Production device and production method for distribution type plant oil transesterification

A technology of vegetable oil and transesterification, which is applied in the direction of fatty acid esterification, petroleum industry, and fat production, etc. It can solve the problems of difficult raw material supply and dispersion, and achieve the effect of short equipment process route, light and simple equipment, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

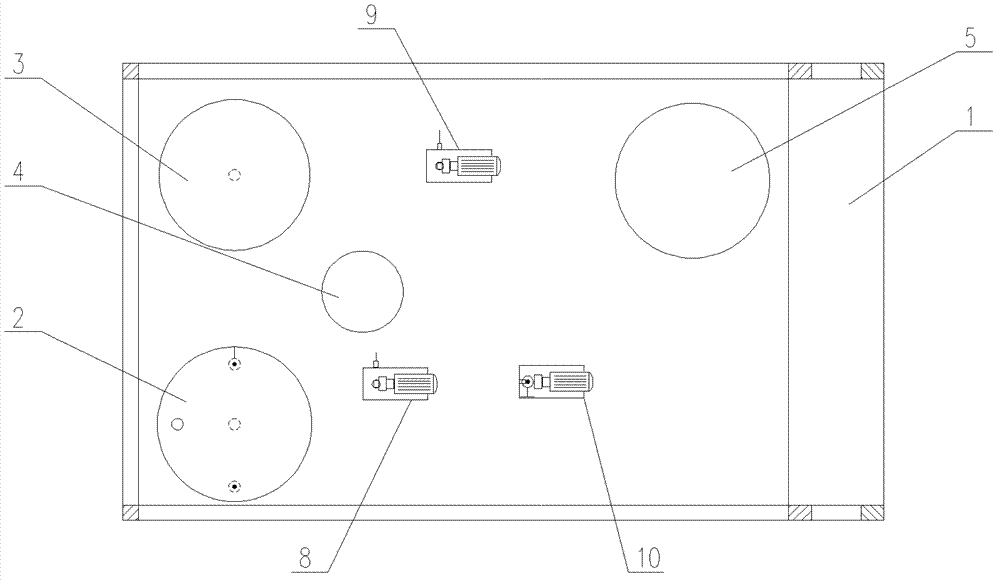

[0030] Such as figure 2 As shown, the device for distributed vegetable oil transesterification production of the present invention includes a reaction kettle 2, a water washing tank 3, a catalyst recovery tank 4, a dryer 5, a warm water storage tank 6, a heat transfer oil heating tank 7, a reaction circulation pump 8, The air pump 9, the material pump 10, the heat transfer oil pump 11 and the equipment rack 1; the warm water storage tank 6 and the heat transfer oil heating tank 7 are all equipped with electric heaters. The equipment frame 1 has a power distribution box and an instrument control box, and is divided into upper and lower layers. The reaction kettle 2, the washing tank 3, the catalyst recovery tank 4, the dryer 5, the reaction circulation pump 8, the air pump 9 and the material pump 10 are installed On the lower layer of the equipment rack 1, the warm water storage tank 6, the heat transfer oil heating tank 6 and the heat transfer oil pump 11 are installed on the...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

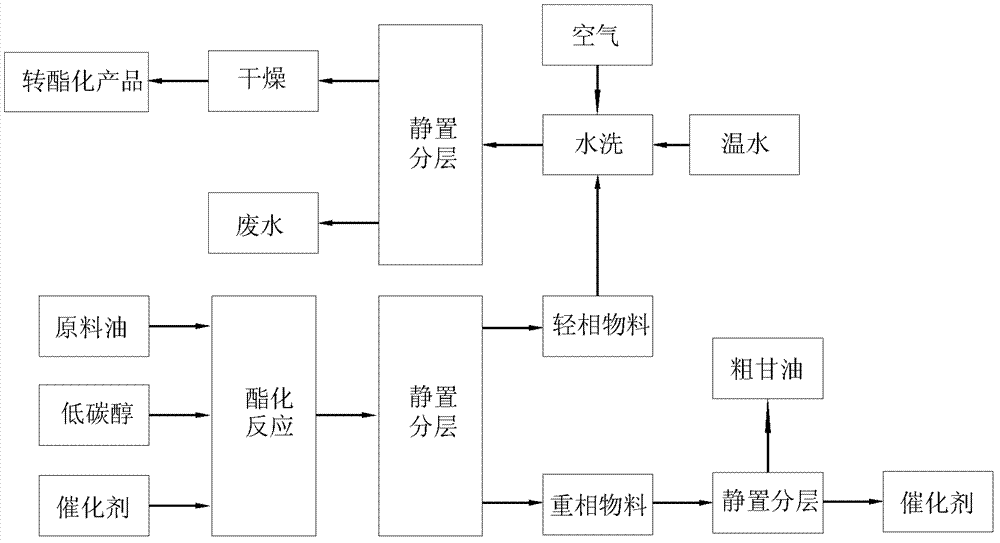

[0050] according to figure 1 As shown in the distributed biodiesel production process flow chart, the specific steps for biodiesel production are as follows:

[0051] (1) Turn on the electric heating equipment of the warm water storage tank 6 and the heat transfer oil heating tank 7 of the distributed biodiesel plant, the water temperature in the warm water storage tank reaches 50°C, and the heat transfer oil in the heat transfer oil heating tank reaches 110°C;

[0052] (2) After the heat-conducting oil and warm water reach the predetermined temperature, add the pyridine trifluoromethanesulfonate ionic liquid catalyst of 50kg rapeseed oil, 8.4kg methyl alcohol and 0.175kg in the reactor 2, methanol and feedstock oil The ratio is 1:6, and the amount of ionic liquid catalyst added is 0.3% (percentage by weight) of the total amount of methanol and feedstock oil;

[0053] (3) Open the reaction circulation pump ...

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is:

[0065] according to figure 1 As shown in the production process flow chart of distributed transesterification reaction to produce plant-based lubricating oil base oil, the specific steps for the production of plant-based lubricating oil base oil are as follows:

[0066] (1) Turn on the electric heating equipment of the warm water storage tank 6 and the heat transfer oil heating tank 7 of the distributed biodiesel plant, the water temperature in the warm water storage tank 6 reaches 50°C, and the heat transfer oil in the heat transfer oil heating tank 7 reaches 110°C;

[0067] (2) After the heat-conducting oil and warm water reach the predetermined temperature, add 50kg of rapeseed oil, 25kg of ethanol and 0.225kg of pyridine trifluoromethanesulfonate ionic liquid catalyst into reactor 2, the ratio of ethanol to raw oil 1: 2, the addition of ionic liquid catalyst is 0.3% (percentage by weight) of the total a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com