Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Acetolactate decarboxylase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In enzymology, an acetolactate decarboxylase (EC 4.1.1.5) is an enzyme that catalyzes the chemical reaction (S)-2-hydroxy-2-methyl-3-oxobutanoate ⇌ (R)-2-acetoin + CO₂ Hence, this enzyme has one substrate, (S)-2-hydroxy-2-methyl-3-oxobutanoate, and two products, (R)-2-acetoin and CO₂. This enzyme belongs to the family of lyases, specifically the carboxy-lyases, which cleave carbon-carbon bonds. The systematic name of this enzyme class is (S)-2-hydroxy-2-methyl-3-oxobutanoate carboxy-lyase [(R)-2-acetoin-forming].

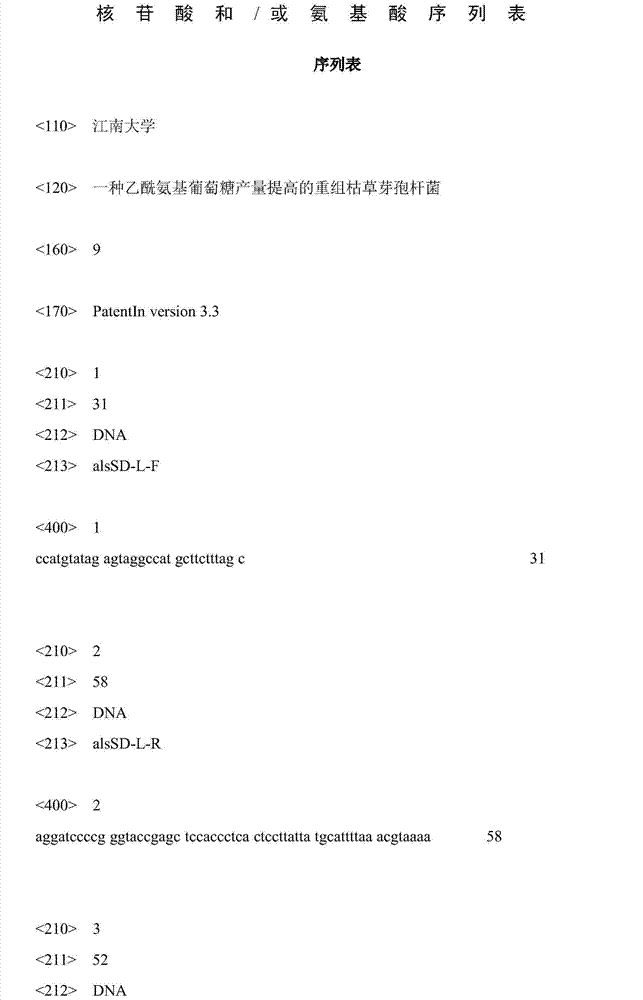

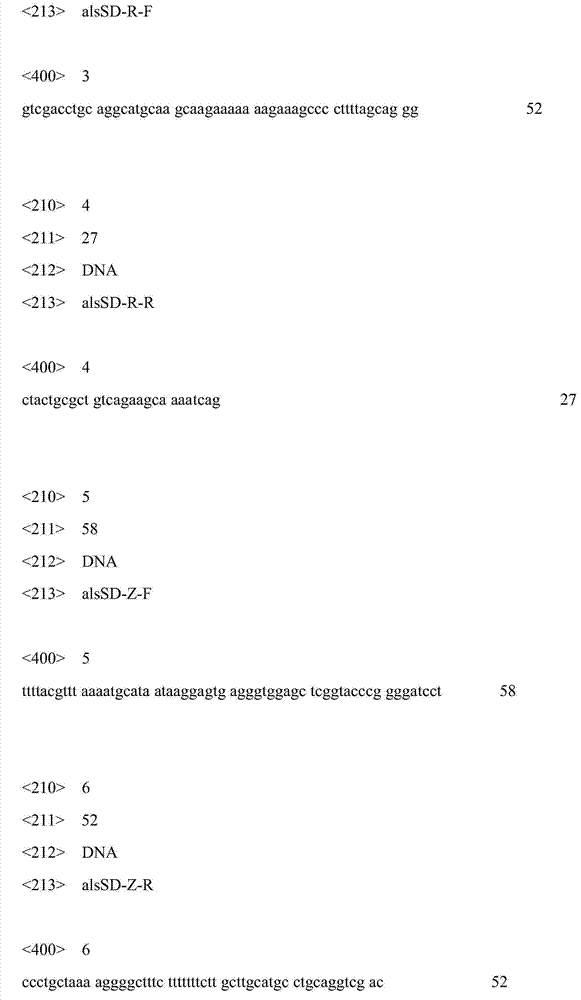

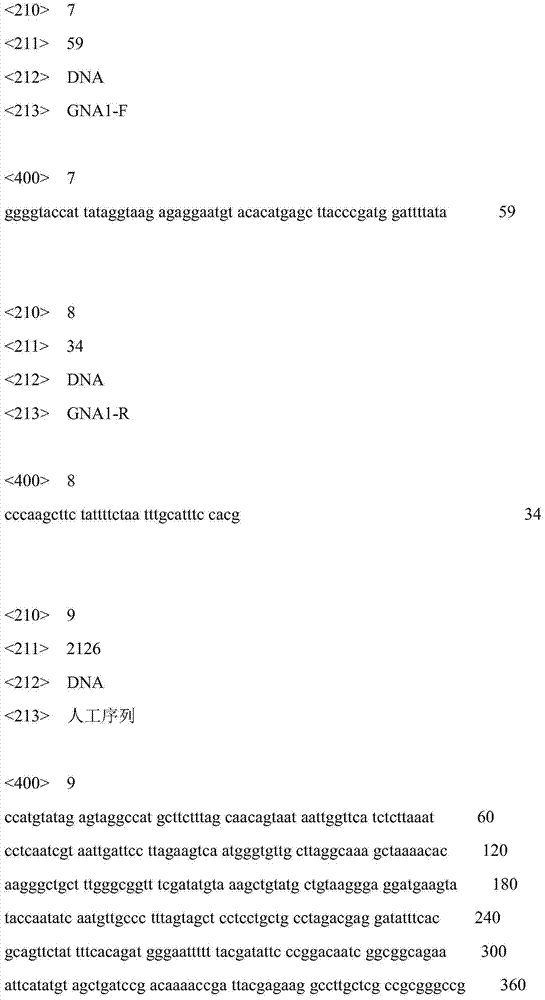

Recombinant bacillus subtilis increased in yield of acetylglucosamine

ActiveCN104498394AEasy to buildEasy to useBacteriaMicroorganism based processes2,3-ButanediolAcetolactate Synthetase

The invention discloses a recombinant bacillus subtilis increased in yield of acetylglucosamine and belongs to the field of genetic engineering. According to the recombinant bacillus subtilis increased in yield of acetylglucosamine, the recombinant bacillus subtilis BSGN6-PxylA-glmS is taken as an original strain, an alpha-acetolactate synthetase encoding gene and an alpha-acetolacetate decearboxylase encoding gene are knocked out by virtue of homologous recombination, and therefore, the approach by which acetoin and butanediol are generated from 2,3-pyroracemic acid in host bacteria is blocked. In the host bacteria from which the alsS and alsD are knocked out, the glucosamine acetylase encoding gene derived from saccharomyces cerevisiae is excessively expressed, and therefore, the route of synthesis of the acetylglucosamine is enhanced, the yield of the acetylglucosamine in the recombinant bacillus subtilis is increased to 38.46g / L, and a foundation is laid for producing the glucosamine by modifying the bacillus subtilis in the metabolic engineering.

Owner:JIANGNAN UNIV

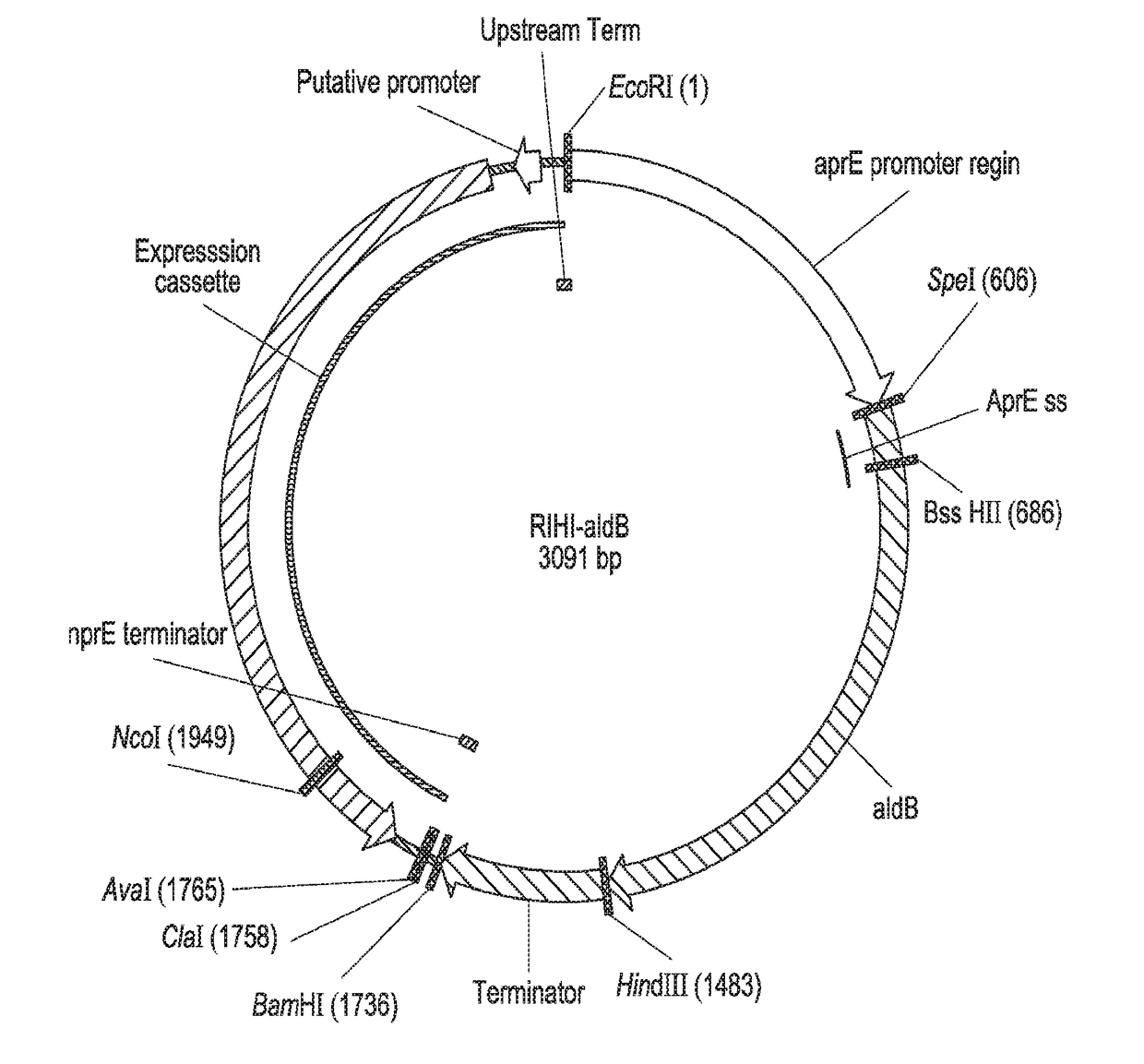

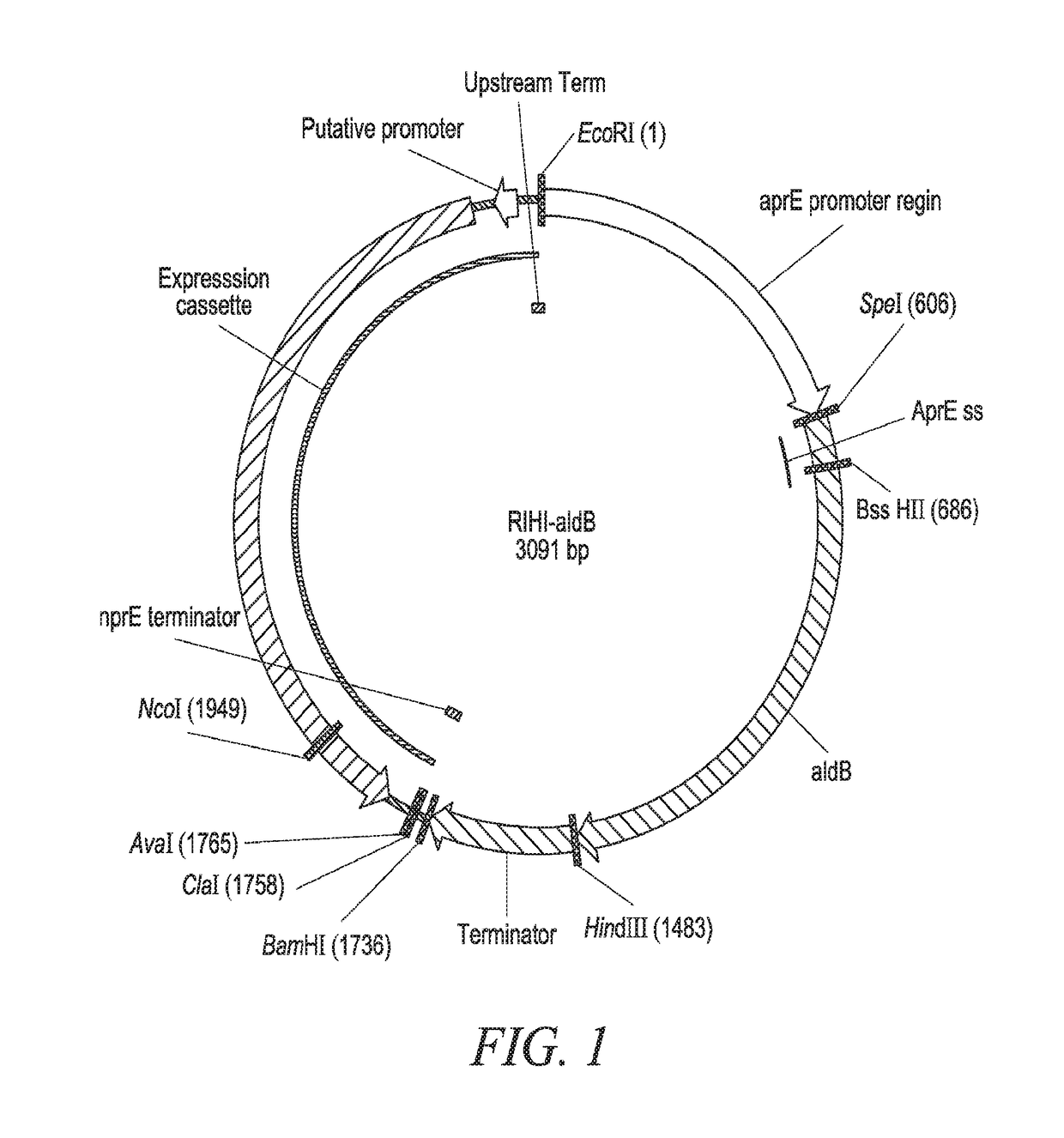

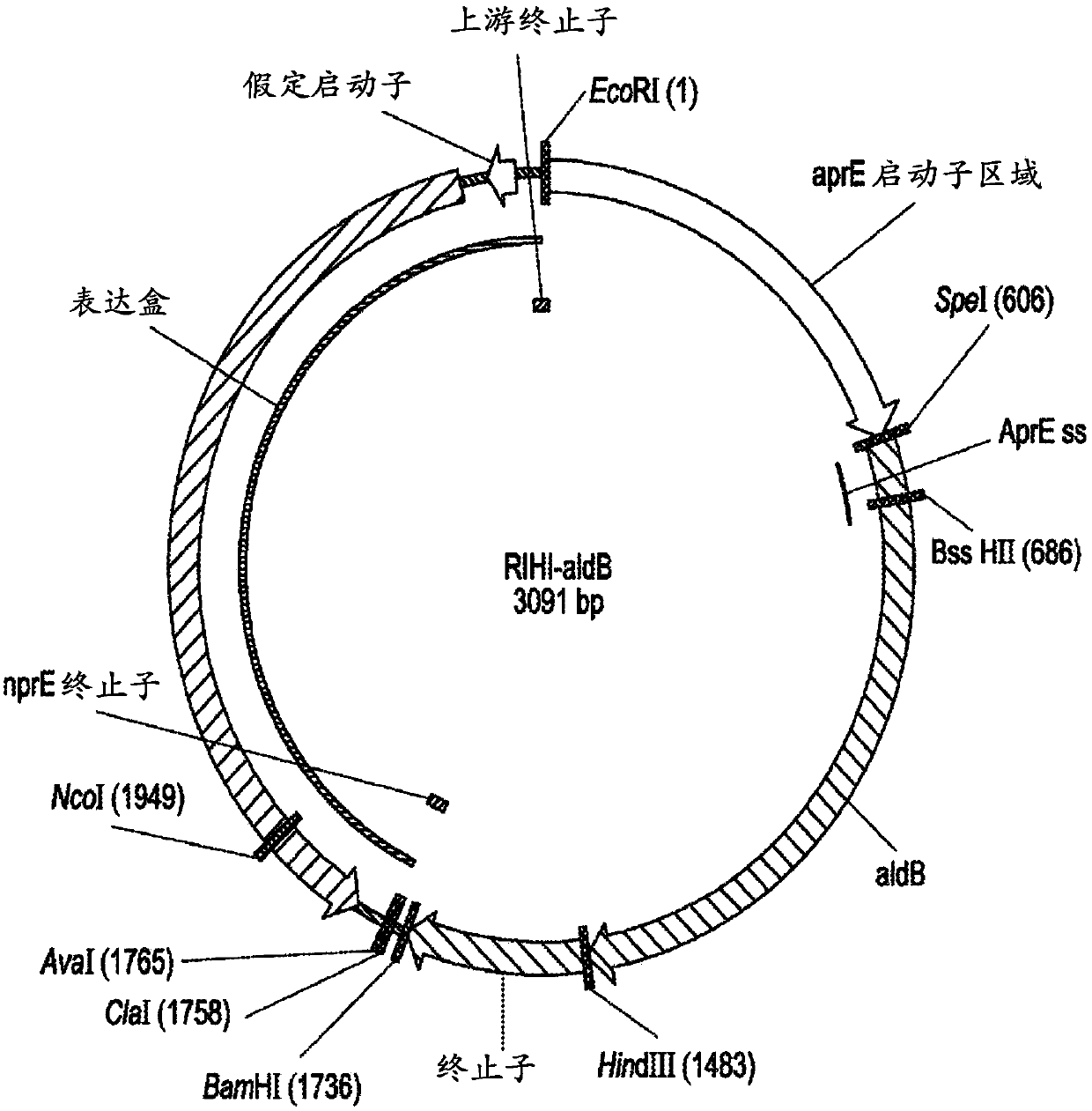

Method for producing alpha-acetolacetate decearboxylase by using integrated recombinant bacillus subtilis as strain

ActiveCN101948821AStable passageStable expressionBacteriaMicroorganism based processesMicrobiologyAntibacterial activity

The invention discloses a method for producing alpha-acetolacetate decearboxylase by using integrated recombinant bacillus subtilis as a strain. The method comprises the following steps of: integrating an alpha-acetolacetate decearboxylase expression element to a bacillus subtilis chromosome to construct the integrated recombinant bacillus subtilis which serves as the strain, and producing the alpha-acetolacetate decearboxylase by fermentation in a nutrient medium. The method has the advantages that: the alpha-acetolacetate decearboxylase is produced by using a food safety expression system, the exogenous gene contained in the strain of integrated expression can stabilize passage and expression, and the product meets the food requirement and has no antibacterial activity.

