Catalyst for hydrogen production by steam high-temperature reforming of methanol and preparation method and application of catalyst

A reforming hydrogen production and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the unfavorable development needs, large Cr consumption, Non-environmental protection and other issues, to achieve the effects of environmental protection, low consumption, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of catalyst for producing hydrogen by methanol steam reforming at high temperature described in this embodiment, its preparation method is:

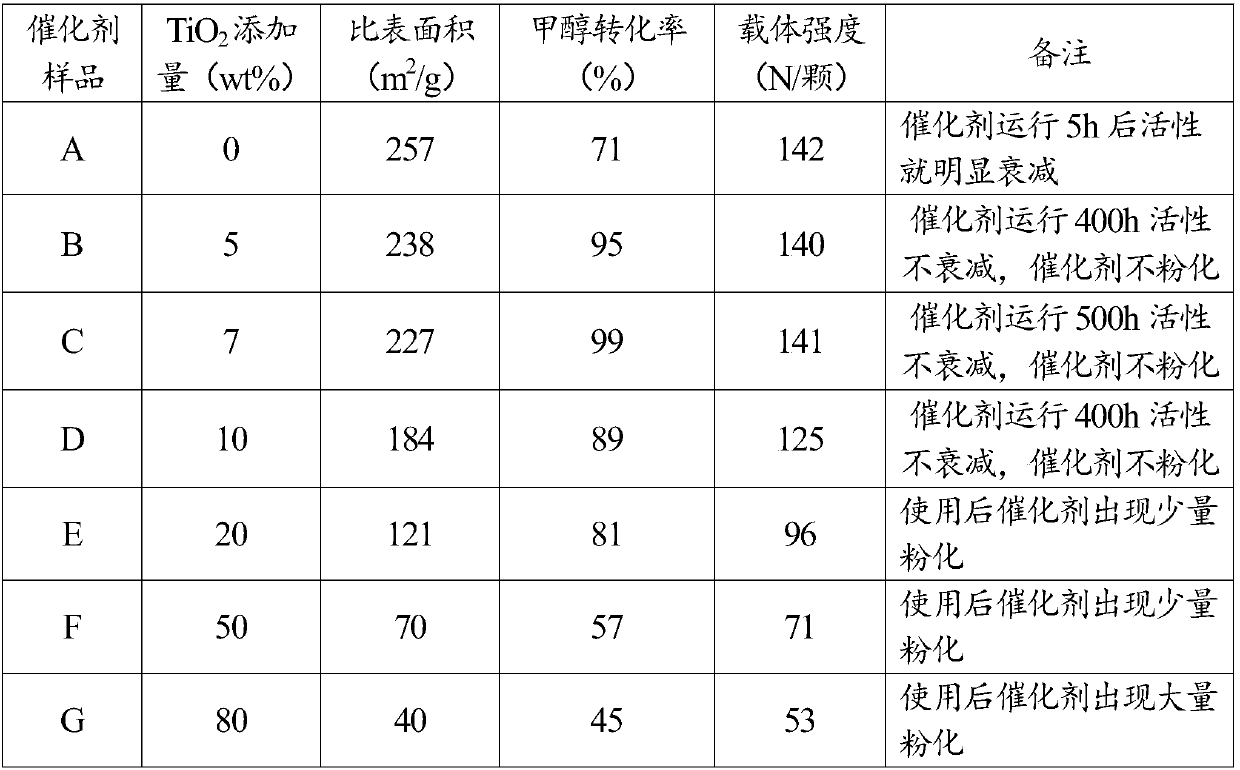

[0022] (1) Mix aluminum hydroxide, titanium dioxide and cellulose with a mass ratio of 85:6:1.5 and ball-mill, add water after ball-milling, mix evenly and granulate, then prepare a spherical carrier, and cure the spherical carrier with steam until the strength reaches 120N / pcs or more, calcined at 500 °C for 2 h to obtain TiO 2 / Al 2 O 3 carrier;

