Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Guaranteed Solderability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

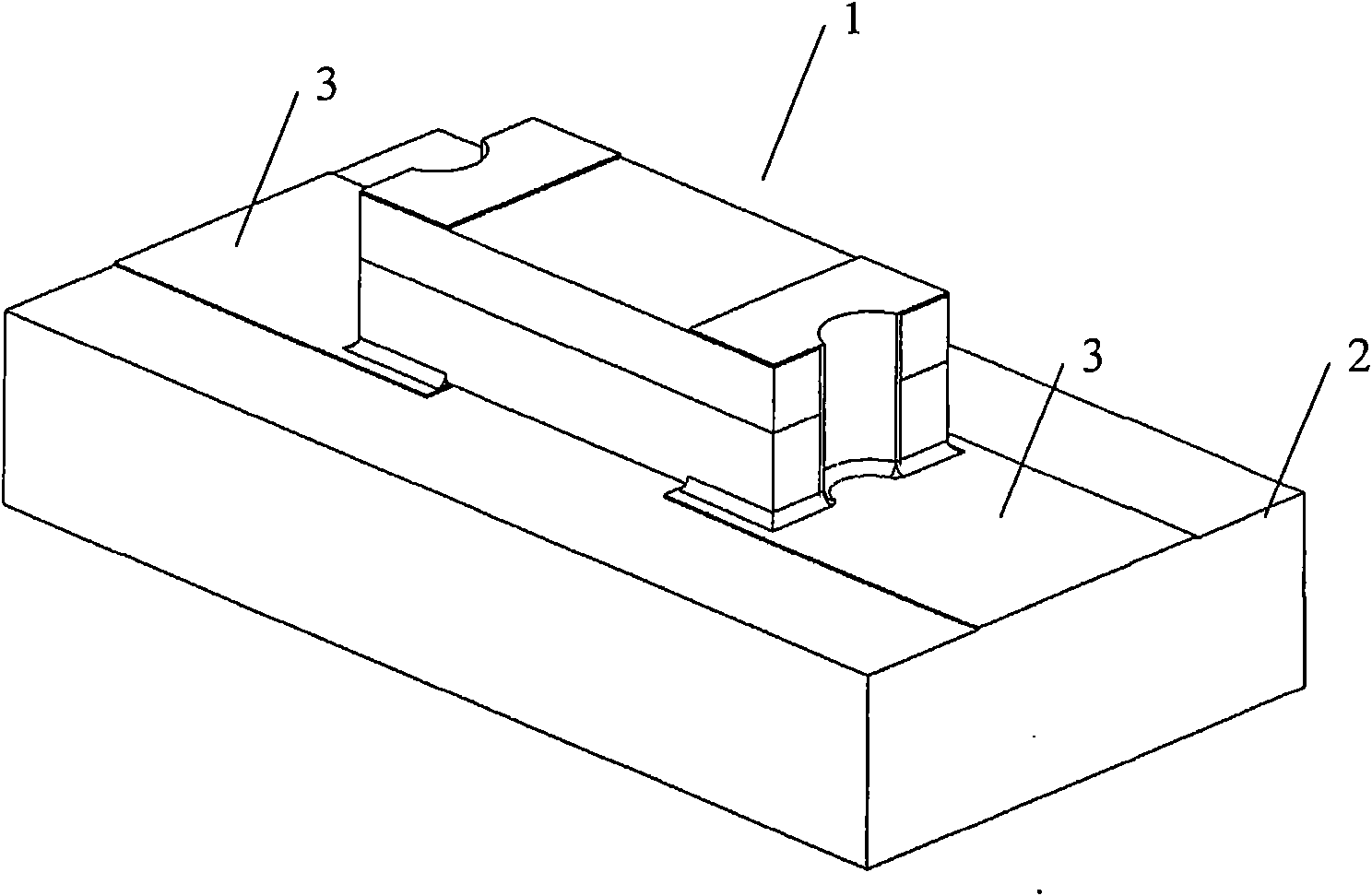

Surface mounting fuse protector and manufacturing method thereof

ActiveCN101567283AGuaranteed reliabilityGuaranteed SolderabilityFuse device manufactureBiochemical engineeringSurface mounting

