Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Microporous reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraporous sol gel monoliths

ActiveUS20060131238A1Shorten the timeEasy to optimizeIon-exchange process apparatusPhysical/chemical process catalystsPorosityHYDROSOL

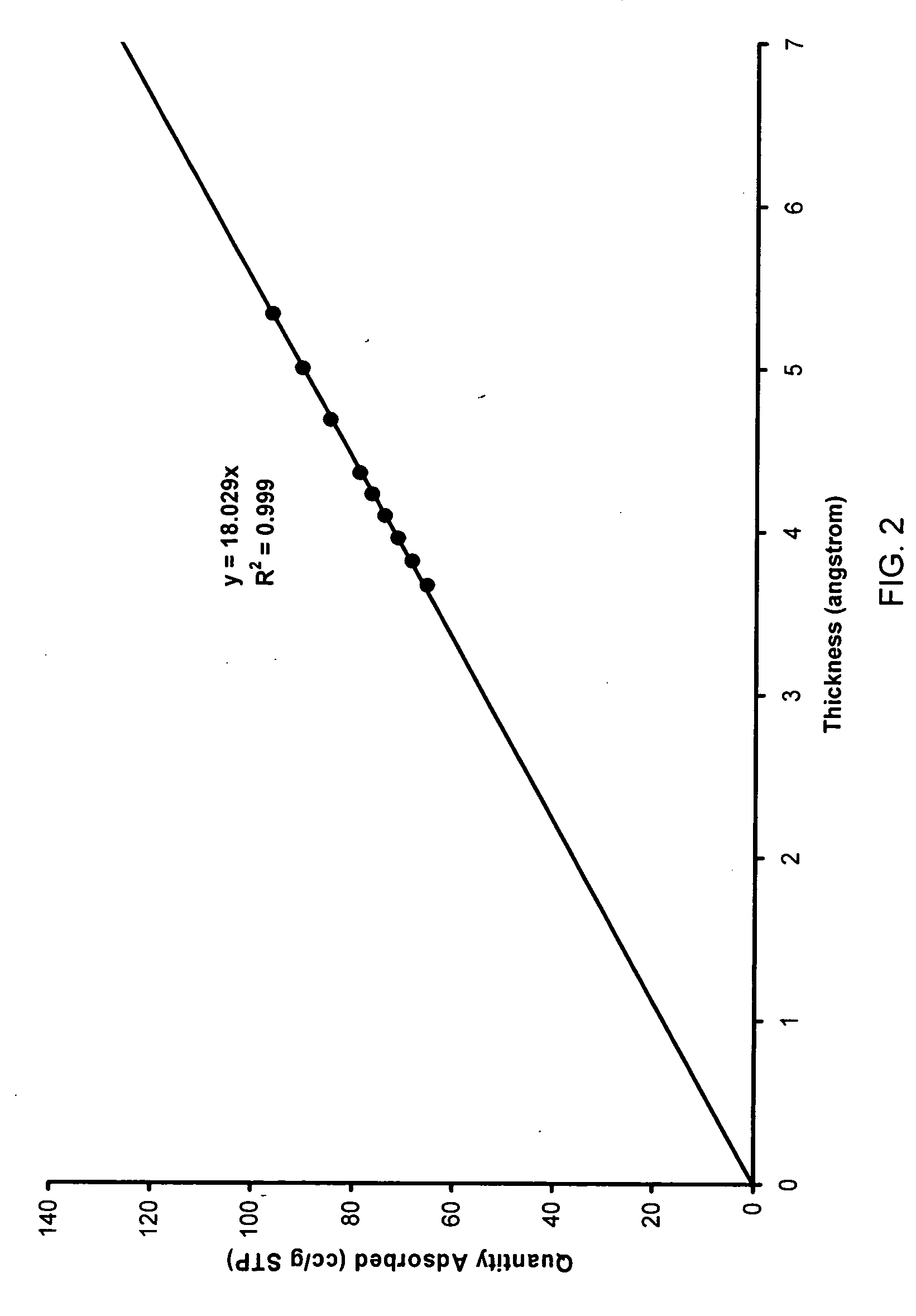

Ultraporous sol gel monoliths and methods for preparing the same are provided, having superior flow characteristics for chromatography and analytical chemistry applications. The methods for forming an ultra porous sol-gel monolith include (a) forming a solution comprising a porogen, a matrix dissolving catalyst and a sol gel precursor; (b) allowing the solution to form a gel; and (c) drying the gel at an elevated temperature. The ultraporous sol gel monoliths are characterized by a porosity of up to about 97%, a BET surface area of at least about 50 m2 / g and substantially no micropores.

Owner:AGILENT TECH INC

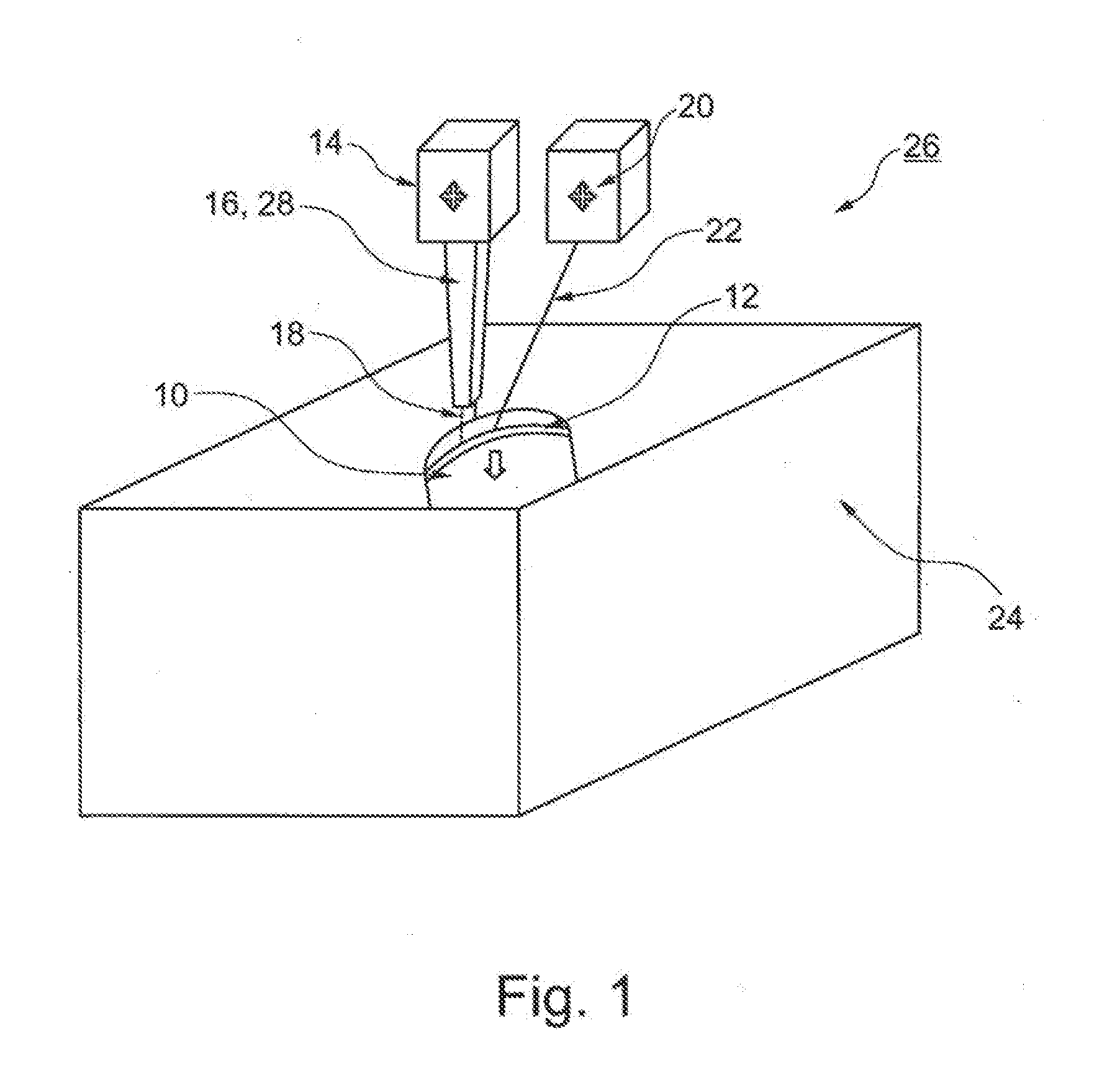

Method and device for producing a component of a turbomachine

InactiveUS20120217226A1High strengthAvoid poor resultsTurbinesAdditive manufacturing apparatusEngineeringTurbine

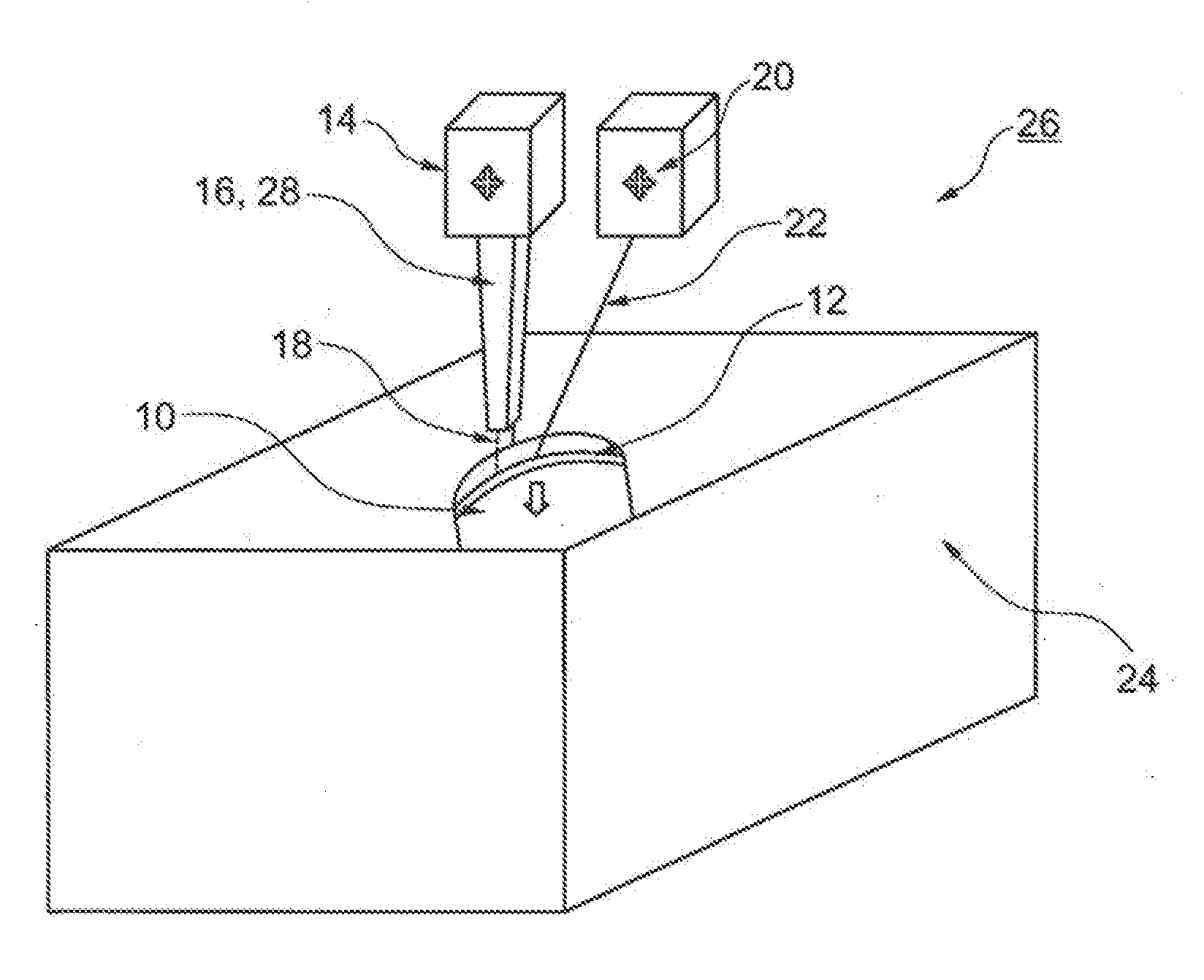

The invention relates to a method for producing a component (10) of a turbomachine, especially a structural part of a turbine or a compressor, the method being a generative production method for the layer-by-layer buildup of the component (10). After production of one or more successive component layers pressure is applied to at least sections of the surface of the most recently produced component layer (12), the pressure being induced by laser or plasma. The invention further relates to a device for producing a component (10) of a turbomachine, especially a structural part of a turbine or a compressor, the device (26) comprising at least one powder feed (28) for the deposition of at least one powder component material (16) onto a component platform, at least one radiation source (14) for a local layer-by-layer fusion or sintering of the component material (16) and at least one laser radiation source (20) or at least one plasma impulse source.

