Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Raw material conversion rate is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

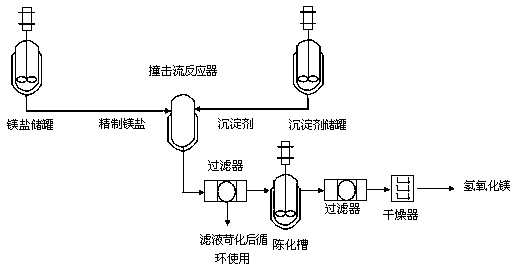

Molecular sieve catalyst for preparing propylene by propane dehydrogenation and preparation method of molecular sieve catalyst

InactiveCN109675548AHigh catalytic activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystDispersityAlkane

The invention discloses a molecular sieve catalyst for preparing propylene by propane dehydrogenation and a preparation method of the molecular sieve catalyst, and belongs to the field of preparationof catalysts. The catalyst consists of a component A and a component B, wherein the component A is one of metal elements Sn, Ga, Fe, Co, Ni or Zn, the use amount of the component A is 1-9wt% of the total amount of the catalyst, the component B is a molecular sieve carrier, and the use amount of the component B is 90-99wt% of the total amount of the catalyst. The preparation method of the catalystcomprises a direct hydrothermal synthesis method and an impregnation method. The high-performance alkane dehydrogenation catalyst is prepared by controlling the use amounts, the structures and the dispersity of active components, has the characteristics of simple preparation process, low price and no toxicity, and has the characteristics of good activity, high selectivity, high stability and the like when applied to preparation of propylene through propane dehydrogenation; and a new technical scheme is provided for development and preparation of a new-generation alkane dehydrogenation catalyst.

Owner:FUZHOU UNIV

Method for fermenting and preparing citric acid by adding saccharifying enzyme

InactiveCN101942487AReduce raw material consumptionRaw material conversion rate is highMicroorganism based processesFermentationIon exchangeChemistry

The invention discloses a method for fermenting and preparing citric acid by adding saccharifying enzyme and belongs to the technical field of fermentation engineering. In the traditional citric acid fermentation, a method of mixing water and starch raw materials for size mixing and adding amylase so as to liquefy, heat, sterilize and ferment the raw materials is adopted, and in the fermentation process, saccharifying enzyme secreted by a production strain aspergillus niger per se is saccharified and fermented simultaneously. The method has the disadvantages that: a time process is needed for the aspergillus niger to grow and secrete saccharifying enzyme; and the acidity is continuously increased along with the increase of the produced acid, and the saccharifying enzyme of the aspergillus niger per se is gradually inhibited and cannot play a role in saccharifying normally at the later stage of the fermentation, so that the residual sugar content in the fermented liquor of the citric acid is higher in the end. The citric acid is prepared by the following steps of: adding the amylase to liquefy the starch raw materials, and heating for sterilization; adding a proper amount of saccharifying enzyme, and fermenting, filtering, decoloring, exchanging ions, separating, crystallizing and performing other processes according to the conventional technology. The method for fermenting and preparing the citric acid has the advantages of reducing raw material consumption, improving the conversion rate of the raw materials, improving the acid-producing rate, shortening the fermentation time and reducing CODCr discharge of wastewater.

Owner:JIANGNAN UNIV +1

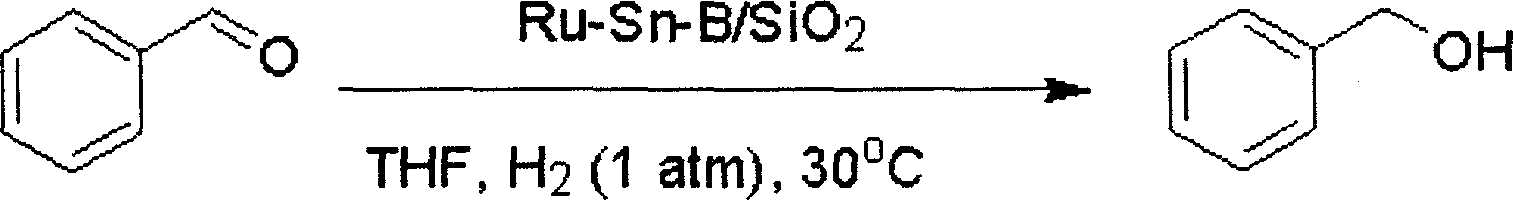

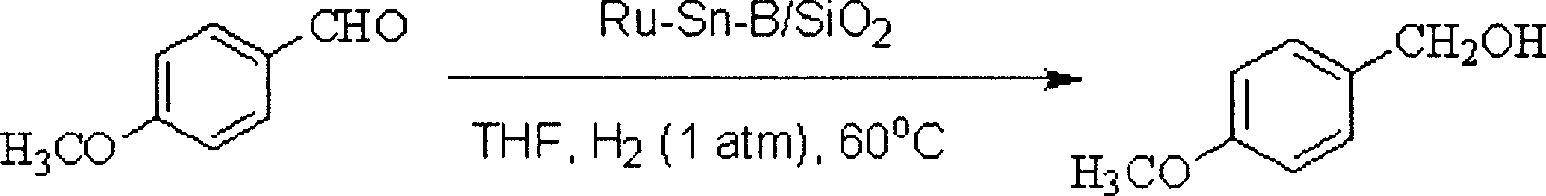

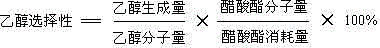

Method for load type amorphous ruthenium boron-containing catalyst to catalyzing hydrogenating and reducing carbonyl compound to prepare alcohol

InactiveCN1994988AMild reaction conditionsRaw material conversion rate is highOrganic reductionCatalyst carriersReaction timingCarbonyl group

The invention discloses a making method of alcohol based on catalytic liquid-phase hydrogenation reducing carbonyl compound under high pressure, which comprises the following steps: adopting carbonyl compound as raw material and ruthenium-boron loaded type non-crystal alloy as catalyst; setting the pressure as normal pressure at 20-90 deg. c; controlling the reacting time at 5-60h; saving energy.

Owner:SOUTH CHINA UNIV OF TECH

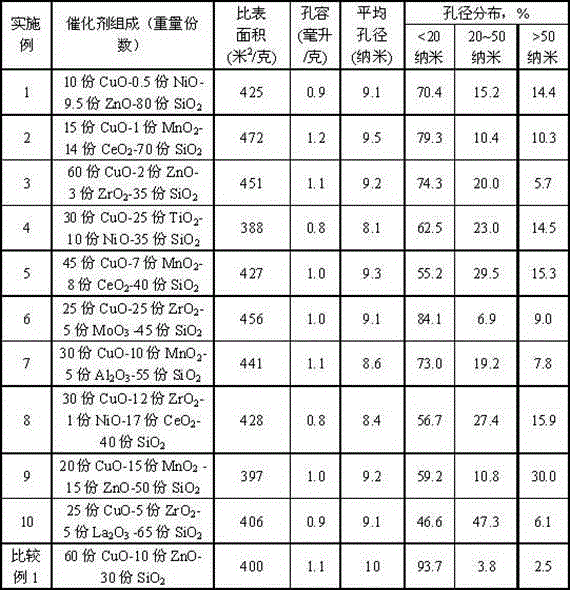

Catalyst and method for preparing ethanol by hydrogenating acetic ester

InactiveCN104148079ALarge specific surface areaIncrease chance of contactOrganic compound preparationHydroxy compound preparationHydrogenGram

The invention relates to a catalyst and a method for preparing ethanol by hydrogenating acetic ester and mainly solves the problems that in the prior art, the ratio of hydrogen to ester is too high, the conversion rate of raw materials is low and the selectivity of ethanol is poor. The catalyst is composed of the following components in parts by weight: (a) 5-80 part of metallic copper or copper oxide, (b) 0.05-60 parts of catalyst promoter and (c) 5-90 parts of silicon dioxide carrier, wherein the catalyst promoter is selected from at least one of transitional metal or oxide of the transitional metal; the specific area of the catalyst is 150-500 m<2> per gram; the total pore volume is 0.1-3.0 ml / gram; the pore volume of the diameter less than 20nm is 40-90% of the total pore volume; the pore volume of the diameter less than 50nm and larger than 20nm is 5-75% of the total pore volume; and the pore volume of the diameter larger than 50nm is 5-75% of the total pore volume. By adopting the technical scheme, the problems are well solved; and the catalyst can be used for industrial production of ethanol by hydrogenating acetic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for preparing 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate

InactiveCN106607044AImprove stabilityImprove conversion rateOrganic compound preparationHydroxy compound preparationCopperAdipate

The invention relates to a catalyst and method for preparing 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate. The catalyst comprises, by weight, a) 20 to 50 parts of metallic copper or an oxide thereof, b) 30 to 60 parts of metal zinc or an oxide thereof, c) 1 to 20 parts of at least one transition metal or its oxide, and d) 1 to 20 parts of alumina. The desired alumina precursor has a specific surface area of 50 to 500m<2> / g and a total pore volume of 0.3 to 2.0ml / g. The volume of pores having diameters less than 20nm is 40-80% total pore volume. The volume of pores having diameters of 20-90nm is 10-40% total pore volume. The volume of pores having diameters greater than 90nm is 0-16% total pore volume. The catalyst can be used in the industrial production of 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate.