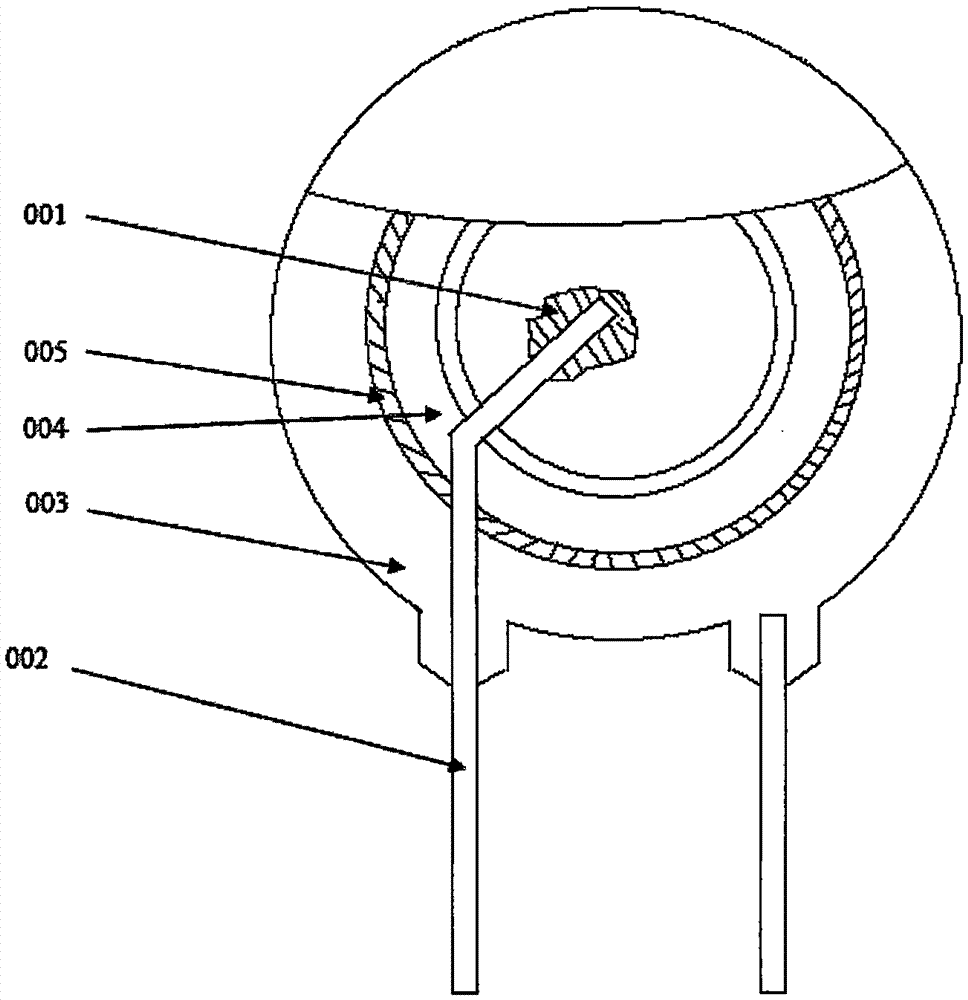

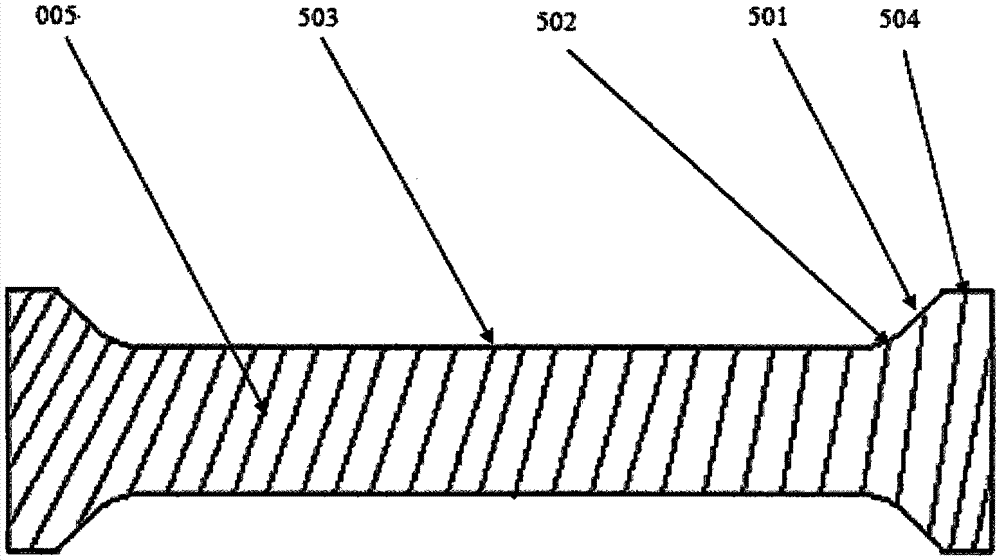

The invention provides a surface mounting fuse protector and a manufacturing method thereof. The surface mounting fuse protector comprises an upper base plate, a lower base plate and a fuse wire, wherein one end of the outer side of the upper base plate is provided with a first end electrode, the other end of the same is provided with a second end electrode, and the middle of the inner side of the upper base plate is provided with a first recessed cavity; one end of the outer side of the lower base plate is provided with a third end electrode corresponding to the first end electrode, the other end of the same is provided with a fourth end electrode corresponding to the second end electrode, the middle of the inner side of the lower base plate is provided with a second recessed cavity corresponding to the first recessed cavity, and the first recessed cavity and the second recessed cavity together form a cavity; the fuse wire is clamped between the upper base plate and the lower base plate, a part of the fuse wire is suspended in the cavity, the first end electrode and the third end electrode are electrically connected with one end of the fuse wire, and the second end electrode and the fourth end electrode are electrically connected with the other end of the fuse wire. The wire suspending type surface mounting fuse protector reduces the heat transfer rate of the fuse wire at the periphery, is simple in structure and has the low stress of the fuse wire.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

Plane button type packing technology of integrated circuit or discrete component and its packing structure

ActiveCN1725460ASmooth productionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

This invention relates to a plane salient point encapsulation technology and its structure of IC or discrete components, among which, the technology includes: taking a base plate, dry-film layers are pasted to the front and back side of the base plate, removing part of the upper layer for the preparation of forming a basic island and pins, plating metal layers on the front, removing the rest dry film on the upper layer of the base plate, semi-etching it, removing the dry film on the back, implanting the chip, wiring, packaging with plastic capsule, pasting a dry film on the back of the base plate again, etching the dry film at the back and the rest of the metal of the semi-etched zone again so as to enable the back of the basic island and the pin projecting over the plastic capsule, removing the rest dry film, plating metal layers on the surface, pasting film on the front of the plastic capsule then cutting.