Owner:南宁邦尔克生物技术有限责任公司

Genetically engineered bacteria realizing high-density fermentation co-production of 2,3-butanediol as well as construction method and application thereof

ActiveCN104560848AReduce culture volumeLess investmentBacteriaHydrolasesBiotechnologyEscherichia coli

The invention discloses genetically engineered bacteria realizing high-density fermentation co-production of 2,3-butanediol as well as a construction method and an application thereof. The genetically engineered bacteria are constructed by integrating three key enzyme genes such as alpha-acetolactate synthetase encoding genes, alpha-acetolacetate decearboxylase encoding genes and 2,3-butanediol dehydrogenase encoding genes onto Escherichia coli chromosomes in a 2,3-butanediol synthesis path. According to the strain fermentation process, the content of the byproduct acetic acid is reduced, so that high-density fermentation can be realized, and 2,3-butanediol with high additional value is co-produced. In addition, the invention also discloses a method for realizing high-density fermentation co-production of other compounds and 2,3-butanediol genetically engineered bacteria and an application thereof. The 2,3-butanediol can be produced by virtue of high-density fermentation, and polyhydroxyalkanoates or functional proteins also can be co-produced, so that low-cost and high-efficiency co-production of the polyhydroxyalkanoates or functional proteins and the 2,3-butanediol is realized, and the genetically engineered bacteria have important industrial application values.

Owner:NANJING UNIV OF TECH

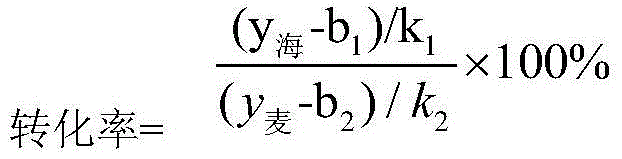

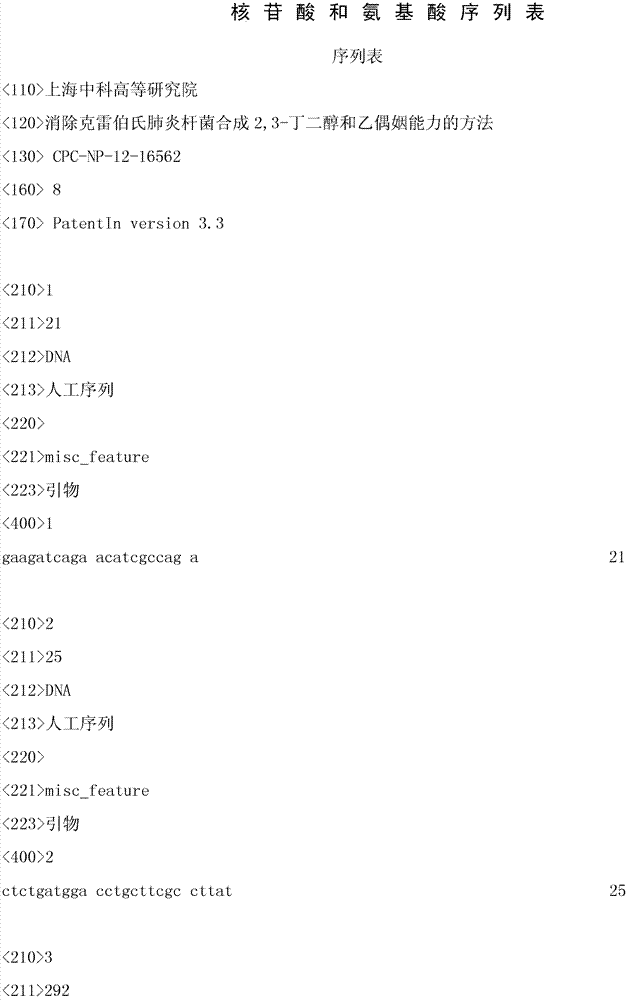

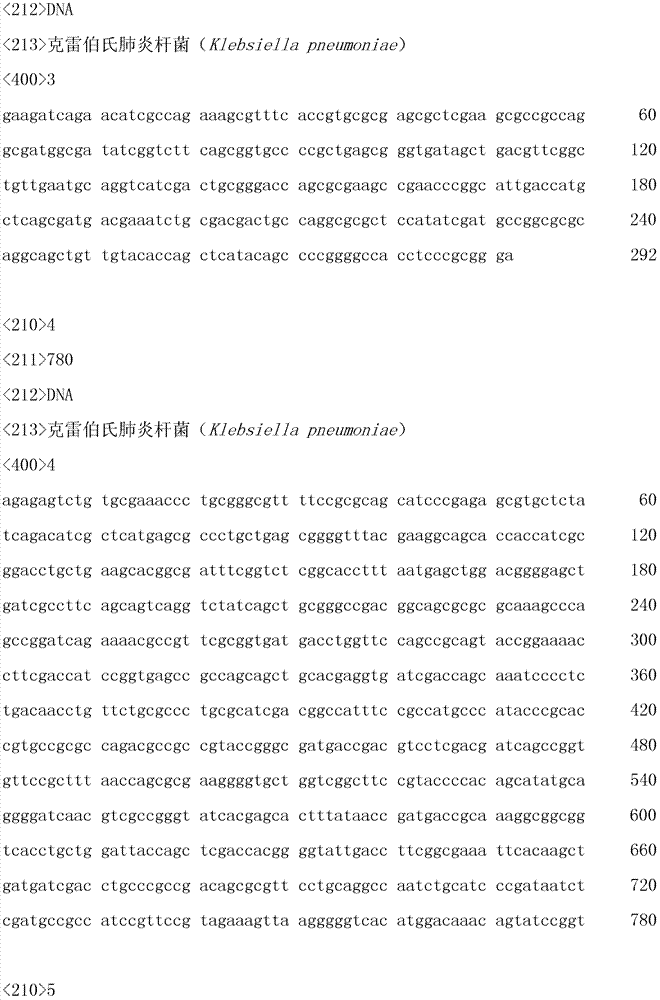

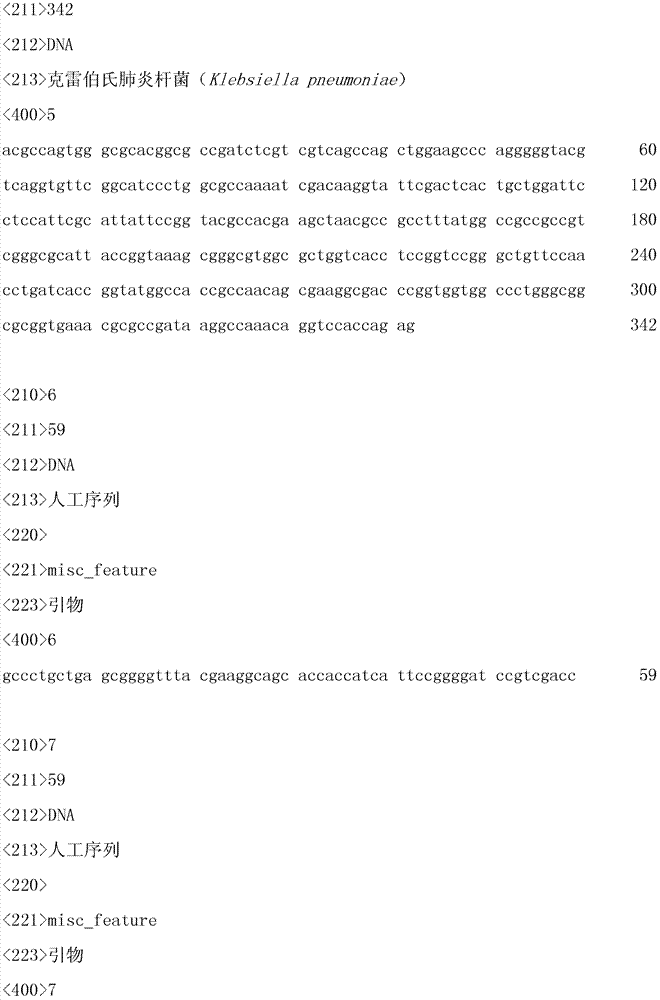

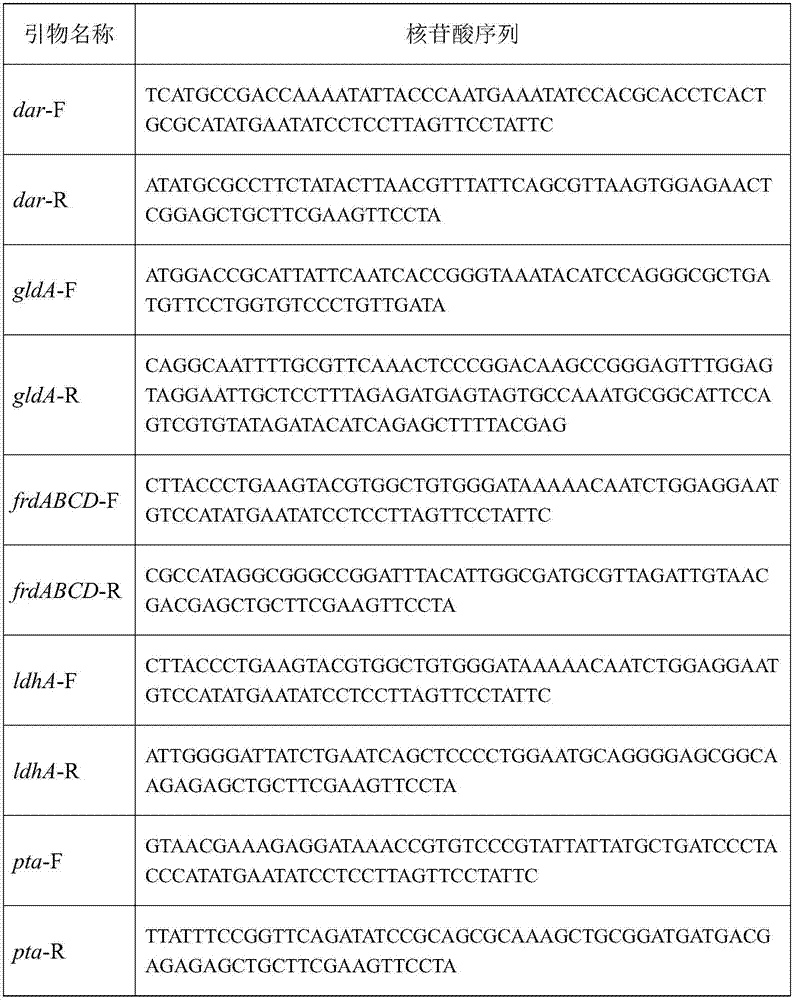

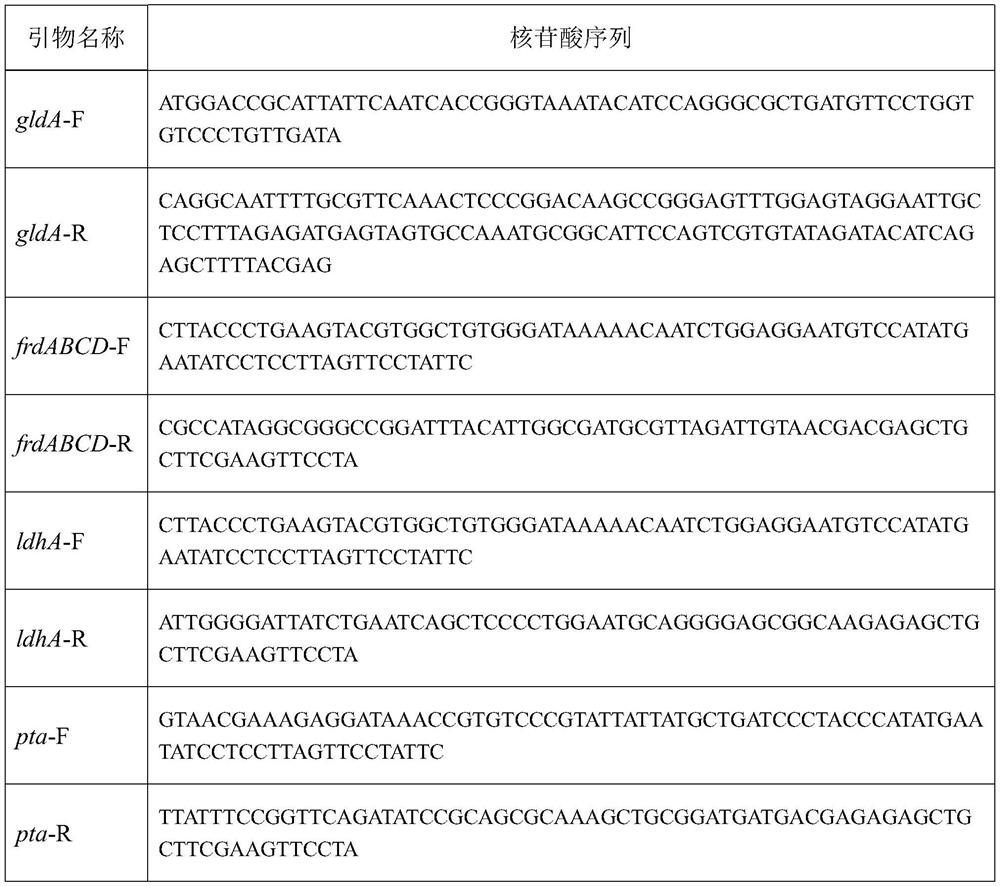

Method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin

ActiveCN102952826AEliminate generationReduce separation and extraction stepsBacteriaStable introduction of DNA2,3-ButanediolGlycerol

The invention discloses a method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin, comprising the following step of inactivating acetolacetate decearboxylase gene in a synthesis route of 2,3-butanediol by lebsiella pneumoniae to cut off the catalytic reaction that acetolactic acid is converted into acetoin. According to the method, when 1,3-propylene glycol is synthesized from glycerol by the klebsiella pneumoniae, the synthesis of byproducts, i.e. 2,3-butanediol and acetoin, can be eliminated, and the conversation rate of glycerol to 1,3-propylene glycol can be improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