Owner:CHINA PETROLEUM & CHEM CORP +1

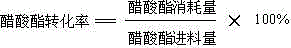

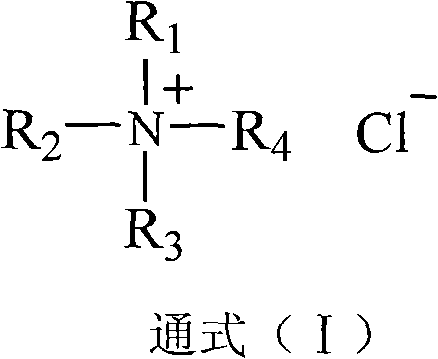

Double-long chain ester-based quaternary ammonium salt and synthesis technology thereof

InactiveCN102351721AImprove degradabilityRaw material conversion rate is highOrganic compound preparationAmino-hyroxy compound preparationSolventDimethyl ethanolamine

The invention provides a double-long chain ester-based quaternary ammonium salt. Through introduction of an ester group in a molecular structure of the double-long chain ester-based quaternary ammonium salt, degradability and environmentally friendly characteristics are obtained. The invention also provides a synthesis technology of the double-long chain ester-based quaternary ammonium salt. The synthesis technology comprises the following steps that N,N-dimethyl ethanolamine and a long-chain alkylogen are mixed; the mixture is added with an appropriate amount of solvents to undergo a reaction under a certain reaction conditions to produce a reaction intermediate of long-chain alkyl ammonium halide; long-chain alkyl ammonium halide and long-chain alkyl acyl chloride are mixed; the mixture is added with an appropriate amount of solvents to undergo a reaction under a certain reaction conditions; after the reaction is finished, the solvents are moved by distillation; and final solid products are obtained through multiple recrystallization processes. The synthesis technology adopts an unconventional quaternary ammonium salt synthesis route comprising carrying out quaternary amination and then carrying out esterification, and thus having the advantages that a raw material conversion rate is high; intermediate products are easy for separation and purification; reaction conditions are mild; a final product color is light; active matter content is high; solvents can be recycled; waste gas, waste water and industrial residues are not produced; and the use of traditional toxic alkylating reagents such as dimethyl sulphate, halomethanes and the like is avoided in synthesis processes.

Owner:JIANGNAN UNIV

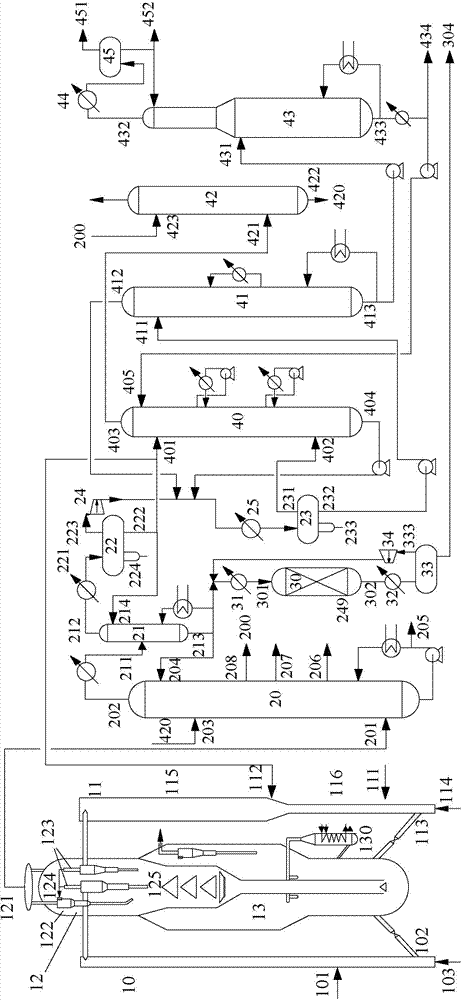

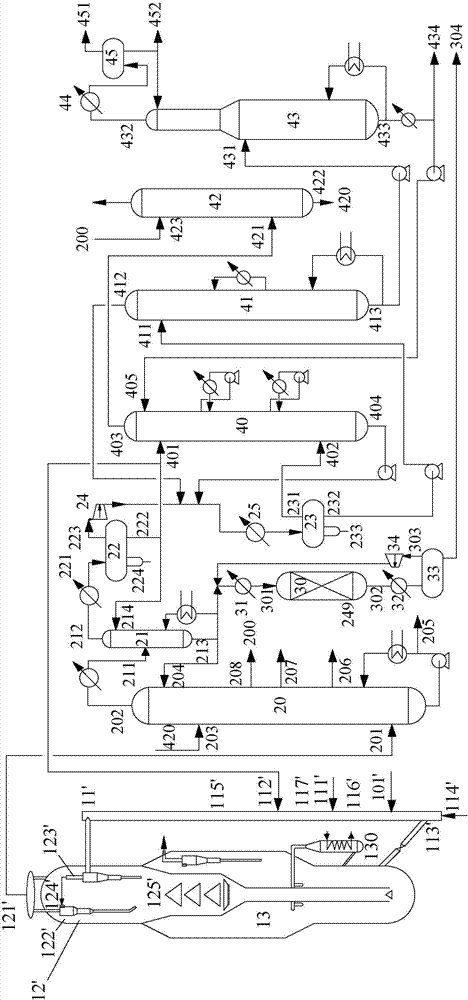

Device and method for producing clean gasoline by combining catalytic cracking and hydrofining

InactiveCN103571534APromote absorptionReduce loadTreatment with hydrotreatment processesGasolineTower

The invention discloses a device and method for producing clean gasoline by combining catalytic cracking and hydrofining. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy fraction gasoline enters the hydrofining unit for selective hydrogenation desulfurization, and one part of the light fraction gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light fraction gasoline directly returns to a reaction area at the upper part of a catalytic cracking second riser reactor to be modified under a mild condition; and blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

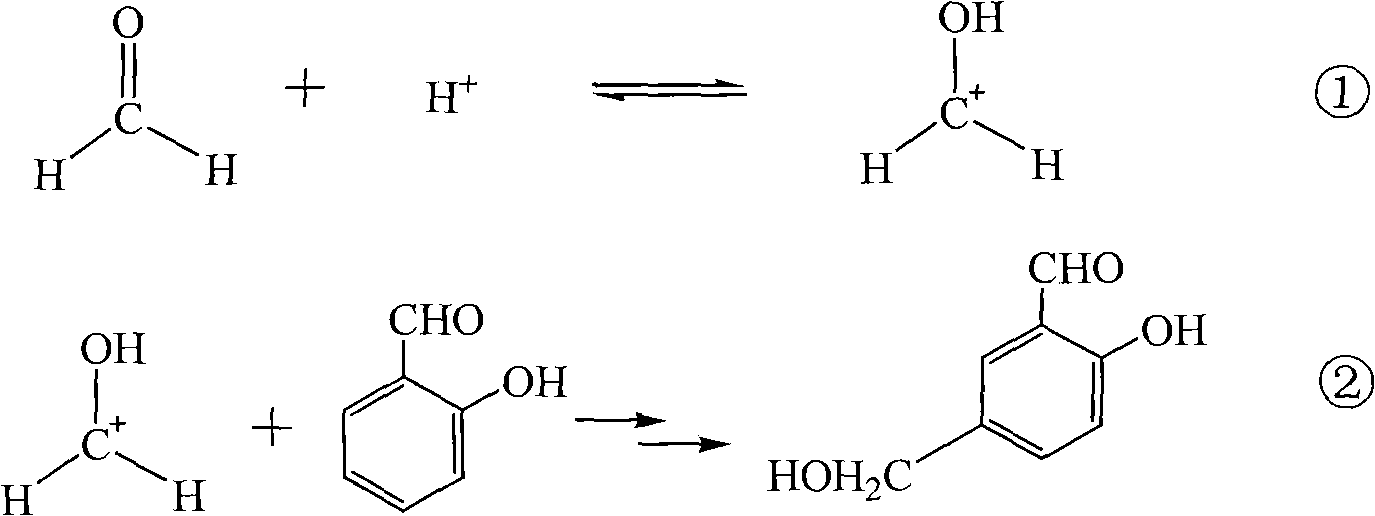

Preparation method of 5-chloromethyl salicylaldehyde

InactiveCN102180779AReduce dosageLow cost impactOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationSalicylaldehyde

The invention relates to a preparation method of 5-chloromethyl salicylaldehyde. The preparation method is realized in a way that: salicylaldehyde, formaldehyde and concentrated hydrochloric acid are used as raw material, quaternary ammonium salt is used as a catalyst, and the 5-chloromethyl salicylaldehyde is prepared by chloromethylation reaction of salicylaldehyde. The quaternary ammonium salt can effectively prevent the 5-chloromethyl salicylaldehyde product and salicylaldehyde from adhesion and agglomeration, thereby greatly increasing the utilization ratio of the raw material salicylaldehyde and the yield of the 5-chloromethyl salicylaldehyde product; and the filtered 5-chloromethyl salicylaldehyde product powder is dry, and is easy for washing and drying, so that the preparation process of the 5-chloromethyl salicylaldehyde is easy to operate.