Owner:MTU AERO ENGINES GMBH

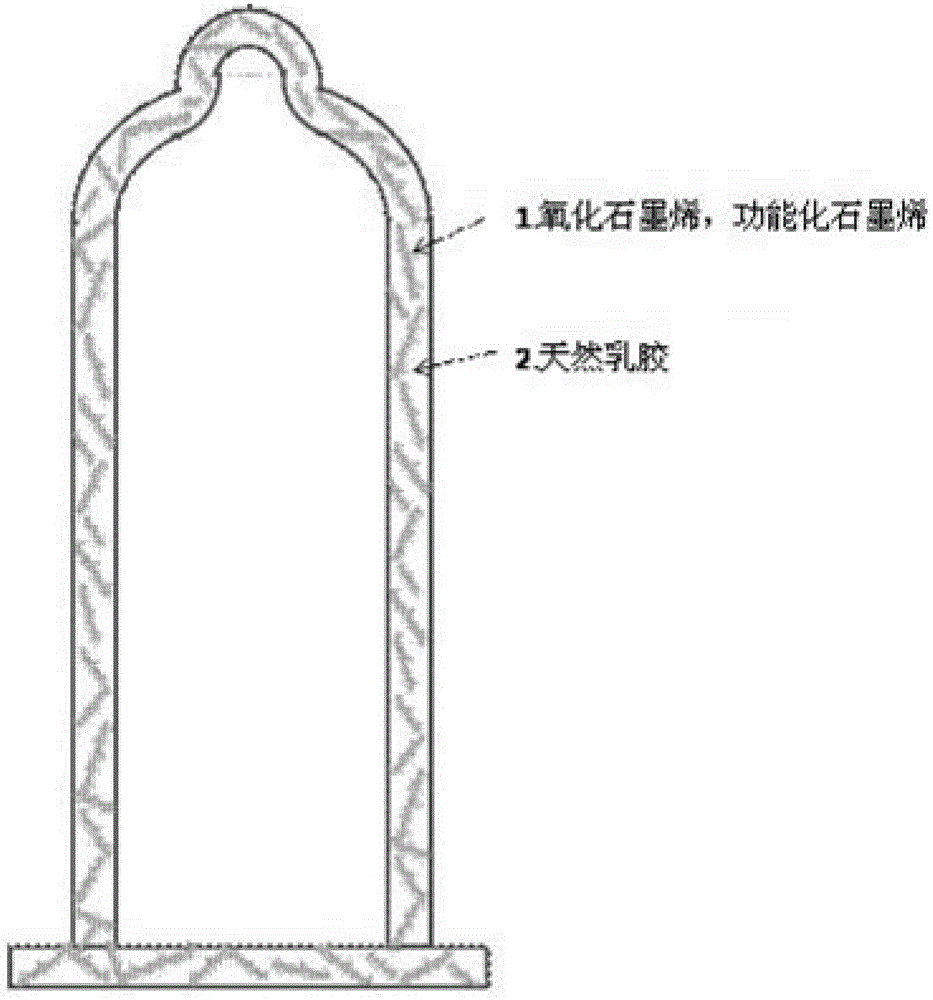

Novel condom based on graphene modification technology and production method thereof

The invention belongs to the technical field of general medical and sanitary products, and particularly relates to a novel condom based on a graphene modification technology and a production method thereof. The novel condom is added with graphene oxide and functionalized graphene by 0.1-25%. The graphene oxide or the chemically-modified functionalized graphene is dispersed into a condom material with natural latex as a base material through an aqueous phase or an emulsion according to demand, thereby producing the condom according to processes in the prior art. The condom holds a high toughness even if the minimum thickness reaches 15 [mu]m, so that use requirement of the condom is satisfied. The condom is increased by 15-40% in strength when compared with original natural latex materials. Because that the graphene is low in breathability and has material composition effects, the condom is less in micro-pores so that virus penetrating probability is greatly reduced. The heat conductivity coefficient of the composite material is increased by 10-20 and the condom is improved in body feel.