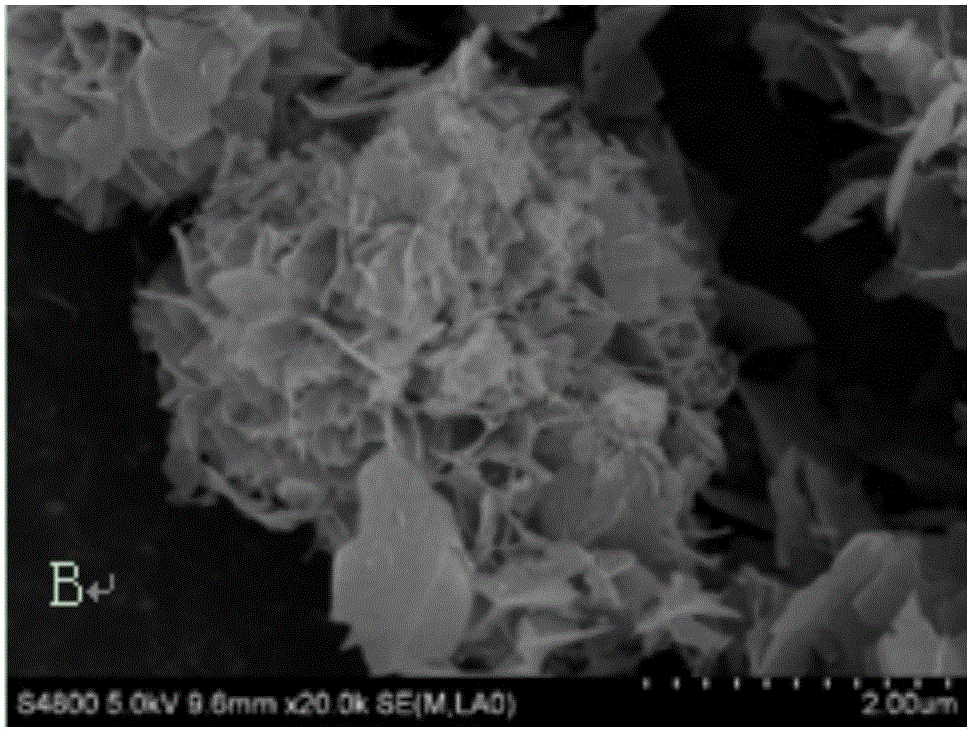

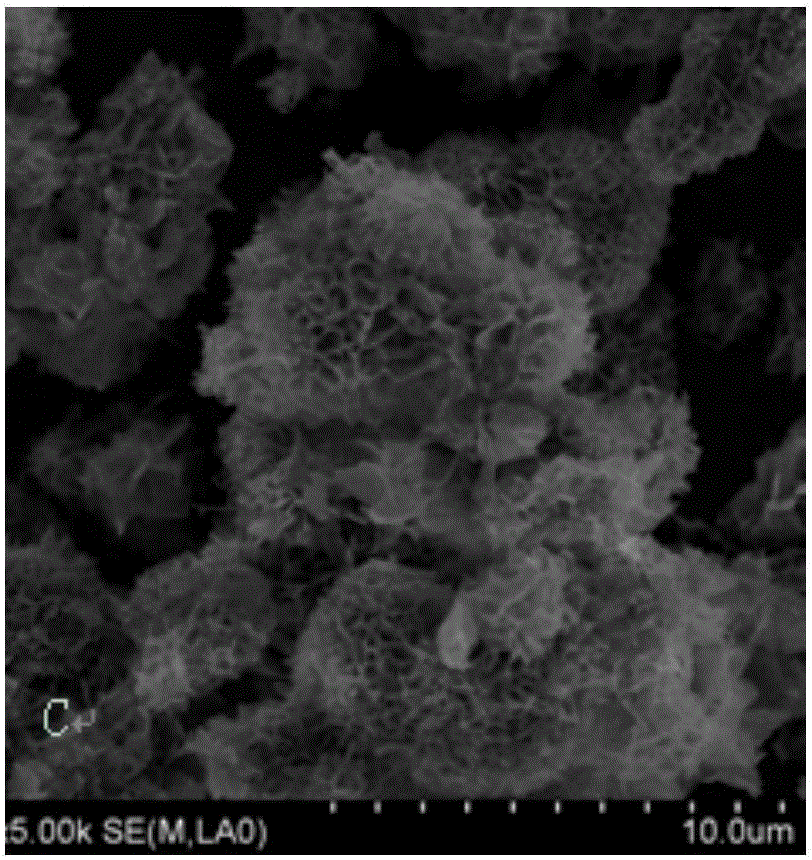

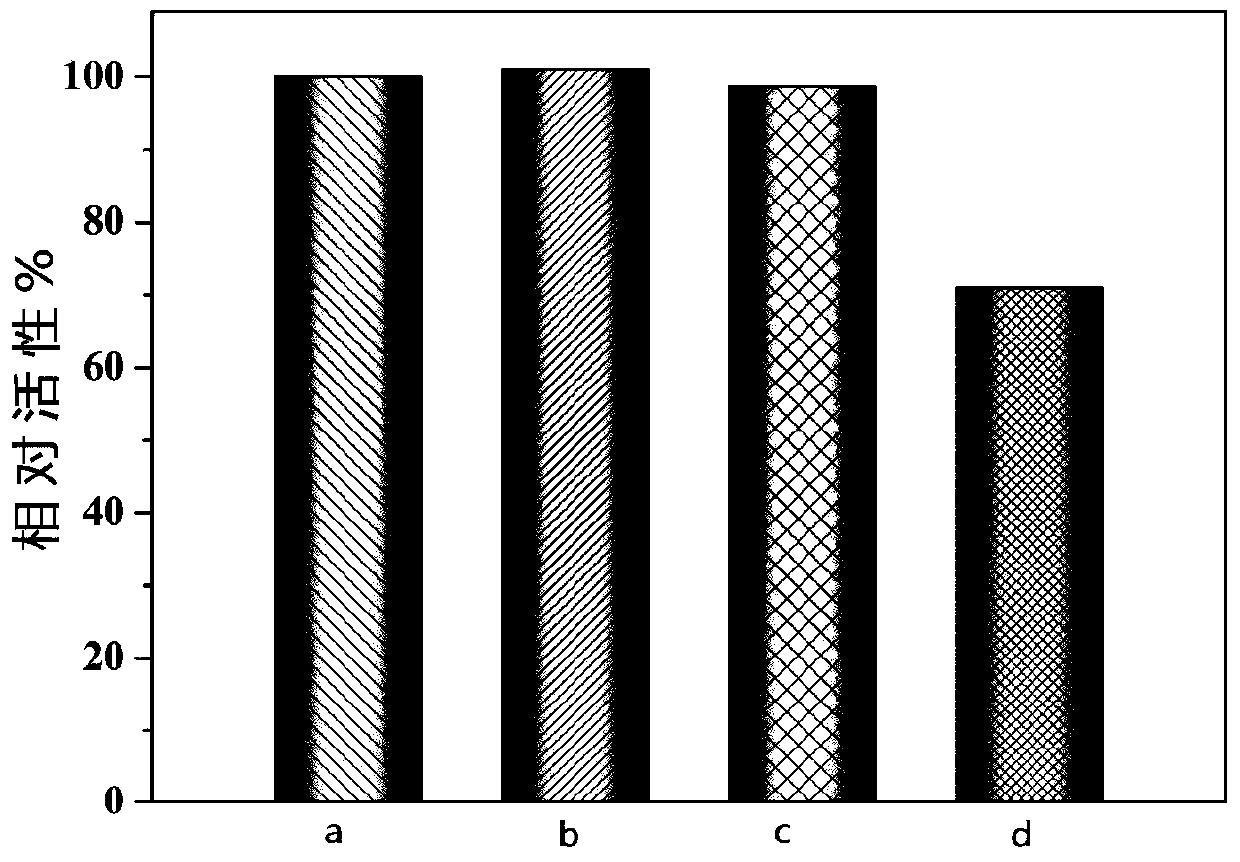

Enzyme immobilization method

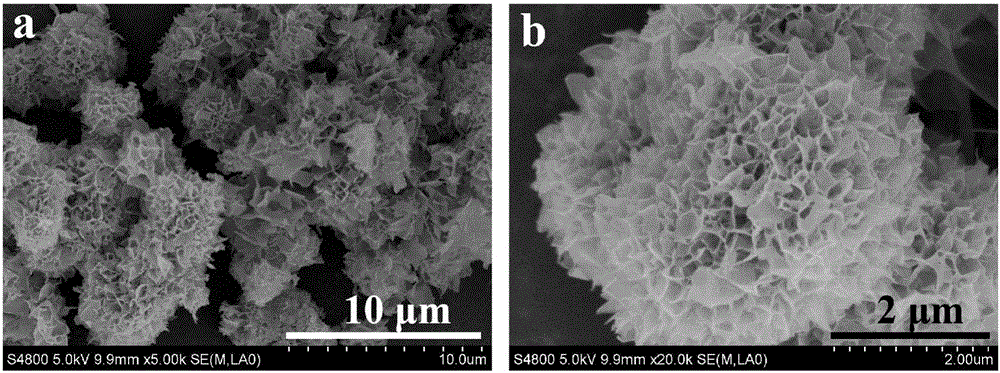

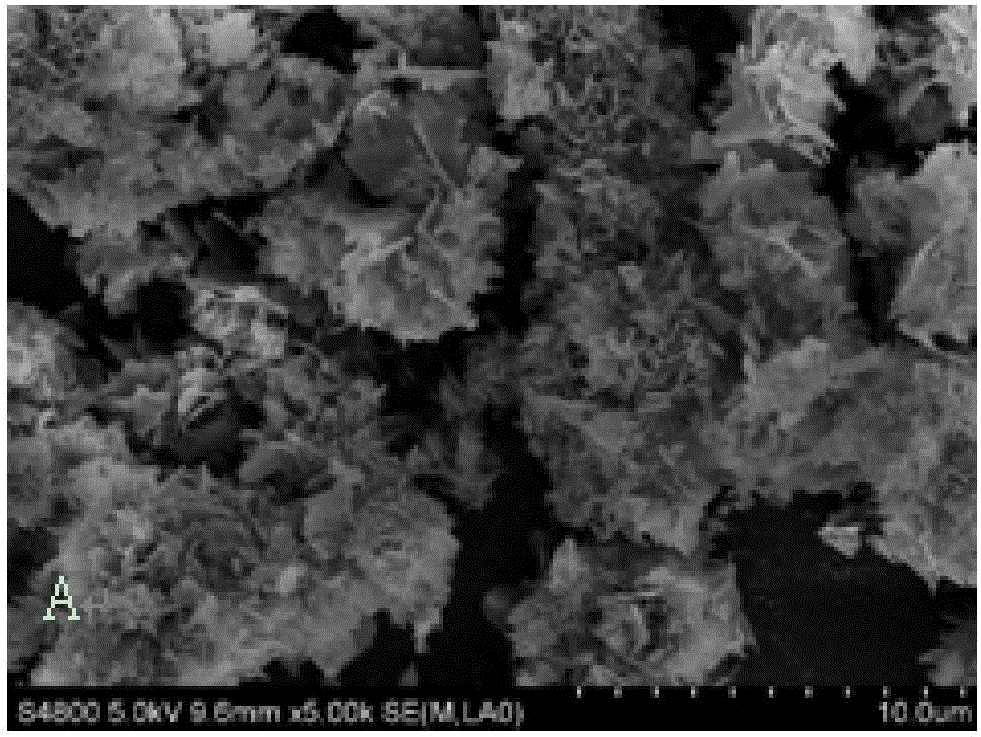

ActiveCN105950604ALimit stabilityLimit repeatabilityOn/in organic carrierBeer brewingMicrosphereChloride

The invention provides an enzyme immobilization method, and particularly relates to a method for immobilization of enzyme for beer production. According to the method, alpha-acetolactate decarboxylase buffer solution is added to calcium chloride solution for reaction to obtain a nanoflower structure provided with preliminary immobilized enzyme, then obtained nanoflower is dispersed in sodium alga acid solution, obtained dispersion liquid is added to the calcium chloride solution dropwise at a certain speed, and stirring and curing are conducted to obtain a final microsphere product. According to microspheres prepared with the enzyme immobilization method, immobilized enzyme activity is higher than free enzyme activity by 98% or more, and immobilized enzyme is stable and recyclable and has broad prospects in industrial application.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

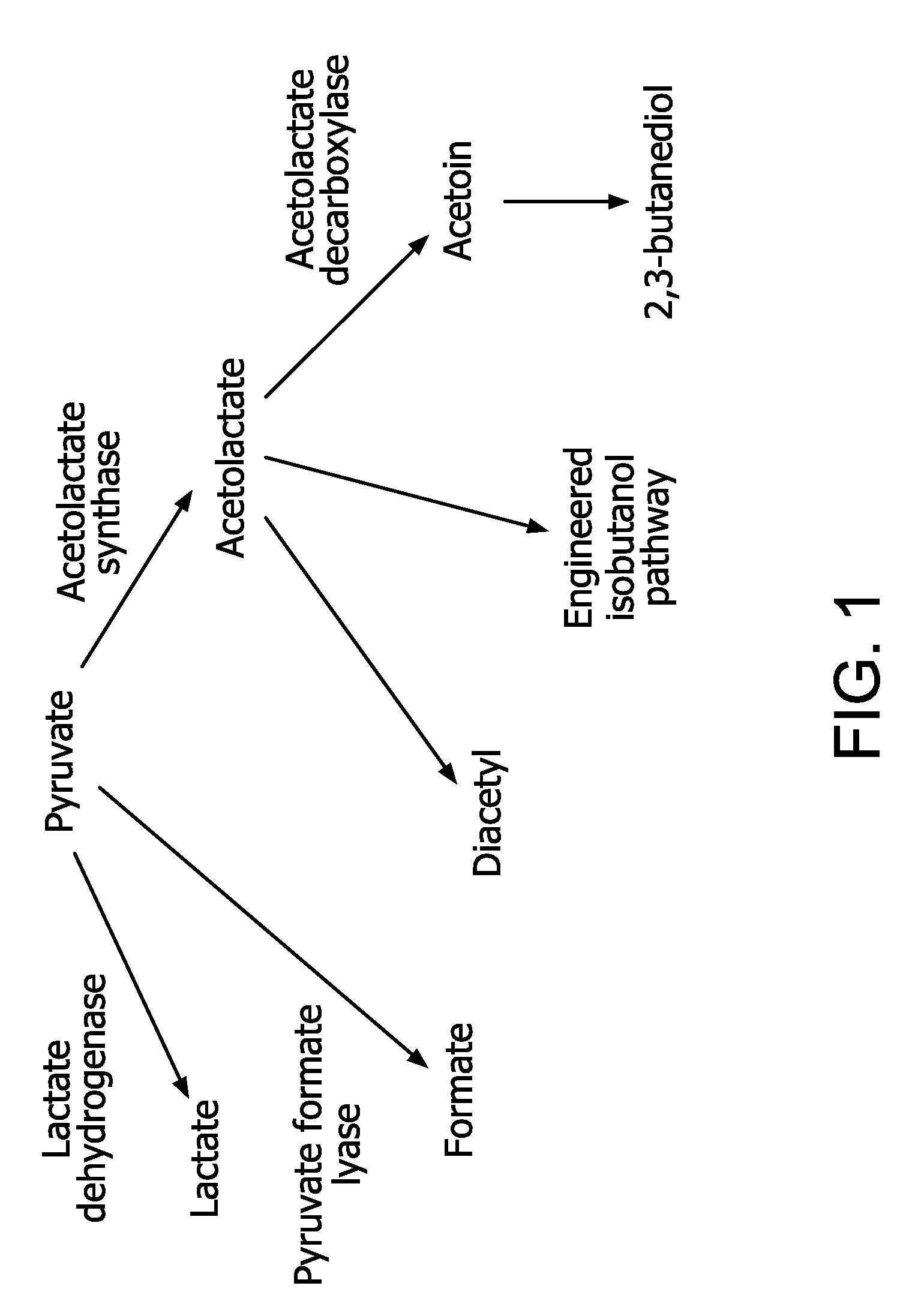

Flux to acetolactate-derived products in lactic acid bacteria

ActiveUS9169499B2Reduces and eliminates enzyme activityReduced activityBacteriaBiofuelsLactobacillusLactate dehydrogenase

Owner:GEVO INC

Method for constructing genetic engineering strains for producing (R)-acetoin and application of genetic engineering strains

ActiveCN107129959AReduce pathogenicityNon-pathogenicBacteriaTransferasesBiotechnologyAcetolactate synthase

The invention discloses a method for constructing genetic engineering strains for producing (R)-acetoin and application of the genetic engineering strains. The method includes optimizing codons of nucleotide sequences of alpha-acetolactate synthase genes, alpha-acetolactate decarboxylase genes and NADH (reduced form of nicotinamide adenine dinucleotide) oxidase genes and acquiring each gene cluster with three genes by the aid of artificial synthesis processes; inserting the gene clusters into expression vectors to obtain polycistron recombinant plasmids; introducing the polycistron recombinant plasmids into host bacteria E. coli and knocking out key genes of main byproduct synthesis paths to obtain the genetic engineering strains for producing the (R)-acetoin. The method and the application have the advantages that raw materials for the genetic engineering strains can come from wide sources and are low in cost, the strains are free of pathogenicity, oxidized form coenzymes NAD+ (nicotinamide adenine dinucleotide+) can be effectively regenerated, the strains are high in (R)-acetoin yield and production efficiency, the maximum yield can reach 72.1 g / L, and the optical purity can reach 99% at least; the (R)-acetoin is produced by the aid of non-grain cassava flour and inexpensive nitrogen sources which are used as fermentation raw materials, and accordingly the production cost can be reduced.

Owner:GUANGXI ACAD OF SCI

Genetically engineered bacterium for co-generating butanol and 2,3-butanediol and construction method and application thereof

The invention discloses a genetically engineered bacterium for co-generating butanol and 2,3-butanediol. The genetically engineered bacterium is a butanol generating clostridium to which an acetoin reductase gene is introduced or a butanol generating clostridium to which an acetolactic acid decarboxylase gene and the acetoin reductase gene are introduced. The nucleotide sequence of the acetolactic acid decarboxylase gene is any one of nucleotide sequences shown in SEQ ID NO:1-7, and the nucleotide sequence of the acetoin reductase gene is any one of nucleotide sequences shown in SEQ ID NO:8-11. An acetolactic acid decarboxylic reaction is enhanced in a clostridium acetobutylicum, the yield of 3-hydroxy butanone is greatly increased to about 6.4 g / L from initial about 1.8 g / L, and then acetoin is converted into 2,3-butanediol reaching up to 8.05 g / L under the effect of acetoin reductase; acetone is reduced to 2.2 g / L from about 4.5 g / L, and economic benefits of fermentation of the clostridium acetobutylicum are remarkably increased.

Owner:NANJING UNIV OF TECH

Double-enzyme co-immobilizing method and immobilized enzyme prepared through method

InactiveCN106497910AImprove toleranceMeet operating conditionsOn/in inorganic carrierBeer brewingChlorideBuffer solution

The invention provides a double-enzyme co-immobilizing method and an immobilized enzyme prepared through the method and belongs to the field of bioengineering, and multiple immobilized enzymes with high catalysis efficiency and low cost can be obtained. The double-enzyme co-immobilizing method comprises the following steps: adding a calcium chloride solution into a buffer solution containing alpha-acetolacetate decearboxylase and proline endoprotease which are to be immobilized, enabling full reaction at set temperature, and centrifugally separating and washing to obtain the immobilized enzymes of nanoflower structures. The double-enzyme co-immobilizing method can be applied to beer production, in particular to the final filter stage of clear wine in a beer production process.

Owner:TSINGTAO BREWERY

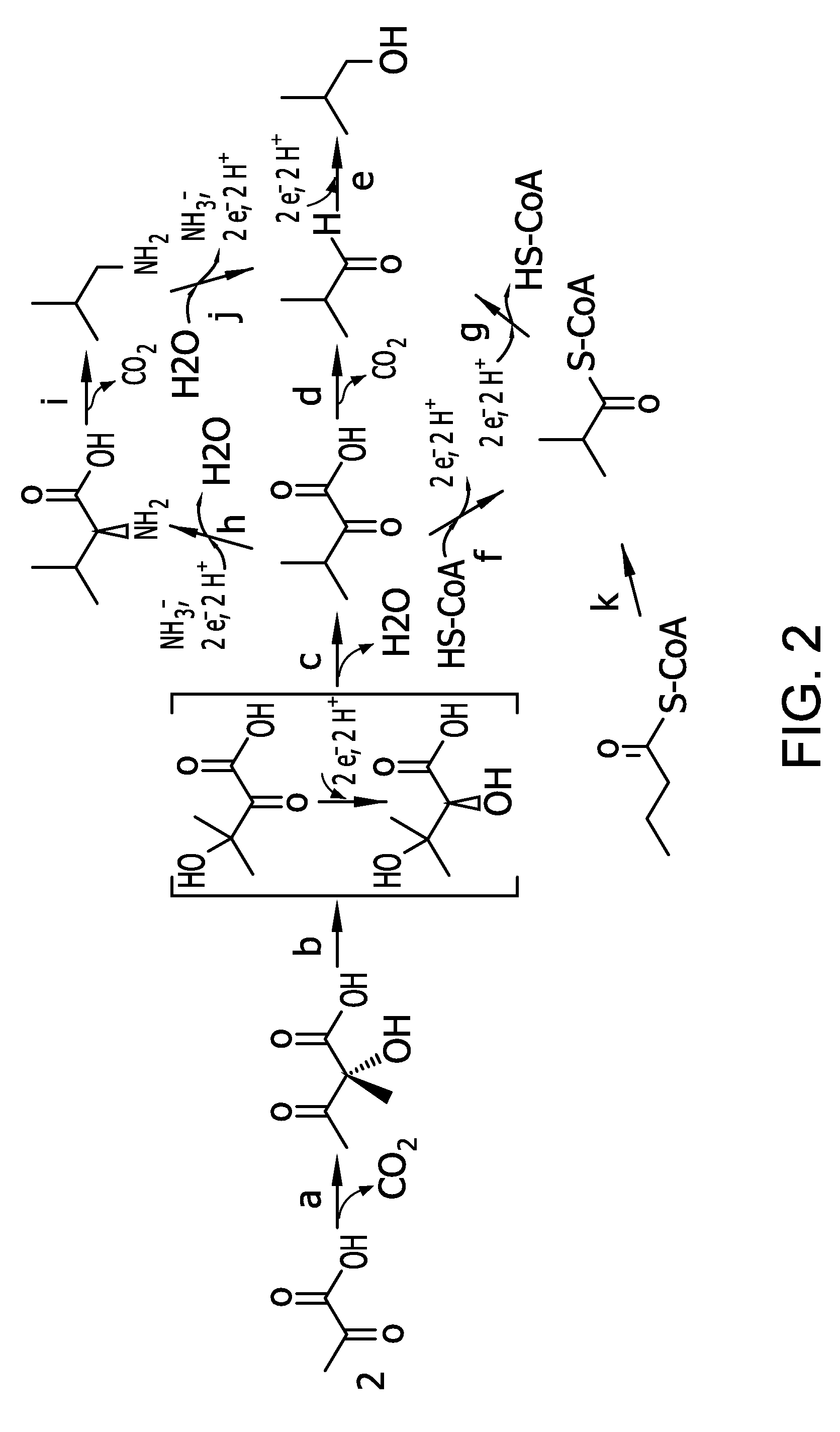

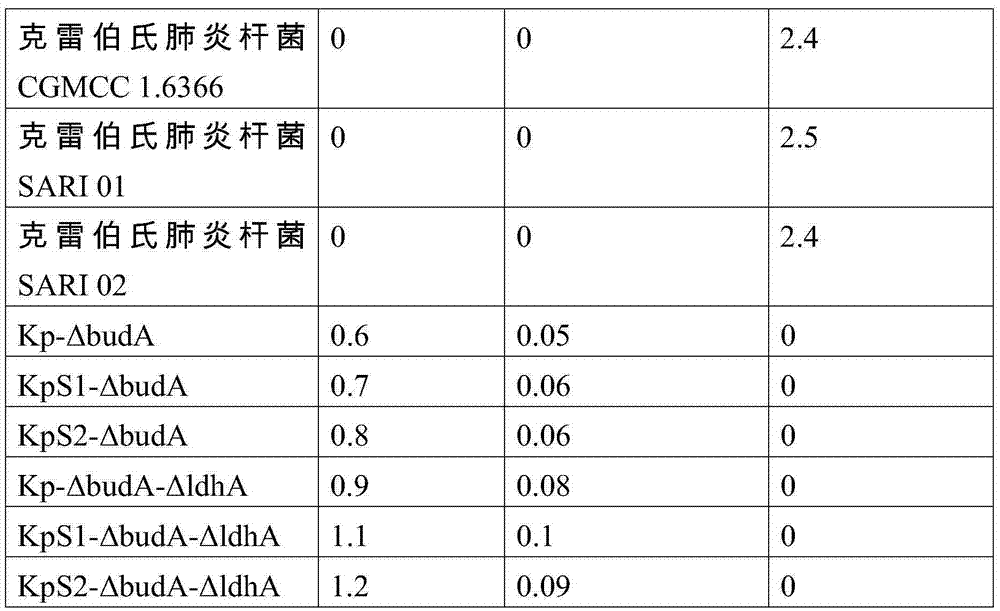

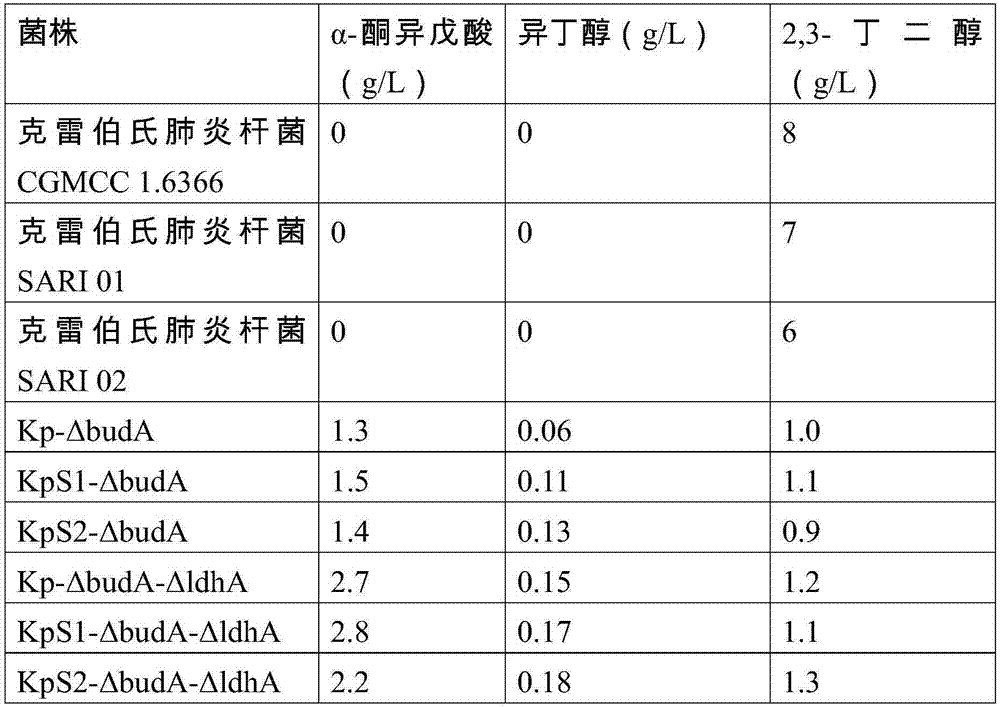

Method for preparing alpha-ketoisovaleric acid and isobutanol by adopting klebsiella pneumoniae

