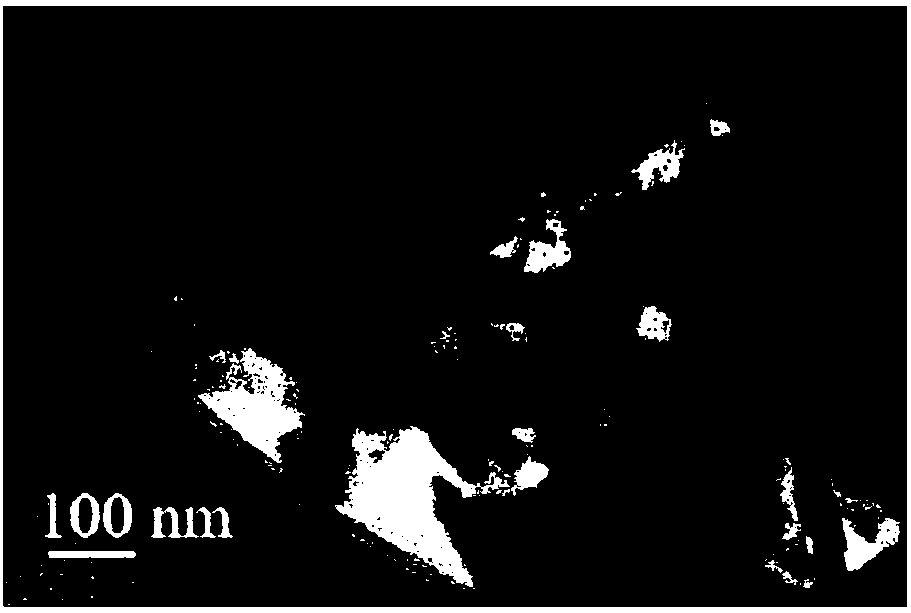

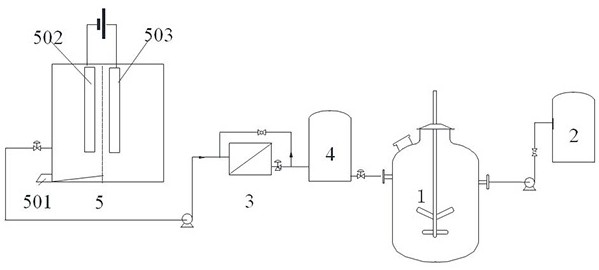

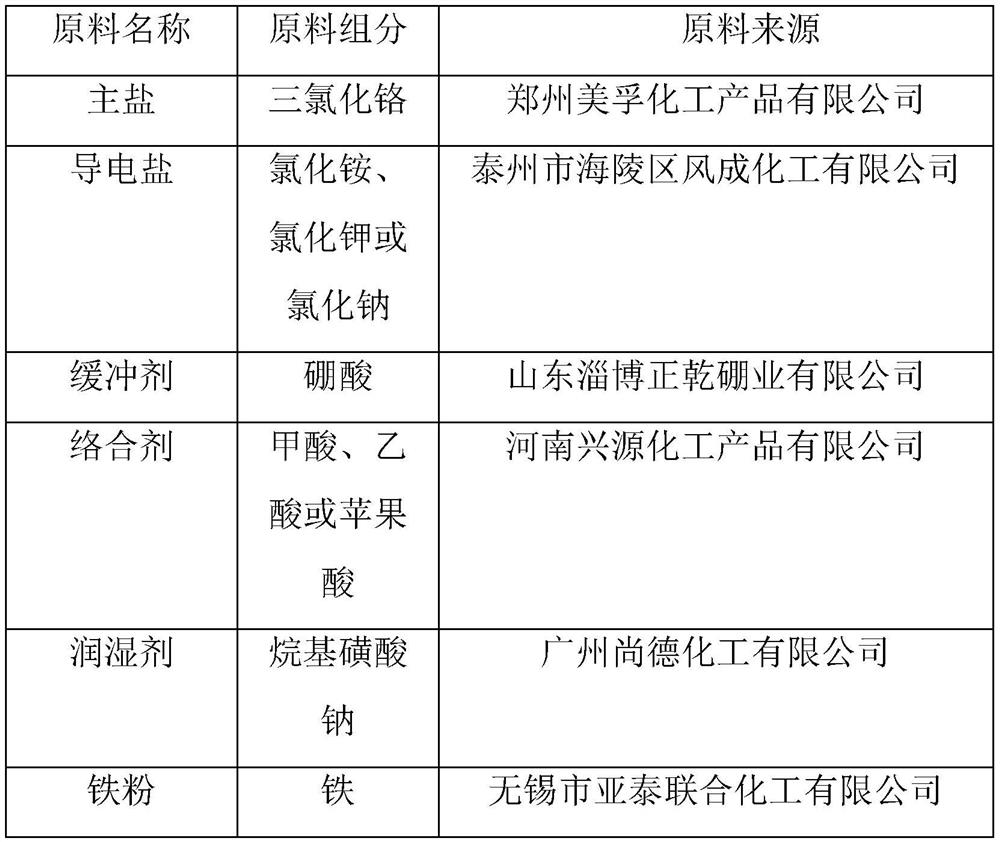

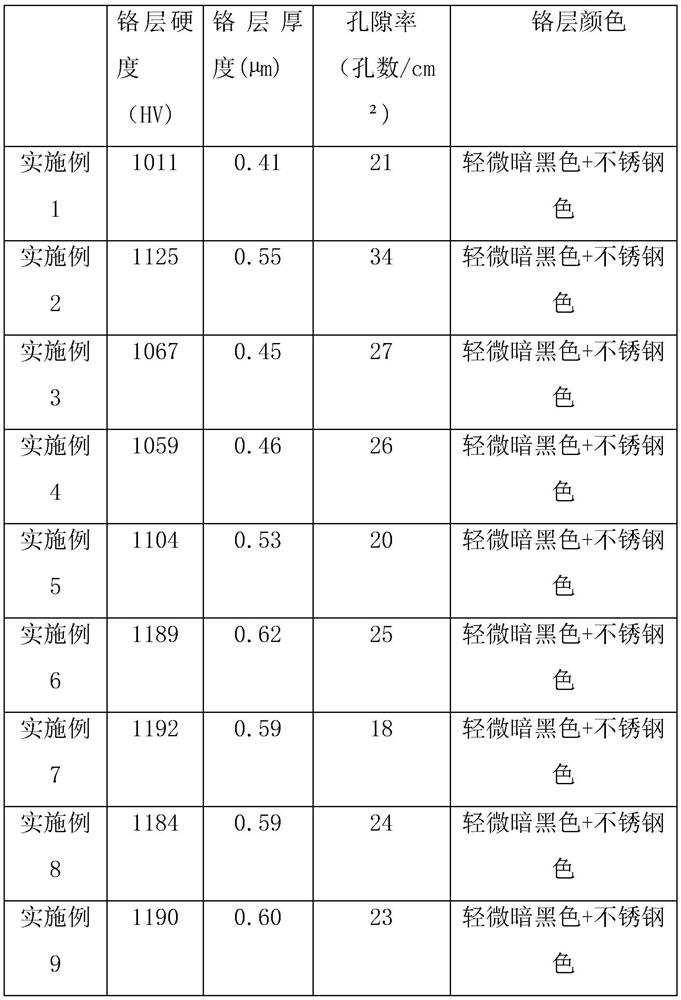

InactiveCN112226791ASimple preparation processProcess conditions are easy to controlIron powderSS - Stainless steel

The invention discloses a trivalent chromium plating solution, a preparation method thereof and a trivalent chromium plating method, and belongs to the technical field of electroplating technologies.The trivalent chromium plating solution is prepared from the components including, by weight, 90-120 parts of chromium trichloride, 200-250 parts of conductive salt, 6-80 parts of a buffer agent, 40-60 parts of a complexing agent, 0.05-0.1 part of a wetting agent, 0.2-0.4 part of iron powder and 450-650 parts of deionized water. With the adoption of a trivalent chromium plating layer prepared fromthe trivalent chromium plating solution, the problems of yellowing and whitening of common trivalent chromium plating layers are solved, and the trivalent chromium plating layer also has the effect of imitating the slight dark color of stainless steel.

Owner:厦门市金宝源实业有限公司

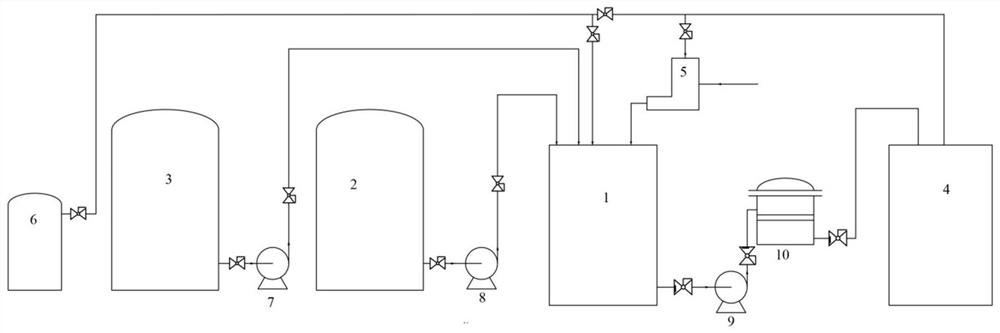

Preparation method and system of iron-chromium redox battery electrolyte

InactiveCN112993358AEfficient productionImprove battery performanceRegenerative fuel cellsAcid electrolytesElectrolytic agentElectrical battery

The invention provides a preparation method and system of an iron-chromium redox battery electrolyte. The preparation method comprises the following steps: 1) adding water into a reaction container; (2) adding CrCl3 and hydrochloric acid into the reaction container under the condition of isolating air, and starting stirring in the process of adding chromium chloride; and 3) after the chromium chloride is completely dissolved, adding ferrous chloride into the reaction container under the condition of air isolation, and stirring until the ferrous chloride is completely dissolved. According to the preparation method of the iron-chromium redox battery electrolyte, heating is not needed, additives are not added, the process is simple, green and environment-friendly, efficient and low-cost electrolyte production is achieved, and the battery performance and capacity of an iron-chromium flow battery are improved. Compared with the electrolyte solution in the prior art, the electrolyte solution produced by the preparation method has the advantage that the performance of the iron-chromium flow battery is obviously improved.