Owner:长电科技管理有限公司

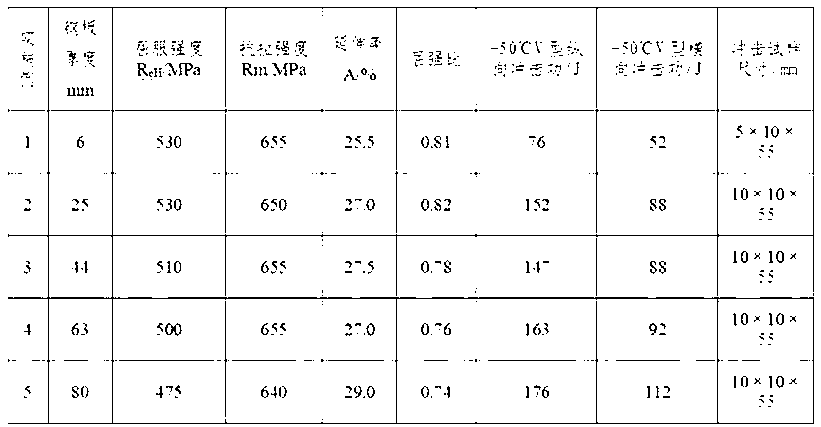

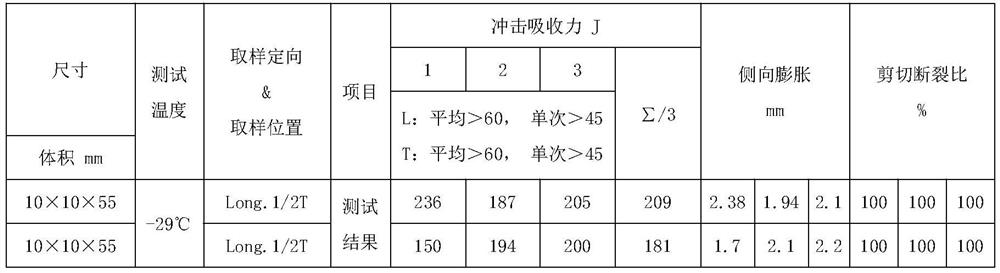

High-strength Q420C level steel tower corner iron and production process

The invention relates to a high tensile Q420C level angle iron applied to pylons and a manufacturing technique thereof, belonging to the technical field of steel making and aiming at improving 0 DEG C ballistic work of the angle iron applied to power system pylons. The angle iron is characterized in that mixture ratio of chemical compositions thereof is as follows: C: 0.01-0.16%, Mn: 1.15-1.45%, Si: 0.30-0.50%, S, P: less than or equal to 0.025%, V: 0.070-0.100%, Ti: 0.004-0.010%, and the balance of Fe and Ceq: less than or equal to 0.42%. In the manufacturing technique of the invention, VN microalloying mode of production is applied to steel making, ferrotitanium is added after deoxidation and alloying, Ca wire is fed to bale liquid steel prior to continuous casting and controlled rolling and cooling is carried out in the rolling process. Measurement indicators show that the steel of the invention meet the requirements for high strength, high impact ductility and 0 DEG C impact ductility; applied to manufacturing of power transmission and transformation pylons, the angle iron of the invention, while not reducing self weight of the pylons, improves safety factor of the pylons when being used in a low temperature environment.

Owner:HEBEI IRON AND STEEL

Lead-free tin-based solder for solar photovoltaic module and preparation method thereof

InactiveCN103801853AImprove wettabilityReduce performance degradationWelding/cutting media/materialsSoldering mediaIndiumSurface oxidation

The invention provides lead-free tin-based solder for a solar photovoltaic module. The lead-free tin-based solder comprises, by mass, stibium 0.05 percent-0.15 percent, silver 0.01 percent-0.05 percent, copper 0.1 percent-0.4 percent, indium 0.01 percent-0.05 percent, bismuth 0.2 percent-0.5 percent, gallium 0.06 percent-0.10 percent, phosphorus 0.02 percent-0.09 percent and the balance tin and inevitable impurities. The invention further provides a manufacturing method of the lead-free tin-based solder. The manufacturing method comprises the step that stibium, silver, copper, indium, bismuth, gallium, tin and phosphorus are placed into a smelting furnace according to the mass percentage and are smelted in an inert atmosphere or a vacuum condition, and the lead-free tin-based solder for the solar photovoltaic module is obtained. According to the lead-free tin-based solder for the solar photovoltaic module, melting temperature is low, surface gloss is good, surface oxidation resistance is high, wetting performance is good, and welding quality is superior. Besides, the lead-free tin-based solder is economical, environmentally friendly and free of threat to human health, thereby being applicable to large-scale industrial production.