ActiveCN106867922AHigh genetic stabilityHigh final concentrationBacteriaMicroorganism based processesIsobutanolLactate dehydrogenase

The invention discloses modified klebsiella pneumoniae and applications of modified klebsiella pneumoniae in producing alpha-ketoisovaleric acid and isobutanol. The modified klebsiella pneumoniae is klebsiella pneumoniae with deactivated acetolactate decarboxylase and deactivated lactic dehydrogenase. The modified klebsiella pneumoniae is adopted for carrying out fermentation production of alpha-ketoisovaleric acid and isobutanol under the neutral pH and micro-oxygen condition. For the method provided by the invention, no exogenous genes are introduced in strain production, thus the genetic stability of the strain is high, the final concentration of the product is high, and the range of the raw materials is wide.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

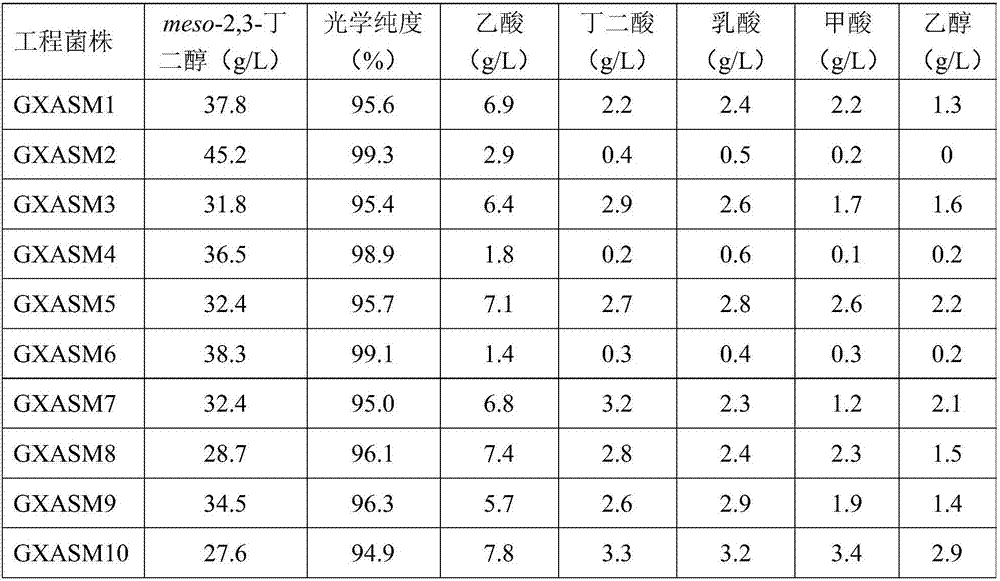

Construction method and application of high-yield engineering strain for optically pure meso-2,3-butanediol

The invention discloses construction of a high-yield engineering strain for optically pure meso-2,3-butanediol. A construction method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and a meso-2,3-butanediol dehydrogenase gene, afterwards, splicing to obtain a gene cluster containing the three genes, then introducing the gene cluster into an expression vector to obtain a polycistronic recombinant plasmid, and finally introducing the recombinant plasmid into a host bacterium E. coli again, so that a high-yield engineering bacterium is obtained. Synthesis raw materials used by the bacterium are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield, high in production efficiency and good in stability, has the highest yield which can reach 91.5g / L and the optical purity which can reach 99 percent or above. The invention discloses application of the high-yield engineering strain to the production of the optically pure meso-2,3-butanediol by utilizing cheap cassava meal as a carbon source and utilizing cottonseed protein powder, soybean pulp powder, soybean cake powder or peanut protein powder as a nitrogen source at the same time. The production cost is lowered.

Owner:GUANGXI ACAD OF SCI

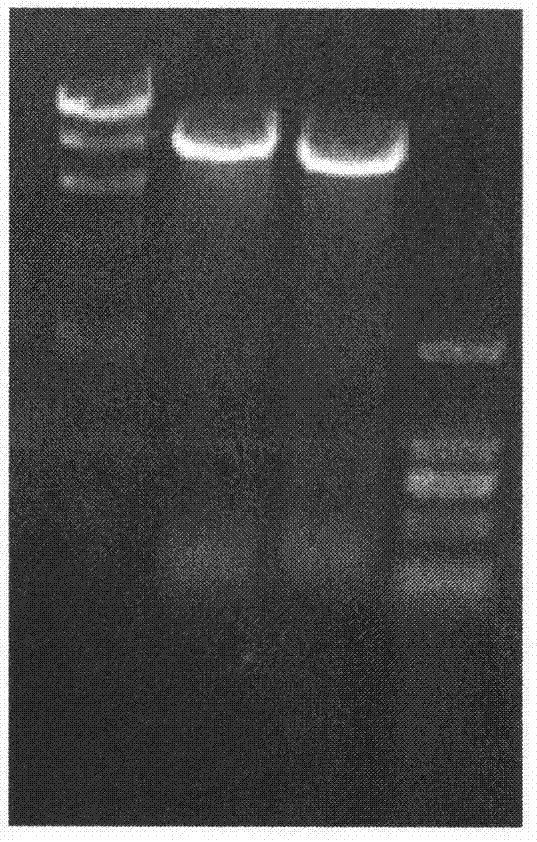

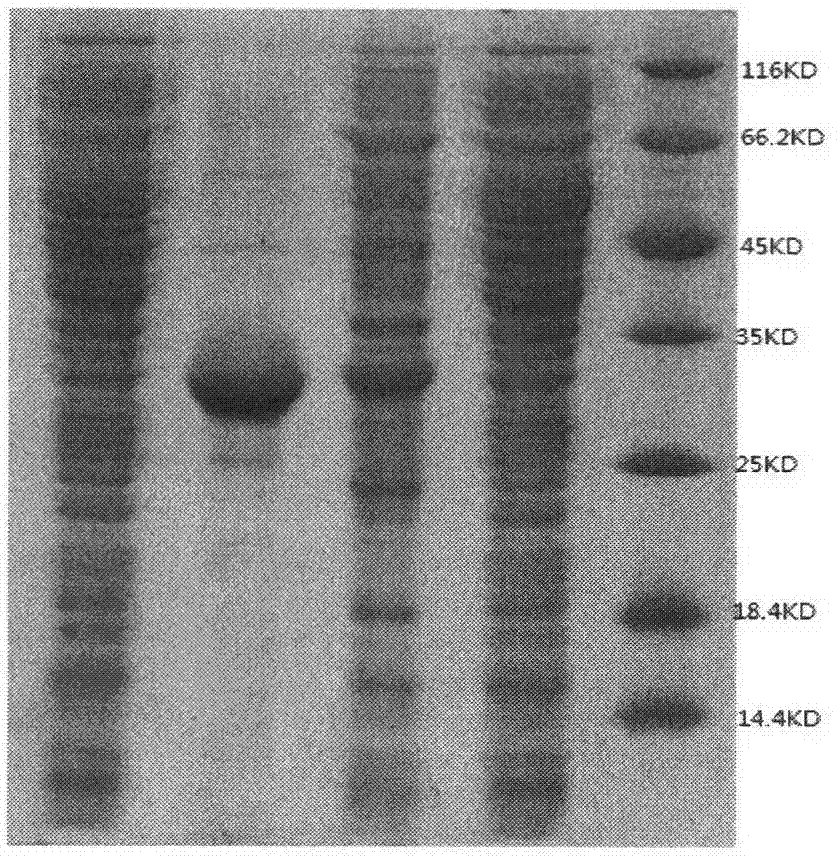

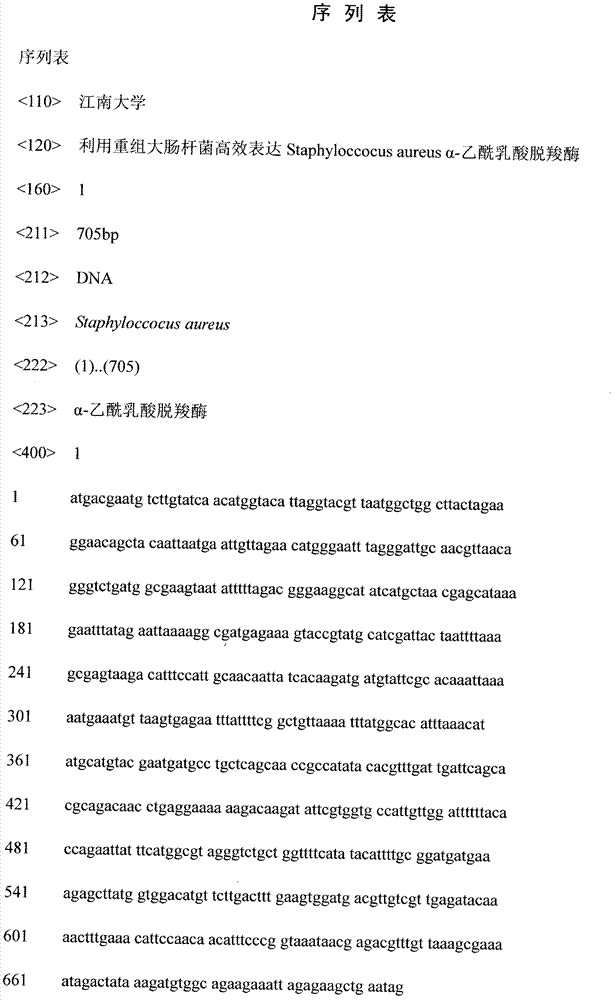

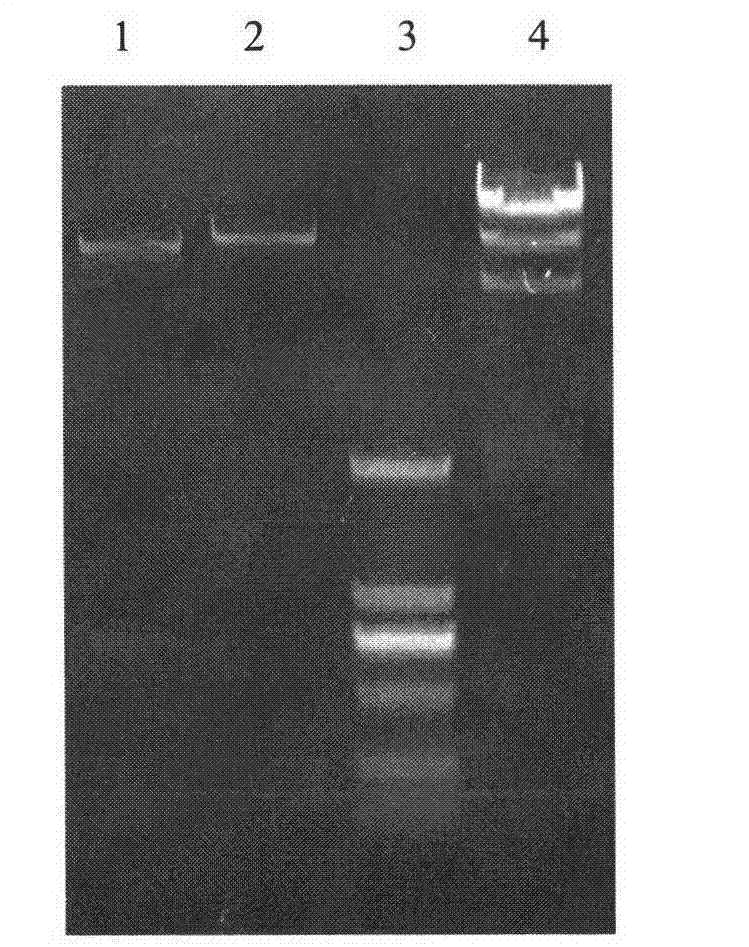

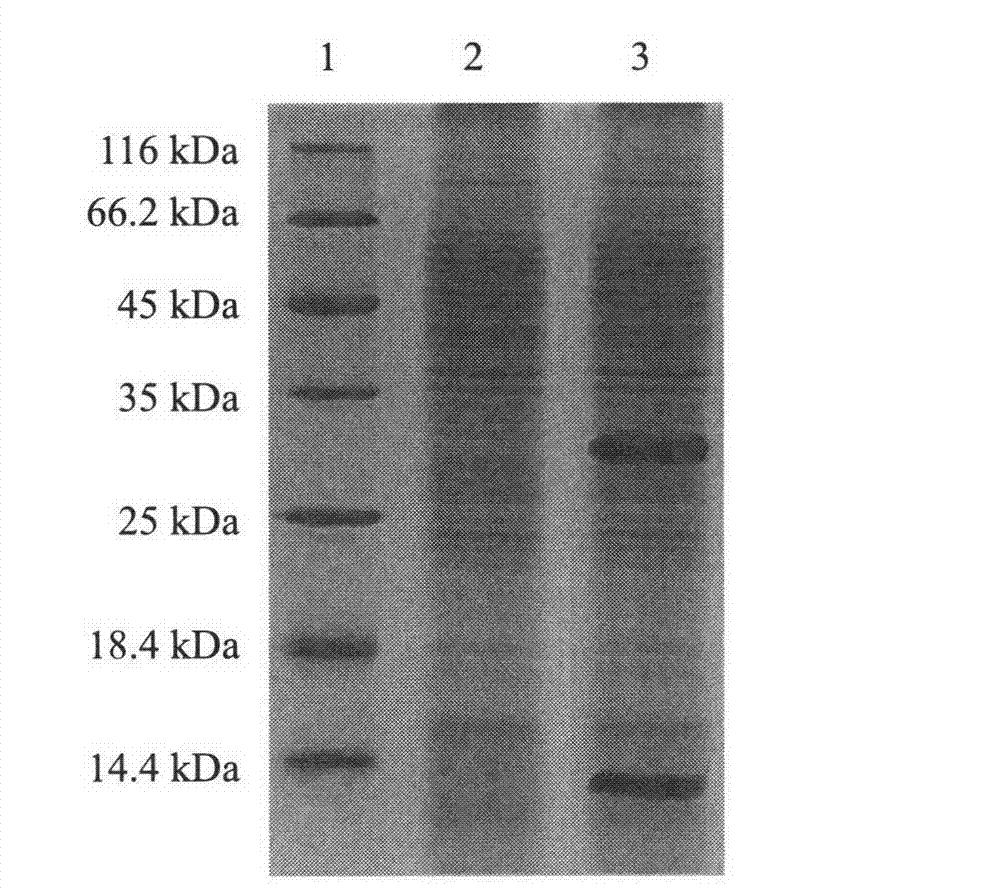

Highly expressed Staphyloccocus aureus alpha-acetolacetate decearboxylase by utilization of recombinant escherichia coli

InactiveCN102816787AHigh activityAvoid generatingBacteriaMicroorganism based processesEscherichia coliSpecific enzyme

A staphylococcus aureus genome DNA is used as a template to be amplified so as to obtain a gene saald for encoding alpha-acetolacetate decearboxylase (ALDC). The gene is cloned to an escherichia coli expression vector pET-28a and inducible expression is carried out on E.coli BL21 by IPTG. By the utilization of 6.His-Tag on the expression vector pET-28a, a Ni column is selected for purification and expression of the active alpha-acetolacetate decearboxylase by affinity chromatography. Specific enzyme activity of crude enzyme is 56 U / mg; specific enzyme activity reaches 469.85 U / mg after purification and the purification multiple reaches 8.36 times; and recovery rate is 87.65%.

Owner:JIANGNAN UNIV

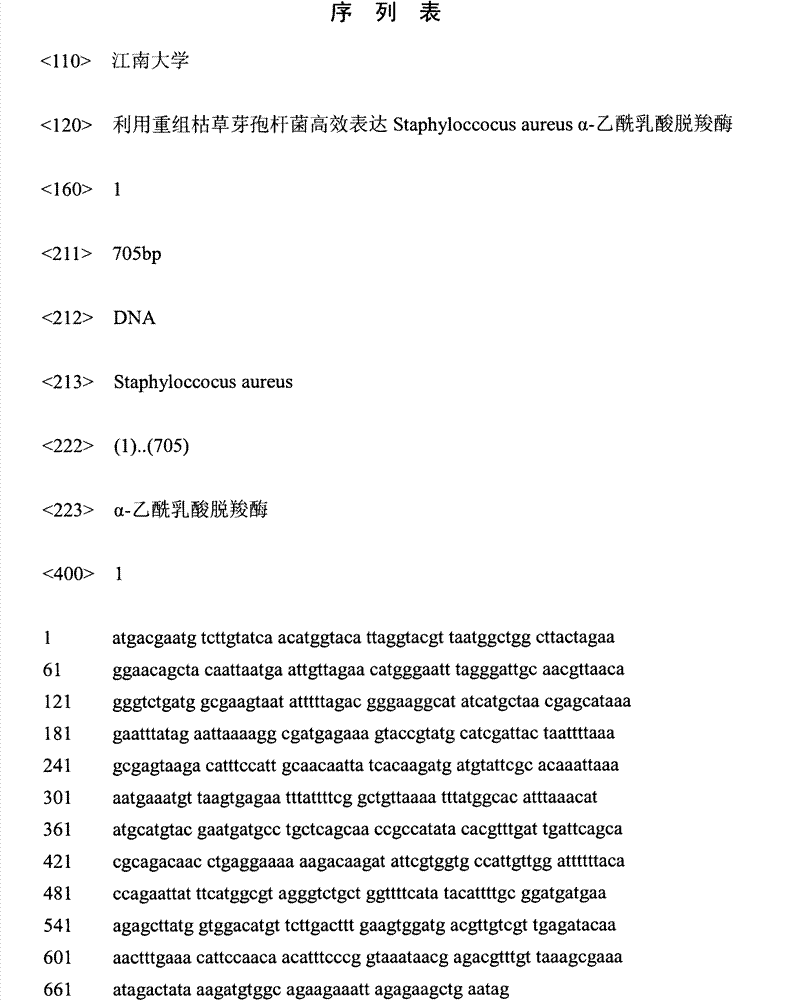

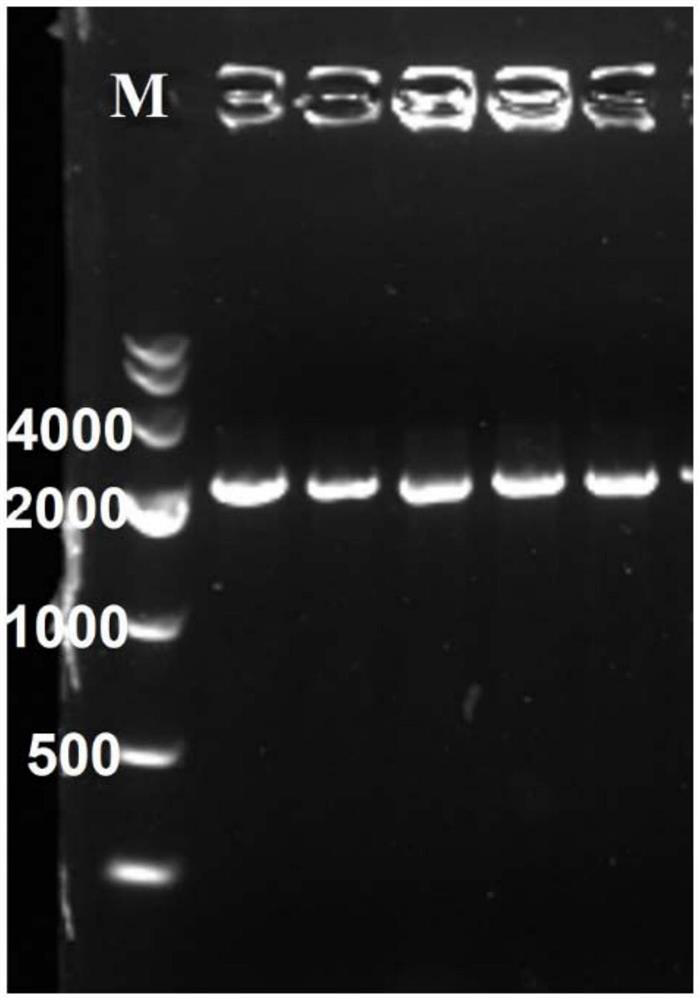

Method for expressing staphyloccocus aureus alpha-acetolactate decarboxylase by utilizing recombinant bacillus subtilis efficiently

InactiveCN102876704AHigh activityAvoid generatingBacteriaMicroorganism based processesStaphylococcus cohniiGenetic engineering

The invention relates to a method for expressing staphyloccocus aureus alpha-acetolactate decarboxylase by utilizing recombinant bacillus subtilis efficiently. The method comprises the following steps of: performing amplification by taking genomic deoxyribonucleic acid (DNA) of a staphyloccocus aureus geneome to obtain a gene saald for encoding alpha-acetolactate decarboxylase (ALDC); and cloning the gene saald on a shuttle expression vector pMA5, and constructing an alpha-acetolactate decarboxylase genetic engineering bacterium pMA5-saald / B.subtilis WB600 by taking B.subtilis WB600 as an expression host to realize the high-efficiency expression of ALDC. The fermenting enzyme activity of the engineering bacterium in a Luria-Bertani culture medium is 36,000 U / L, is improved by about 1,200 times compared with an original strain S. aureus and is improved by about 10,588 times compared with a host strain B. subtilis WB600. The recombinant bacterium is fermented and cultured in the fermentation culture medium for 48 hours, the enzyme activity of the ALDC is 66,500 U / L.