Owner:范志明 +1

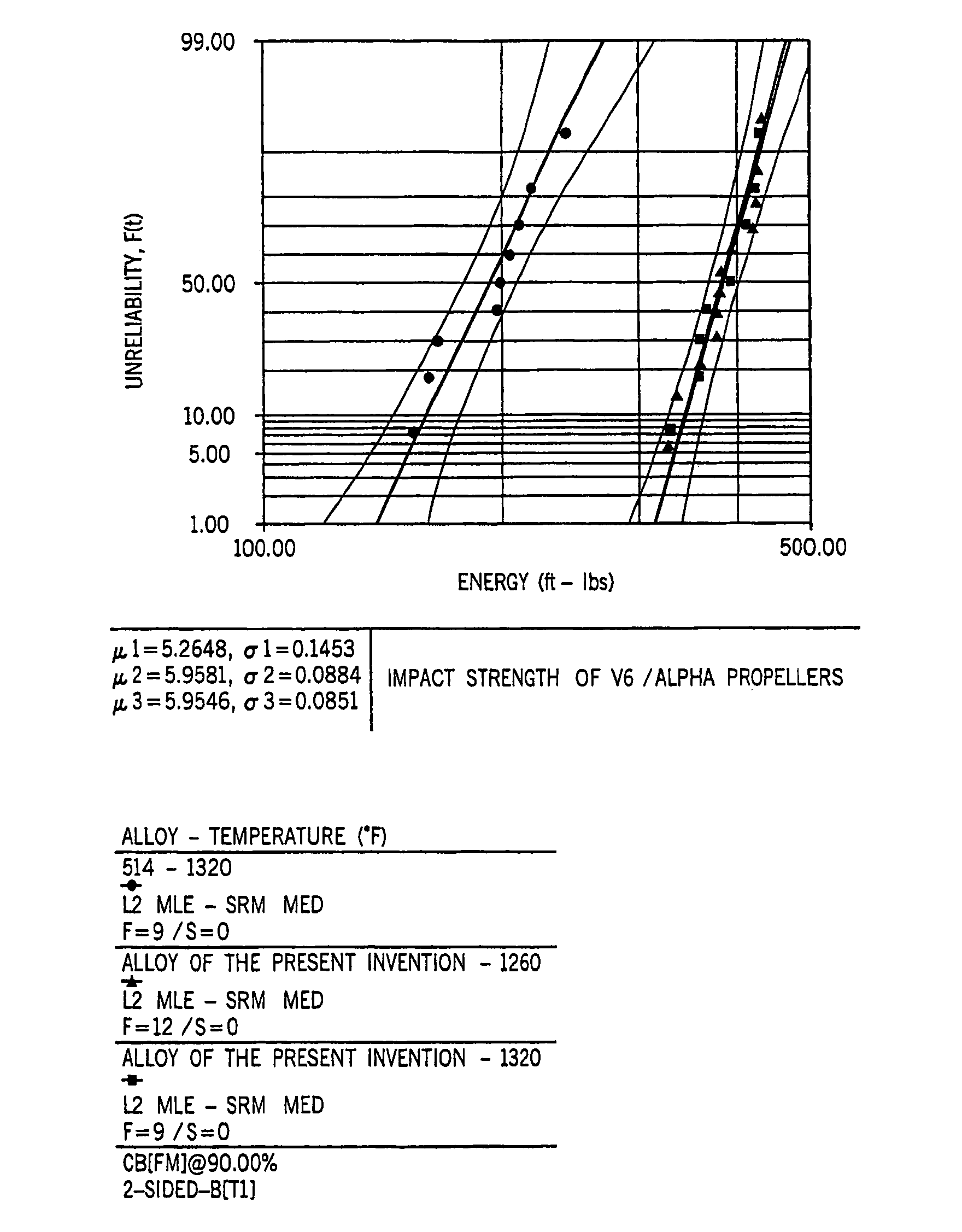

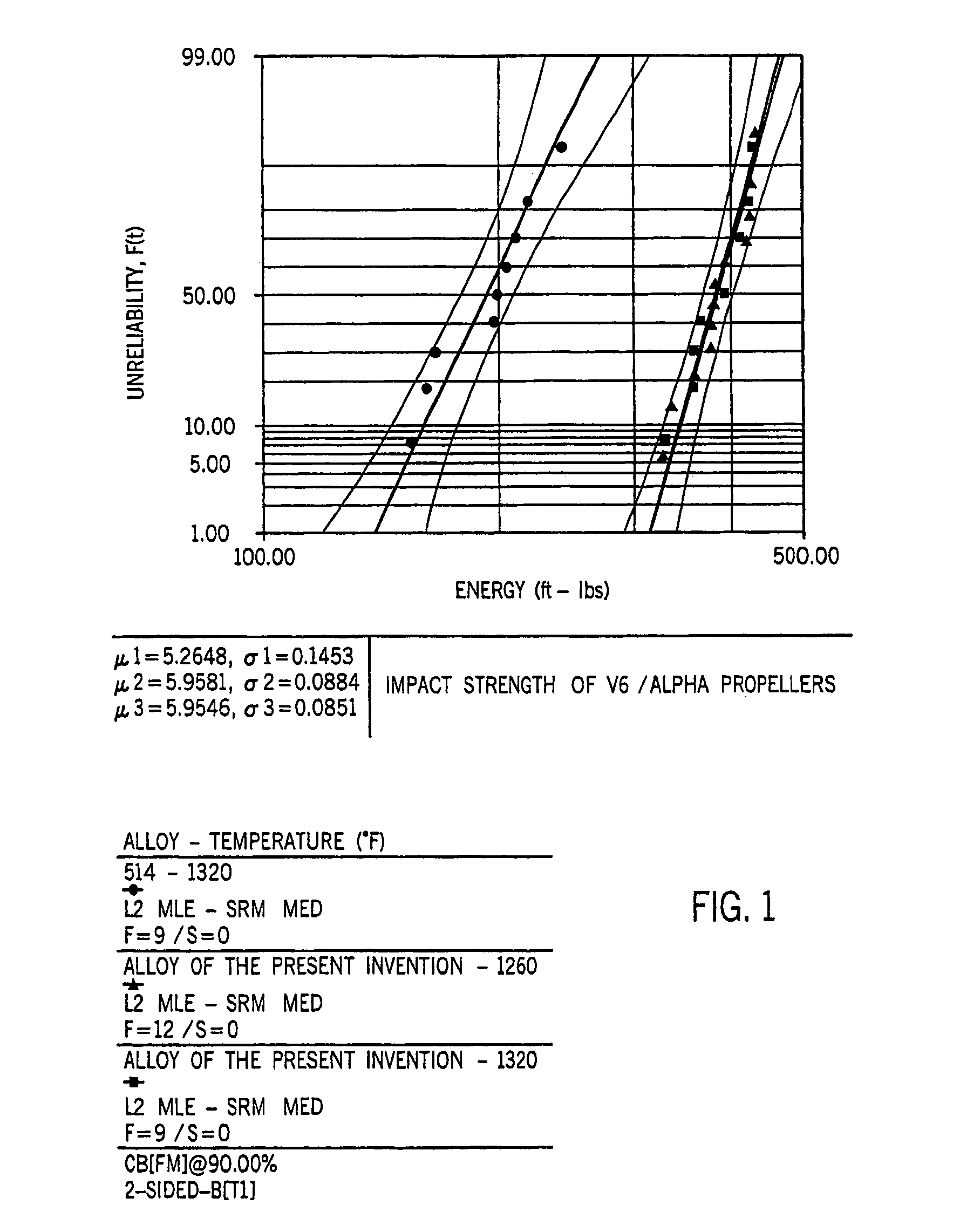

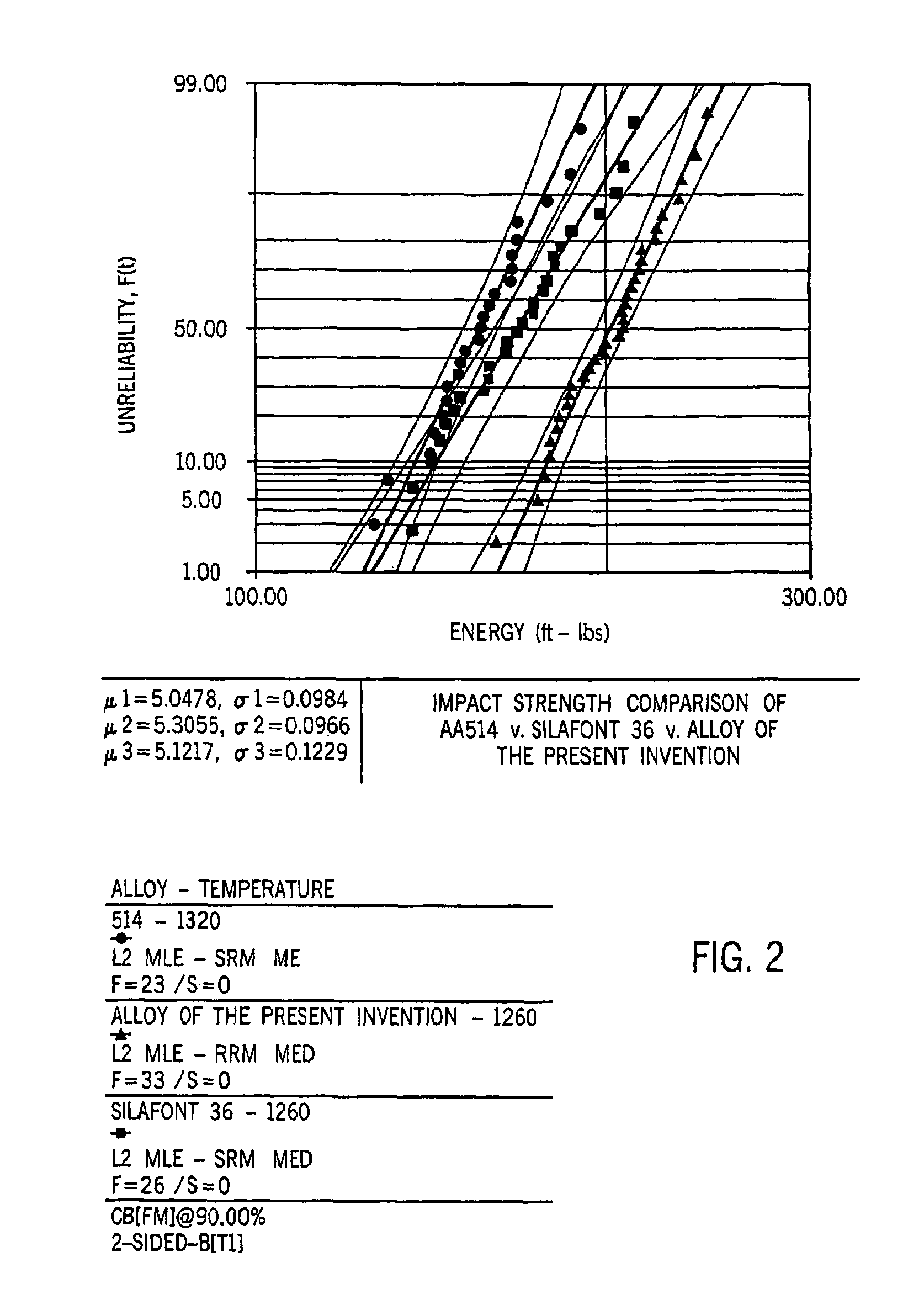

Aluminum-silicon alloy having reduced microporosity

An aluminum silicon die cast alloy having a very low iron content and relatively high strontium content that prevents soldering to dies into die casting process. The alloys of the present invention also have a modified eutectic silicon and modified iron morphology, when iron is present, resulting in low microporosity and high impact properties. The alloy comprises 6-22% by weight silicon, 0.05 to 0.20% by weight strontium and the balance aluminum. Preferably, the alloy of the present invention contains in weight percent: 6-20% silicon, 0.05-0.10% strontium, 0.40% maximum iron and most preferably 0.20% maximum iron, 4.5% maximum copper, 0.50% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, balance aluminum. On cooling from the solution temperature, the strontium serves to modify the eutectic silicon structure as well as create an iron phase morphology change if iron is present, facilitating feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The strontium content also appears to create a non-wetting monolayer of strontium atoms on the surface of a molten casting, preventing die soldering, even at very low iron contents. The alloy may be used to cast any type of object and is particularly suited for casting outboard marine propellers, driveshaft housings, gear case housings, Gimbel rings and engine blocks.

Owner:BRUNSWICK CORPORATION

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

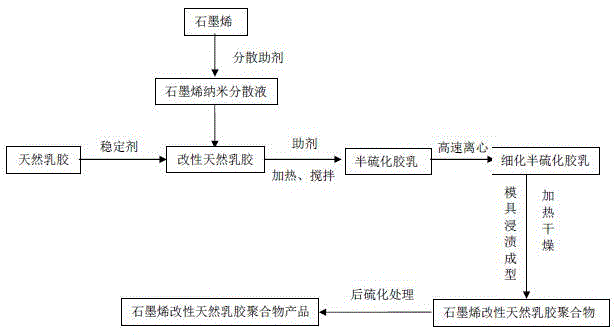

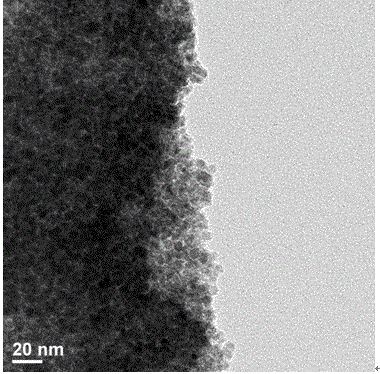

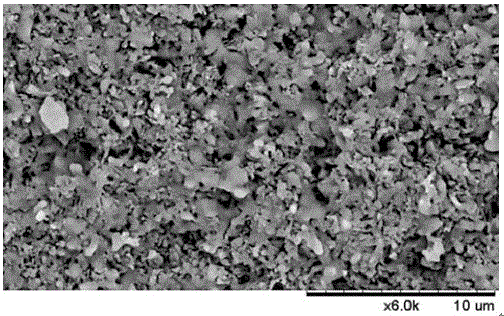

Graphene modified natural emulsion preparation method and high barrier condom

ActiveCN105542248AMeet the use requirementsHigh strengthMale contraceptivesComposite materialHuman papilloma virus

The invention discloses a graphene modified natural emulsion preparation method and a high barrier condom. The graphene modified natural emulsion preparation method and the high barrier condom have the beneficial effects that firstly graphene and a dispersing agent mixed liquor are mixed, ground and stirred and then the product is mixed in a natural emulsion aqueous solution, so that graphene can be uniformly dispersed in emulsion and the strength of a natural emulsion composite material is improved; meanwhile, the number of micropores is smaller due to the graphene / emulsion composite action, thus greatly reducing the virus penetration probability; the thickness of the graphene condom can be 5-80mu m, so that the use requirements of the condom can be met; dense high barrier packing layers are formed by the composite crosslinked nano-packing technology, so that the natural gaps among molecules are reduced; therefore not only can HIVs be blocked but also hepatitis B viruses, hepatitis C viruses, human papilloma viruses, and the like, and most harmful bacteria, which are smaller than the HIVs, can not pass through the micropores.

Owner:沈阳天地乳胶有限公司

Hypoeutectic aluminum-silicon alloy having reduced microporosity

A hypoeutectic aluminum silicon casting alloy having a refined primary silicon particle size and a modified iron morphology. The alloy includes 10 to 11.5% by weight silicon, 0.10 to 0.70% by weight magnesium and also contains 0.05 to 0.07% by weight strontium. On cooling from the solution temperature, the strontium serves to modify the silicon eutectic structure as well as create an iron phase morphology change. Such changes facilitate feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The alloy may be used to cast engine blocks for marine outboard and stern drive motors. Furthermore, when the magnesium levels are adjusted to approximately 0.10 to 0.20% by weight magnesium, propellers having a highly advantageous ductility may be obtained.

Owner:BRUNSWICK CORPORATION

Preparation process of mica-based pearlescent pigment with high weather resistance

ActiveCN103421357AGuaranteed high dispersionThe operation process is simplePigment treatment with organosilicon compoundsIron oxideWeather resistance

The invention relates to a preparation process of a mica-based pearlescent pigment with high weather resistance. The preparation process comprises the following steps: using metal oxide such as titanium dioxide and ferric oxide to clad the surface of mica with a certain grain size distribution to obtain a base material in a certain series of the pearlescent pigment, using photostable substances such as SiO2, Al2O3 and CeO2 to cover the surface of the base material, performing organic modification on the surface of the pigment by using a silane coupling agent KH570, and then obtaining the mica-based pearlescent pigment with the high weather resistance after suction filtration, washing and drying. The preparation process of the mica-based pearlescent pigment is reasonable in design, simple in operation, low in equipment cost, low in energy consumption, and suitable for large-scale production; the prepared pearlescent pigment is good in color and gloss, and suitable for occasions such as automotive, marine and outdoor decoration which have high weather resistance requirements.

Owner:杭州弗沃德精细化工有限公司

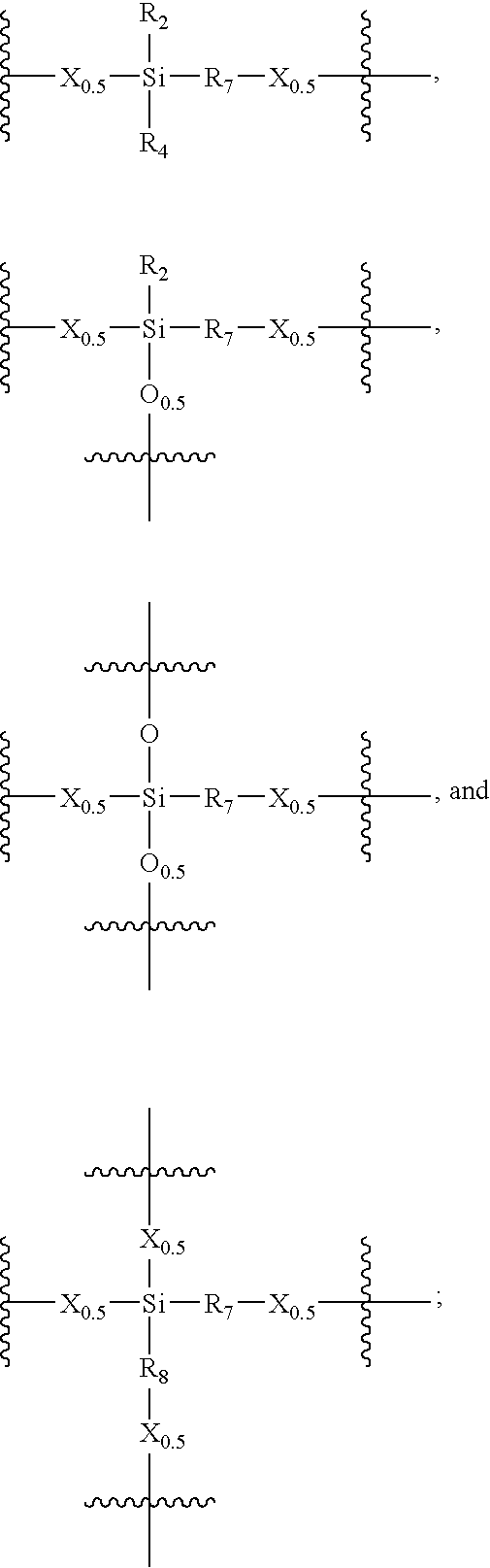

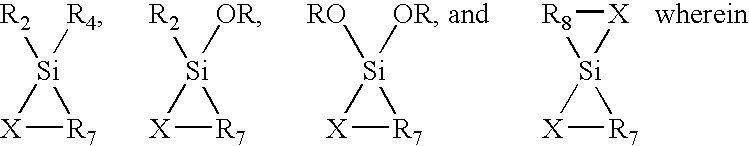

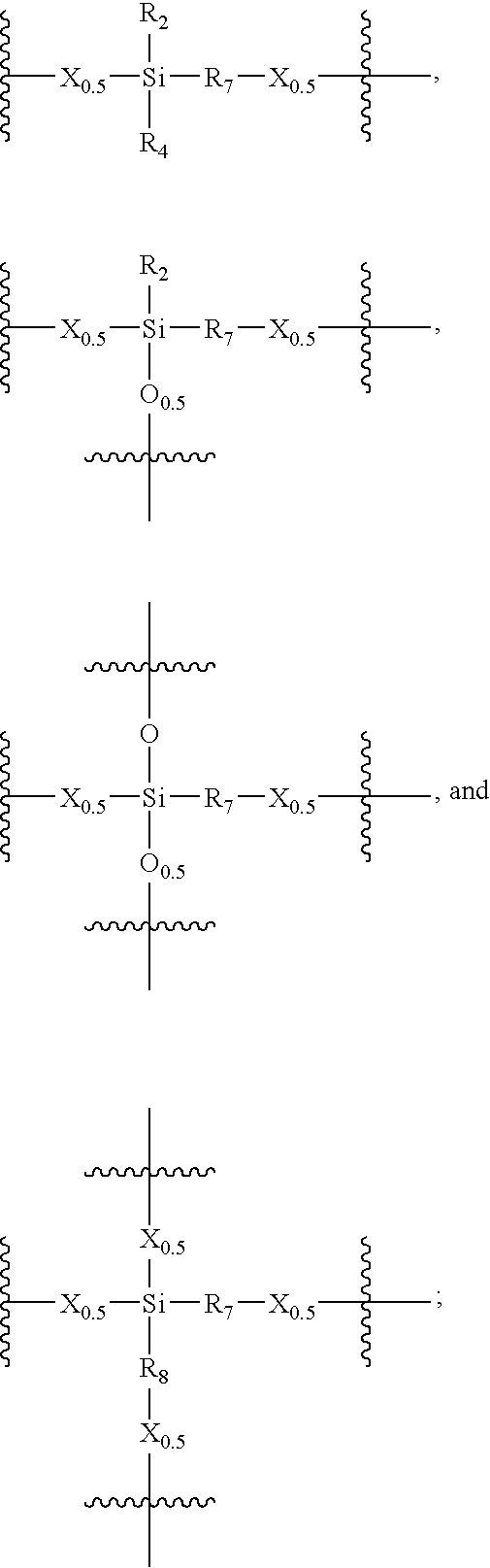

Porous carbon-heteroatom-silicon hybrid inorganic/organic materials for chromatographic separations and process for the preparation thereof

ActiveUS20100076103A1Increased chemical stabilityIncreased mechanical stabilityChromatographic separationChromatography

The present invention provides porous carbon-heteroatom-silicon inorganic / organic homogenous copolymeric hybrid materials, methods for their preparation, and uses thereof, e.g., as chromatographic separations materials.