Owner:HUAIHAI INST OF TECH

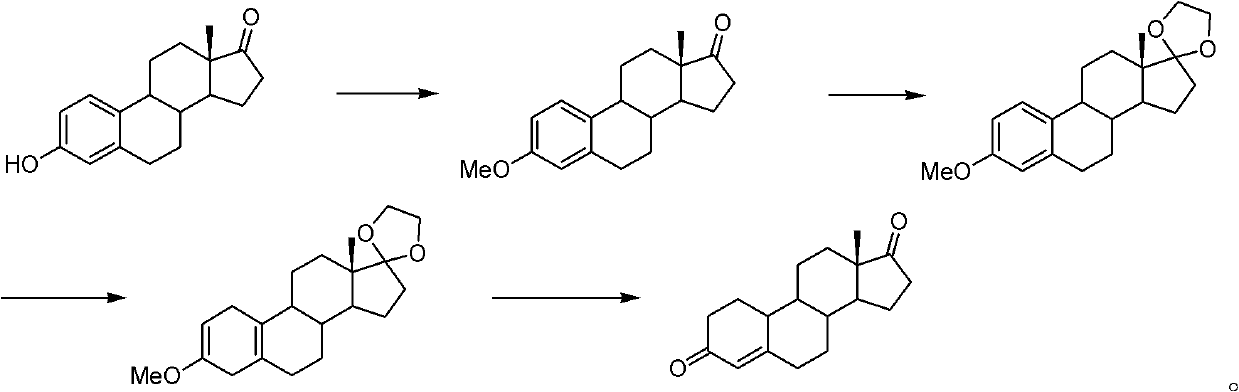

Method for preparing 19-demethyl-4-androstenedione

The invention discloses a method for preparing 19-demthyl-4-androstenedione, which comprises the steps of: based on estrone as a raw material, sequentially carrying out etherealization reaction, ketalation, Birch reducing reaction and hydrolysis reaction to obtain19-demethyl-4-androstenedione, wherein the reaction formula is shown in the specification. According to the method provided by the invention, the traditional phenolic group methyl etherealization process is improved, methyl carbonate replaces traditional high-toxicity carcinogenic etherealization reagents dimethyl sulfate and iodomethane, and inexpensive potassium carbonate is used as a base, so that the production cost is lowered, the method is environment-friendly, the yield is high, and the method is suitable for scaled industrial production.

Owner:ZHEJIANG XIANJU PHARMA

Preparation method of natural banana spice

ActiveCN104939014ARaw material conversion rate is highIncrease the income of fruit farmersFood ingredient as clouding agentFood ingredient as flavour affecting agentAlglucerasePectinase

The invention discloses a preparation method of natural banana spice. The preparation method comprises the following steps that a whole washed banana is subjected to microwave enzyme deactivation and mashed into thick liquid; pectinase, cellulose and beta glucosidase are added to the obtained thick banana liquid, the mixture is stirred and reacts for 30-120 min at the temperature ranging from 40 DEG C to 50 DEG C, and banana syrup is obtained after enzymolysis is conducted; the banana syrup subjected to enzymatic hydrolysis is filtered centrifugally, and centrifugate is obtained; acid proteinase is added into the centrifugate to be subjected to enzymolysis and clarification at the temperature ranging from 34 DEG C to 36 DEG C for 30-90 min; the obtained matter is subjected to instant enzyme deactivation at the superhigh temperature and then is subjected to sterile filling and sealing, and the liquid natural banana spice is obtained. The natural banana spice has rich, pure and mellow banana flavor, and can be applied to flavor allocation and directly used for food charging.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

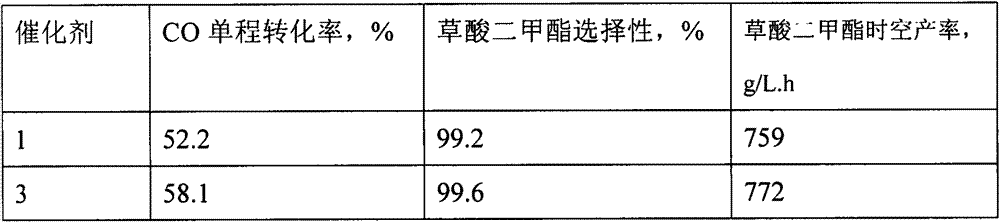

Catalyst for synthesizing dimethyl oxalate by CO as well as preparation method and application of catalyst

ActiveCN106925263AReduce manufacturing costImprove solubilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsDimethyl oxalateOrganic polymer

The invention discloses a catalyst for synthesizing dimethyl oxalate by CO. The catalyst is prepared from metallic palladium as an active component, Al2O3 as a carrier and metallic strontium or metallic barium as an auxiliary catalyst, wherein the content of the metallic palladium is 0.05 to 1.0 percent of the weight of the carrier; the content of the metallic strontium or the metallic barium is 0.02 to 0.5 percent of the weight of the carrier. The catalyst is prepared by the following steps: preparing acetate of the metallic strontium or the metallic barium and deionized water into an aqueous solution; adding water into the acetate or oxalate of the metallic barium to obtain an aqueous solution; adding a water-soluble organic polymer into the aqueous solution to form a mixed solution; washing a solid substance obtained in the second step with water at room temperature for 5 to 10 hours, then drying the washed substance at the temperature of 100 to 120DEG C for 8 to 12 hours, and subsequently roasting the dried substance at the temperature of 400 to 500DEG C for 10 to 15 hours to obtain the required catalyst. The catalyst has the advantages that the loading capacity of metal is low, the conversion rate of raw materials is high, and the production cost of the catalyst is effectively reduced; the problem of equipment corrosion in a preparation process of the catalyst is solved, and the production cost of the catalyst is reduced.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

N,N-bis(trimethylsilyl)allylamine and preparation method thereof

InactiveCN106749377ALess by-productsRaw material conversion rate is highSilicon organic compoundsAllylamineBis(trimethylsilyl)amine

The invention discloses N,N-bis(trimethylsilyl)allylamine and a preparation method thereof, and relates to the field of organic polymer materials. The preparation method comprises the following steps of at the temperature lower than 30 DEG C, adding a catalyst and 1 parts of allylamine into a reaction kettle in parts by mass, and uniformly stirring, wherein the catalyst is lewis acid; B, adding 1.1 to 1.3 parts of hexamethyl-disilazane into the reaction kettle, heating to 90 to 110 DEG C, and conducting heat preservation for 4 to 6h, so as to obtain a crude product of N,N-bis(trimethylsilyl)allylamine. The preparation method has the advantages that the yield rate and the product purity are increased, the product cost is reduced, and the friendly effect on equipment and environment is good.

Owner:湖北新蓝天新材料股份有限公司

Cu/SiO2 catalyst and method therefor for synthesizing tetrahydrofuran

InactiveCN105032420AHigh activityRaw material conversion rate is highOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPolyethylene glycolActive component

The invention discloses a Cu / SiO2 catalyst. A preparation method for the Cu / SiO2 catalyst comprises: by taking SiO2 as a carrier, loading an active component copper, wherein the loading capacity of copper is 10-40wt%; preparing a copper ammine solution through precusor salt of copper and ammonia water; then adding polyethylene glycol; then adding the SiO2 carrier, stirring, drying, roasting and reducing the mixture to prepare the Cu / SiO2 catalyst with high dispersity and high activity; and catalyzing dimethyl maleate for one-step hydrogenation to efficiently synthesizing tetrahydrofuran by using the Cu / SiO2 catalyst. The Cu / SiO2 catalyst disclosed by the invention has the advantages of being high in raw material conversion rate and good in target product selectivity.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing epiandrosterone

The invention discloses a method for preparing epiandrosterone. 4-androstenedione (I) is used as a raw material to prepare the epiandrosterone. The reaction formula is shown in the description. The low-cost 4-androstenedione is used as the raw material for the first time, and the epiandrosterone is obtained through synthesis on the mild reaction conditions, so that the production cost is greatly lowered, and the method is suitable for large-scale industrial production.