Owner:坤厚储能科技有限公司

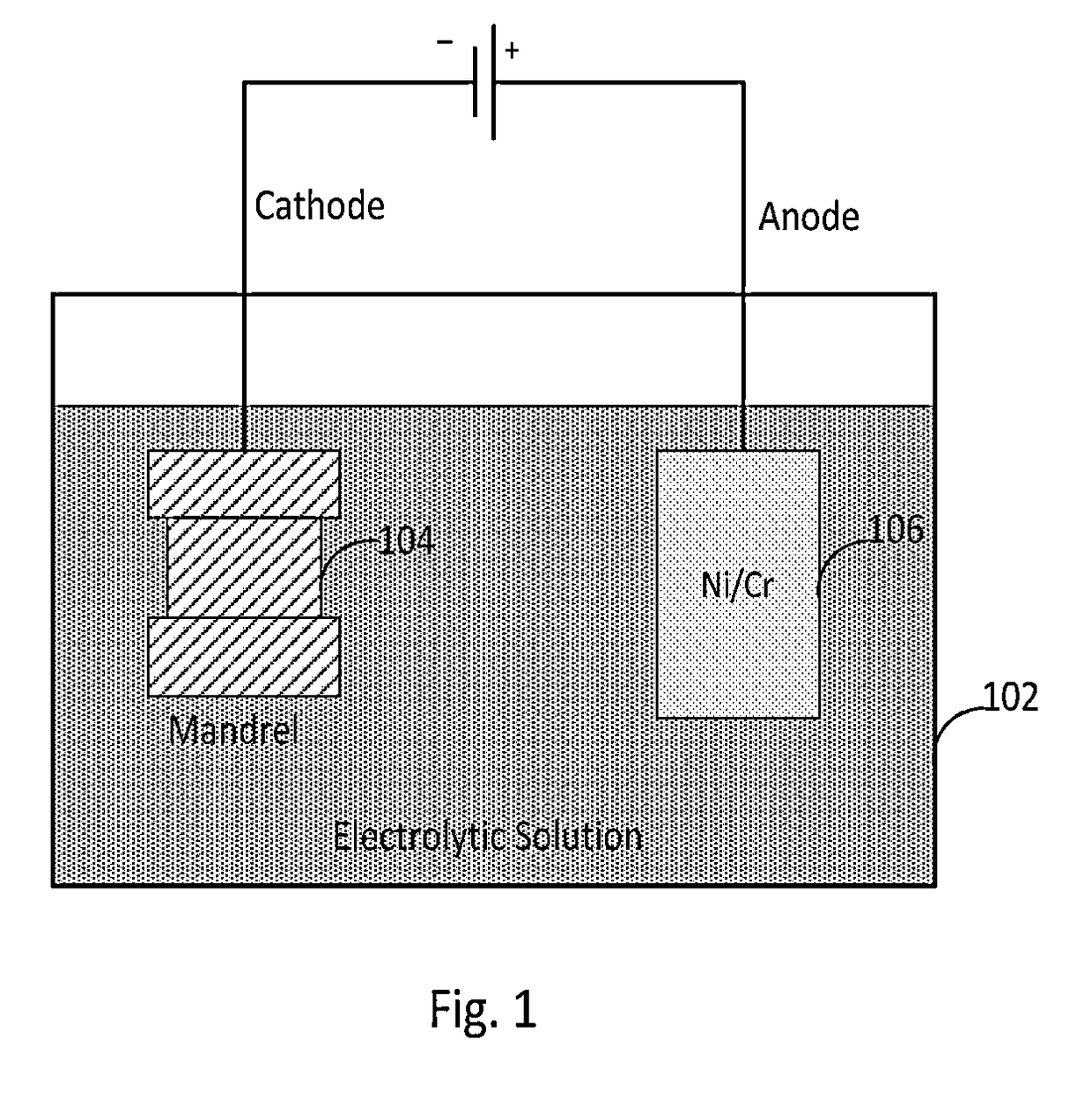

Electroformed nickel-chromium alloy

ActiveUS20190072683A2Oxidation resistance can be improvedSeismic data acquisitionBlade accessoriesNichromeChromium(III) chloride

An article comprising a turbine component formed of a nickel-chromium (Ni—Cr) alloy including from 2 to 50 wt % chromium balanced by nickel is disclosed. The Ni—Cr alloy is thicker than at least 125 μm to make a self-supporting turbine component, and the turbine component includes a rotor blade, a stator, or a vane. The Ni—Cr alloy is electroformed on a mandrel by providing an external supply of current to an anode and a cathode in a plating bath containing a solvent, a surfactant, and an ionic liquid including choline chloride, nickel chloride, and chromium chloride.

Owner:RTX CORP

Chloride type trivalent chromium black chromium plating solution

The invention discloses a chloride type trivalent chromium black chromium plating solution which comprises the following components by weight: 30 to 70g / L of chromium trichloride, 150-320g / L of conducting salt, 20 to 70g / L of complexing agent, 2 to 10g / L of blackening agent, and 0.2 to 1g / L of surfactant, wherein the conducting salt is one of or a mixture of potassium chloride, sodium chloride, ammonia chloride, sodium sulfate and potassium sulfate; the complexing agent is one of or a mixture of ammonium oxalate, malic acid and formic acid; and the blackening agent is one of or a mixture of ferric chloride, potassium thiocyanate, ammonium thiocyanate and cobalt nitrate. According to the chloride type trivalent chromium black chromium plating solution, a trivalent black chromium plating layer with thickness being 0.2 to 0.5microns can be obtained, an appearance of the plating layer is uniform and bright black, and the colors of a high electric current density region and a low electric current density region are essentially identical; and the chloride type trivalent chromium black chromium plating solution does not yellow or change color even if being placed in air in a plum rain season, and the mildews can not be found.

Owner:NANJING DADI REFRIGERATION FOOD

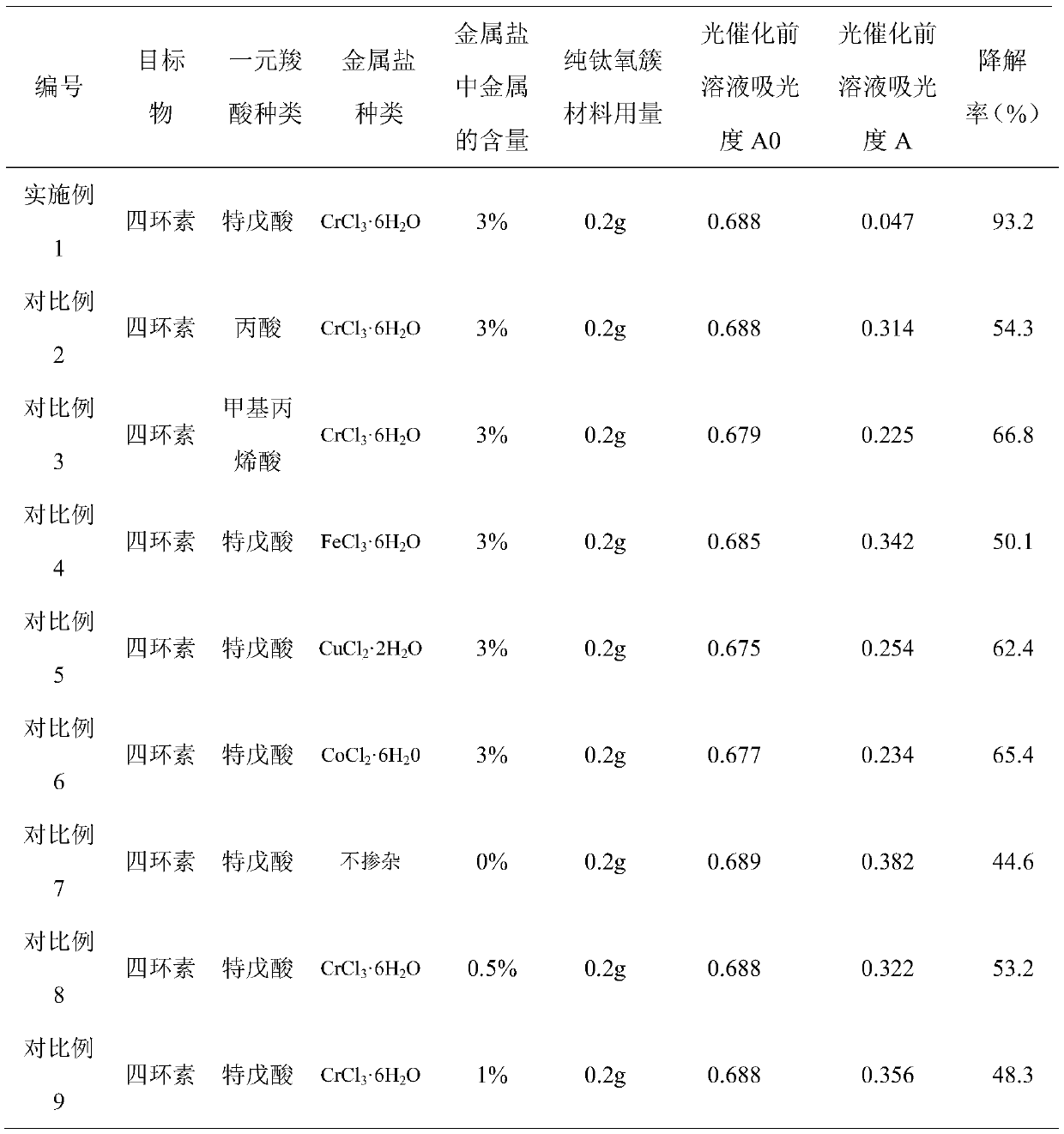

Chromium-doped titanium oxygen cluster nano catalytic material, preparation method and applications thereof