Owner:WATERS TECH CORP

Cultivation method of pleurotus geesteranus

InactiveCN106927943AReduce odorFast growthCalcareous fertilisersAnimal corpse fertilisersPassion fruitCompost

The invention relates to a cultivation method of pleurotus geesteranus and belongs to the technical field of cultivation of the pleurotus geesteranus. The cultivation method of the pleurotus geesteranus comprises the following steps: (1) batching: preparing a cultivation material by mixing and composting cottonseed hulls, corn straws, wheat bran, sawdust, peanut cake powder, grape residues, pitaya stems, passion fruit peel, banana peel, bee pupae, beancurd, durian peel, pineapple peel, expired yogurt, coffee residues and lime, and adjusting the moisture content to be 65 to 70 percent and the pH value to be 8 to 10; (2) bagging; (3) sterilizing; (4) inoculating; (5) performing mycelium culture; (6) performing fruiting management; and (7) harvesting. According to the cultivation method of the pleurotus geesteranus, the raw materials of the cultivation materials are wide in source and rich in nutrient, and the yield of the pleurotus geesteranus can be increased.

Owner:陆川县新英食用菌专业合作社

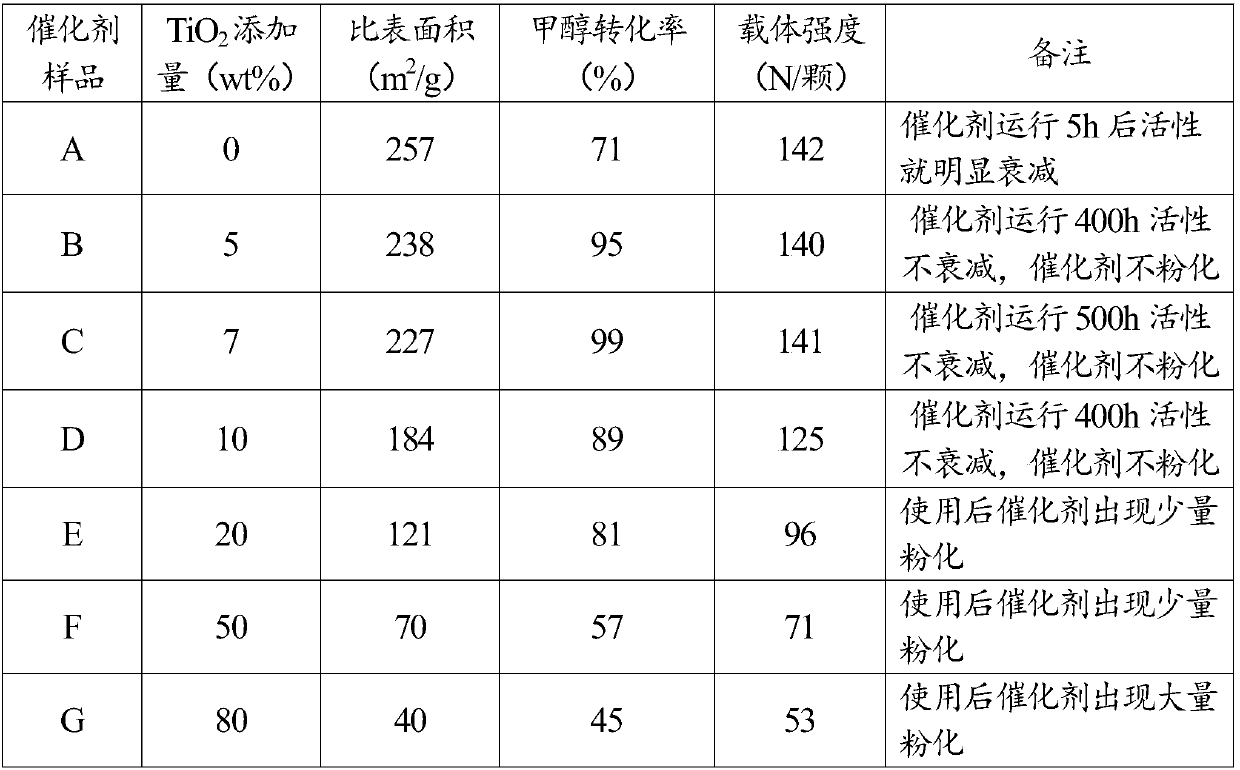

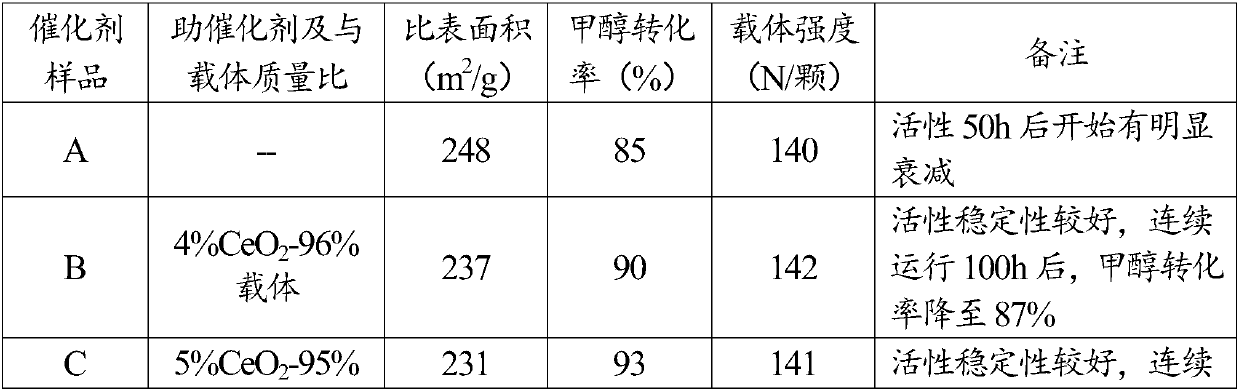

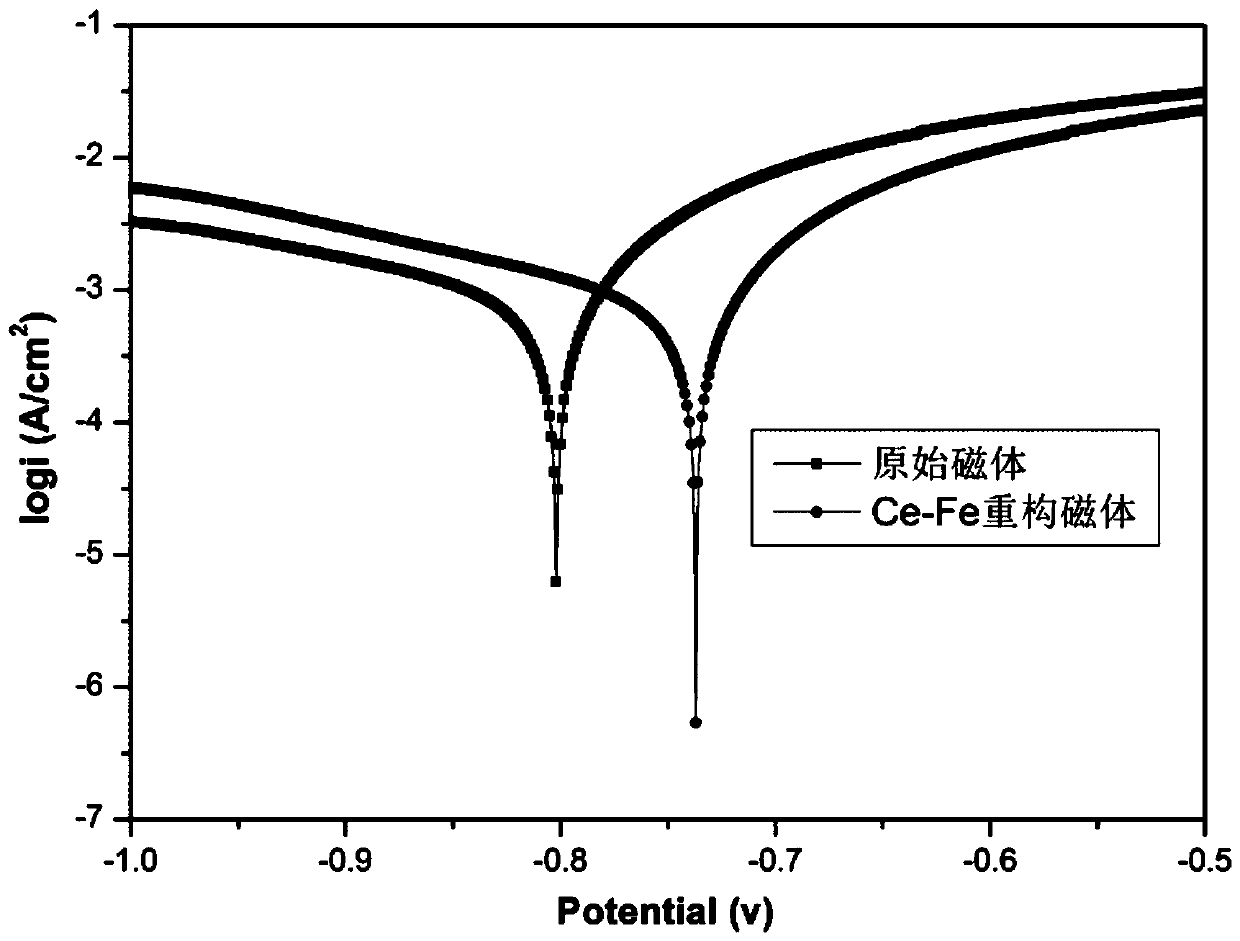

Catalyst for hydrogen production by steam high-temperature reforming of methanol and preparation method and application of catalyst

ActiveCN107649137AHigh activityThe active center acts as a catalyst for increased activityHydrogenHeterogenous catalyst chemical elementsWater vaporActive component

The invention discloses a catalyst for hydrogen production by steam high-temperature reforming of methanol and a preparation method and application of the catalyst. The catalyst takes TiO2 / Al2O3 as acarrier, CeO2 and / or ZrO2 loaded on the carrier as a promoter and a ZnO-NiO bi-active center dispersed on the carrier as a catalyst active component, wherein the mass of the catalyst active componentaccounts for 15-30% of the total mass of the catalyst; and in the ZnO-NiO bi-active center, the mass ratio of ZnO to NiO is (70-90):(10-30), and the mass ratio of the promoter to the carrier is (5-15):(85-95). A noble metal is not taken as the raw material, shortcomings of a traditional Zn-Cr catalyst can be overcome, the catalyst can be applied to the high-temperature range of 350-550 DEG C and has high activity and selectivity and stable catalytic performance.