Owner:JIANGNAN UNIV

Method of producing D-(-)-acetoin by in-vitro enzyme reaction

ActiveCN107653259AAchieve productionIncrease productionBacteriaTransferasesEscherichia coliThiamine pyrophosphate

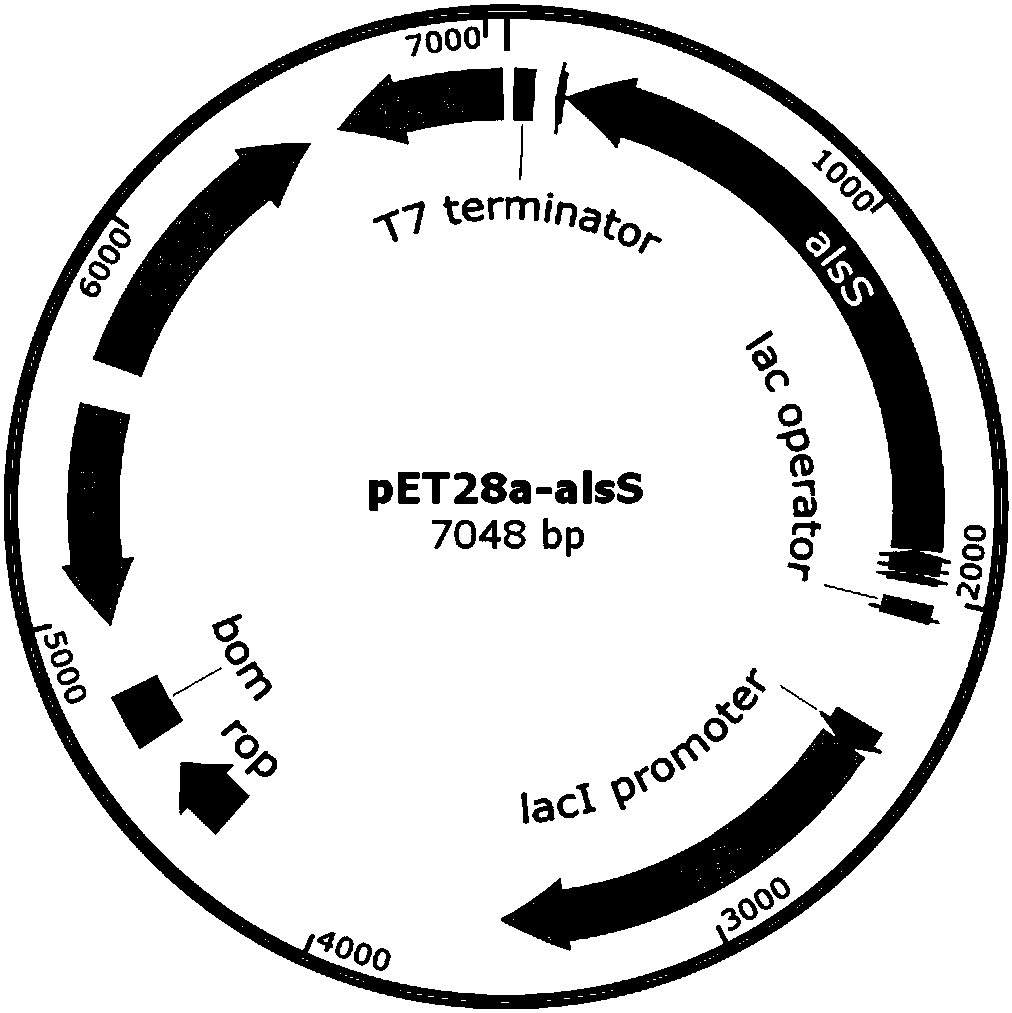

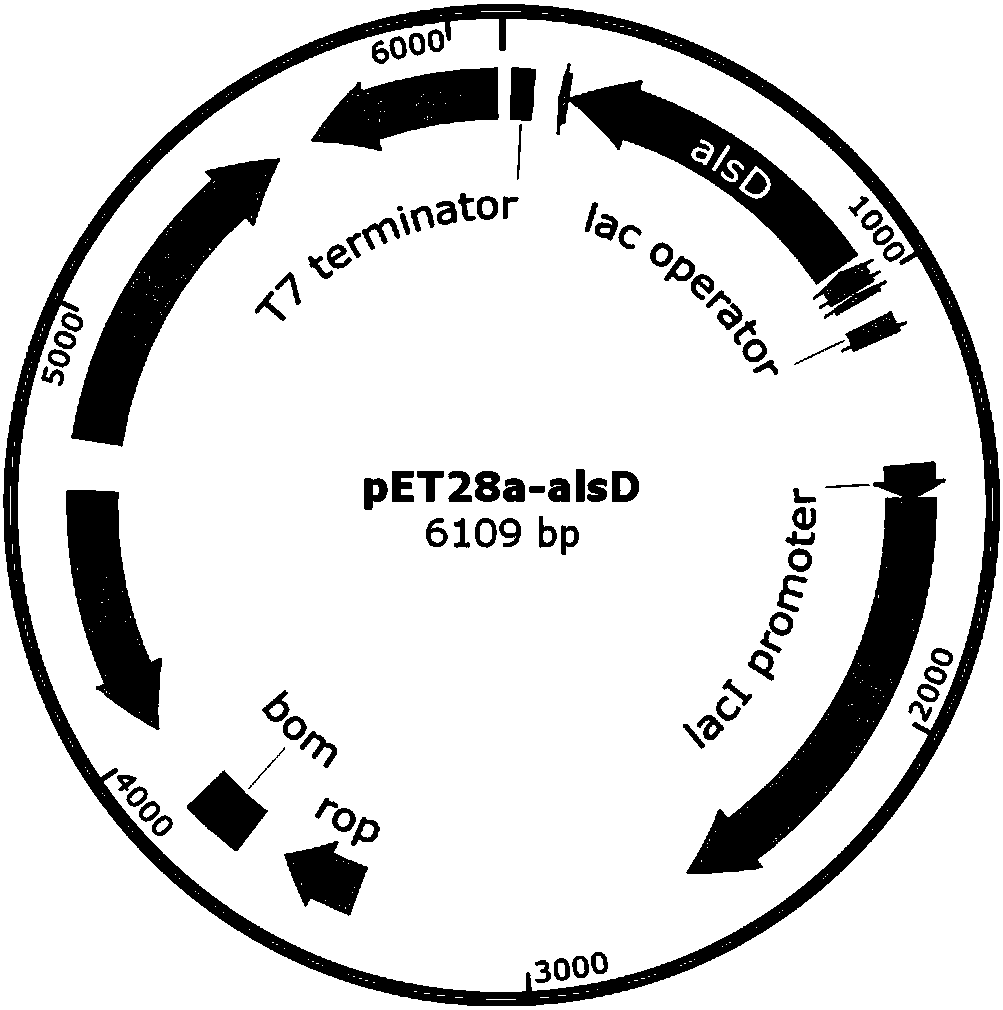

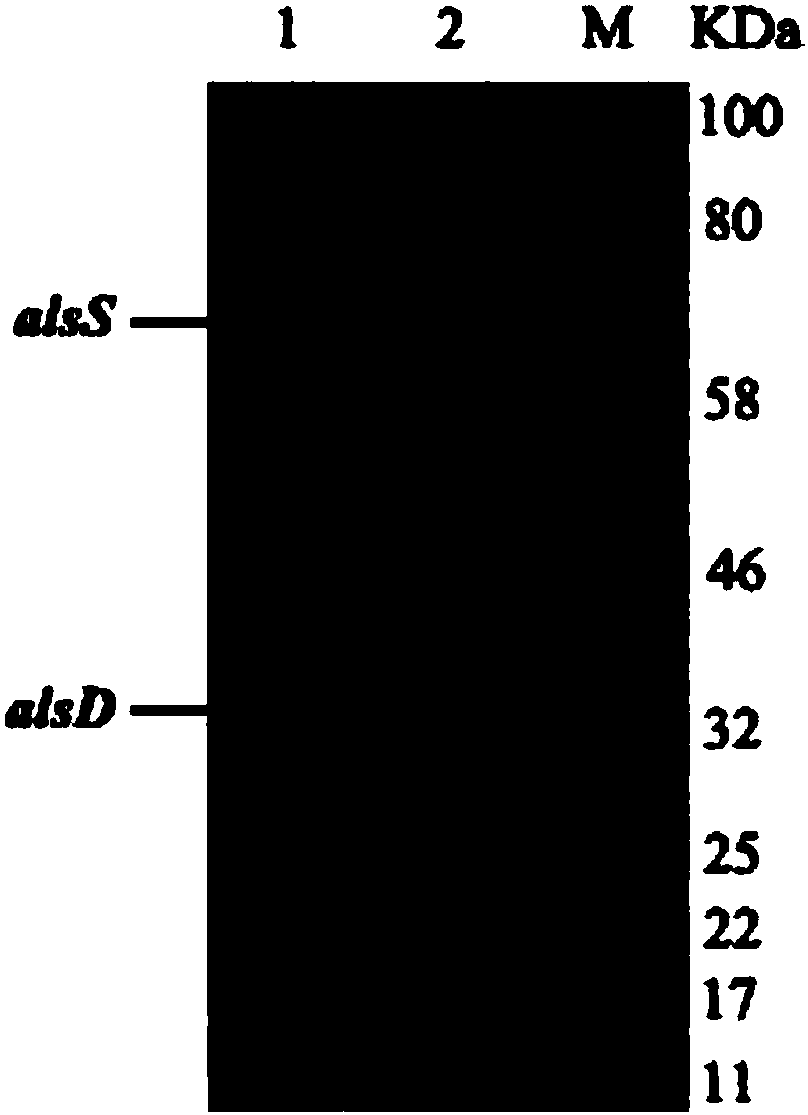

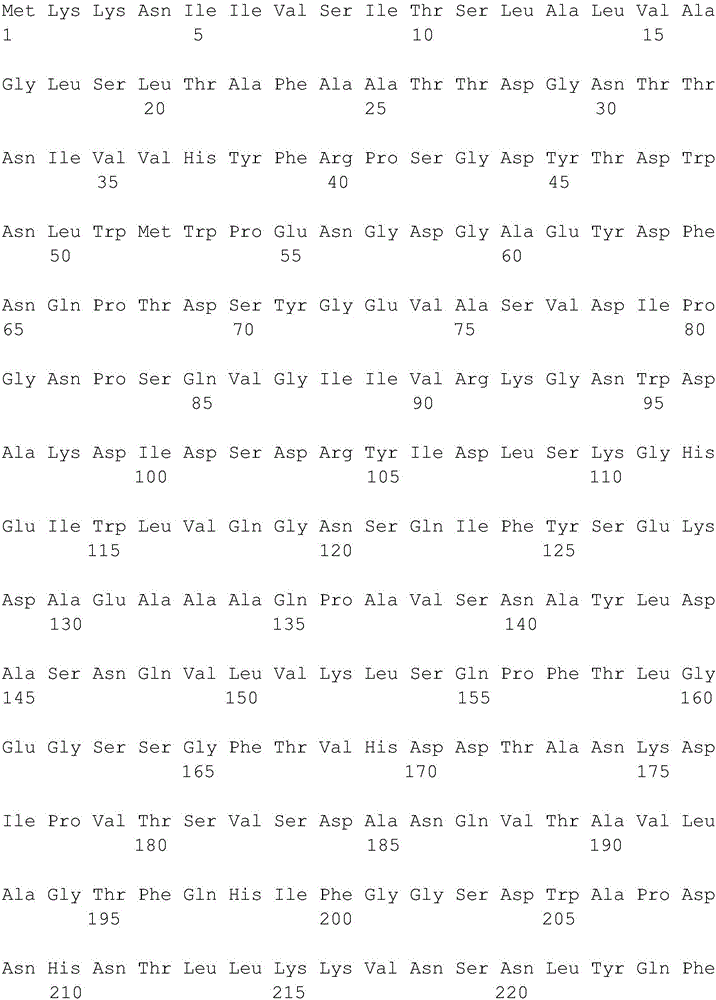

The invention discloses a method of producing D-(-)-acetoin by in-vitro enzyme reaction, comprising the steps of (1) linking the carrier pET28a and alpha-acetolactate synthase encoding gene alsS to obtain pET28a-alsS, introducing the pET28a-alsS into Escherichia coli, fermenting, purifying, and concentrating to obtain alpha-acetolactate synthase concentrate; linking the carrier pET28a and alpha-acetolactate decarboxylase encoding gene alsD to obtain pET29a-alsD, introducing the pET29a-alsD to Escherichia coli, fermenting, purifying, and concentrating to obtain alpha-acetolactate decarboxylaseconcentrate; (2) mixing well the two concentrates, sodium pyruvate, Mg2+ and thiamine pyrophosphate, and allowing reaction to obtain the D-(-)-acetoin. The sodium pyruvate low in cost is used as a substrate to provide in-vitro efficient production of high-added-value chiral D-(-)-acetoin, and the finished D-(-)-acetoin has high purity.

Owner:TIANJIN UNIV

Alpha-acetyl lactate dehydrogenase dry powder and its preparation process

InactiveCN1624121AActive properties do not changeEasy to transportLyasesFood preparationLactate dehydrogenaseXanthan gum

An alpha-acetolactate decarboxylase powder is prepared from the alpha-acetolactate decarboxylase liquid and the spray-frying protector composed of mycose, xanthan gum, sodium alginate and dextrin through spray drying. Its advantage is high stability.