ActiveCN110975860ARich varietyLow costWater/sewage treatment by irradiationWater treatment compoundsPivalic acidQuantum efficiency

The invention discloses a chromium-doped titanium oxygen cluster nano catalytic material, a preparation method and applications thereof. The preparation method comprises the following steps: preparingtitanium oxygen cluster powder by taking pivalic acid as a precursor; and then adding the titanium oxygen cluster powder and chromium chloride into tetrabutyl titanate, carrying out ultrasonic dissolution, and reacting under a boiling condition to prepare the chromium-doped titanium oxygen cluster nano catalytic material, wherein a mass ratio of the titanium oxygen cluster powder to the chromiumchloride is (6-8):1. The chromium-doped composite titanium-oxygen cluster nano catalytic material prepared by the invention has the advantages of low technical cost, environmental friendliness, easiness in operation, high degradation efficiency and multiple types of degraded tetracycline, and overcomes the defects of poor quantum efficiency, poor visible light absorption efficiency, easiness in photo-induced charge combination and the like of the single-molecule photocatalyst. The titanium oxygen cluster compound has a large specific surface area, is easy to form a vacuum position under an illumination condition, has more pores and has high catalytic performance.

Owner:河北地质大学

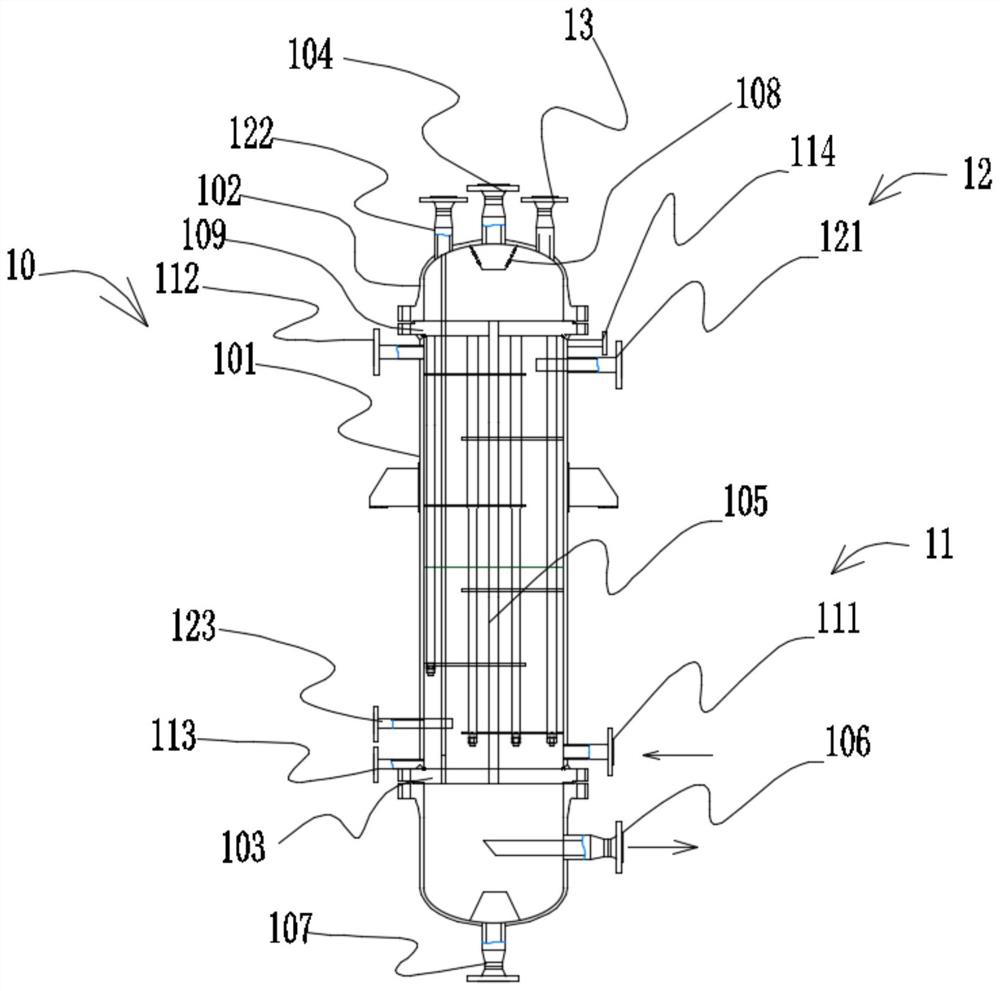

Three-stage rectification method of electronic-grade CHF3

The invention provides a novel preparation method of electronic-grade CHF3, which comprises the following steps: S1, reaction gas formed by mixing HF and monochlorodifluoromethane is introduced into a catalyst tube nest (105) from top to bottom, and the ratio of HF to monochlorodifluoromethane is (1.05-1.1):1, wherein the catalyst tube nest (105) comprises activated catalyst particles, the catalyst particles are formed by mixing 8-10 parts by weight of chromium trichloride / activated carbon compound, 50-70 parts by weight of aluminum trichloride, 2-5 parts by weight of nickel chloride and 2-5 parts by weight of magnesium chloride, and the content of chromium trichloride in the chromium trichloride / activated carbon compound is 15-25 wt%; s2, controlling the upper temperature of the catalyst tube nest (105) to be 220-230 DEG C, the middle temperature of same to be 245-255 DEG C, the lower temperature of same to be 230-240 DEG C, the reaction pressure to be 0.05-0.2 Mpa and the retention time to be 40-80 s, so as to obtain a trifluoromethane crude product with the purity of 98% or above; s3, carrying out water washing, alkali washing, drying and rectification on the trifluoromethane crude product to obtain the electronic-grade CHF3 with the purity of 99.9999%.