Owner:四川蜀泰化工科技有限公司

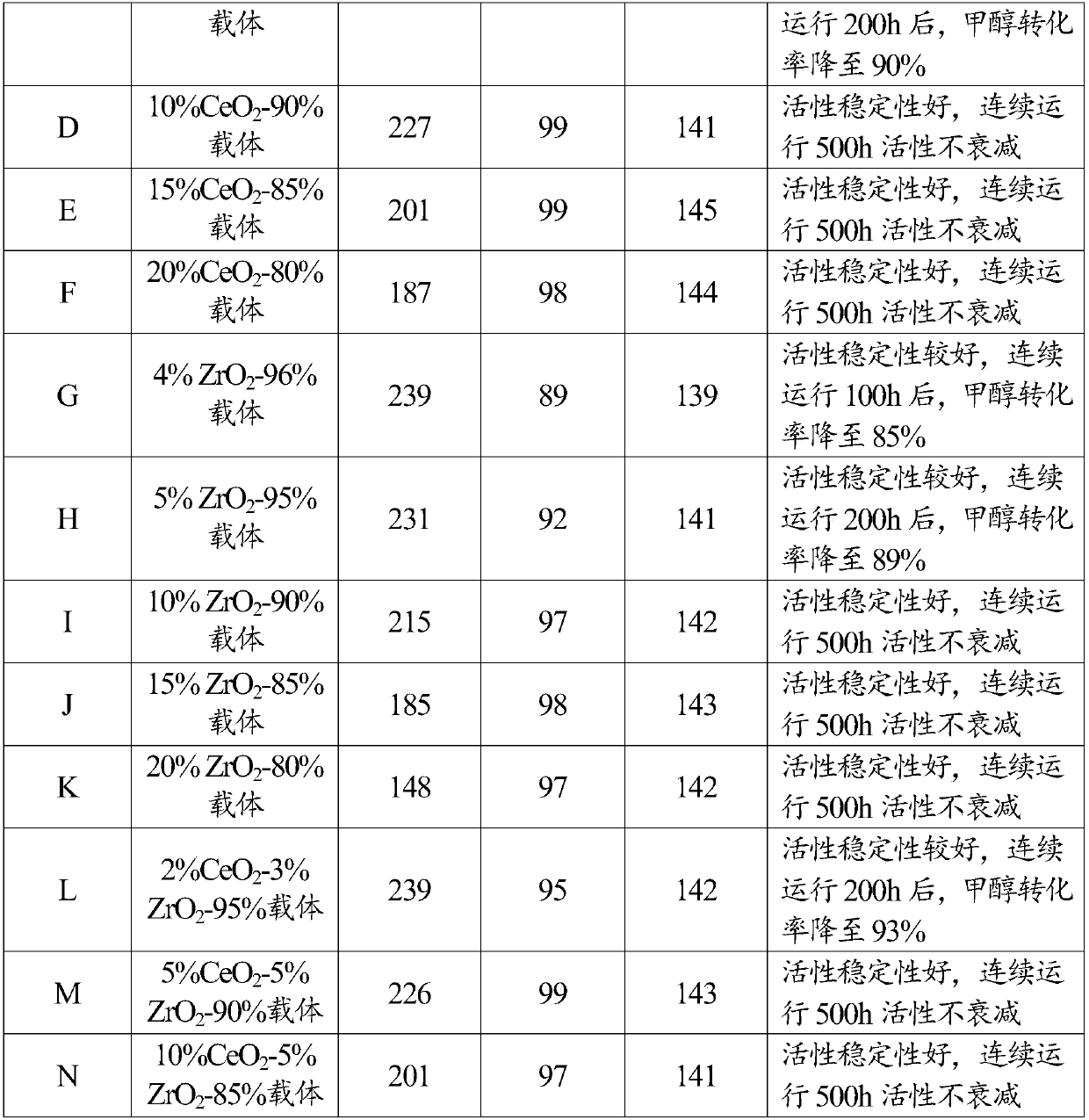

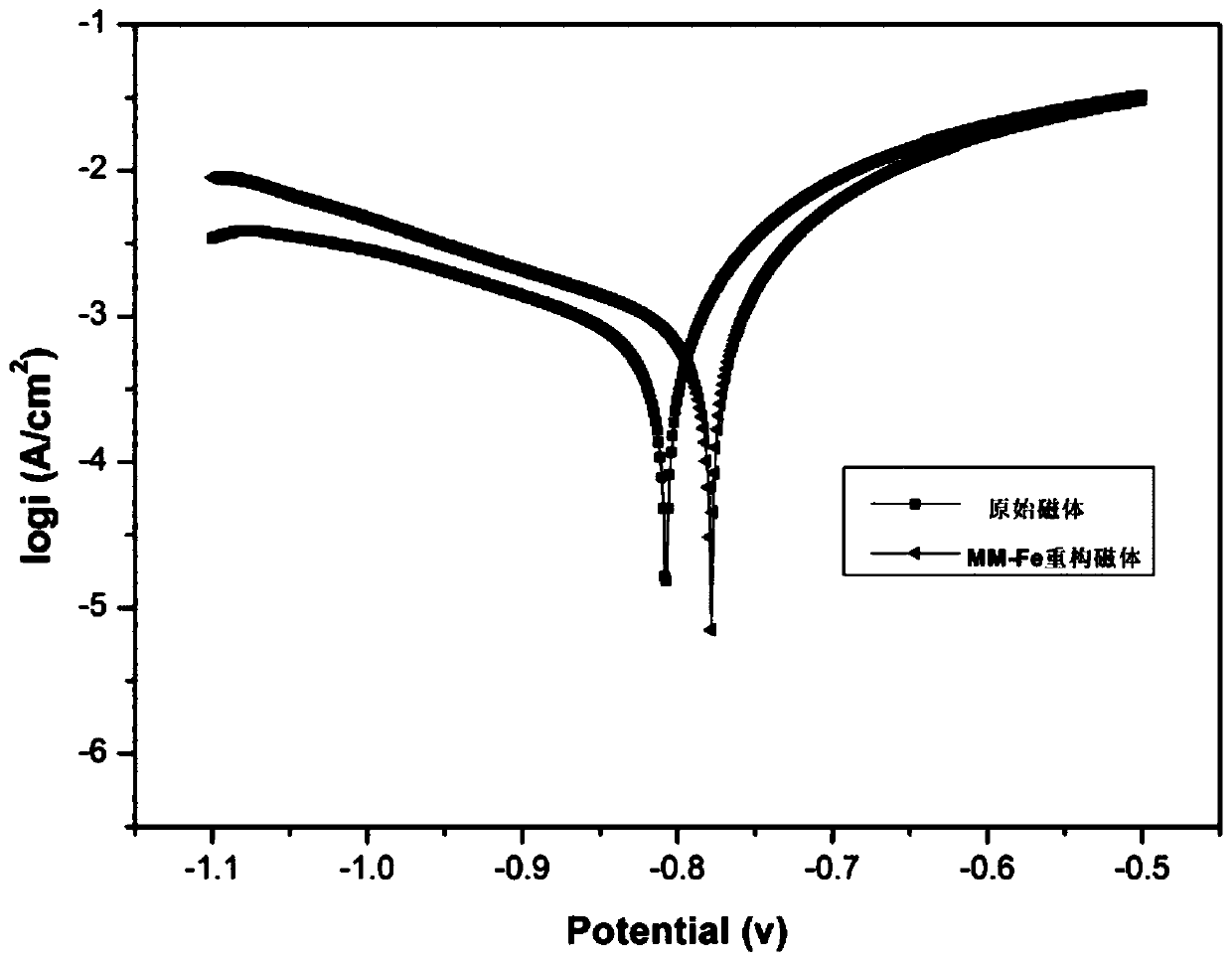

High-corrosion-resistance permanent magnet rich in high-abundance rare earth and preparation method of high-corrosion-resistance permanent magnet rich in high-abundance rare earth

ActiveCN109859920AIncrease the proportionIncrease useInductances/transformers/magnets manufactureMagnetic materialsMagnetic phaseSintered magnets

The invention belongs to the technical field of permanent magnet materials, and particularly relates to a high-corrosion-resistance permanent magnet rich in high-abundance rare earth and a preparationmethod of the high-corrosion-resistance permanent magnet rich in the high-abundance rare earth. The high-corrosion-resistance permanent magnet rich in the high-abundance rare earth comprises a strongmagnetic phase and a crystal boundary rare-earth-rich phase, wherein the strong magnetic phase e is an MM-Fe-B phase, and the crystal boundary rare-earth-rich phase is an MM-Fe phase. According to the method for preparing the permanent magnet, through a double-alloy process, an MM-Fe-B main phase alloy and an MM-Fe auxiliary alloy are prepared, smelted and crushed to prepare powder; the preparedMM-Fe auxiliary alloy powder is added into the main alloy to be evenly mixed according to the mass percent of 1% to 5%; and orientation pressing, sintering and heat treatment are conducted, and the finally sintered magnet is obtained. MM-Fe is introduced in a crystal boundary, thus distribution of the crystal boundary rare-earth-rich phase can be optimized, the crystal boundary rare-earth-rich phase partially replaces an original crystal boundary phase prone to corrosion, the intrinsic corrosion resistance of the MM-Fe-B magnet is improved, through the method, the proportion of low-cost rare earth La / Ce in the magnet is further increased, the material cost is lowered, the technological process is simple, and the high-corrosion-resistance permanent magnet rich in high-abundance rare earth is suitable for scale production.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing doping type carbon dioxide adsorbent ceramic

ActiveCN106362677AImprove adsorption efficiencySmall sizeGas treatmentOther chemical processesSorbentCeramic

The invention relates to a method for preparing a doping type carbon dioxide adsorbent ceramic. The doping type carbon dioxide adsorbent ceramic prepared by adopting the method is smaller in particle size, larger in specific surface area, high in material activity and strong in carbon dioxide adsorbing capability, and industrial production can be achieved through large-scale preparation.

Owner:方兴河北新材料科技有限公司

Method of increasing content of magnetic powder in magnesium alloy micro-arc oxidation membrane

InactiveCN104313665AImprove corrosion resistanceEmbodies electromagnetic wave absorptionAnodisationMicro arc oxidationElectrolysis

The invention relates to a preparation method of a magnesium alloy with corrosion resistance in the surface and a functional protective layer on the surface, in particular to a method of increasing content of magnetic powder in a magnesium alloy micro-arc oxidation membrane, belongs to the technical field of surface processing. The method comprises the following steps: putting a magnesium alloy matrix in an electrolytic bath with a magnet arranged at the bottom firstly, adding the magnetic powder in electrolyte in the electrolytic bath, enabling the magnetic powder to uniformly cover the electrolyte, then adopting a micro-arc oxidation method to compound a ceramic membrane on the surface of the magnesium alloy, and forming a composite micro-arc oxidation ceramic membrane which is uniformly covered by the magnetic powder on the surface of the magnesium alloy, wherein the composite membrane layer is capable of reducing the number of micropores and cracks on the surface of the micro-arc oxidation membrane layer and improving corrosion resistance of the magnesium alloy. According to the method disclosed by the invention, the micro-arc oxidation membrane is enabled to have a magnetic function, by virtue of the magnet arranged at the bottom of the outer side of the electrolytic bath, the magnetic powder enters the oxidation membrane through a micro-arc oxidation fusion and discharge channel under the effect of magnetism, so that compound quantity of the magnetic powder in the micro-arc oxidation membrane is increased, the micro-arc oxidation membrane can more reflect the functions of the magnetic powder of electromagnetic wave absorption and shielding, and the application field of the micro-arc oxidation coating is widened.

Owner:SHENYANG LIGONG UNIV

Corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid and preparation method thereof

InactiveCN105200416AGood film formingImprove antibacterial propertiesMetallic material coating processesSilanesRare earth

The invention discloses a corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid. The corrosion-resistant anti-microbial aluminum-profile rare-earth silane treating fluid is prepared from, by weight, 120-130 parts of CeCl<3>7H2O, 180-190 parts of H2O2, 0.5-0.6 part of poly-sebacic glyceryl monolaurate, 0.3-0.4 part of nano samarium, 0.4-0.6 part of turpentine oil liquid anhydride, 0.4-0.5 part of itaconic acid, an appropriate amount of deionized water, 1-1.2 parts of tetraethyl orthosilicate, 5-5.2 parts of methyl triethoxysilane, 50-53 parts of ethanol, 10-11 parts of ammonia water, 15-15.6 parts of fluorine and silicon-containing polyacrylate emulsion and 2-2.5 parts of nano zirconium dioxide. The compactness of a film formed by the treating fluid is greatly improved, and the film has certain water-repellent performance. The film forming speed is high and the film is uniform and compact by using the poly-sebacic glyceryl monolaurate, the turpentine oil liquid anhydride and the itaconic acid. The antibacterial property, the oxidation resistance and abrasion resistance of the film are improved by using the nano samarium.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

Compound formaldehyde adsorbent

InactiveCN103240062AImprove adsorption capacityOvercome the disadvantage of low reaction rateOther chemical processesDispersed particle separationActivated carbonDecomposition

The invention provides a compound formaldehyde adsorbent which is prepared by the following specific steps: mixing 180-200 parts by weight of activated carbon powder with 10-30 parts by weight of titanium dioxide powder uniformly, adding 25-40 parts by weight of potassium hydroxide water solution with mass fraction of 5-10% to the mixture and drying the mixture after uniformly stirring; and adding 2-8 parts by weight of microcrystalline cellulose to the dried mixture, then adding 9-20 parts by weight of sodium peroxide powder and mixing the materials uniformly, thus obtaining the compound formaldehyde adsorbent. The adsorbent utilizes various mechanisms which adsorb and decompose formaldehyde, is thorough in adsorption, has good decomposition effects and has the advantages of simple preparation method and low cost.