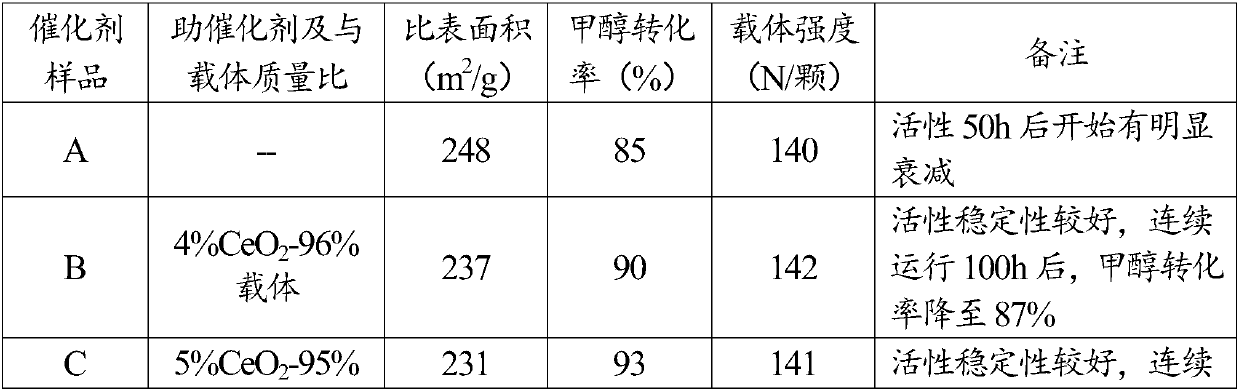

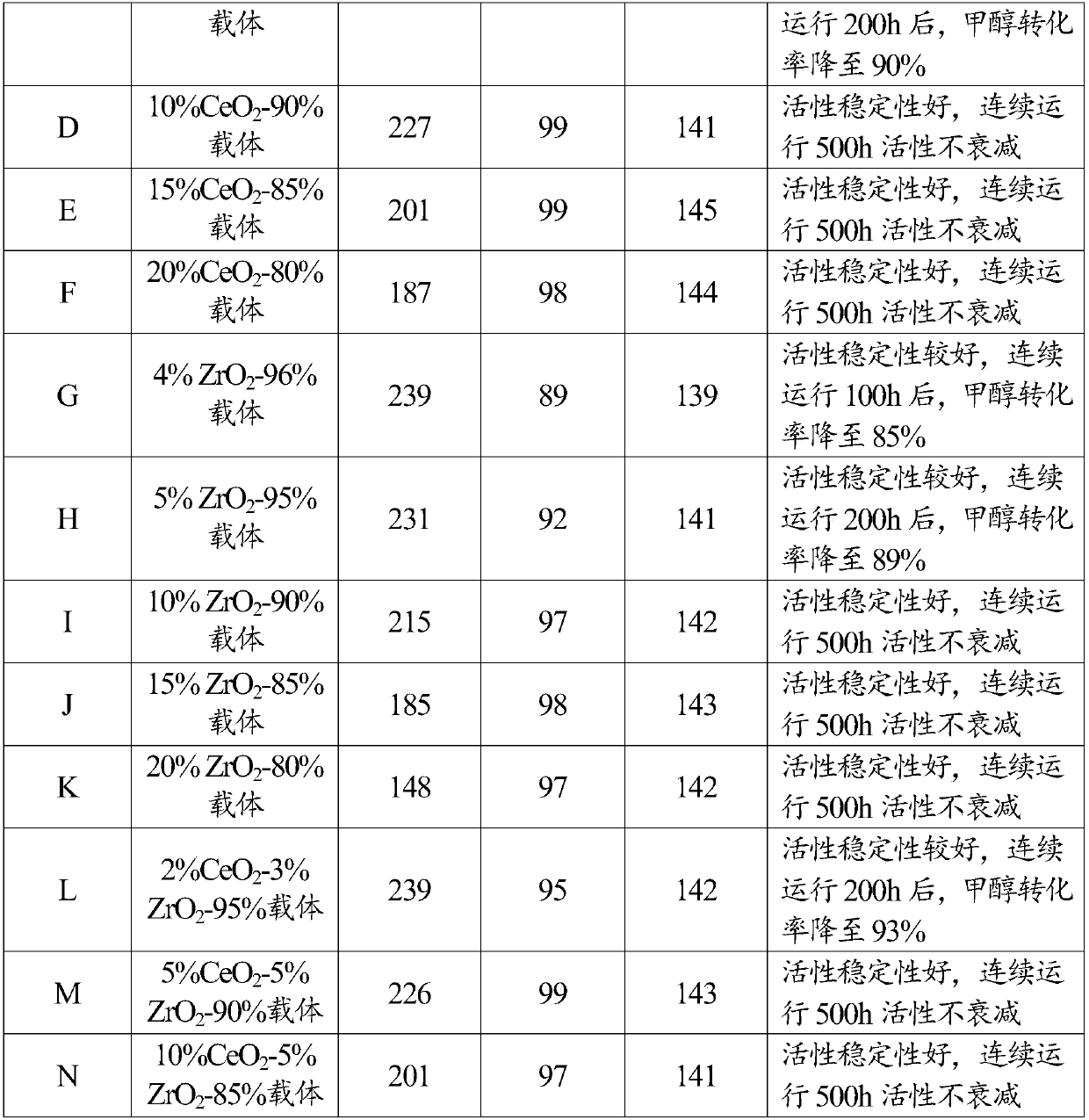

[0023] (2) prepare a cerium nitrate solution according to the final oxide content, the total concentration of the mixed solution of the metal nitrate salt is 2mol / L, and the TiO described in step (1) is mixed under the condition of 70°C. 2 / Al 2 O 3 The carrier is immersed in the metal nitrate solution, and the immersion time is controlled at 45 minutes. After the immersion is completed, it is dried at 160 °C for 4 hours, then calcined at 450 °C for 6 hours and then placed...

Embodiment 2

[0028]A kind of catalyst for producing hydrogen by methanol steam reforming at high temperature described in this embodiment, its preparation method is:

[0029] (1) Mix aluminum hydroxide, titanium dioxide and cellulose with a mass ratio of 90:8:3 and ball-mill, add water after ball-milling and mix evenly and granulate, then prepare a spherical carrier, and cure the spherical carrier with steam until the strength reaches 120N / pcs or more, calcined at 700 °C for 6 h to obtain TiO 2 / Al 2 O 3 carrier;

[0030] (2) The cerium nitrate solution is prepared according to the final oxide content, the total concentration of the mixed solution of metal nitrate salt is 1.5mol / L, and the TiO2 described in step (1) is mixed at 50°C. 2 / Al 2 O 3 The carrier is immersed in the metal nitrate solution, and the immersion time is controlled at 30 minutes. After the immersion is completed, the carrier is dried at 120 °C for 2 hours, then calcined at 400 °C for 3 hours and then placed to co...

Embodiment 3

[0035] A kind of catalyst for producing hydrogen by methanol steam reforming at high temperature described in this embodiment, its preparation method is:

[0036] (1) Mix aluminum hydroxide, titanium dioxide and cellulose with a mass ratio of 88:7:2 and ball-mill, add water after ball-milling and mix evenly and granulate, then prepare a spherical carrier, and cure the spherical carrier with steam until the strength reaches 120N / pcs or more, then calcined at 600 °C for 4 h to obtain TiO 2 / Al 2 O 3 carrier;

[0037] (2) The cerium nitrate solution is prepared according to the final oxide content, the total concentration of the metal nitrate mixed solution is 3 mol / L, and the TiO described in step (1) is mixed at 90° C. 2 / Al 2 O 3 The carrier is immersed in the metal nitrate solution, and the immersion time is controlled at 60 minutes. After the immersion is completed, it is dried at 120-200 °C for 2-6 hours, and then calcined at 550 °C for 10 hours and then placed to coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com