Owner:FUJIAN DEER TECH CORP

Chromium-containing light hydrocarbon combustion catalyst and preparation method thereof

InactiveCN102198396AGood catalytic combustion activity for light hydrocarbonsImprove stabilityGaseous fuelsCatalyst activation/preparationAlkanePtru catalyst

The invention relates to a chromium-containing light hydrocarbon combustion catalyst and a preparation method thereof, and belongs to the technical field of catalysts. The chromium-containing light hydrocarbon combustion catalyst is characterized in that a mass ratio of Al2O3 to Cr2O3 to CeO2 or Al2O3 to CrCl3 to CeO2 is A:B:C, wherein A:B is between 1 / 0.05 and 1 / 0.5, C is between 1 and 5 percent, Al2O3 is between 65 and 95 percent (W / W percent), Cr2O3 is between 5 and 50 percent (W / W percent), CrCl3 is between 5 and 50 percent (W / W percent), and CeO2 is between 0 and 5 percent (W / W percent). The preparation method comprises the following steps of: dissolving chromium nitrate or chromium chloride and aids of nitrates in water, dripping onto an aluminum oxide carrier, stirring, standing, drying, calcining at a certain temperature, cooling, grinding, tabletting, crushing and sieving to prepare the chromium-containing light hydrocarbon combustion catalyst. The chromium-containing light hydrocarbon combustion catalyst has the advantages of high low-carbon alkane catalytic combustion activity, high stability, simple preparation process, readily available raw materials, low cost and environment friendliness.

Owner:DALIAN UNIV OF TECH

Process for preparing grist powder contained chrome-enriched yeast

The preparation method of chromium-enriched yeast containing malt powder for improving sugar tolerence includes the following steps: 1. preparing chromium-enriched malt powder, culturing malt in chromium chloride or chromium sulfate solution, drying by airing and pulverizing for stand-by; 2. preparing chromium-enriched yeast, using malt wort or basic culture medium, adding chromium chloride or chromium sulfate, inoculating yeast, culturing and extracting for stand-by; 3. combining the above-mentioned chromium-enriched malt and chromium-enriched yeast paste so as to obtain the invented product with the health-care functions of reducing sugar and reducing blood fat, etc.

Owner:郑彦巍

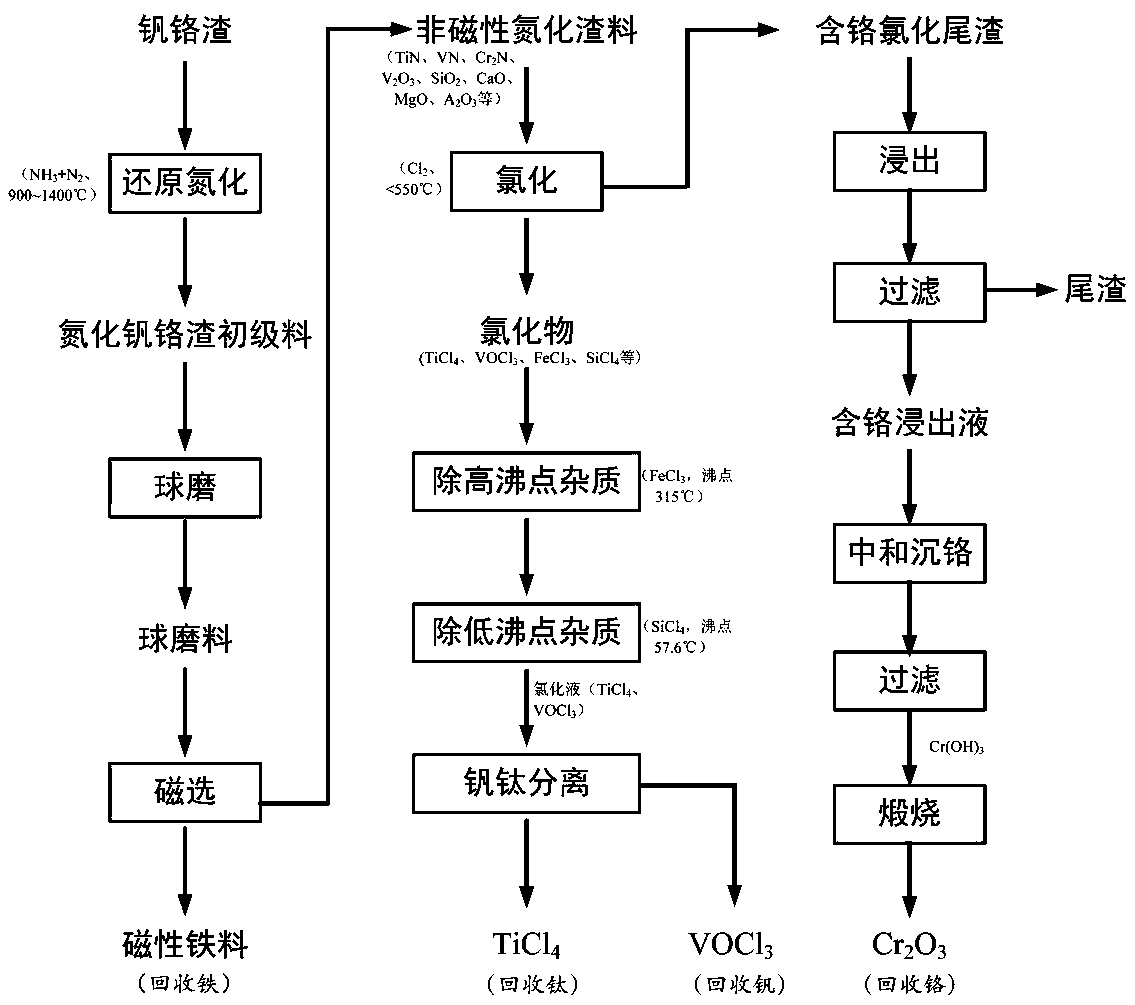

Recovery method of valuable metal in vanadium chromium slag

InactiveCN109868370ALower operating temperatureIncrease reaction rateChromium trioxideVanadium oxidesRecovery methodSlag