Owner:WUXI KAILI PHARMA

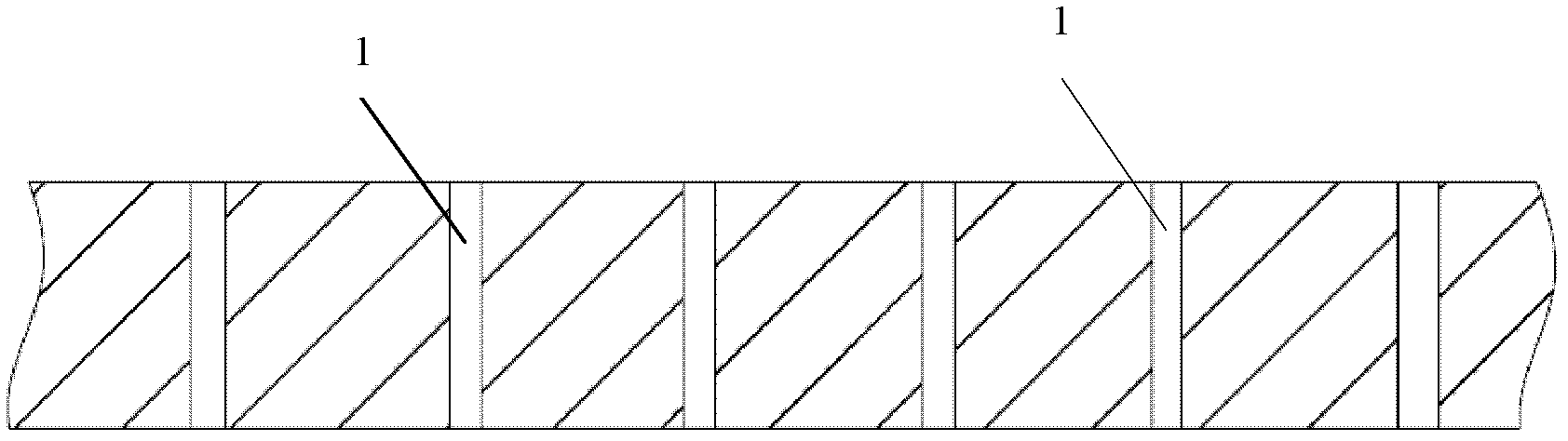

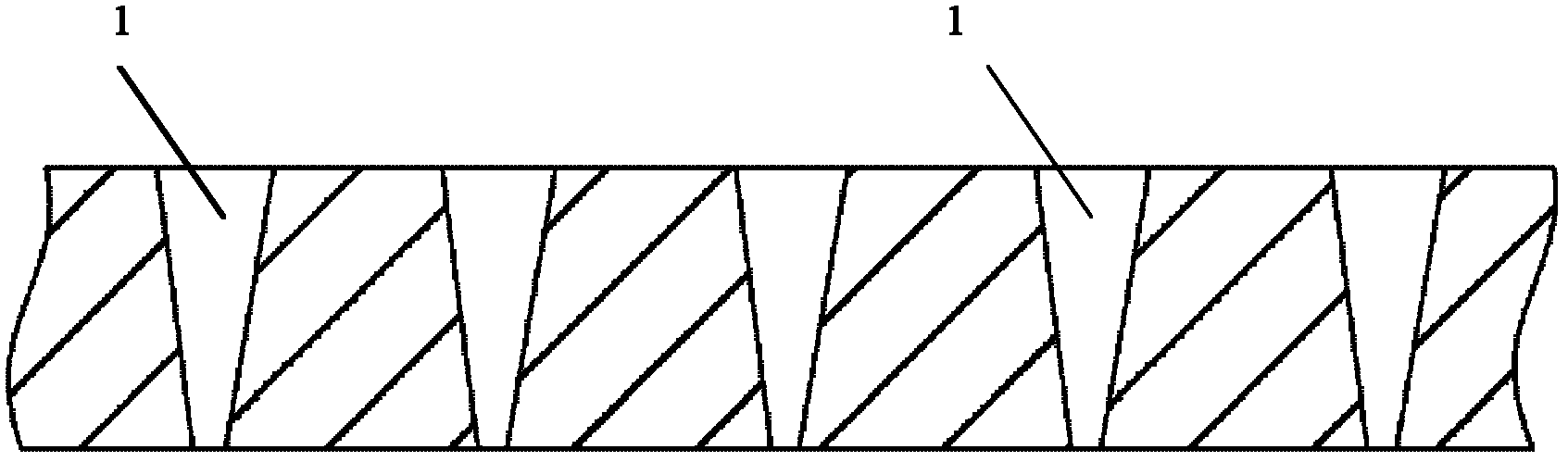

Process for coating film on sheet material

InactiveCN103072360AOvercoming Stripping ProblemsMicroporous reductionLiquid surface applicatorsLaminationInjection portElectric machine

The invention discloses a process for coating liquid medicine on surfaces of patterns and letters on a sheet material to form a protecting film. The process comprises the following steps: a coating rubber roll is driven to rotate through a motor; a material guide roll is driven to rotate in the same direction through another motor; a liquid medicine roll is arranged behind the coating rubber roll, and is clung to and extruded with the coating rubber roll; liquid medicine enters the space between the liquid medicine roll and the coating rubber roll through an injection port; the liquid medicine roll is driven to rotate through a motor, so as to generate a medicine film with certain thickness on the surface of the coating rubber roll; simultaneously, the material to-be-coated is guided by the guide roll, and passes through the gap between the guide roll and the coating rubber roll; and the medicine film is coated on the material to-be-coated. According to the process, the film coated on the sheet material is level, the quantity of micro-pores is greatly reduced, and requirements for solidification can be met without further carrying out a flattening step.

Owner:宋瑞娥

Aluminum profile rare earth silane treatment liquid good in thermal stability and preparation method thereof

InactiveCN105200408AGood film formingReduced porosity and cracksMetallic material coating processesIonTetraethyl orthosilicate

The invention discloses aluminum profile rare earth silane treatment liquid good in thermal stability. The aluminum profile rare earth silane treatment liquid is prepared from, by weight, 120-130 parts of CeC137H2O, 180-190 parts of H2O2, 1.1-1.3 parts of nanometer montmorillonite, 2-2.3 parts of cellulose nanocrystals, 2.3-2.5 parts of lanthanum laurate, an appropriate amount of deionized water, 1-1.2 parts of tetraethyl orthosilicate, 5-5.2 parts of methyl triethoxysilane, 50-53 parts of ethyl alcohol, 10-11 parts of ammonia water, 15-15.6 parts of fluorine and silicon containing polyacrylate emulsion and 2-2.5 parts of nanometer zirconium dioxide. Through using fluorine and silicon containing polyacrylate emulsion and nanometer zirconium dioxide, emulsion is prepared, the treatment liquid is good in film-forming performance, micropores and cracks on the surface of a film are obviously reduced, certain hydrophobic performance is achieved, and the corrosion speed is decreased. Through using nanometer montmorillonite, cellulose nanocrystals and lanthanum laurate, the film-forming performance, thermal stability and compactness of a film layer are improved.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

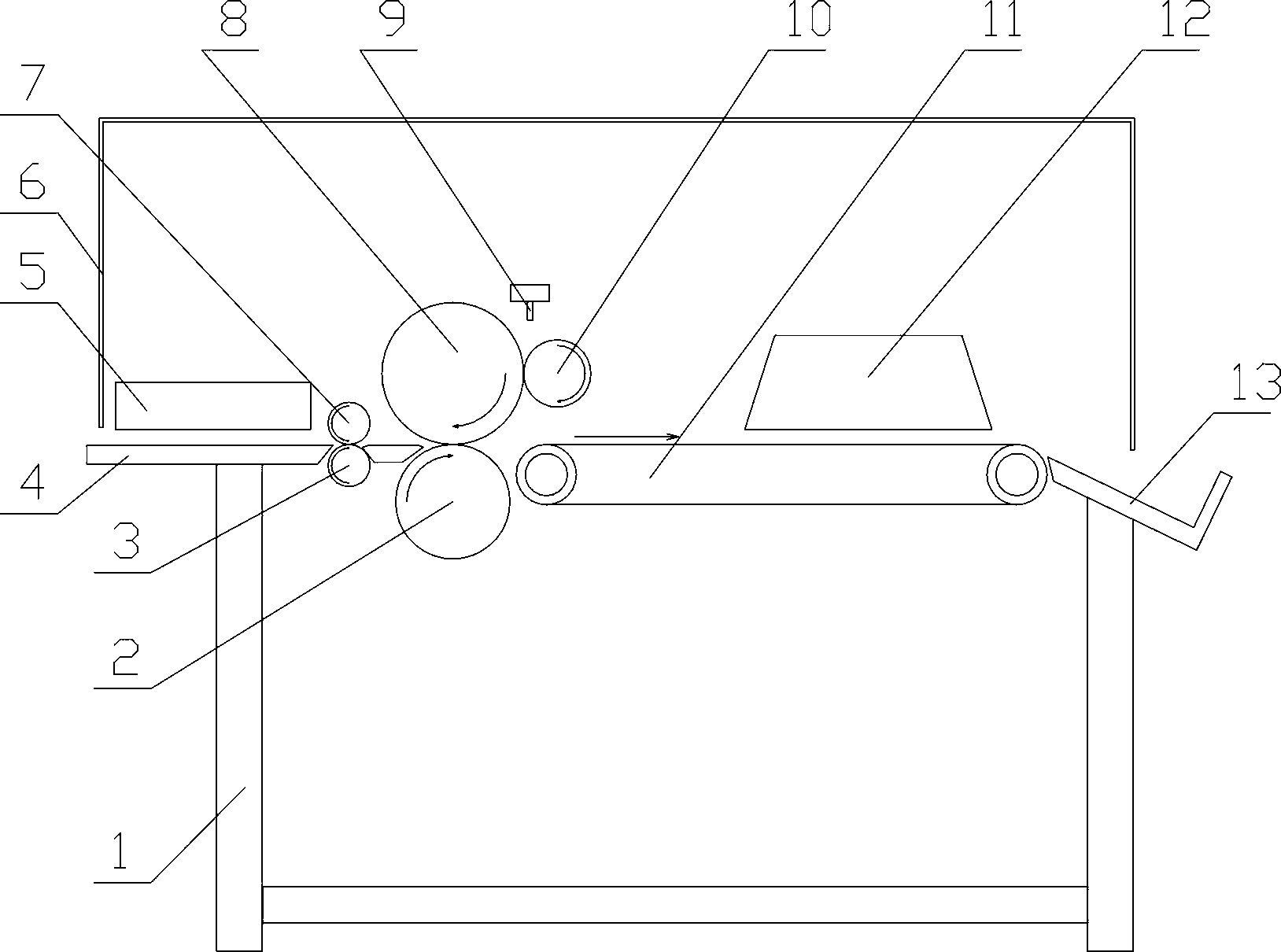

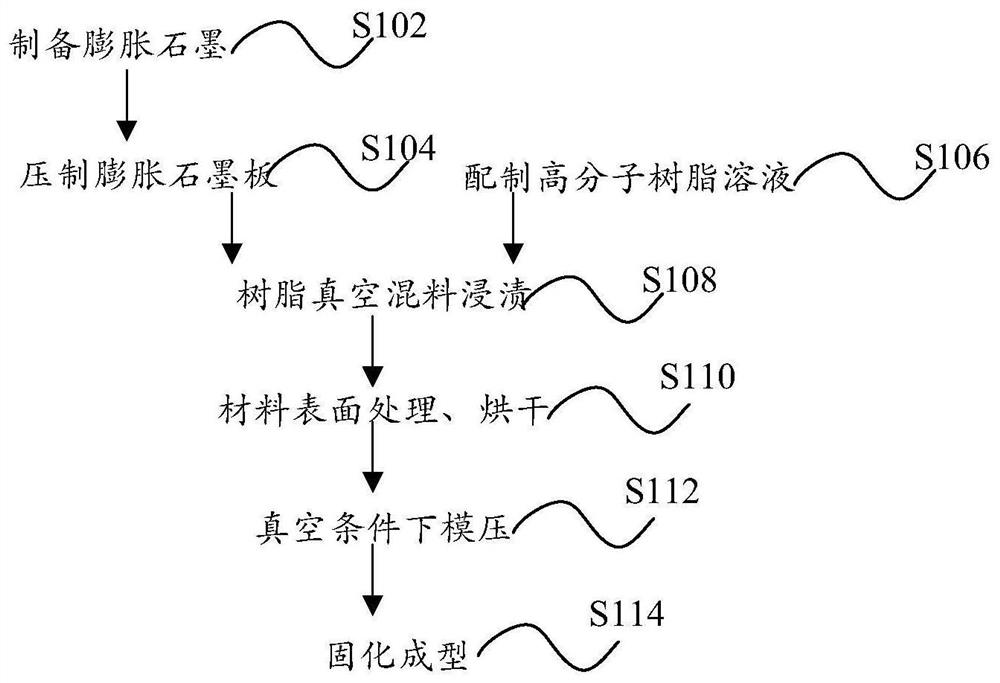

Graphite bipolar plate preparation method and graphite bipolar plate prepared by same

InactiveCN112310426AEasy to control the amount of impregnationImprove bending strengthFinal product manufactureFuel cellsPhysical chemistryOrganosolv

The invention provides a graphite bipolar plate preparation method and the graphite bipolar plate. The method comprises the following steps of firstly, carrying out intercalation treatment on crystalline flake graphite, carrying out instantaneous expansion at a high temperature to obtain expanded graphite, pre-pressing the expanded graphite into plates with different densities, and carrying out pressure or vacuum impregnation in a low-viscosity organic solvent containing resin, and heating and evaporating the plate subjected to surface treatment in an oven to remove the solvent, carrying out die pressing under a vacuum condition to form a flow field, and curing to form the bipolar plate. According to the technical scheme, the density of the prepared graphite bipolar plate is 1.0-2.0 g / cm<3>, the tensile strength of the bipolar plate subjected to impregnation treatment is 25-35 MPa, the mechanical property is improved along with the increase of the resin content, the gas sealing property is good, the preparation method is beneficial to reducing the thickness of the polar plate, and batch production is easy.