Owner:THE NORTHWEST MACHINE

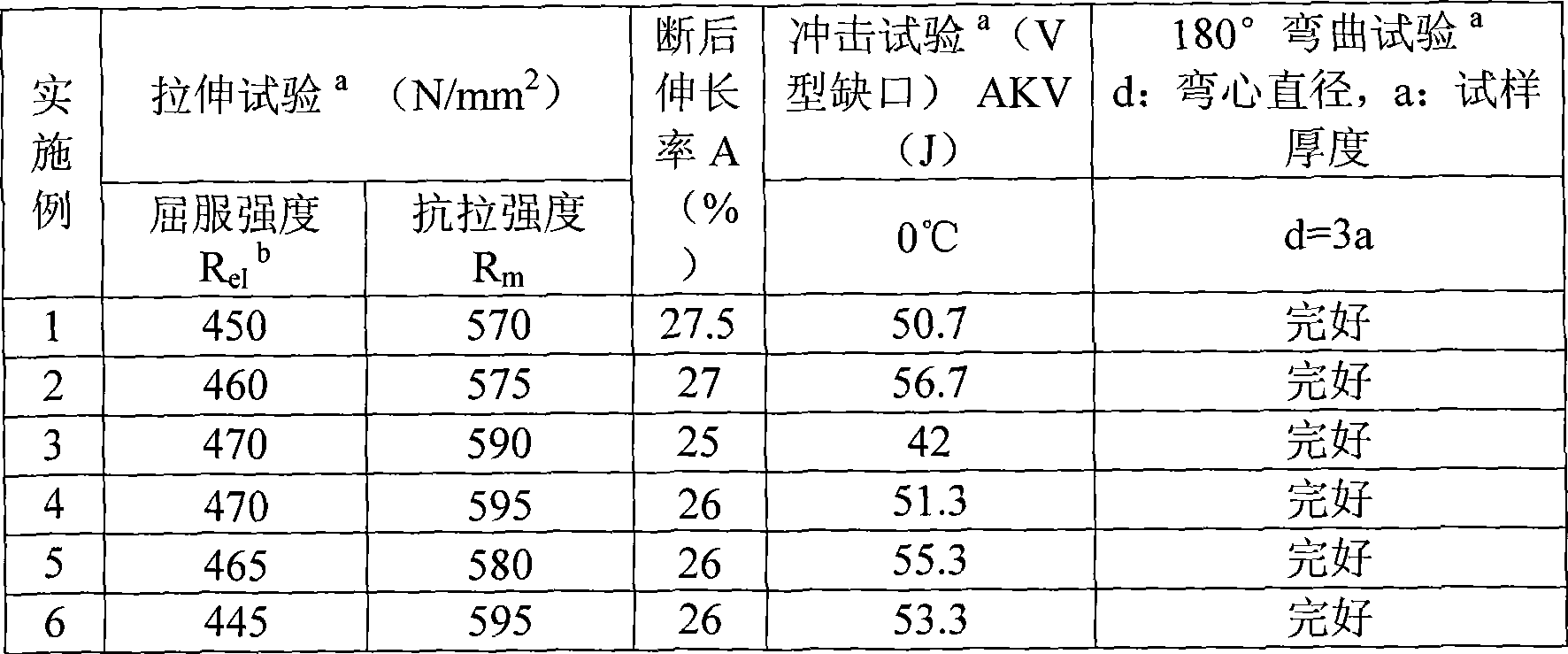

High-toughness normalizing steel plate with 460MPa yield strength and manufacturing method thereof

ActiveCN102719737BFine grainSpread evenlyHeat treatment process controlSheet steelChemical composition

The invention relates to the technical field of manufacture of medium steel plates, and discloses a high-toughness normalizing steel plate with 460MPa yield strength and a manufacturing method thereof. The high-toughness normalizing steel plate comprises the following chemical components by weight percent: 0.14%-0.20% of C, 0.20%-0.60% of Si, 1.20%-1.70% of Mn, 0.12%-0.20% of V, 0.15%-0.40% of Ni, 0.005%-0.020% of N, 0.005%-0.040% of Alt, less than or equal to 0.015% of P, less than or equal to 0.005% of S, and the balance of Fe and inevitable impurity. The manufacturing method disclosed by the invention comprises the steps of: heating a continuous casting blank to be at 1210-1240 DEG C by using a controlled rolling process and a normalizing process; controlling the total heating time according to 1.0-1.2min / mm; adopting a two-stage rolling mode, and controlling the initial rolling temperature of a non-recrystallization zone to be at 850-920 DEG C, and controlling the finishing temperature to be at 780-840 DEG C; carrying out air cooling after rolling; and controlling the normalizing temperature of the steel plate to be at 880-920 DEG C, and controlling the heat preservation time for 15-40 minutes. According to the high-toughness steel plate manufactured by using the method, the quality is stable, the performance is good and the production cost is low.