The invention relates to a recovery method of valuable metal in vanadium chromium slag. According to the method, vanadium chromium slag fine powder and mixed gas mainly dominated by NH3+N2 are subjected to reduction and nitridation to obtain a vanadium chromium nitride slag primary material; then metal iron is removed through ball milling magnetic separation, so that non-magnetic nitridation slagis obtained; then the non-magnetic nitridation slag and chlorine react in a fluidized bed at a low temperature, thus TiN, VN, V2O3 and the like and chlorine react to generate chloride, and chromium chloride is left in the chlorination tailings to obtain chromium-contained chlorination tailings; then after high-boiling-point and low-boiling-point impurities in the chloride are removed, separation is carried out so that pure VOC13 and TiC14 products are obtained; and finally, the chromium-contained chlorination tailings are subjected to the working procedures of leaching out, neutralizing chromium depositing, calcining and the like, so that a Cr2O3 product is obtained. The method achieves comprehensive recovery and utilization of valuable metal iron, chromium, vanadium and titanium in the vanadium chromium slag, and has the characteristics of being high in comprehensive recovery rate, clean and environmentally friendly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Preparation method of high-efficiency blue-white passivation and closing passivator

InactiveCN103668152AUniform film formationImprove performanceMetallic material coating processesEthylene diamineMalonic acid

The invention provides a preparation method of a high-efficiency blue-white passivation and closing passivator. The igh-efficiency blue-white passivator is composed of chromium trichloride, sodium silicate, nitric acid, sodium nitrate, malonic acid, sodium fluoride, EDTA (ethylene diamine tetraacetic acid), KH550 silane coupling agent and deionized water. The trivalent chromium passivating film has blue-white color and high uniformity, and the neutral salt fog experiment test 96H indicates that the trivalent chromium passivating film reaches Grade 8-9. The corrosion resistance is favorable. The passivation solution has the advantages of stable performance, low cost price and favorable properties.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

Preparation method of trivalent chromium black passivator

InactiveCN103668146AImprove bindingImprove performanceMetallic material coating processesMalonic acidNitrate

The invention provides a preparation method of a trivalent chromium black passivator. The trivalent chromium black passivator is composed of chromium chloride, chromic nitrate, cobalt nitrate, sodium dihydrogen phosphate, nickel sulfate, malonic acid and deionized water. The black trivalent chromium passivator can obtain a black film with favorable binding force, and the white rust appearance time in the neutral salt fog experiment is longer than 96 hours. The passivation solution has the advantages of stable performance, low cost price and favorable properties.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

Low toxicity low irritation Commassie brilliant blue fast staining solution and dyeing and decoloring method

ActiveCN109632434AToxic reductionLow in irritating ingredientsPreparing sample for investigationMaterial analysis by electric/magnetic meansIrritationPhosphate

The invention discloses a low toxicity low irritation Commassie brilliant blue fast staining solution and a dyeing and decoloring method. The low toxicity low irritation Commassie brilliant blue faststaining solution contains 0.005 percent-0.02 percent of Commassie brilliant blue, 1 percent -5 percent (v / v) of concentrated hydrochloric acid or 1 percent -5 percent (v / v) of 85% phosphate, 1 percent -5 percent (v / v) of glacial acetic acid, 1.5 per thousand-5 per thousand of anhydrous copper sulfate or chromium trichloride, and 3 percent -5 percent (v / v) of mixed water solution of absolute ethanol. The staining solution has low toxicity and low irritation, dyeing and decoloring time is short, and dyeing resolution and color fastness are high.

Owner:苏州译酶生物科技有限公司

Anti-shedding environmental protection waterproof coating material

InactiveCN103602218ANo pollutionHard and smooth coating filmCarboxyl rubber coatingsEpoxy resin coatingsWater chlorinationChromium(III) chloride

The present invention discloses an anti-shedding environmental protection waterproof coating material, which is prepared from the following raw materials by weight: 1.5-4.8 parts of bisphenol A glycidyl ether, 1.2-2.3 parts of gasoline, 3.2-4.5 parts of chromium chloride, 3.2-3.5 parts of sodium sulfate, 2.3-2.8 parts of wollastonite powder, 1.5-2.8 parts of 3,5-tert-butyl-4-hydroxyphenyl thioether, 2.3-3.6 parts of isophorone diamine, and 2-3.5 parts of a carboxylated liquid nitrile rubber. Compared with the existing waterproofing coating material, the anti-shedding environmental protection waterproof coating material of the present invention has advantages of no environment pollution, hard and smooth paint film, scratch resistance, super strong water resistance and the like, wherein the paint film is hard after water washing, no peeling and shedding is generated even if the wall is wet, the wall surface is not subjected to condensation in winter, and characteristics of high water resistance and good permeability are provided. In addition, the coating material has characteristics of no odor and environmental protection, and can be scraped or sprayed during construction.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