Owner:仙琚(嘉兴)医药科技有限公司 +1

Method of producing gasoline blending component with high octane value by light aromatic hydrocarbon and/or alcohol/ether compound

InactiveCN104419441ABoost octaneHigher octane gasolineLiquid hydrocarbon mixture productionBio-feedstockPolycyclic aromatic hydrocarbonHydrogen

The invention discloses a method of producing a gasoline blending component with a high octane value by a light aromatic hydrocarbon and / or alcohol / ether compound. The method comprises the following steps: enabling raw material light aromatic hydrocarbon to enter a reactor from the top of a reactor, dividing alcohol / ether oxygenated compounds into a plurality of paths, enabling each path to enter each reaction bed layer of a multi-section quench type fixed bed reactor and then mix with the light aromatic hydrocarbon entering from the top of the reactor to react on a special catalyst to produce an alkyl-rich aromatic hydrocarbon gasoline blending component with the high octane value. The method disclosed by the invention has characteristics of a high raw material conversion ratio, good catalyst stability, a high gasoline product octane value, a simple process, low energy consumption, strong flexibility in operation scheme, and the like, and can be used for effectively promoting the light aromatic hydrogen and the alcohol / ether oxygenated compounds to efficiently convert to the gasoline blending component with the high octane value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing lower olefins from synthesis gas

ActiveCN111036278AHigh catalytic activityHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a method for preparing lower olefins from synthesis gas, which comprises the following steps: (1) carrying out reduction treatment on an initial catalyst in a hydrogen-containing reducing atmosphere to obtain a reduced catalyst; (2) carrying out activation treatment on the reduced catalyst obtained in the step (1) in an activation atmosphere containing gaseous hydrocarbonsand optional inert gases to obtain an activated catalyst; (3) enabling synthesis gas to be in contact with the activated catalyst obtained in the step (2) for reaction; wherein the initial catalyst comprises a carrier and an active component, the carrier is a manganese oxide molecular sieve OMS-2, and the active component is one or more of group VIII metals. The method disclosed by the inventioncan still have relatively high raw material conversion rate and target product selectivity at a high space velocity.

Owner:CHINA PETROLEUM & CHEM CORP +1

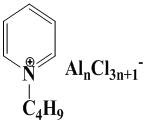

Method for disproportionating methyl chlorosilane

InactiveCN102140107ASimple processRaw material conversion rate is highGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsMethyl palmoxirateCombinatorial chemistry

The invention relates to a method for disproportionating methyl chlorosilane, belonging to the field of ion liquid catalysis, and discloses a method for preparing dimethyl dichlorosilane or trimethyl chlorosilane by catalyzing the disproportionating reaction between methyl trichlorosilane and a low-boiling-point substance with N-butyl pyridine chloroaluminate ionic liquid serving as a catalyst. The method for catalyzing the disproportionating reaction between the methyl trichlorosilane and the low-boiling-point substance has the advantages of simple and convenient process, high raw material conversion ratio, high product yield, low reaction temperature, short time, easily-controlled condition, catalyst reusability realized by simple liquid separation, and the like.