Owner:南宁邦尔克生物技术有限责任公司

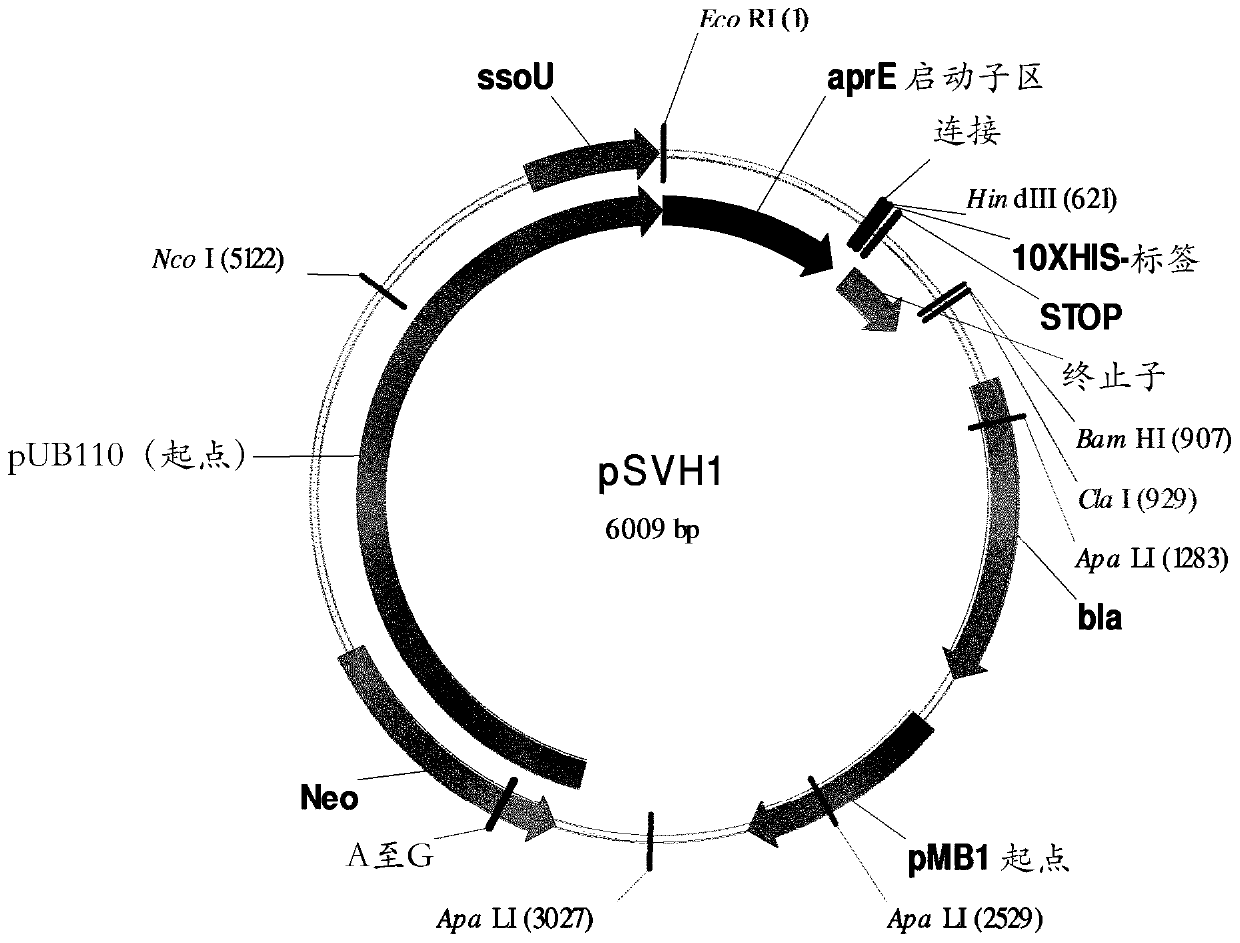

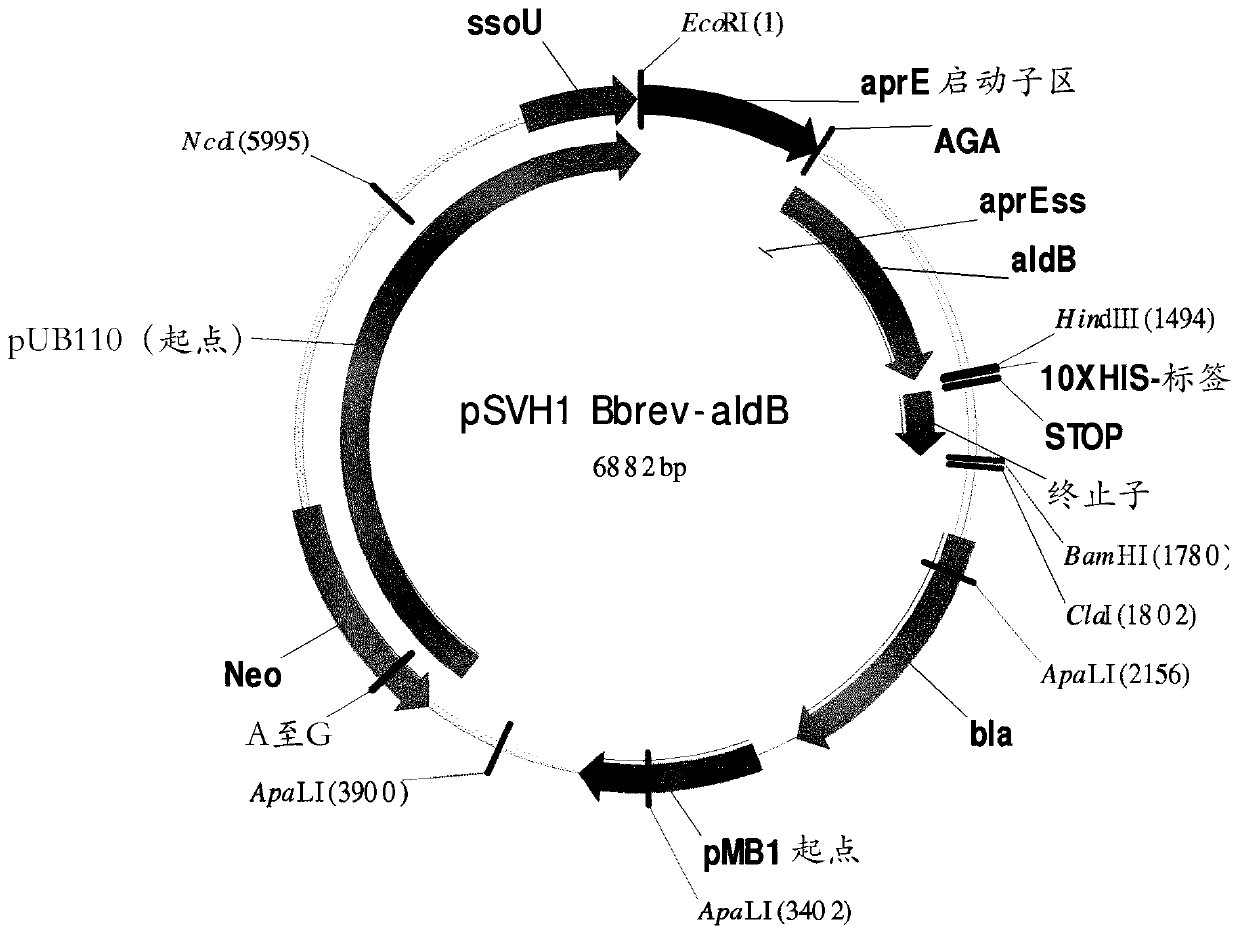

Signal peptide mutant capable of improving expression quantity of recombinant pullulanase and application thereof

ActiveCN106084016AIncrease extracellular expressionBacteriaMicroorganism based processesBacillus naganoensisThreonine

The invention discloses a signal peptide mutant capable of improving the expression quantity of recombinant pullulanase and an application thereof. The signal peptide mutant is obtained by saturation mutagenesis of an N end of a sequence of an alpha-acetolactate decarboxylase gene signal peptide derived from bacillus brevis. A specific mutation site is a seventh-site threonine replaced with valine. Compared with a no-mutation signal peptide, the signal peptide mutant can improve extracellular expression of the recombinant pullulanase derived from bacillus naganoensis in bacillus subtilis by more than or equal to 50%, and has good application value.

Owner:南宁邦尔克生物技术有限责任公司

Method for producing tetramethylpyrazine from cheap raw materials

ActiveCN107177620AIncrease productionIncrease productivityFermentationVector-based foreign material introductionBiotechnologyHigh concentration

The invention discloses a method for producing tetramethylpyrazine from cheap raw materials. The method comprises steps as follows: nucleotide sequences of an alpha-acetolactate synthase gene, an alpha-acetolacetate decearboxylase gene and an NADH oxidase gene are subjected to codon optimization; a gene cluster containing the three genes is obtained through splicing; the gene cluster is inserted into an expression vector, and polycistron recombinant plasmid is obtained; the polycistron recombinant plasmid is introduced into a host strain E.coli, and a gene engineering strain producing acetylmethylcarbinol is obtained; a fermentation medium containing the cheap raw materials is inoculated with the activated strain for fermentation culture, and fermentation broth containing acetylmethylcarbinol is obtained; the fermentation broth is subjected to centrifugal treatment, a supernatant is taken, diammonium hydrogen phosphate is added, acetylmethylcarbinol produced through fermentation reacts with NH4<+>, and tetramethylpyrazine is synthesized. The widely sourced and low-cost raw materials can be effectively utilized by the strain for producing a high-concentration precursor substance, namely, acetylmethylcarbinol, oxidative coenzyme NAD<+> can be regenerated effectively, yield and production efficiency of acetylmethylcarbinol can be increased, so that the production cost of acetylmethylcarbinol is effectively reduced, and production period is shortened.

Owner:南宁中诺生物工程有限责任公司 +1

Recombinant microorganisms exhibiting increased flux through a fermentation pathway

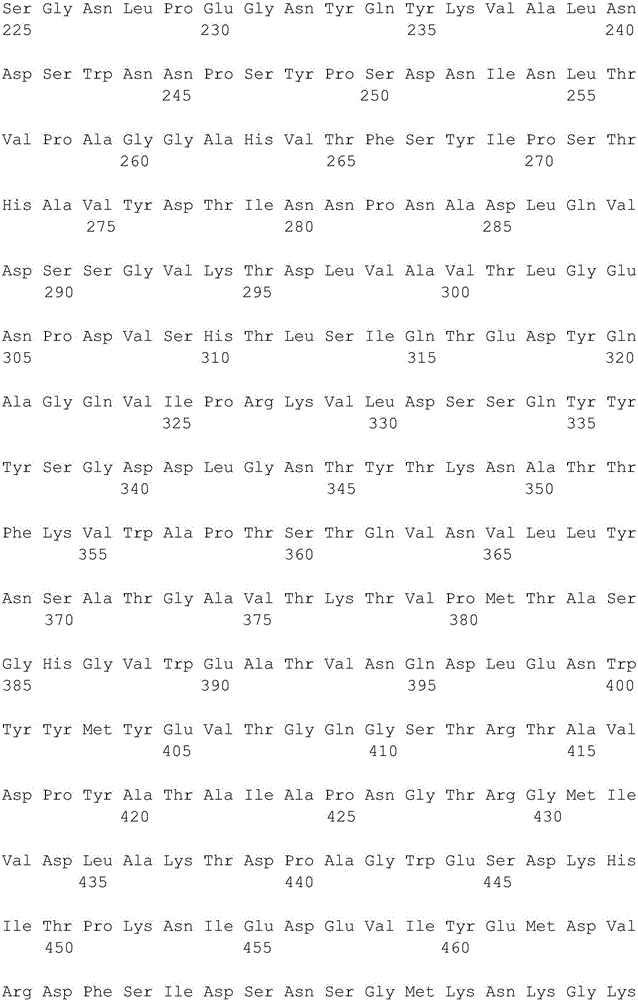

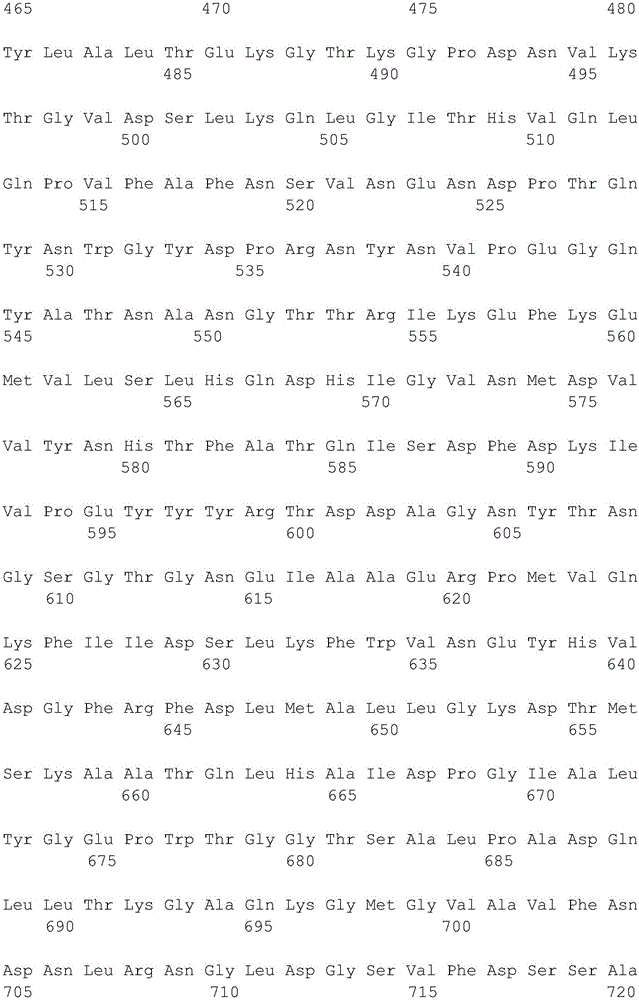

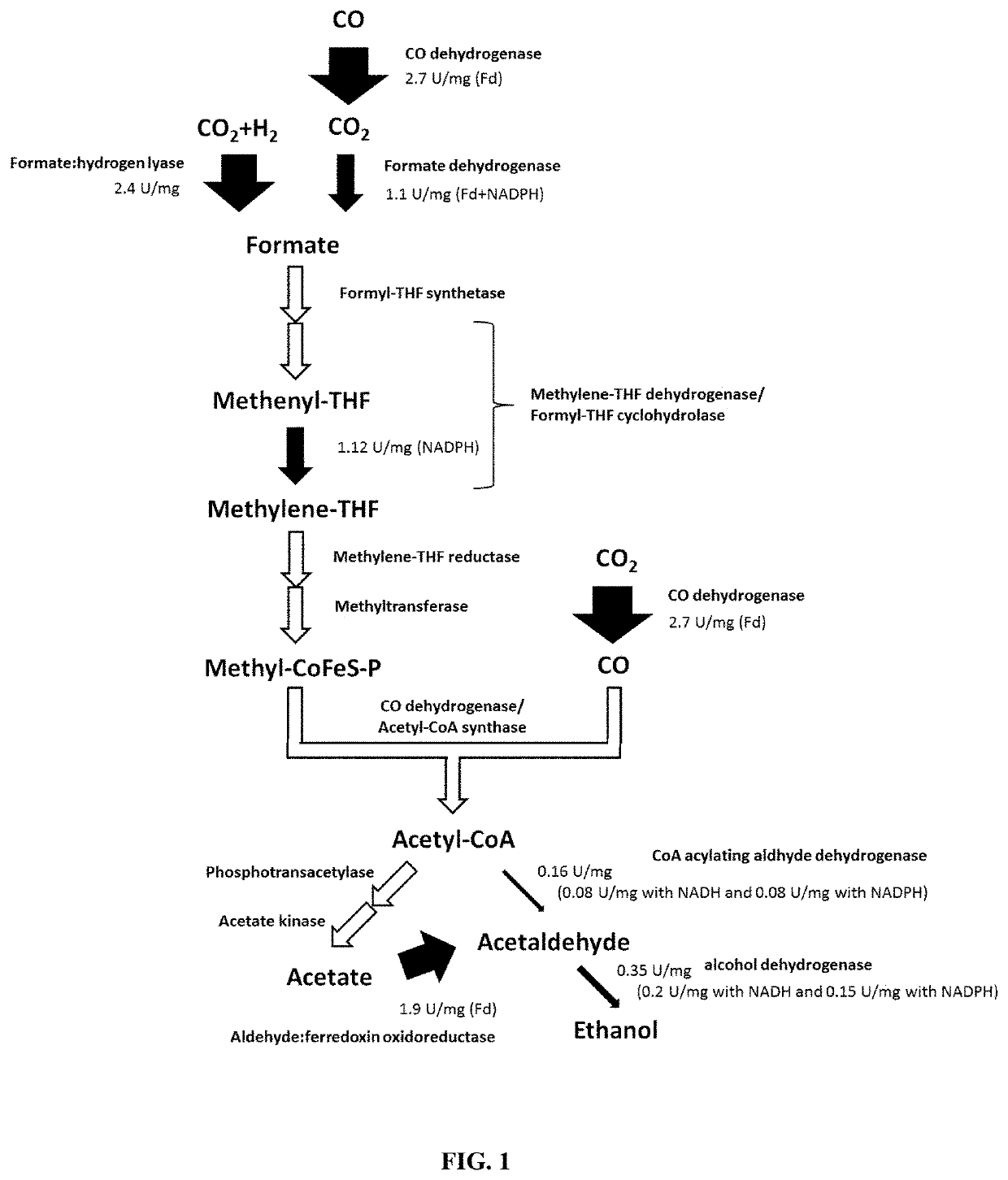

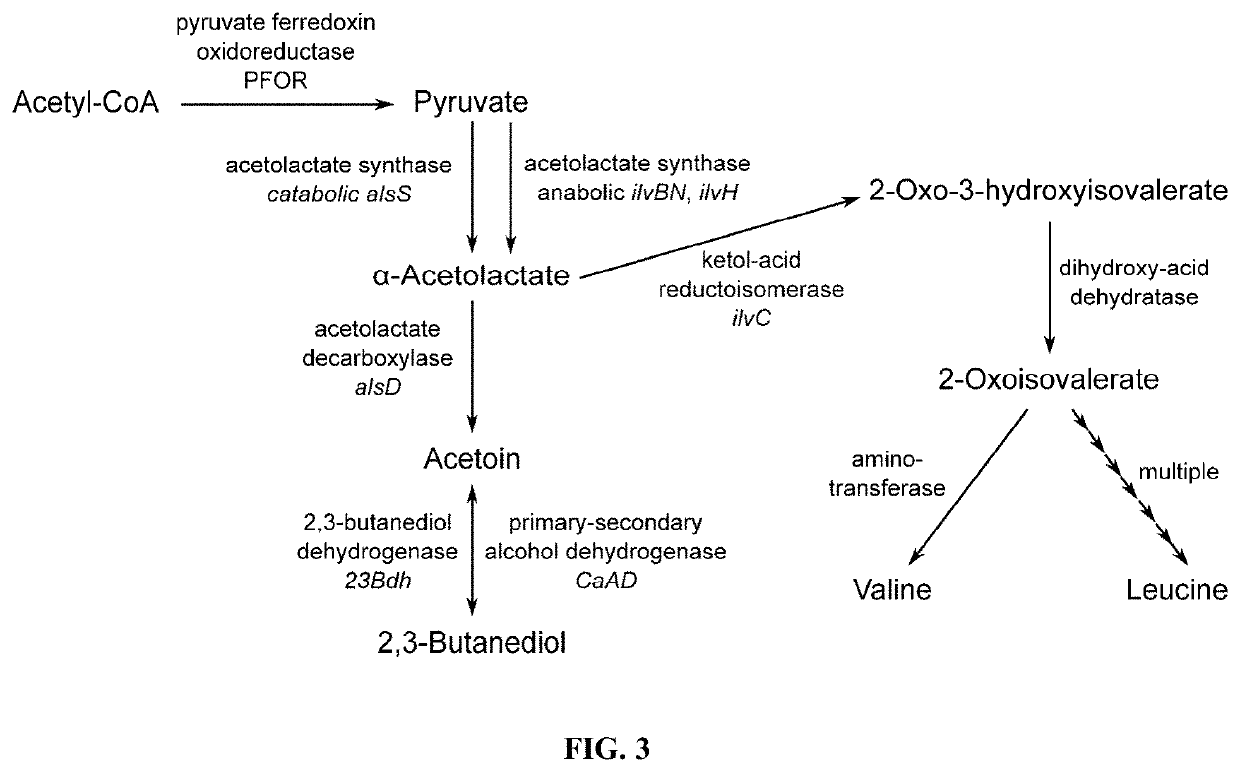

The invention provides a recombinant, carboxydotrophic Clostridium bacterium that expresses one or more of pyruvate:ferredoxin oxidoreductase (EC 1.2.7.1), acetolactate synthase (EC 2.2.1.6), and acetolactate decarboxylase (EC 4.1.1.5). The invention further provides a method of producing a fermentation product by fermenting the recombinant bacterium in the presence of a gaseous substrate comprising CO to produce one or more of ethanol, butanol, isopropanol, isobutanol, higher alcohols, butanediol, 2,3-butanediol, succinate, isoprenoids, fatty acids, biopolymers, and mixtures thereof.