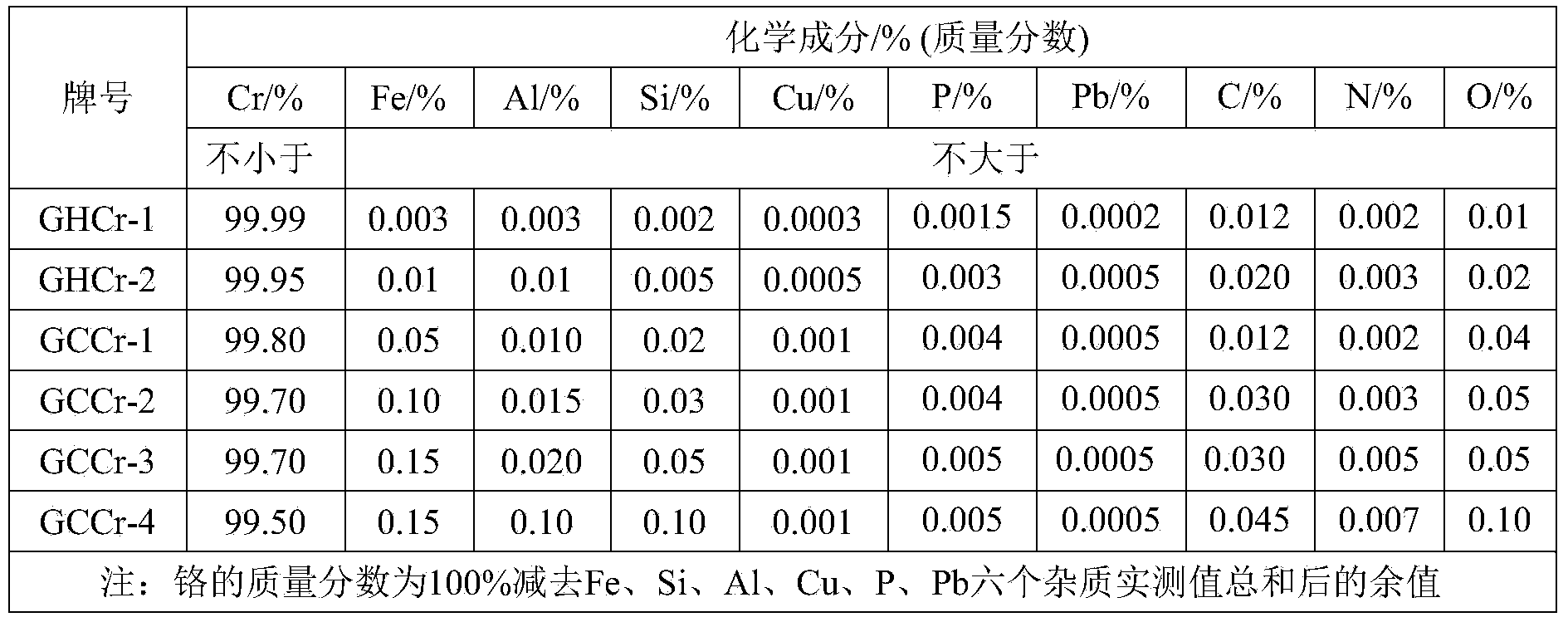

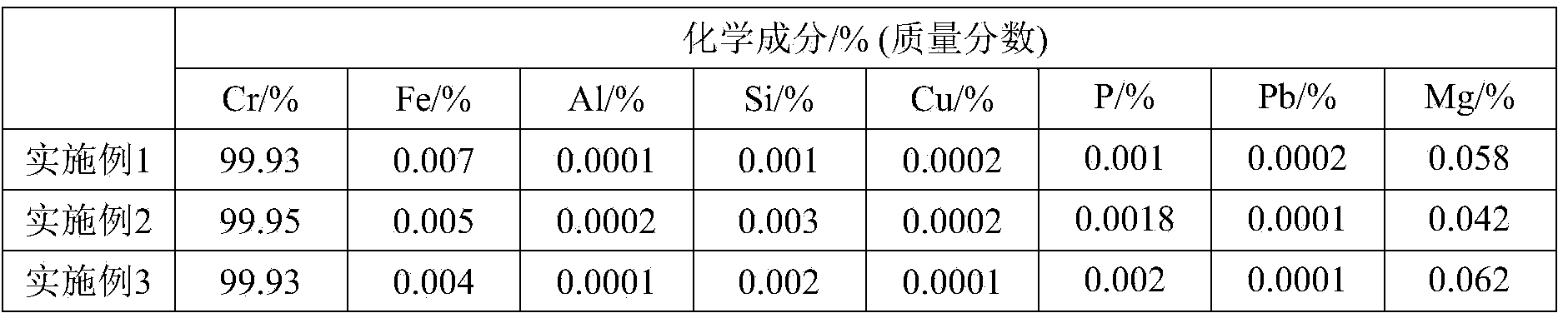

Method for producing high-purity metal chromium by reducing anhydrous chromium chloride through utilizing metal magnesium

The invention belongs to the field of producing metal chromium, and particularly relates to a method for producing high-purity metal chromium by reducing anhydrous chromium chloride through utilizing metal magnesium. The method comprises the following steps: (1) subliming and purifying anhydrous chromium chloride; (2) fusing the anhydrous chromium chloride purified in the step (1) into fused salt, adding metal magnesium for carrying out reduction reaction; or, directly carrying out reduction reaction on the metal magnesium and anhydrous chromium chloride without adoption of a fused salt medium; (3) rinsing and filtering a reduced product; (4) performing acid washing and filtering to the rinsed metal chromium filter cake; and (5) rinsing the acid-washed metal chromium filter cake to be neutral, and drying to obtain a high-purity metal chromium product. By adopting anhydrous chromium chloride as a raw material, the anhydrous chromium chloride can be sublimed and purified, and the introduction of metal impurities can be reduced from the source compared with the electrolysis technology and the vacuum carbon reduction technology. Compared with the metal thermal reduction and vacuum carbon reduction, the reaction conditions are milder.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cr2O3 supported reduced graphene oxide lithium battery anode material and preparation method

InactiveCN108428886AWell mixedHigh specific capacityCell electrodesCharge dischargeChromium(III) chloride

The invention discloses a preparation method of a Cr2O3 supported reduced graphene oxide lithium ion battery anode material. The preparation method comprises steps as follows: S101: preparing a graphene oxide solution and a chromium chloride hexahydrate solution; S102: adding the graphene oxide solution to the chromium chloride hexahydrate solution, and performing uniform ultrasonic mixing and drying to obtain a molten sample; S103: putting the sample in a porcelain boat, putting the porcelain boat in a tubular furnace, performing calcination and annealing under the inert gas, and naturally cooling a product to the room temperature to obtain a final product. The material takes chromium chloride hexahydrate as a precursor, the graphene oxide solution and the dissolved chromium chloride hexahydrate solution are mixed uniformly through ultrasonic treatment, the cathode material is prepared through calcination at the high temperature, the conductivity of the material is effectively increased through supporting of graphene, the volume expansion effect in the charge-discharge process is effectively relieved, and the lithium ion battery anode material with high specific capacity and longcyclic life is prepared. Raw materials are widely sourced, and the method is simple, controllable and easy to operate, uses simple equipment and causes little pollution.

Owner:UNIV OF JINAN

Blue and white passivating agent preparation method

InactiveCN103695882AColorfulUniform film formationMetallic material coating processesHydrogen fluorideMalonic acid

The invention discloses a blue and white passivating agent preparation method. A formula of a blue and white passivating agent comprises chromium trichloride, KH550, cobalt sulfate, sodium nitrate, propane diacid, ammonium bifluoride and deionized water. A trivalent chromium passivating film developed in the invention has the advantages of brilliant color, uniform film formation, and excellent corrosion resistance. A passivatign liquid has the advantages of stable performances, low cost and price, and good performances.