Owner:JIANGSU UNIV

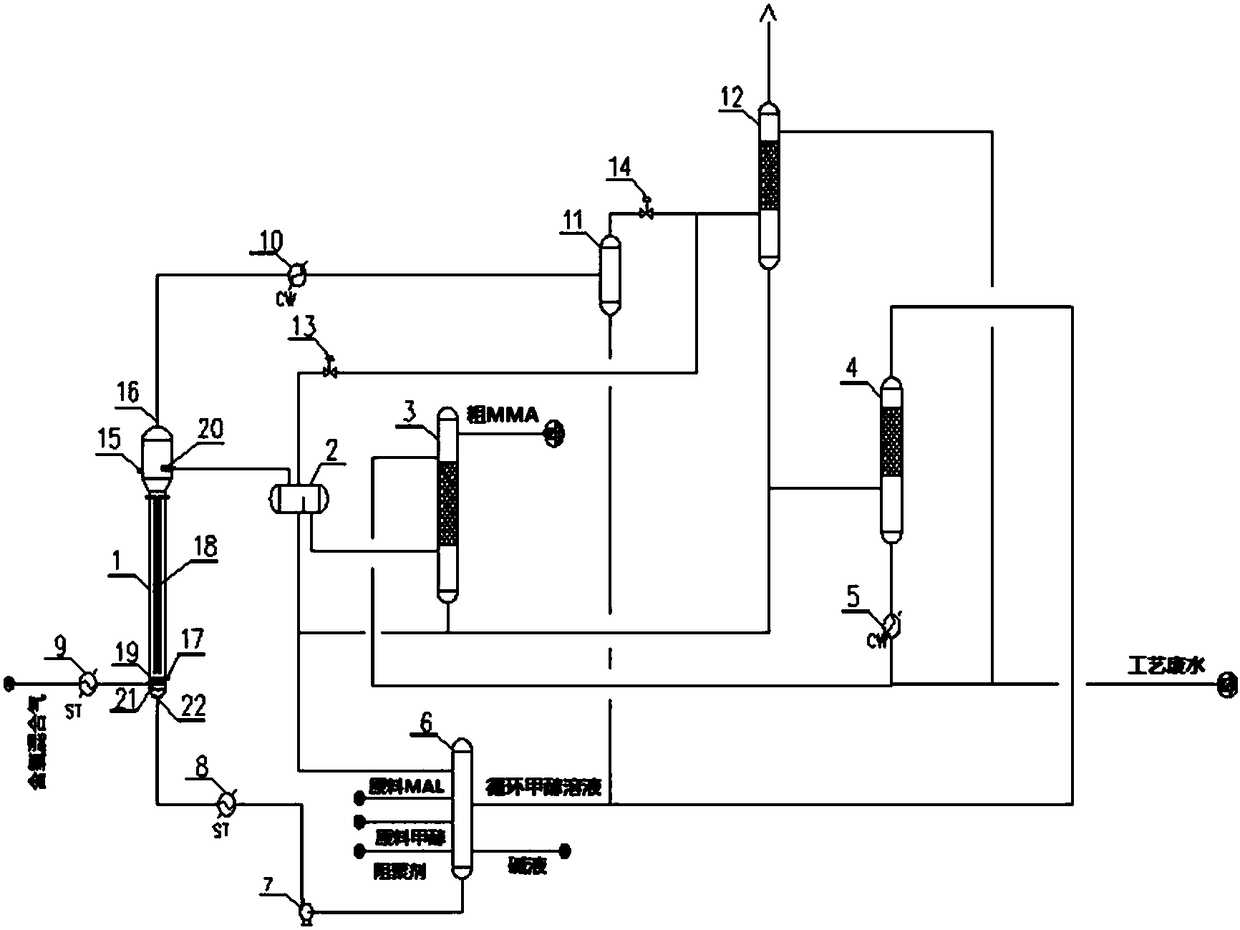

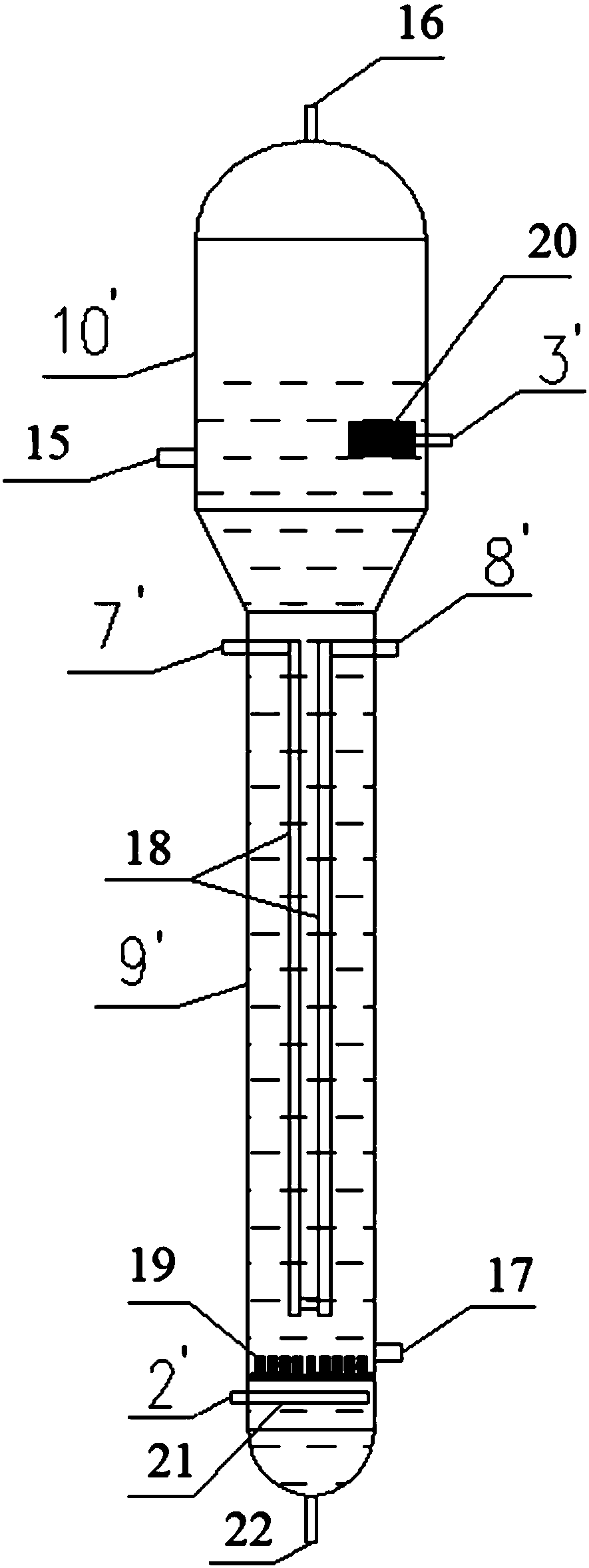

Chemical reaction device and application thereof

ActiveCN108440281AGood choiceHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationChemical reactionThree-phase

The invention discloses a chemical reaction device, which comprises a reaction unit, a separation unit and a recovery unit, wherein the reaction unit, the separation unit and the recovery unit are sequentially connected; the reaction unit comprises a three-phase bubble bed synthesis reactor. The invention also discloses a reaction device and method for preparing methyl methacrylate. The device provided by the invention is used for preparing the methyl methacrylate, and has the advantages that the raw material conversion rate is high; the target product yield is high; the selectivity of the methyl methacrylate is high.

Owner:上海载正化工科技发展有限公司

L-cyclic alkylamino acid synthesis method and medicinal composition containing L-cyclic alkylamino acid

ActiveCN103361388AHigh chiral selectivityRaw material conversion rate is highOrganic active ingredientsPeptide/protein ingredientsFormate dehydrogenaseLeucine dehydrogenase

The invention provides an L-cyclic alkylamino acid synthesis method and a medicinal composition containing L-cyclic alkylamino acid. The synthesis method comprises the following steps: 1, preparing cyclic alkyl ketonic acid or cyclic alkyl ketonate having a structure represented by formula (I) or formula (II); and 2, mixing the cyclic alkyl ketonic acid or cyclic alkyl ketonate with ammonium formate, a leucine dehydrogenase, a formate dehydrogenase and a coenzyme NAD<+>, and carrying out a reduction amination reaction to generate the L-cyclic alkylamino acid, wherein n1 in the formula (I) is not lower than 1, m1 in the formula is not lower than 0, and M1 is H or a univalent cation; n2 in the formula (II) is not lower than 0, m2 in the formula (II) is not lower than 0, and M2 is H or a univalent cation; and the amino acid sequence of the leucine dehydrogenase is represented by SEQ ID No.1. The method utilizes specific leucine dehydrogenase, the formate dehydrogenase and the coenzyme NAD<+> to carry out the reduction amination reaction of the cyclic alkyl ketonic acid or cyclic alkyl ketonate, and has a high raw material conversion rate and a high chiral selectivity.

Owner:ASYMCHEM LAB TIANJIN +4

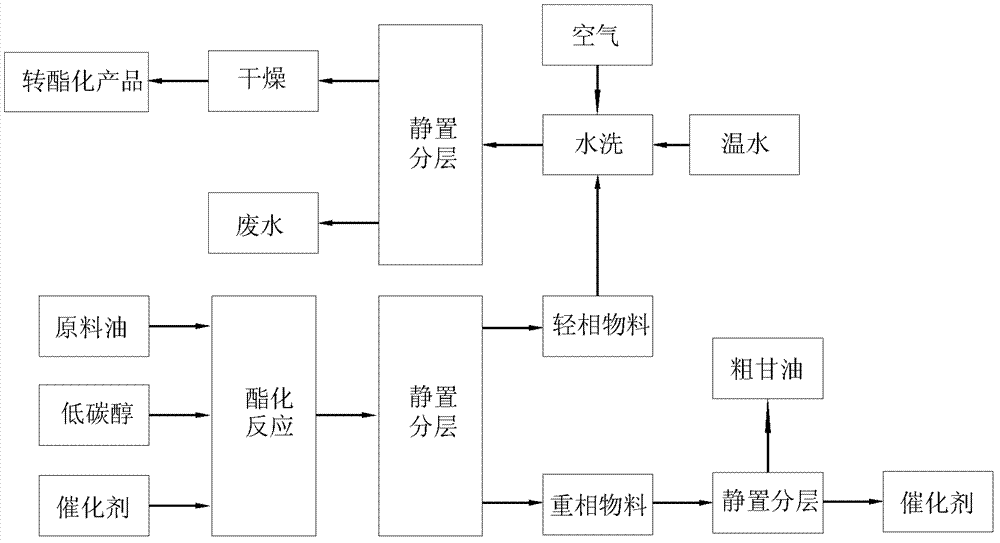

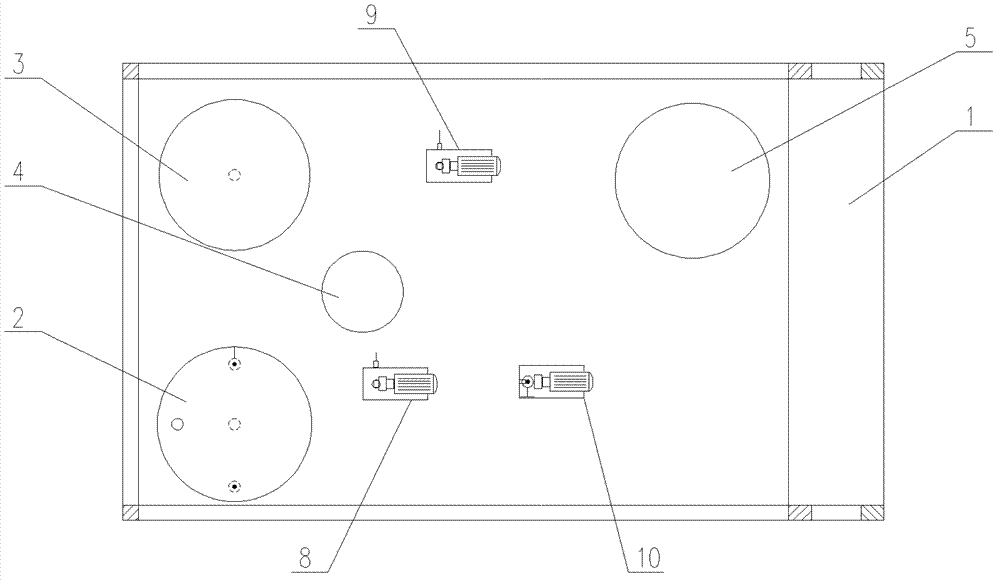

Production device and production method for distribution type plant oil transesterification

InactiveCN102492560BEasy to recycleShort process routeFatty acid esterificationFatty-oils/fats refiningHeat conductingWarm water

The invention discloses a production device and a production method for distribution type plant oil transesterification. The production device comprises an equipment frame, a reaction kettle, a washing tank, a catalyst recovering tank, a drier, a warm water storage tank, a heat conducting oil heating tank, a reaction circulating pump, an air pump, a material pump and a heat conducting oil pump. The production method comprises the following steps of: heating and stirring a mixture of plant fat raw material oil, low-carbon alcohol and a pyridyl trifluoromethanesulfonate ion liquid catalyst to react for 3-5 hours; standing so that reaction materials are divided into a light phase and a heavy phase, and separating the light phase from the heavy phase; standing the heavy-phase material and naturally cooling, so that the catalyst is precipitated to the bottom, and the rest is crude glycerol containing alcohol; adding warm water to the light-phase material for washing, and then standing so that the light phase and the heavy phase are formed again; and pumping the light-phase material into the drier for drying, so as to obtain the plant oil. The production method disclosed by the invention can achieve homogeneous catalysis and different-phase separation through process integration, and the yield of the plant oil is improved; and the production device disclosed by the invention is handy and simple, and is convenient for real-time processing of a dispersed raw material.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing BTX and co-producing tetramethylbenzene from C9<+> heavy aromatic hydrocarbons

