Catalyst for vinyl toluene production and preparation method thereof

A technology of vinyl toluene and catalyst, applied in the chemical industry, to achieve the effects of low energy consumption, increased conversion rate, and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

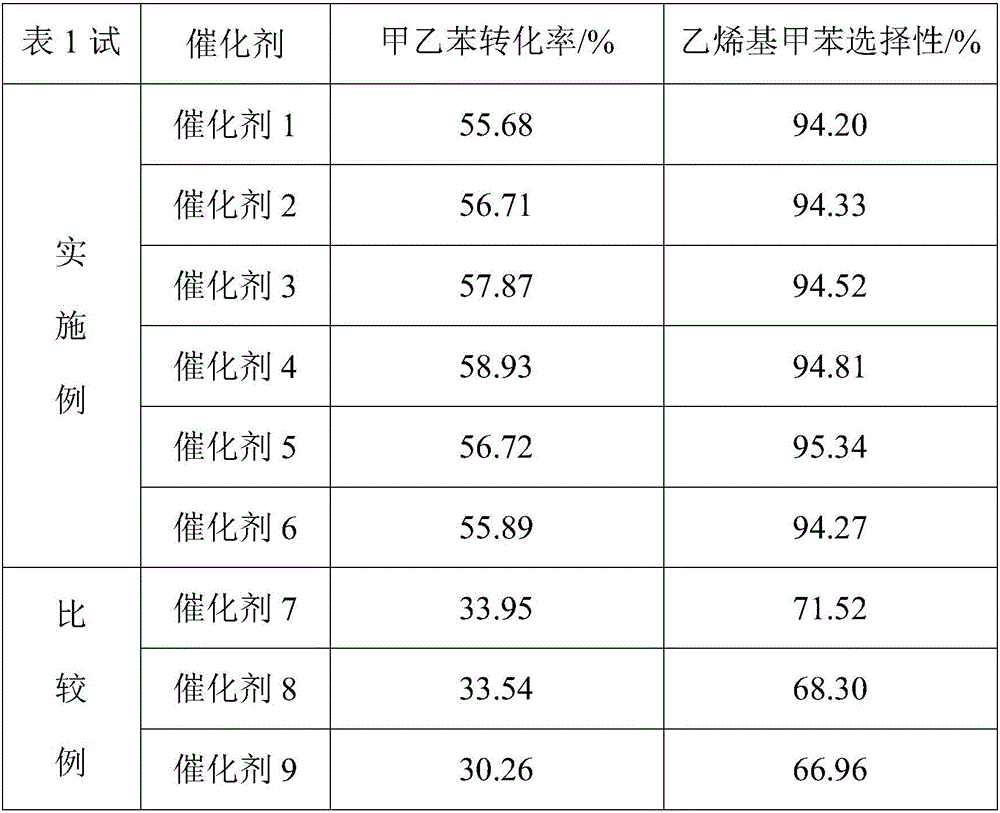

Examples

Embodiment 1

[0031] 1. Catalyst preparation

[0032] Synthetic process of vanadium-modified molecular sieve: Add 1 part of alumina, 0.01 part of sodium orthovanadate, 0.05 part of sodium hydroxide, and 0.1 part of adamantane into 1 part of distilled water, mix well, and add 30 parts of diatomaceous earth while stirring , after 2h, transferred to a stainless steel autoclave, airtight, under dynamic stirring, crystallized at 150°C, and reacted for 12h. The product is filtered, washed and dried to obtain the vanadium-modified molecular sieve raw powder.

[0033] In parts by weight, add 6 parts of vanadium-modified molecular sieve raw powder, ferric nitrate, magnesium nitrate, and 5 parts of cement to 10 parts of distilled water, disperse uniformly by ultrasonic, dry, knead, extrude, and roast at 480°C for 24 hours to obtain Iron magnesium vanadium supported molecular sieve catalyst 1. Wherein, the consumption of described iron salt and magnesium salt is, according to the weight of the oxide...

Embodiment 2

[0036] 1. Catalyst preparation

[0037] Synthetic process of vanadium-modified molecular sieve: Add 1 part of aluminum trichloride, 0.04 part of sodium orthovanadate, 0.15 part of sodium hydroxide, and 0.2 part of phosphoadamantane into 1 part of distilled water, mix well, and add 45 A part of amorphous silica, after 2 hours, transferred to a stainless steel autoclave, sealed, crystallized at 160°C under dynamic stirring, and reacted for 14 hours. The product is filtered, washed and dried to obtain the vanadium-modified molecular sieve raw powder.

[0038]In parts by weight, add 7 parts of vanadium-modified molecular sieve raw powder, ferric nitrate, magnesium nitrate, and 7 parts of cement to 10 parts of distilled water, ultrasonically disperse evenly, dry, knead, extrude, and roast at 500°C for 36 hours to obtain Iron magnesium vanadium supported molecular sieve catalyst 2. Wherein, the consumption of described iron salt and magnesium salt is, according to the weight of th...

Embodiment 3

[0041] 1. Catalyst preparation

[0042] Synthesis process of vanadium-modified molecular sieve: add 1 part of sodium metaaluminate, 0.07 part of sodium metavanadate, 0.25 part of sodium hydroxide, and 0.4 part of adamantane into 1 part of distilled water, mix well, and add 55 parts of alkali under stirring After 2 hours, the silica sol was transferred to a stainless steel autoclave, sealed, and crystallized at 170°C under dynamic stirring, and reacted for 16 hours. The product is filtered, washed and dried to obtain the vanadium-modified molecular sieve raw powder.

[0043] In parts by weight, add 8 parts of vanadium-modified molecular sieve raw powder, ferric nitrate, magnesium nitrate, and 10 parts of cement to 10 parts of distilled water, disperse uniformly by ultrasonic, dry, knead, extrude, and roast at 510 ° C for 48 hours to obtain Iron magnesium vanadium supported molecular sieve catalyst 3. Wherein, the consumption of described iron salt and magnesium salt is, accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com