Owner:天津祥和兴金属制品有限公司

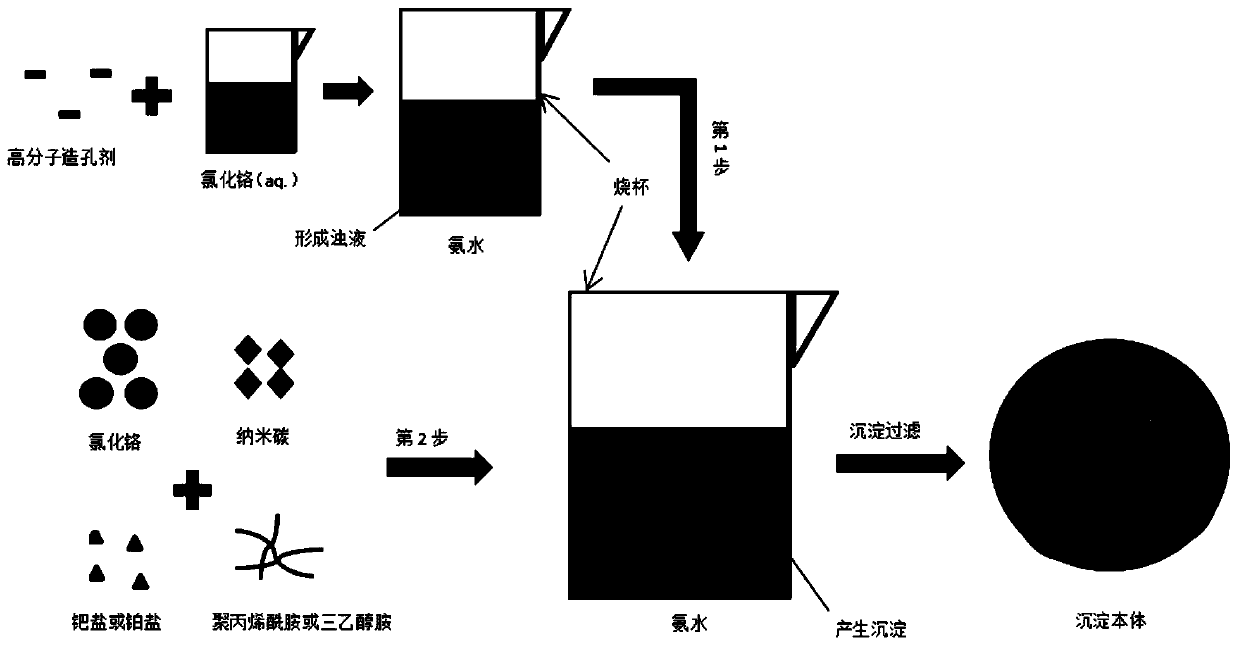

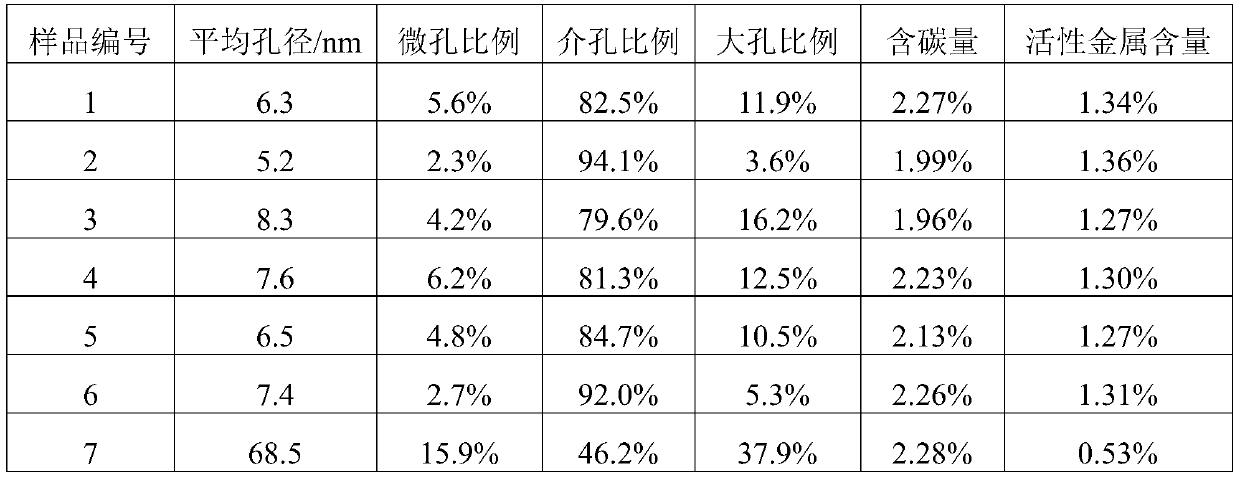

Fluorination catalyst precursor and preparation method of fluorination catalyst

ActiveCN110841637AHigh activityHigh reactivityPreparation by halogen replacementCatalyst activation/preparationCellulosePlatinum salts

The invention provides a preparation method of a fluorination catalyst precursor. The method comprises the following steps: (1) carrying out first mixing treatment on a chromium chloride solution andammonia water, wherein the chromium chloride solution contains a polymer pore-forming agent; (2) allowing an aqueous solution containing nanocarbon and platinum salt or palladium salt and the mixed solution obtained in the step (1) to be subjected to second mixing treatment and filtering treatment so as to obtain a filter cake, and the aqueous solution further contains at least one of chromium chloride and a pore channel compound; and (3) baking the filter cake to obtain the fluorination catalyst precursor, wherein the polymer pore-forming agent is at least one of lignin, cellulose, lignosulfonate and starch. The catalyst prepared by the method is high in mesoporous proportion, firm in macroporous structure, high in catalytic activity, high in weather resistance and long in service life.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

High-temperature electric heating tube

InactiveCN106350795AExcellent anti-rustImprove corrosion resistanceMetallic material coating processesChromium(III) chlorideAmmonium sulfate

The invention discloses a high-temperature electric heating tube. A metal electric heating pipe main body of the high-temperature electric heating tube is subjected to passivation treatment including the following steps: 1) sequentially dropping 1-2 parts of dodecyl trimethyl ammonium sulfate, 1.6 parts of sodium methyl oleoyl ethanesulfonic acid, 1.1 parts of gamma (methacryloyl oxygen) mercaptopropyltrimethoxysilane, 0.8 part of chromium chloride, and 5.2 parts of malonic acid into 35 parts of deionized water and evenly stirring; 2) sequentially dropping 1.1 parts of urotropine, 1.5 parts of oleic acid triethanolamine soaps, 0.8 part of zinc dialkyl dithiophosphate, 1.6 parts of phosphonic acid di-n-buyl ester salt and 1.8 parts of multi-component copolymerized sodium polyacrylate again and continuously stirring until the components are fully and evenly mixed to prepare a passivation treatment solution; 3) putting the metal electric heating pipe main body into the passivation treatment solution to carry out passivation treatment for 30 seconds at the treatment temperature of 50 DEG C, taking out, cleaning with pure water and drying again. The high temperature electric heating pipe of which the metal electric heating pipe main body is subjected to passivation treatment has good performance and is good in surface finish.

Owner:常熟市江南电热元件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com