The invention relates to a method for preparing BTX and co-producing tetramethylbenzene from C9<+> heavy aromatic hydrocarbons. The method comprises: carrying out catalytic cracking conversion on C9<+> heavy aromatic hydrocarbons to obtain a first-stage hydrocarbon mixing product using BTX and trimethylbenzene as main components, and separating respectively with an ethane removing tower, a butane removing tower, a hexane removing tower, a BTX removing tower and a trimethylbenzene removing tower to obtain dry gas, liquefied gas, C5-C6 non-aromatic hydrocarbons, BTX, trimethylbenzene and C10<+> heavy aromatic hydrocarbons, wherein the dry gas, the liquefied gas, the C5-C6 non-aromatic hydrocarbons and the BTX are adopted as products; carrying out a reaction on the trimethylbenzene and a certain amount of methanol to obtain a tetramethylbenzene-rich second-stage mixing product, and separating the products to obtain dry gas, wastewater and liquid-state hydrocarbons, wherein the liquid-state hydrocarbon products return to the ethane removing tower so as to be separated; and carrying out crystallization separation on the C10<+> heavy aromatic hydrocarbons to obtain tetramethylbenzene and a heavy component residue liquid, wherein the tetramethylbenzene and the part of the heavy component residue liquid are adopted as the product, and the remaining heavy component residue liquid return to a catalytic cracking reactor. According to the present invention, with the method, the moving bed non-hydrogen cracking and the tetramethylbenzene preparation using trimethylbenzene alkylation are compounded, such that the BTX is produced at a maximum while the high added value tetramethylbenzene can be co-produced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

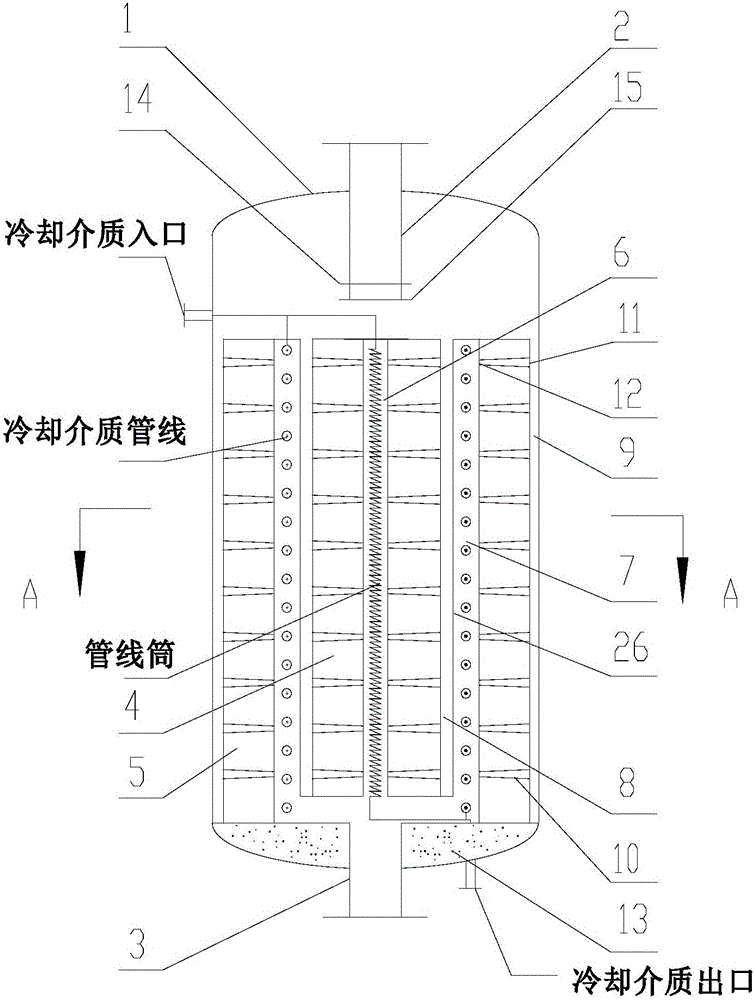

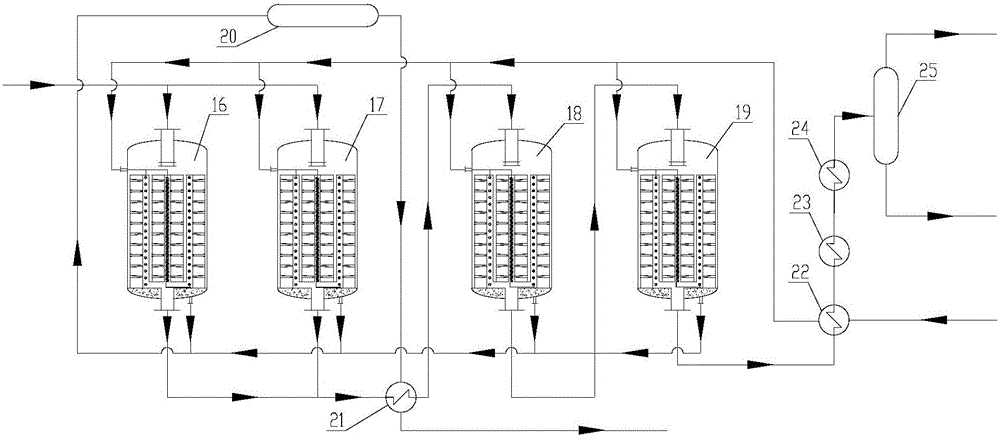

Methanation reactor and methanation process

ActiveCN106693839AGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsActive componentMethanation

The invention discloses a methanation reactor and a methanation process; the methanation reactor comprises a shell body, a gas inlet pipe, a central cylinder, a central pipe, a gas outlet pipe, a cooling medium inlet, a cooling medium outlet and a micro reaction channel, and includes or does not include a sleeve; the micro reaction channel can be internally loaded with a catalytic active component. Compared with the prior art, the methanation reactor has less catalyst use amount; according to the methanation process adopting the methanation reactor, the bed pressure is reduced, the gas residence time is short, the space utilization rate of a reaction bed is high, and gas bias current and short-circuit phenomena do not exist.

Owner:SINOPEC ENG +1

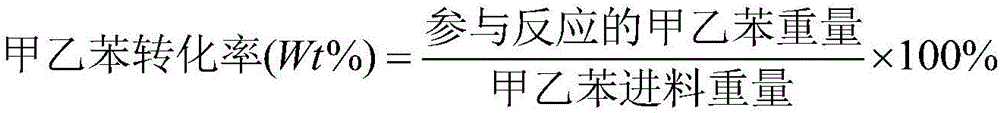

Catalyst for vinyl toluene production and preparation method thereof

ActiveCN106000448AInhibit surface carbonImprove conversion rateMolecular sieve catalystsMolecular sieve catalystMagnesium saltAdhesive

The invention discloses a catalyst for vinyl toluene production and a preparation method thereof. The catalyst is prepared from the following components in parts by weight: 6-10 parts of vanadium modified molecular sieve, 60-75 parts of iron oxide, 14-15 parts of magnesium oxide and 5-15 parts of an adhesive. The preparation method of the catalyst comprises the following steps: firstly performing synthesis and crystallization in a high-pressure reactor to obtain the vanadium modified molecular sieve; secondly, performing ultrasonic dispersion on the vanadium modified molecular sieve raw powder, ferric salt and magnesium salt; then adding the adhesive, kneading and performing extrusion forming on the mixture, and finally, roasting the mixture, thereby obtaining a iron-magnesium-vanadium loaded molecular sieve catalyst. When applied to production of vinyl toluene by dehydrogenizing methyl-ethylbenezene, the prepared catalyst has the advantages of high raw material conversion rate, good product selectivity, low energy consumption, capability of inhibiting carbon deposition on the surface of the catalyst, and the like.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Continuous reaction device and method for preparing aldehyde through hydroformylation reaction

ActiveCN110526807AEvenly dispersedImprove defectsPreparation by carbon monoxide reactionChemical recyclingContinuous reactionRaw material

The invention discloses a continuous reaction device for preparing aldehyde through a hydroformylation reaction. The reaction device comprises a reaction unit, a separation unit and a circulation unit; the circulation unit is located between the reaction unit and the separation unit; the reaction unit is connected with the separation unit; and a catalyst is circulated between the reaction unit andthe separation unit through the circulation unit. The invention further discloses a method for preparing the aldehyde by adopting the reaction device. According to the method and device provided by the invention, the catalyst can be uninterruptedly and continuously recycled without being separated by external equipment, continuous production of the aldehyde can be realized, reaction heat can be rapidly removed, the progress of the hydroformylation reaction is facilitated, the conversion rate of raw materials is high, the yield of the target products is high, and the ratio of a n-configurationproduct to an iso-configuration product is high.