Owner:BINZHOU DOUBLE PEAKS GRAPHITE SEALING MATERIAL

Waterproof and air-permeable shoe and production method thereof

ActiveCN102349722AReduce material costsImprove breathabilityDomestic footwearUpperWork in processEngineering

Owner:丁国南

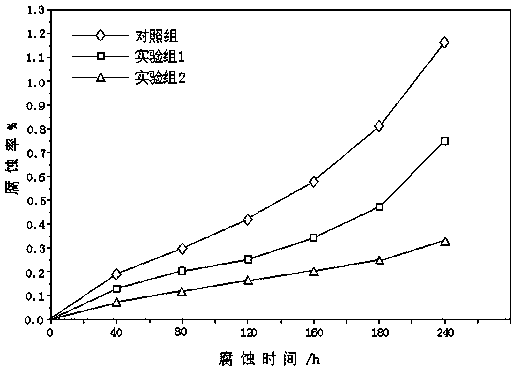

Method of preparing oxidation film on surface of magnesium alloy by utilizing micro-arc oxidation

InactiveCN108642544AImprove conductivityMicroporous reductionAnodisationEthylenediamineMicro arc oxidation

The invention provides a method of preparing an oxidation film on the surface of a magnesium alloy by utilizing micro-arc oxidation. The method comprises the following steps that the magnesium alloy is placed into an electrolytic tank filled with an alkaline electrolyte, the magnesium alloy serves as an electrolytic anode, the electrolytic tank serves as an electrolytic cathode, voltage is appliedto allow plasma discharge to be generated on the magnesium alloy, the oxidation film is formed on the surface of the magnesium alloy by utilizing the micro-arc oxidation, and the components of the alkaline electrolyte are 8-12 g / L of NaOH, 10-15 g / L of Na2SiO3, 6-8 g / L of KF, 2-3 mL / L of H2O2, 6-8 mL / L of glycerol, 1-2 g / L of sodium ethylenediamine teramethylene phosphonate and the balance water;and in the micro-arc oxidation process, zeolite powder and gamma-aluminum oxide nano micropowder are sequentially added into the electrolyte, and a micro-arc oxidation reaction is continued to be carried out until the preparation of the oxidation film is completed. The reaction process of the micro-arc oxidation is affected through the synthetic action of the components, the amount of microporeson the surface layer of the oxidation film is reduced, the compactness of the oxidation film is improved basically, and the corrosion-resistant performance is strengthened.

Owner:HENAN UNIV OF SCI & TECH

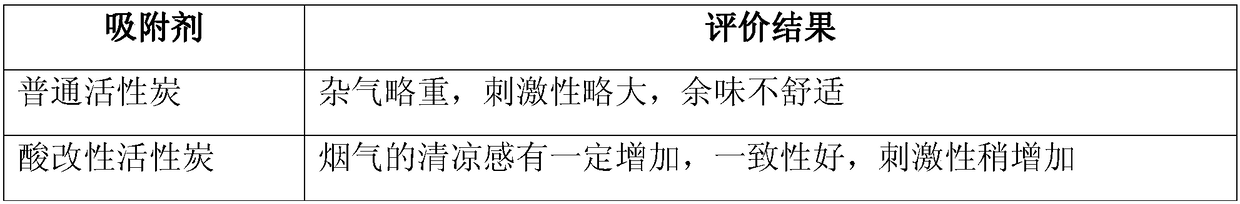

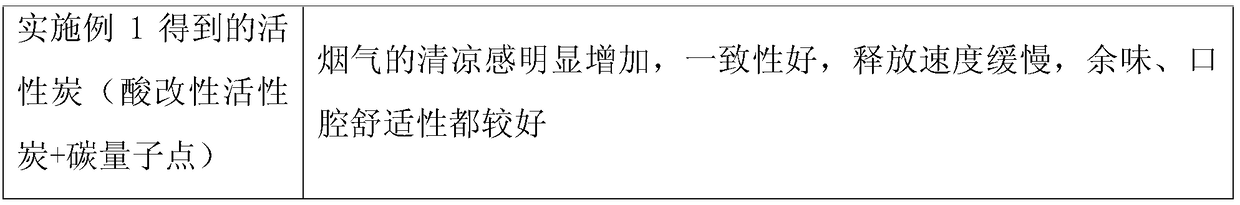

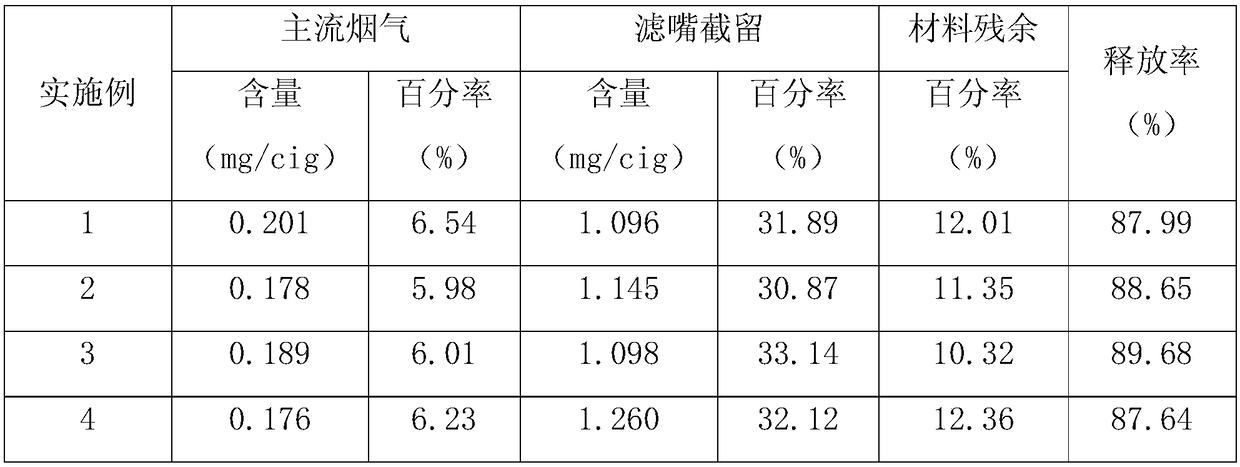

Method and application for improving sustained release properties of activated carbon on essence

ActiveCN109174004AHigh affinityIncrease surface polarityTobacco preparationTobacco treatmentActivated carbonDesorption

The invention discloses a method and application for improving the sustained release properties of activated carbon on essence. The method comprises: acidifying activated carbon so that the surface contains acidic groups such as a hydroxyl group and a carboxyl group, and mixing water-soluble carbon quantum dots, acidified activated carbon and liquid essence. The water-soluble groups rich in the surfaces of the carbon quantum dots improve the dispersibility of activated carbon in the liquid essence, types of adsorption sites and the penetration of essence into activated carbon are increased andadsorption is convenient. In desorption, the specific surface area and pore volume of the acidified activated carbon are increased and the release rate is increased. The quantization of the surface of activated carbon does not influence the adsorption of the activated carbon on the essence, reduces the adsorption and adhesion of the surface of the activated carbon to the essence and improves thesustained release ability. The modified activated carbon adsorption essence can be used in a cigarette filter tip, can stably and uniformly release the fragrance at 45-65 DEG C and has good sustainedrelease effects.

Owner:CHINA TOBACCO GUANGXI IND

Wire enamel with high temperature classification and preparation method

InactiveCN103725191AImprove scratch resistanceHigh hardnessPolyamide coatingsEpoxy resin coatingsTripropylene glycolEpoxy

The invention discloses wire enamel with high temperature classification. The wire enamel is characterized by being prepared by raw materials in parts by weight (kilogram) as follows: 30-35 parts of nylon 12, 10-12 parts of E-12 epoxy resin, 1-2 parts of magnesium hydrate, 8-10 parts of aluminum triphosphate, 12-15 parts of ethylene glycol, 6-9 parts of dimethyl terephthalate, 4-6 parts of trimethyl trimellitate, 2-3 parts of 3-methylphenol, 8-10 parts of nano bentonite, 10-12 parts of tripropylene glycol diacrylate, 1-2 parts of nano emery powder, 2-3 parts of dicumyl peroxide DCP, 8-12 parts of potassium hexatitanate whiskers, 7-9 parts of an auxiliary, 120-130 parts of cresol and 110-120 parts of xylene. With the adoption of the wire enamel with high temperature classification, forming of a paint film with uniform, dense and smooth surface can be facilitated during coating in the follow-up process, micropores are greatly reduced, and scratch resistance, harness, salt mist resistance and severe environment resistance of the paint film are remarkably improved.

Owner:铜陵天河特种电磁线有限公司

Low-melting-point and high-hardness lead-free solder and preparation method thereof

InactiveCN106514032AGuaranteed touch resistanceGuaranteed SolderabilityWelding/cutting media/materialsSoldering mediaHardnessImpurity

The invention relates to a low-melting-point and high-hardness lead-free solder and a preparation method thereof. The low-melting-point and high-hardness lead-free solder is prepared from the following raw materials in percentage by weight: 5 to 8 percent of Zn, 30 to 40 percent of Bi, 0.2 to 0.5 percent of Mg, 0.1 to 0.2 percent of In, 0.01 to 0.015 percent of grapheme, and the balance being Sn and inevitable impurities. According to the low-melting-point and high-hardness lead-free solder disclosed by the invention, by optimizing components of the raw materials and adding the Mg and the grapheme, the hardness of the solder is effectively improved, a melting point is reduced, and the solder is enabled to have good welding performance.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