Owner:LANZATECH NZ INC

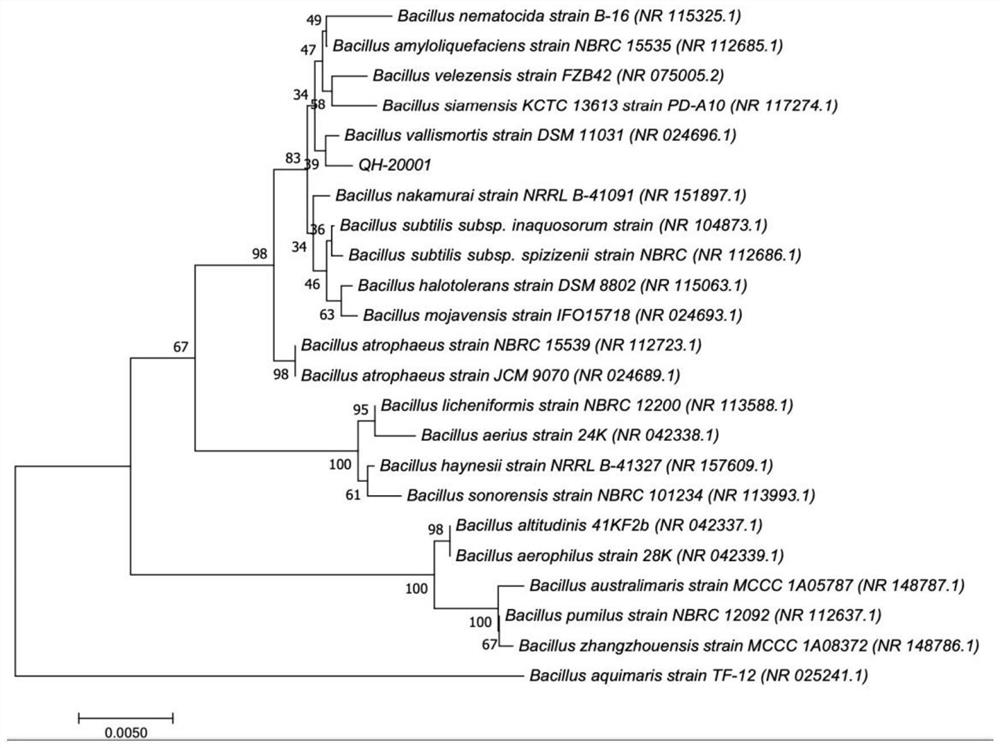

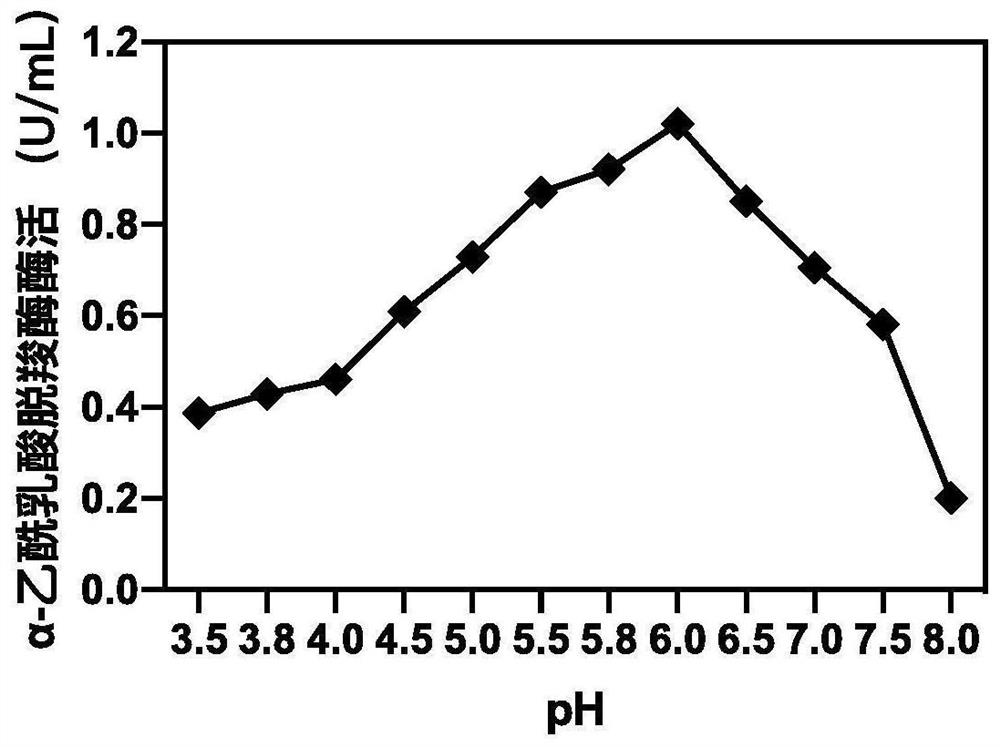

Bacillus vallismortis and application thereof in vinegar brewing

ActiveCN113930368APromote oxidationIncrease contentBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention discloses Bacillus vallismortis and application thereof in vinegar brewing. The name of the strain is Bacillus vallismortis QH-20001, the preservation number is CGMCC No.22251, the preservation date is April 27, 2021, the strain is preserved in the China General Microbiological Culture Collection Center, and the preservation address is Institute of Microbiology, Chinese Academy of Sciences, No. 3 , No. 1 Yard, Beichenxi Road, Chaoyang District, Beijing. The Bacillus vallismortis is applied to cellar vinegar brewing, can grow and metabolize under an acidic condition and produce alpha-acetolactate decarboxylase, the step of oxidizing alpha-acetolactate into diacetyl and then reducing the diacetyl to obtain acetoin can be avoided, and the alpha-acetolactate is quickly converted into the acetoin, thus, sufficient premise substances of ligustrazine is provided, the content of the acetoin and the ligustrazine in cellar vinegar can be obviously increased, and the production amount of the diacetyl is balanced.

Owner:QIANHE CONDIMENT & FOOD CO LTD

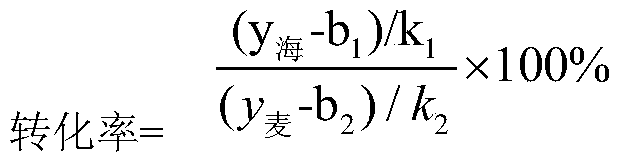

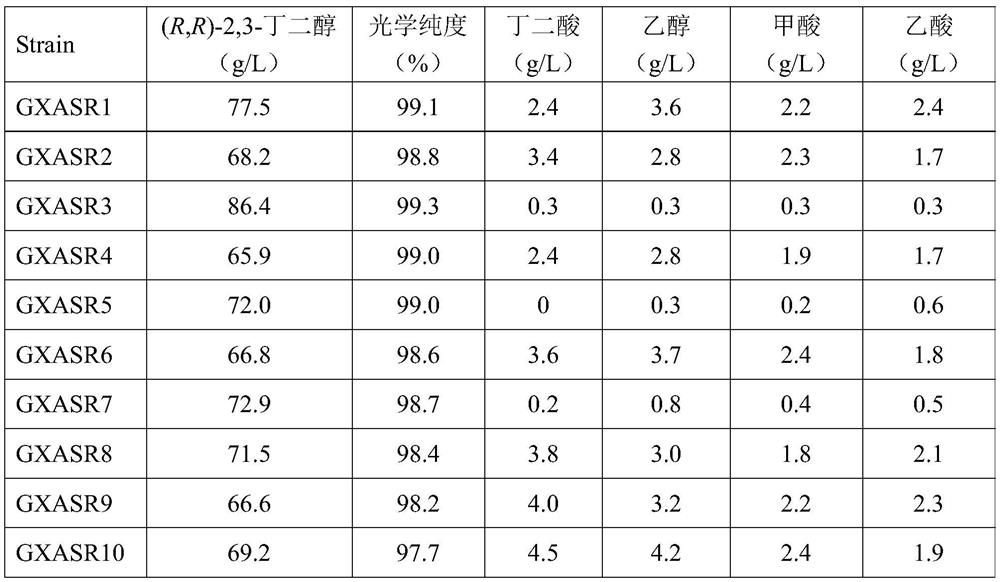

Construction method and application of gene engineering strain for producing (R,R)-2,3-butanediol

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

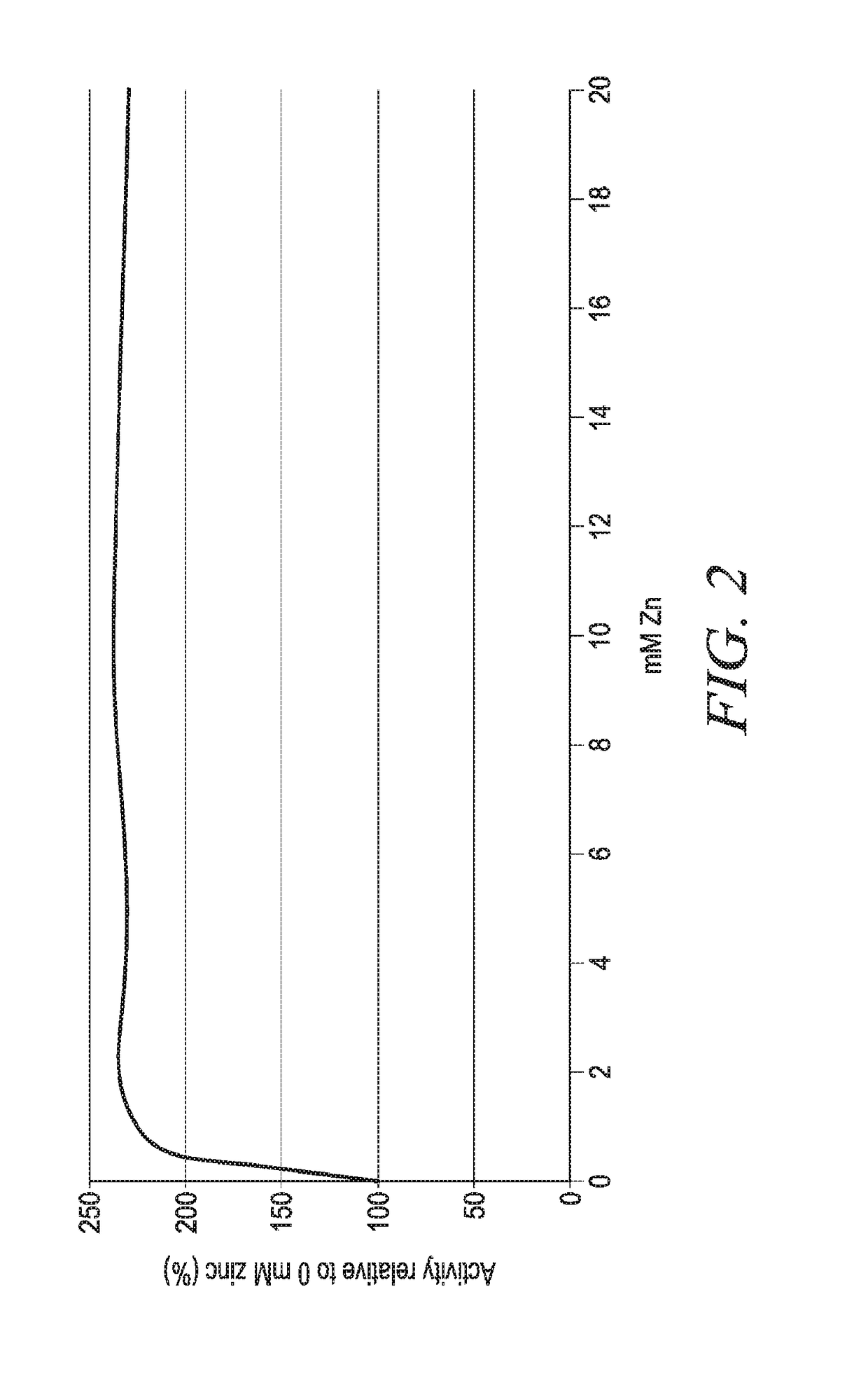

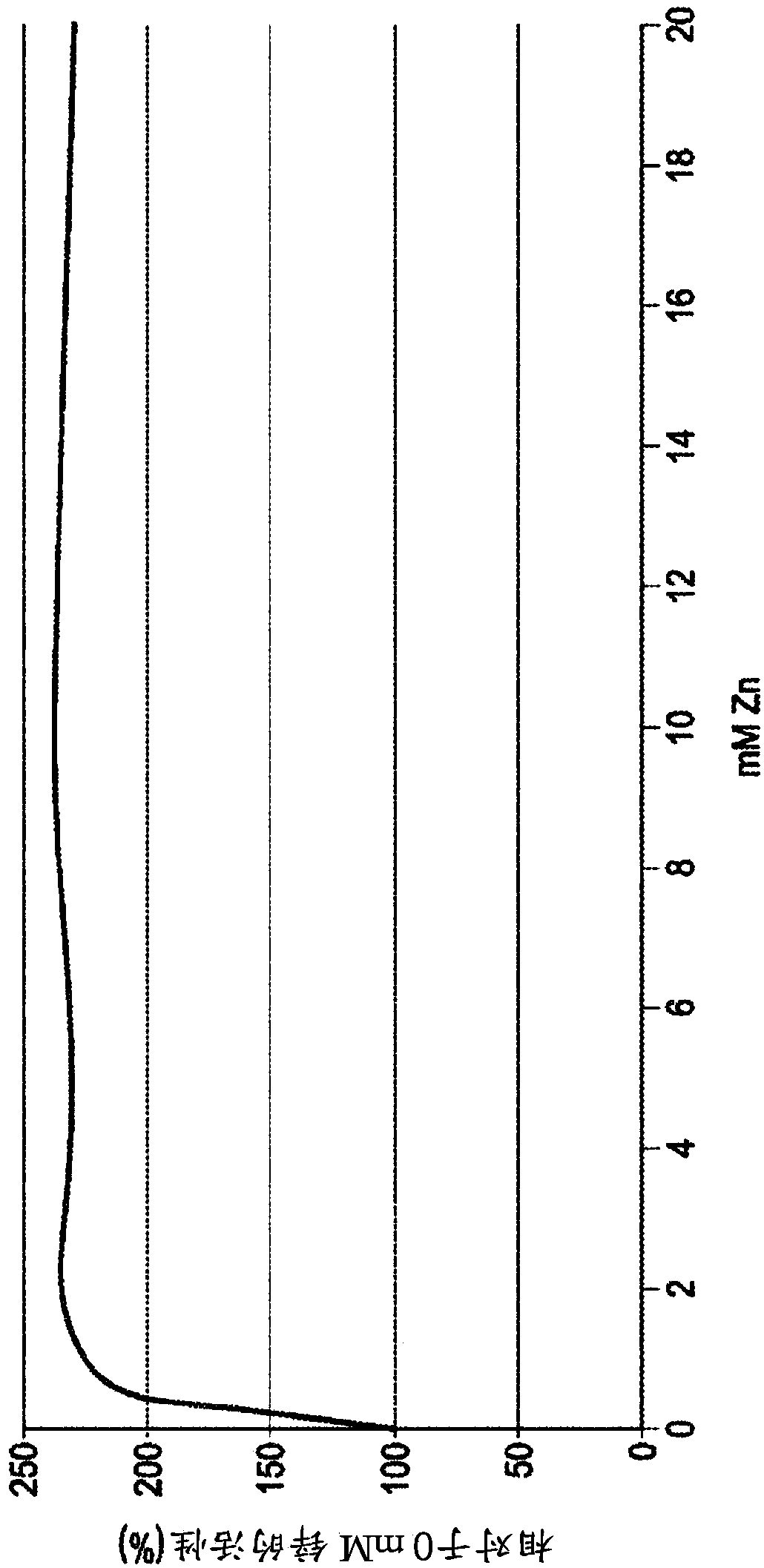

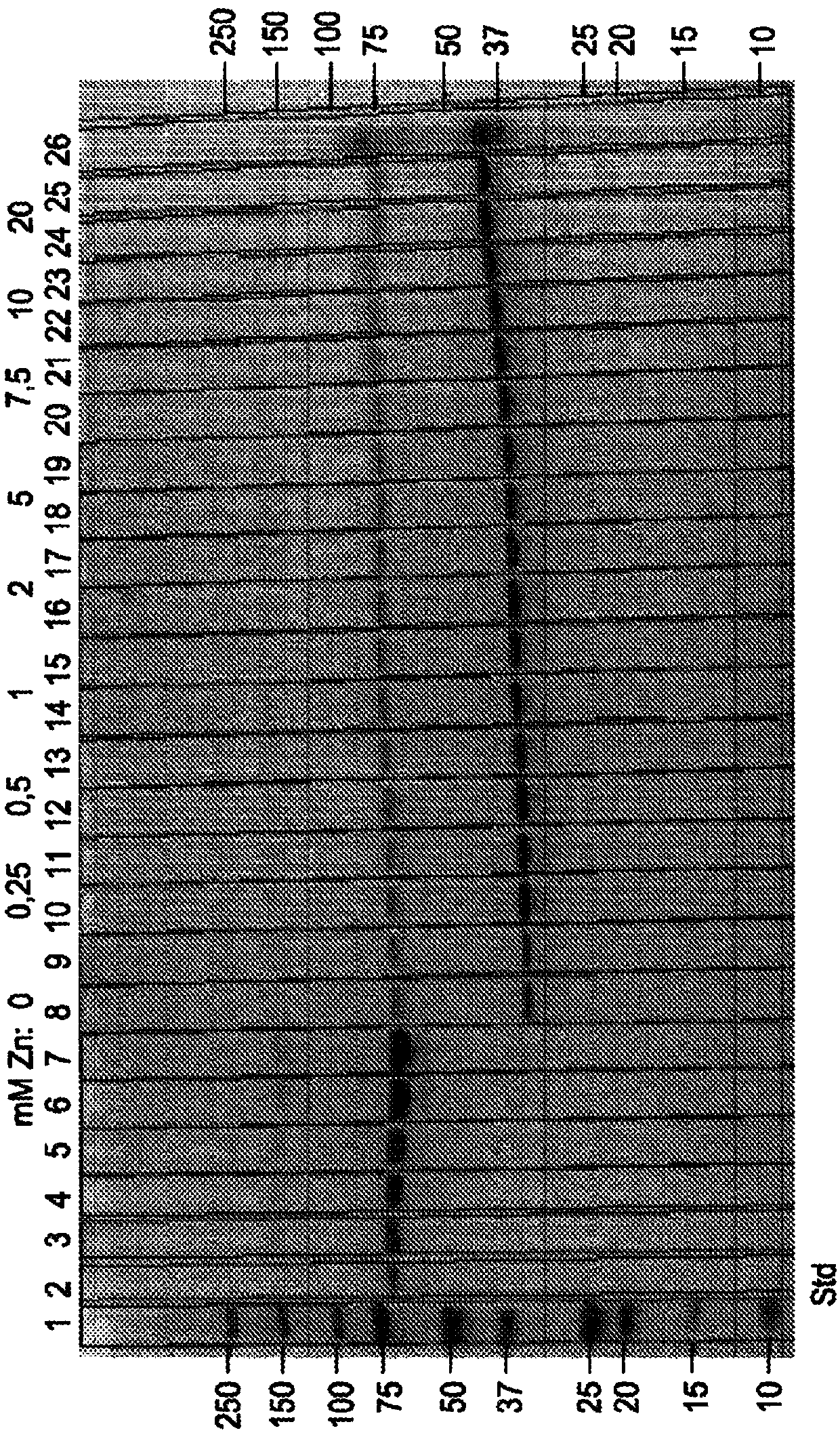

Acetolactate decarboxylase

The present disclosure provides methods, compositions, apparatuses and kits comprising ALDC enzymes having a better stability and / or activity, and, optionally, the yield of ALDC enzymes which can be recovered from microorganisms is improved. In some embodiments, the present disclosure provides methods, apparatuses, compositions and kits for the use of metal ions to increase stability and / or activity, and which further can be used to recover the enzymes from microorganisms in improved yields.