Owner:上海载正化工科技发展有限公司

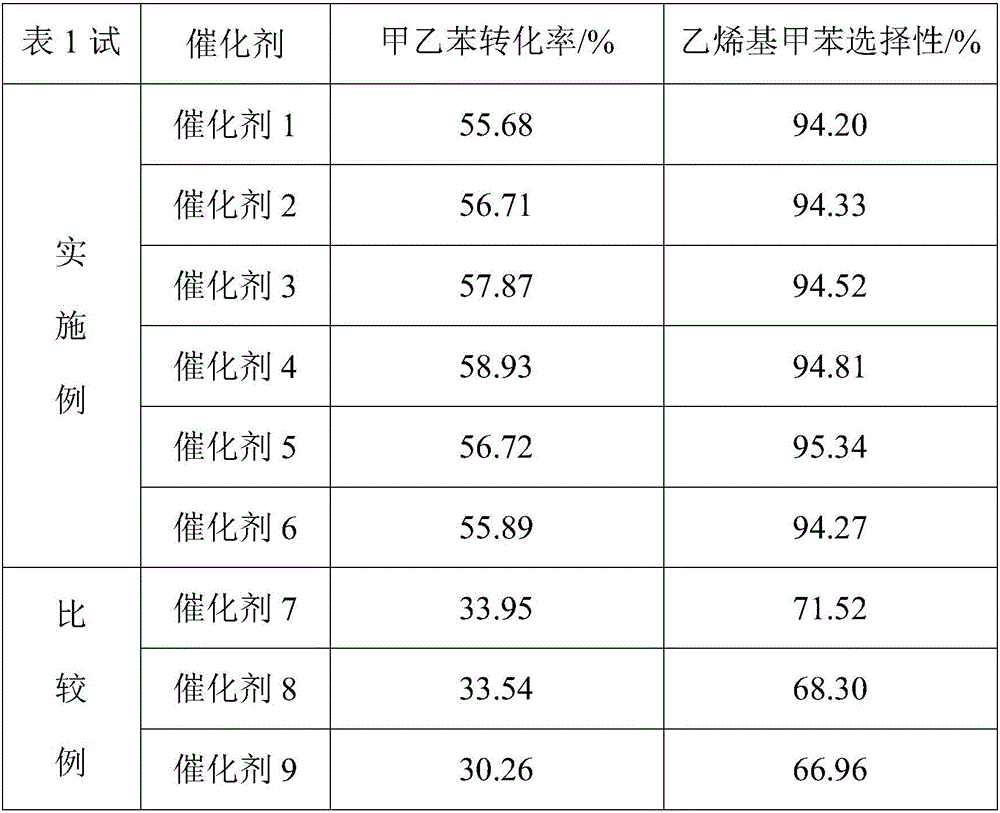

Method for producing propenyl alcohol

InactiveCN101139256AReasonable technical routeRaw material conversion rate is highPreparation by alcoholysisChemical synthesisMethanol

The present invention belongs to the chemosyntheise field, which relates to a preparation method for allyl alcoh; the method adopts two-step reaction processes that are as follows: (1) sodium acetate is reacted with a 3-chloropropene in the alcohols catalyzer to create a propyl ester acetic acid alkene; (2) the propyl ester acetic acid alkene produced in Step 1 is reacted with a methanol alcohol in the resin catalyzer to create allyl alcoh. The present invention replaces the traditional ''One step'' technics with rational technical process and high conversion ratio for the material; the product is easy to be separated; the post-treatment technics is simpler; the produced waste can be recycled repeatedly; so the present invention can not only save the cost, but also can not pollute the environment; the technics process is stable and easy to be controlled and operated.

Owner:邹平容诚金属科技集团有限公司

Single-phase composite metal oxide catalyst as well as preparation method and application thereof

PendingCN111185186AImprove redox abilityImprove conversion rateOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystMeth-

The invention belongs to the technical field of catalysts, and particularly relates to a single-phase composite metal oxide catalyst as well as a preparation method and application thereof. The catalyst provided by the invention shows a very high raw material conversion rate and high product selectivity in the reaction of preparing methacrolein by selective oxidation of isobutene; compared with existing heterogeneous composite metal oxide catalysts, the prepared single-phase catalyst can effectively reduce the barrier between the active sites required to be overcome by the component transfer,can accelerate the electron transfer rate, improve the oxidation reduction ability of the catalyst, and reduce the surface acidity so as to improve the isobutene conversion rate and the yield of the target product methacrolein, and is expected to be industrially applied.