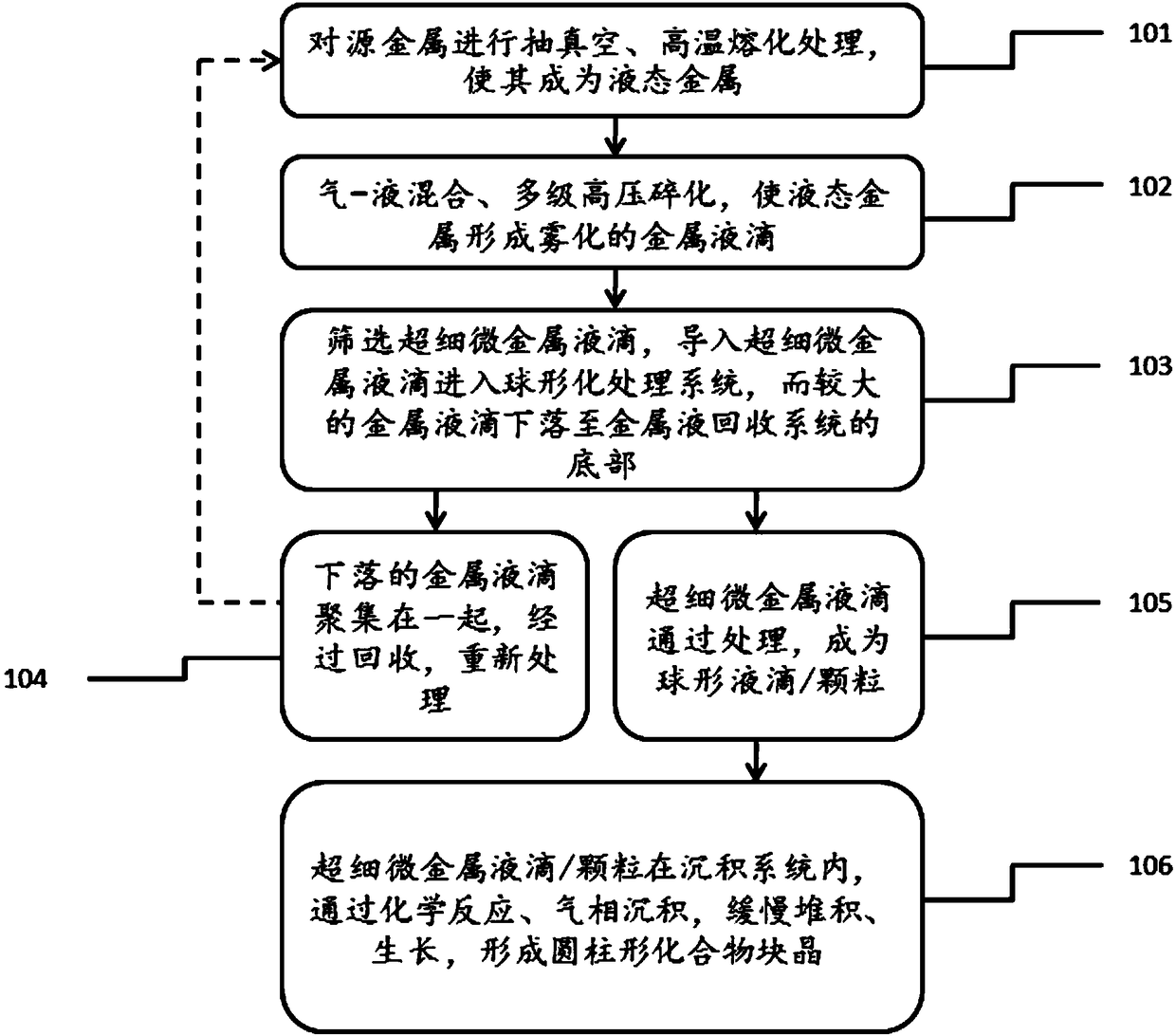

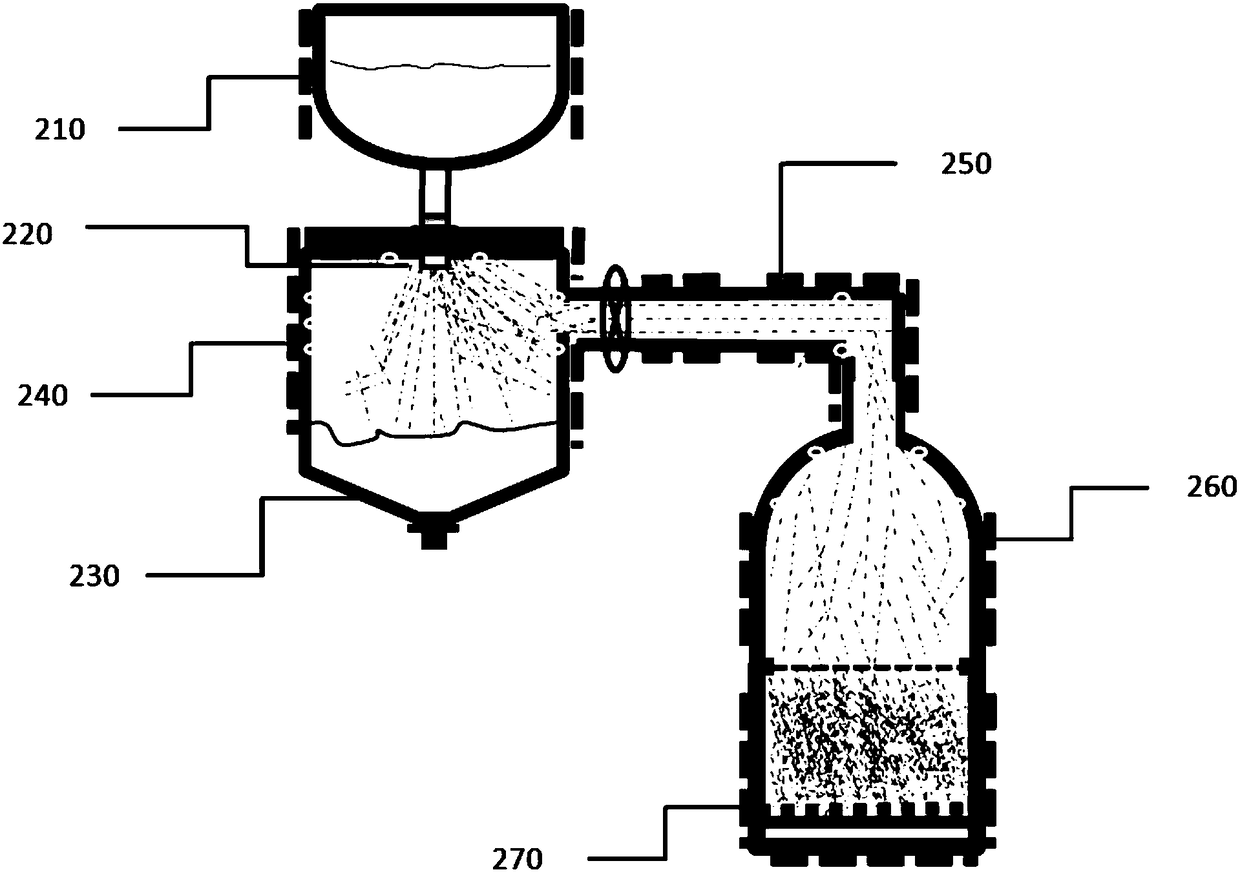

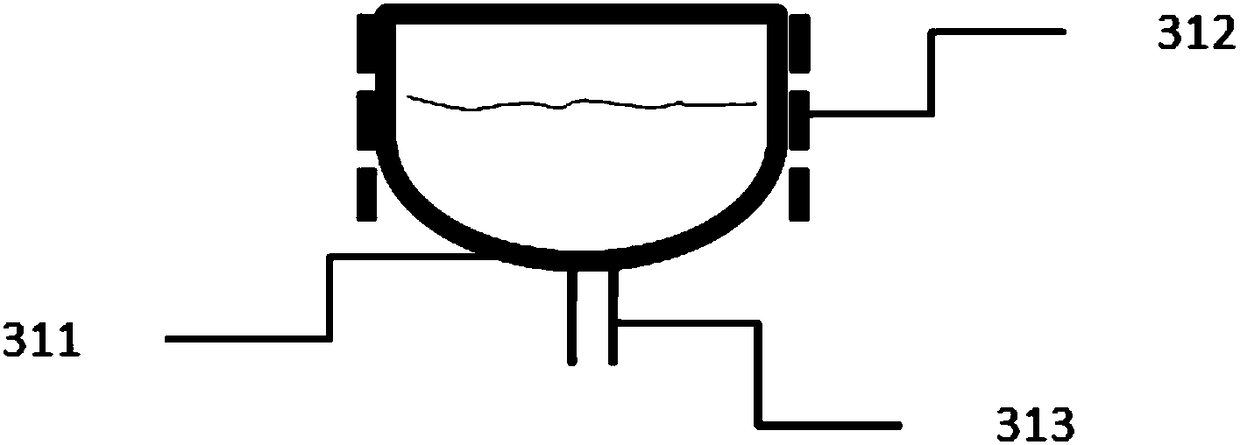

Method for preparing high-temperature compound bulk crystals

ActiveCN108296489ASmall sizeLow bit error rateTransportation and packagingMetal-working apparatusChemical reactionBulk crystal

The invention discloses a method for preparing high-temperature compound bulk crystals. The vacuuming and high-temperature melting treatment is performed on source metal to form liquid-state metal; gas / liquid mixing and multistage high-pressure crushing are performed to form the liquid-stage metal to atomized metal drops; ultrafine metal drops are screened, and are guided into a spherical treatment system; larger metal drops fall to the bottom of a metal liquid recovery system; the falling metal drops are collected for recovery and retreatment; the ultrafine metal drops are treated to form spherical drops / particles; and the ultrafine metal drops / particles are slowly accumulated and grown in reaction and deposition systems through chemical reaction and vapor deposition to form cylindrical compound bulk crystals.

Owner:张格梅

Non-chrome silver-based soldering flux and preparation method thereof

InactiveCN106862798AAvoid harmReduce pollutionWelding/cutting media/materialsSoldering mediaGrapheneImpurity

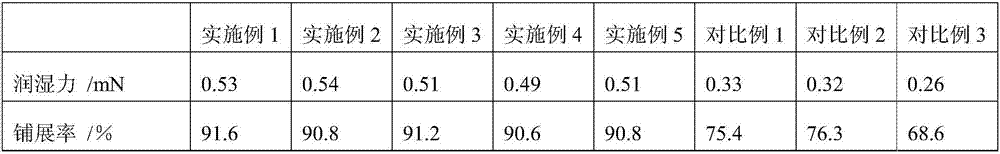

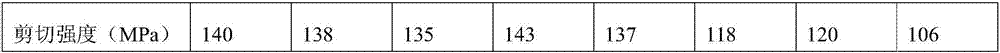

The invention discloses non-chrome silver-based soldering flux and a preparation method thereof, and belongs to the field of soldering materials. The non-chrome silver-based soldering flux comprises, by weight, 39.0-41.0% of Ag, 29.5-31.5% of Zn, 2.5-3.5% of Sn, 1.3-1.7% of Ni, 0.1-0.2% of In, 0.05-0.1% of Co, 0.01-0.02% of graphene and the balance Cu and inevitable impurities. The soldering strength of the prepared soldering flux for stainless steel joints can reach 140 MPa, and the spreading performance and plasticity of the soldering flux are good.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Preparation method of micro-arc oxidation membrane of magnetic powder composite magnesium alloy

InactiveCN104294347AImprove corrosion resistanceWith magnetic functionAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method of a magnesium alloy surface corrosion-resistant and functional protective layer, particularly relates to the preparation method of a micro-arc oxidation membrane of a magnetic powder composite magnesium alloy, and belongs to the technical field of surface treatment. By adding nano magnetic powder into a micro-arc oxidation electrolyte, a composite micro-arc oxidation ceramic membrane uniformly covered with magnetic powder can be formed on the surface of a magnesium alloy, micro-pores and cracks in the surface of a micro-arc oxidation membrane layer can be reduced by virtue of a composite membrane layer, and the corrosion resistance of the magnesium alloy is improved; meanwhile, the micro-arc oxidation membrane has a magnetic function and certain properties such as electromagnetic wave absorption, and the application field of the micro-arc oxidation membrane is expanded.

Owner:SHENYANG LIGONG UNIV

Oxidation-resisting corrosion-resisting aluminum profile rare earth silane treating fluid and preparation method thereof

InactiveCN105177552AGood film formingMicroporous reductionMetallic material coating processesSilanesRare earth

The invention discloses oxidation-resisting corrosion-resisting aluminum profile rare earth silane treating fluid. The oxidation-resisting corrosion-resisting aluminum profile rare earth silane treating fluid is made from raw materials including, by weight, 120 parts to 130 parts of CeCl37H2O, 180 parts to 190 parts of H2O2, 1.6 parts to 1.8 parts of tetrabutyl titanate, 2.2 parts to 2.3 parts of chitosan, 0.5 part to 0.6 part of acetylacetone, 0.4 part to 0.5 part of H2SO4, a proper amount of deionized water, 1 part to 1.2 parts of tetraethoxysilane, 5 parts to 5.2 parts of methyl triethoxysilane, 50 parts to 53 parts of ethyl alcohol, 10 parts to 11 parts of ammonium hydroxide, 15 parts to 15.6 parts of fluorine-silicon-contained ylate emulsion and 2 parts to 2.5 parts of nanometer zirconium dioxide. According to the fluid, micropores and cracks on the surface of a film formed by the treating fluid are obviously reduced, the compactness is high, and a certain hydrophobic property is achieved; through using of the tetrabutyl titanate, the chitosan, the acetylacetone and the H2SO4, the crosslink level of the passivation film can be strengthened, forming of surface gathering objects can be restrained, and corrosion resistance and oxidation resistance of the passivation film can be strengthened.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

Epoxy wire enamel and preparation method thereof

The invention discloses epoxy wire enamel which is characterized in that the viscosity flow time of the wire enamel is 20-50 s; and the epoxy wire enamel is prepared from raw materials in parts by weight (kilogram) as follows: 12-14 parts of nylon 11, 10-12 parts of E-44 epoxy resin, 3-4 parts of 2-butoxy-ethanol, 6-9 parts of isopropyl alcohol, 10-12 parts of ethoxylated trimethylolpropane triacrylate, 2-3 parts of aluminum dihydrogen phosphate, 1-2 parts of cellulose acetate, 2-3 parts of isocyanate, 1-2 parts of tannic acid, 10-12 parts of ethylene glycol, 10-12 parts of dimethyl terephthalate, 2-3 parts of 3-methylphenol, 5-6 parts of tetrabutyl titanate, 7-9 parts of an assistant, 100-110 parts of xylene and 120-130 parts of m, p-cresol. According to the epoxy wire enamel, a film with a uniform, compact and smooth surface can be formed in the follow-up process during coating, the micropores are reduced greatly, and the scratching resistance, the hardness, the salt spray resistance and the severe environment resistance of the film are remarkably improved.

Owner:铜陵天河特种电磁线有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com