Owner:DUPONT NUTRITION BIOSCIENCES APS

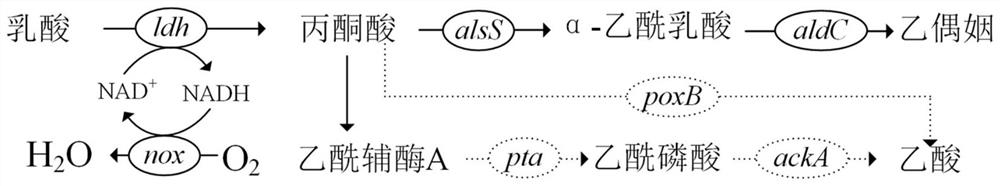

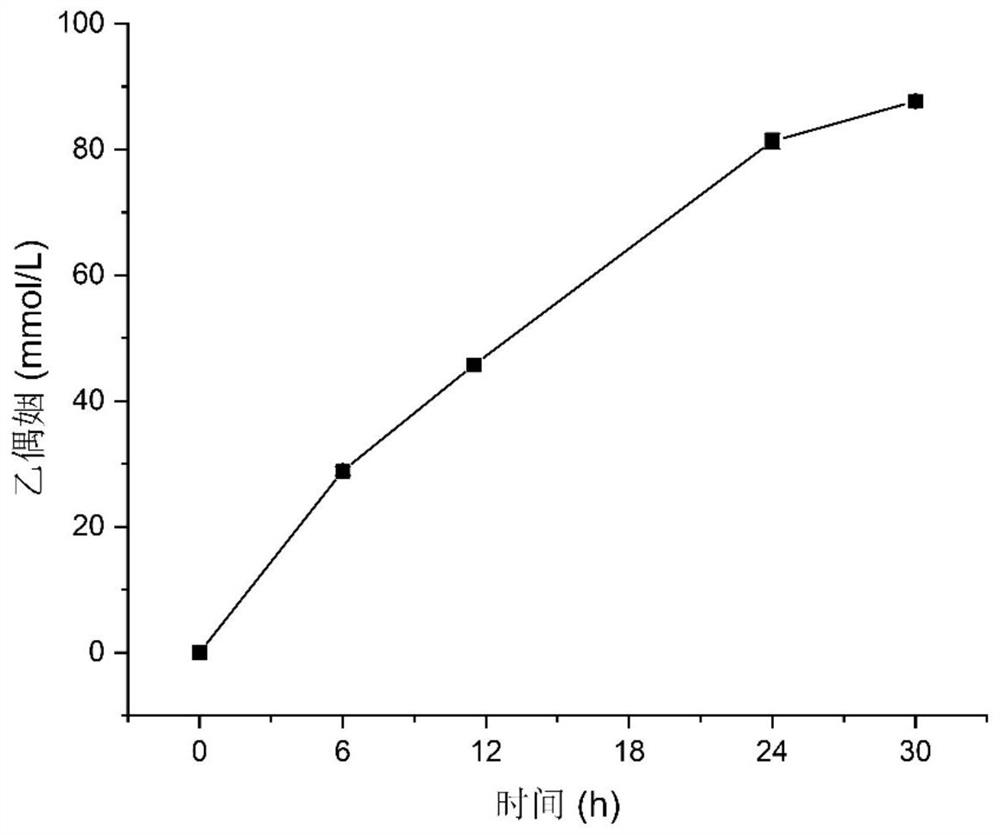

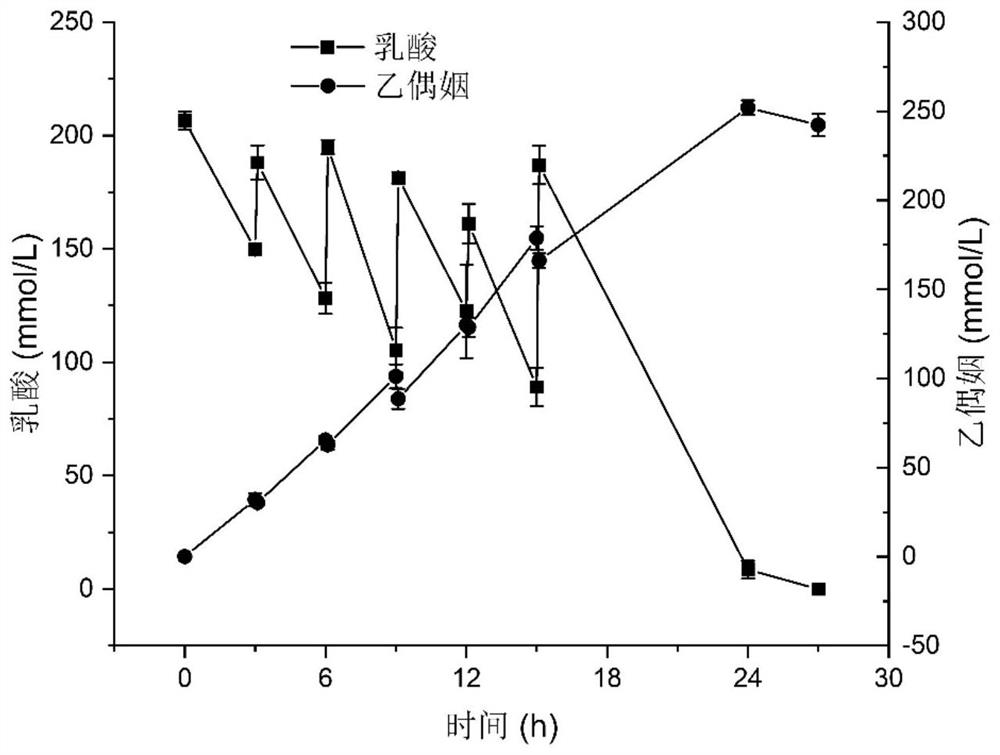

Escherichia coli engineering bacterium for producing acetoin as well as construction method and application of escherichia coli engineering bacterium in whole-cell catalytic production of acetoin

ActiveCN113604416AIncrease productionLow substrate costBacteriaTransferasesEscherichia coliOxidative enzyme

The invention discloses an escherichia coli engineering bacterium for producing acetoin as well as a construction method and application of the escherichia coli engineering bacterium in whole-cell catalytic production of acetoin. The construction method of the escherichia coli engineering bacterium for producing acetoin comprises the following steps: co-expressing alpha-acetolactate synthetase, alpha-acetolactate decarboxylase, lactic dehydrogenase and NADH oxidase to obtain the escherichia coli engineering bacterium for producing acetoin; and constructing a host bacterium used in the escherichia coli engineering bacterium as mutant escherichia coli BL-2. The acetoin is produced by taking lactic acid as a substrate, the product yield is high, the substrate cost is low, extra NAD+ does not need to be added in a reaction system, and the production cost is further reduced. According to the method, the acetoin yield reaches 87.5 mM or above, the yield reaches 3.65 mM / h or above, and the yield reaches 0.444 mol / mol or above, namely the theoretical yield is 88.8% or above. The method is mild in reaction condition and simple in process.

Owner:TIANJIN UNIV

Acetolactate decarboxylase

The present disclosure provides methods, compositions, apparatuses and kits comprising ALDC enzymes having a better stability and / or activity, and, optionally, the yield of ALDC enzymes which can be recovered from microorganisms is improved. In some embodiments, the present disclosure provides methods, apparatuses, compositions and kits for the use of metal ions to increase stability and / or activity, and which further can be used to recover the enzymes from microorganisms in improved yields.

Owner:DUPONT NUTRITION BIOSCIENCES APS

A genetically engineered bacterium for realizing high-density fermentation and co-production of 2,3-butanediol, its construction method and application

The invention discloses a genetically engineered bacterium for realizing high-density fermentation and co-production of 2,3-butanediol, and a construction method and application thereof. Key enzyme genes: α-acetolactate synthase encoding gene, α-acetolactate decarboxylase encoding gene and 2,3-butanediol dehydrogenase encoding gene are integrated into the chromosome of Escherichia coli and constructed. The product acetic acid is reduced, so that it can realize high-density fermentation and co-produce high value-added 2,3-butanediol; in addition, the invention also discloses a method for realizing high-density fermentation and co-producing other compounds and 2,3-butanediol. ‑Butanediol genetically engineered bacteria and its application, in addition to high-density fermentation to produce 2,3‑butanediol, it can also co-produce polyhydroxy fatty acid or functional protein, so as to realize polyhydroxy fatty acid or functional protein, and 2,3‑ The low-cost and high-efficiency co-production of butanediol has important industrial application value.

Owner:NANJING TECH UNIV

Construction method and application of genetic engineering strain for producing (r,r)-2,3-butanediol

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

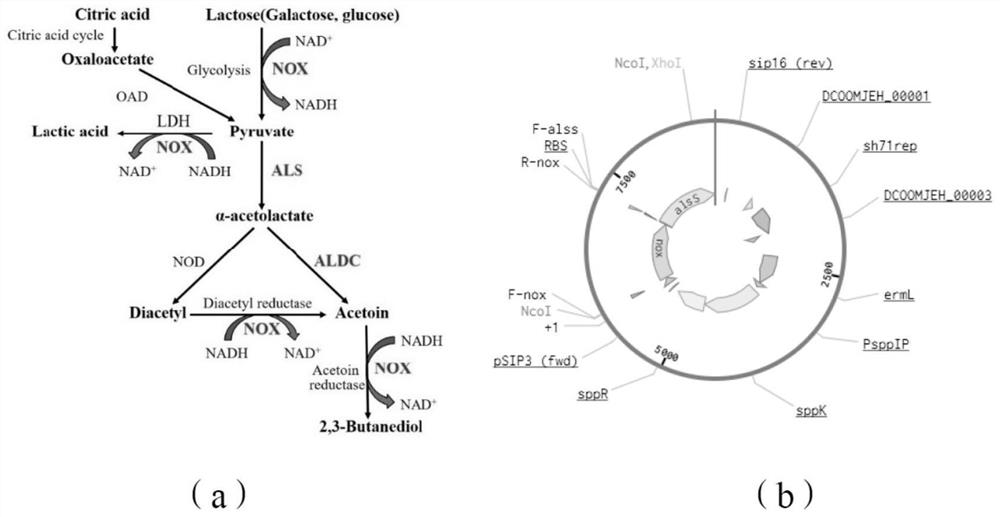

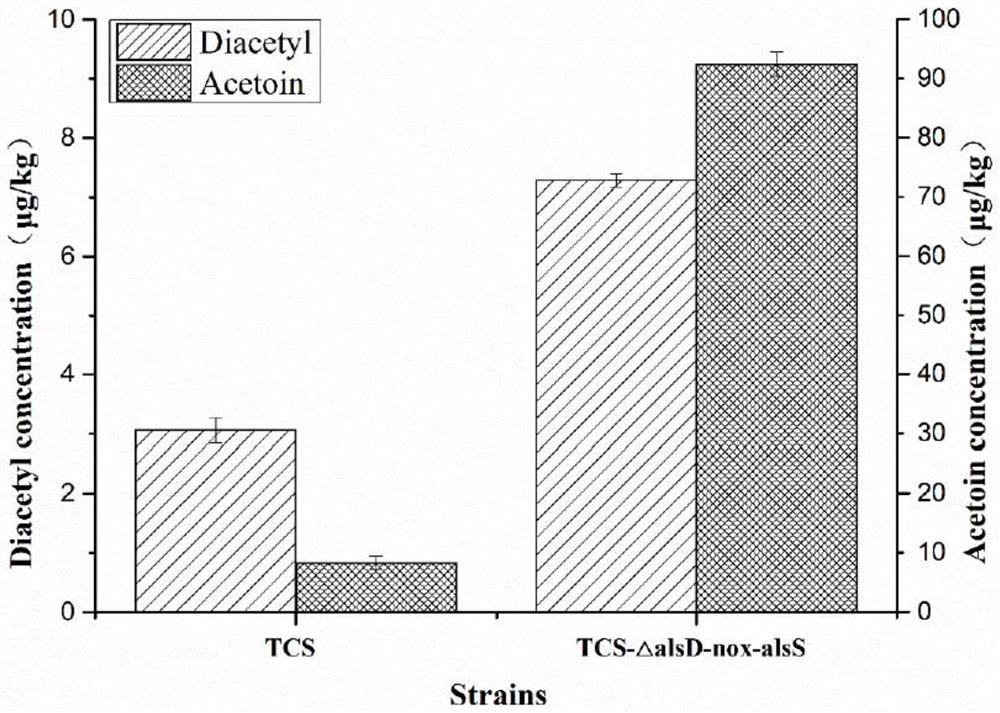

Genetically engineered bacterium for increasing butanedione content and acetoin content in yoghourt and application thereof

InactiveCN113755420AOptimize flavor productionIncrease enzyme activityMilk preparationBacteriaOxidative enzymeEngineered genetic

The invention discloses a genetically engineered bacterium for increasing the content of butanedione and acetoin in yoghourt and application thereof. The genetically engineered bacterium disclosed by the invention is lactobacillus casei which contains pSIP409-nox-alsS plasmids and is expressed on lactobacillus casei of which an alpha-acetolactate decarboxylase gene (alsD) is knocked out, and the pSIP409-nox-alsS plasmids can express NADH oxidase and alpha-acetolactate synthetase and cannot express the alpha-acetolactate decarboxylase. The genetically engineered bacterium has higher enzyme activity than wild lactobacillus casei, the yield of butanedione and the yield of acetoin in fermented yoghurt are 2.38 times and 11.19 times that of a wild strain TCS respectively, a new thought is provided for biosynthesis of butanedione and acetoin through lactobacillus casei, a theoretical basis is provided for yoghurt flavor optimization production in the future, and the application prospect is wide.

Owner:SHANGHAI INST OF TECH

Acetolactate decarboxylase variants having improved specific activity

Compositions and methods are provided comprising acetolactate decarboxylase (ALDC) enzyme variants having higher specific activity. Composition and method are provided where the ALDC variants are usedin combination with metal ions to further increase stability and / or activity.

Owner:DUPONT NUTRITION BIOSCIENCES APS

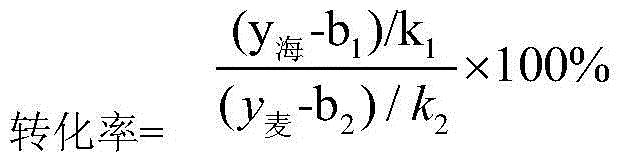

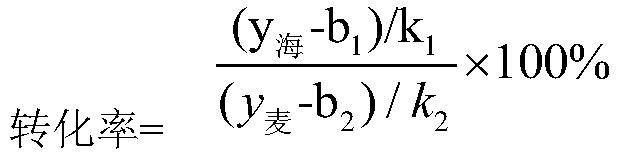

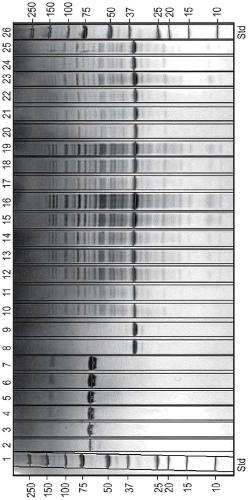

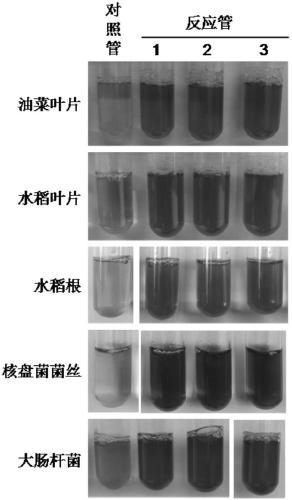

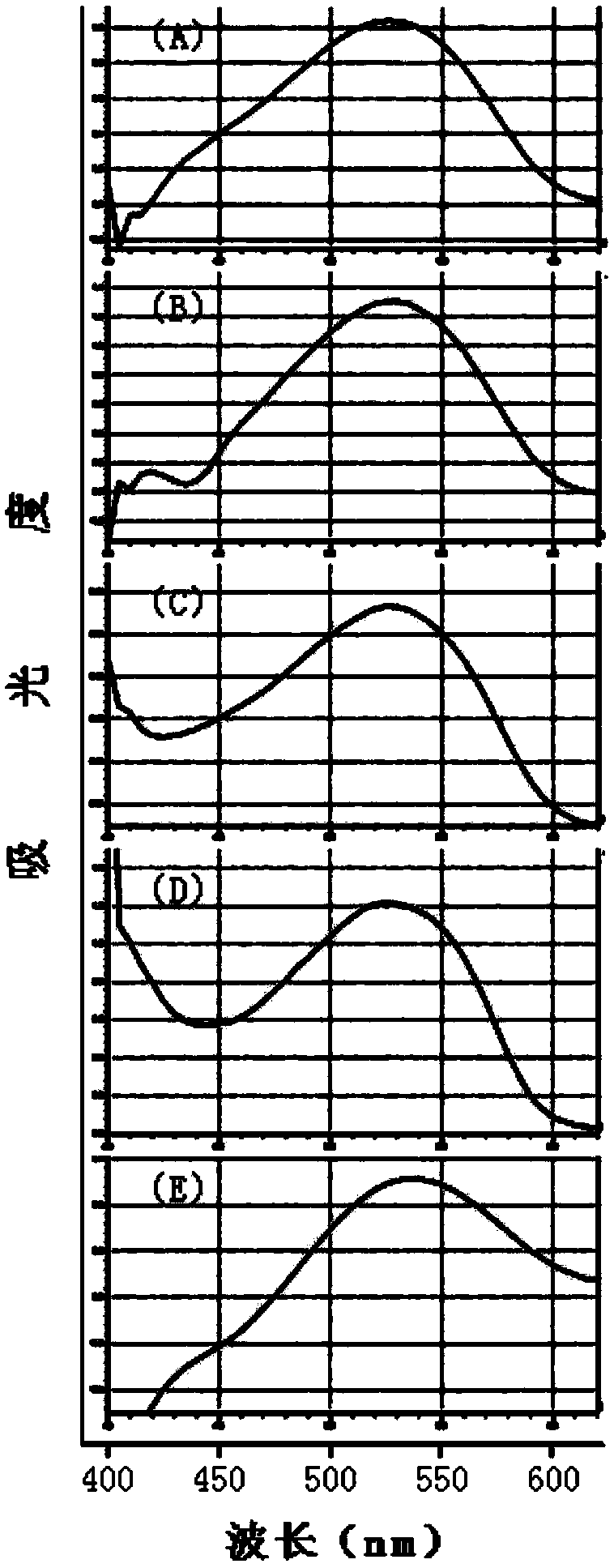

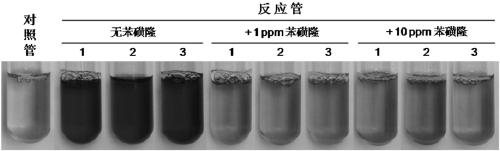

A method for measuring the activity of acetolactate synthase by using acetolactate decarboxylase to catalyze decarboxylation and its application

The invention discloses a method for testing activity of acetolactate synthetase through catalyzing and decarboxylation by acetolacetate decearboxylase. The method comprises the following steps that (1) coarse acetolactate synthetase solution, acetolacetate decearboxylase, distilled water and sodium-pyruvate-containing reaction buffer solution are uniformly mixed; then, enzymatic reaction is performed to obtain enzymatic reaction liquid; (2) a color developing agent is added into the enzymatic reaction liquid and blank control liquid for color developing reaction; supernatant fluid is taken through centrifugation after the color development; the light absorption degree A<530> in a 530nm wavelength position of the enzymatic reaction liquid is detected by a spectral photometer; the enzyme activity of the coarse acetolactate synthetase solution is calculated according to the following formula of the activity of the acetolactate synthetase equals to delta A<530> / ([Pr].t). The method can be widely used for testing the activity of the acetolactate synthetase in various biological materials such as plants, fungi and germs, and can be used for screening or identifying acetolactate synthetase inhibitors.

Owner:ZHEJIANG UNIV

A kind of method utilizing cheap raw material to produce tetramethylpyrazine

ActiveCN107177620BIncrease productionIncrease productivityFermentationVector-based foreign material introductionTetramethyl pyrazineAcetolactate synthase

The invention discloses a method for producing tetramethylpyrazine from cheap raw materials. The method comprises steps as follows: nucleotide sequences of an alpha-acetolactate synthase gene, an alpha-acetolacetate decearboxylase gene and an NADH oxidase gene are subjected to codon optimization; a gene cluster containing the three genes is obtained through splicing; the gene cluster is inserted into an expression vector, and polycistron recombinant plasmid is obtained; the polycistron recombinant plasmid is introduced into a host strain E.coli, and a gene engineering strain producing acetylmethylcarbinol is obtained; a fermentation medium containing the cheap raw materials is inoculated with the activated strain for fermentation culture, and fermentation broth containing acetylmethylcarbinol is obtained; the fermentation broth is subjected to centrifugal treatment, a supernatant is taken, diammonium hydrogen phosphate is added, acetylmethylcarbinol produced through fermentation reacts with NH4<+>, and tetramethylpyrazine is synthesized. The widely sourced and low-cost raw materials can be effectively utilized by the strain for producing a high-concentration precursor substance, namely, acetylmethylcarbinol, oxidative coenzyme NAD<+> can be regenerated effectively, yield and production efficiency of acetylmethylcarbinol can be increased, so that the production cost of acetylmethylcarbinol is effectively reduced, and production period is shortened.

Owner:南宁中诺生物工程有限责任公司 +1

A kind of immobilization method of enzyme

ActiveCN105950604BMaintain stabilityFully retain activityOn/in organic carrierBeer brewingAceglatoneNanoflower

The invention provides an enzyme immobilization method, and particularly relates to a method for immobilization of enzyme for beer production. According to the method, alpha-acetolactate decarboxylase buffer solution is added to calcium chloride solution for reaction to obtain a nanoflower structure provided with preliminary immobilized enzyme, then obtained nanoflower is dispersed in sodium alga acid solution, obtained dispersion liquid is added to the calcium chloride solution dropwise at a certain speed, and stirring and curing are conducted to obtain a final microsphere product. According to microspheres prepared with the enzyme immobilization method, immobilized enzyme activity is higher than free enzyme activity by 98% or more, and immobilized enzyme is stable and recyclable and has broad prospects in industrial application.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com