Owner:YANTAI UNIV

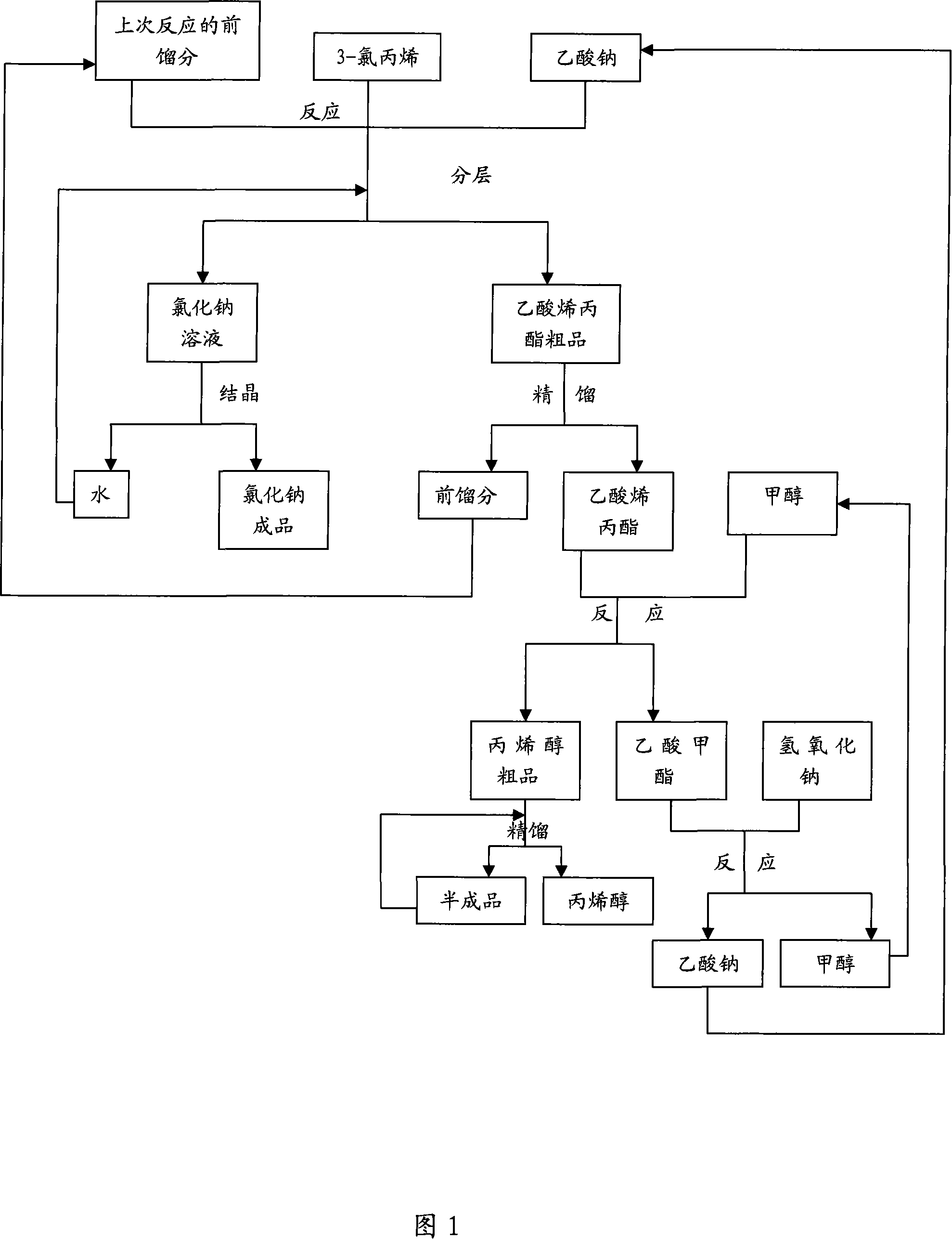

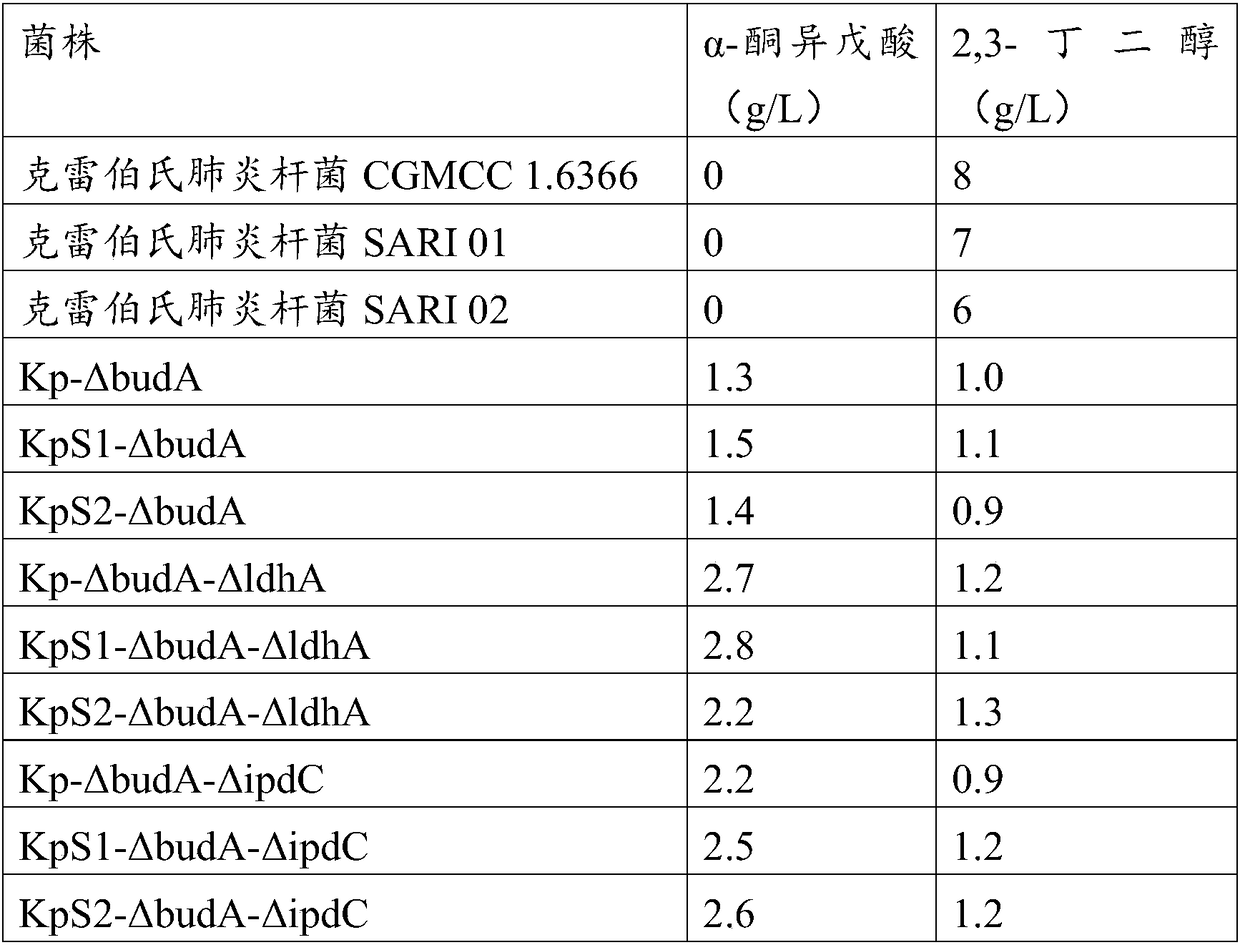

Method for improving alpha-ketoisovaleric acid yield of Klebsiella pneumoniae, and modified strain

ActiveCN108570438AHigh genetic stabilityRaw material conversion rate is highBacteriaMicroorganism based processesCarbon sourceAcetolactate decarboxylase

The invention discloses a method for improving the alpha-ketoisovaleric acid yield of Klebsiella pneumoniae, and a modified strain. The method comprises: inactivating acetolactate decarboxylase in Klebsiella pneumoniae, or simultaneously inactivating indole-3-pyruvate decarboxylase and / or lactate dehydrogenase, wherein the Klebsiella pneumoniae inactived with the enzyme is the modified strain; andinoculating the modified Klebsiella pneumoniae in a carbon source culture medium, and carrying out fermentation culture, wherein the carbon source in the culture medium is converted into alpha-ketoisovaleric acid by the modified Klebsiella pneumoniae during the fermentation culture. According to the present invention, with the method, the exogenous gene is not introduced into the modified strain,such that the strain has high genetic stability, the final concentration of the product is high, and the range of the raw material is wide.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

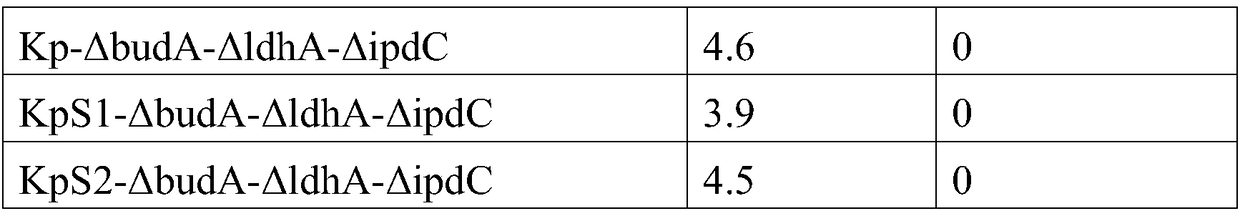

Impinging-stream-based continuous magnesium hydroxide production process

InactiveCN110117021AIncrease production capacityImprove sealingMagnesium hydroxideMagnesium saltStorage tank

The invention discloses an impinging-stream-based continuous magnesium hydroxide production process, and relates to a magnesium hydroxide production process. The process comprises the steps that a magnesium salt and precipitant with certain concentration serve as raw materials, an impinging stream reactor is adopted, in the impinging stream reactor, the magnesium salt and the precipitant react at20-90 DEG C, magnesium hydroxide precipitates are generated, the obtained precipitates are aged at 50-120 DEG C for 1-10 hours, then filtering and drying are conducted, and a magnesium hydroxide product is finally obtained. Auxiliary equipment of the process comprises a raw material storage tank, a pump, a flowmeter, a filter, an ageing tank, a dryer and the like. Accordingly, the impinging streamreactor is adopted, the magnesium salt and the precipitant serve as the raw materials, and the magnesium hydroxide product which is high in dispersion, small in specific surface area, uniform in particle size and consistent in crystal form can be obtained. By means of the continuous magnesium hydroxide production process, the materials are mixed rapidly, the reaction is efficient, and residence time distribution is narrow. The process flow is short, the equipment is less, and the product quality is good and stable.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Methanation reactor and methanation technology

InactiveCN106693849AGreat driving forceShort stayGaseous fuelsChemical/physical/physico-chemical processesActive componentMethanation

The invention discloses a methanation reactor and a methanation technology. The methanation reactor comprises a shell, a gas inlet tube, a cylinder, a gas outlet tube and a micro-reaction channels, and a catalytic active component can be loaded in the micro-reaction channels. Compared with methanation reactors in the prior art, the methanation reactor disclosed in the invention has the advantages of small use amount of a catalyst, low bed pressure drop, short gas retention time, high reaction bed space utilization rate, no gas flow deflection and no short circuit in the methanation reaction process.

Owner:SINOPEC ENG +1

Catalyst, preparation method thereof and method for preparing lower olefin from synthesis gas

ActiveCN111036284AHigh catalytic activityHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a catalyst, a preparation method thereof and a method for preparing lower olefin from synthesis gas. The catalyst comprises a carrier and an active component, the carrier contains a manganese oxide molecular sieve OMS-2, and the active component is one or more selected from metal components of group VIII metals. Compared with catalysts in the prior art, the catalyst has improved catalytic activity, and can enable a relatively high raw material conversion rate and target product selectivity at a high space velocity when the catalyst is used for preparing the lower olefin from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com