Owner:XINYU IRON & STEEL CO LTD

Butt mag welding method of low-alloy ultra-high-strength steel and high-quality carbon structural steel after quenching

ActiveCN102267000AWell formed weldReduce welding start and end pointsArc welding apparatusWelding/soldering/cutting articlesCarbon steelCrazing

The invention relates to a metal active gas (MAG) welding method for butting quenched low-alloy super-high-strength steel and high-quality carbon structural steel and a low-alloy super-high-strength steel MAG welding method, which solve the welding technical problems that the thickness difference and the material performance difference of heterogeneous steel, namely the quenched low-alloy super-high-strength steel and the high-quality carbon structural steel, are large and the weldability of the quenched super-high-strength steel is low. The MAG welding method comprises the following main steps of: machining a part to be welded; quenching and tempering a 35CrMnSiA barrel piece; preheating, tacking and welding; and slowly cooling the 35CrMnSiA barrel piece; and detecting the 35CrMnSiA barrel piece. By the MAG welding method, the weldability of the quenched super-high-strength steel and the carbon structural steel is enhanced; fusion of a welding line is high; and through penetrant flawdetection and coloring flaw detection, the most sensitive crack defects of the super-high-strength steel are not found in a welding bead and a heat affected zone, so the shape of the welding line is good. The MAG welding method belongs to semi-automatic welding; and compared with manual arc welding, the MAG welding method has the advantages of reducing arc striking points and arc receiving points, so that welding defects can be reduced effectively.

Owner:HARBIN JIANCHENG GRP

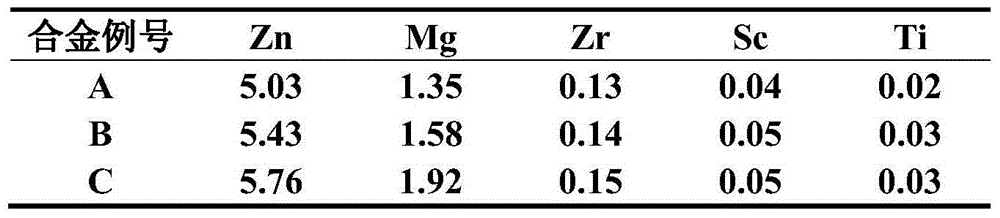

High-strength weldable aluminum alloy for vehicle bodies and preparation method thereof

The invention relates to the technical field of non-ferrous metals, in particular to a high-strength weldable aluminum alloy for vehicle bodies and a preparation method thereof. The alloy comprises: 4.8-6.6wt.% of Zn, 1.0-2.0wt.% of Mg, 0.08-0.16wt.% of Zr, 0.03-0.06wt.% of Sc, 0.01-0.03wt.% of Ti, less than 0.15wt.% of Fe, less than 0.15wt.% of other unavoidable impurity elements, each of which is not less than 0.05wt.%, and the balance Al. The preparation method consists of: subjecting a cast ingot obtained by semicontinuous casting to uniform annealing at 200-220DEG C for 2h, then conducting furnace heating to 470-480DEG C and performing thermal insulation for 8h, then conducting hot extrusion and online water-crossing quenching, then performing heat preservation at 480-490DEG C for 1-3h, and conducting solution treatment, performing water quenching, then carrying out heat preservation at 130-160DEG C for 12-24h and conducting aging treatment. By adding elements Zr, SC and Ti, a lot of Al3Zr(Sc, Ti) dispersed phase is generated in the alloy to play a role of inhibiting recrystallized grains from nucleating and growing and obstructing dislocation migration, thereby obtaining excellent strength and toughness. The high-strength weldable aluminum alloy can be suitable for production of high-strength light structural parts for vehicle bodies.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD

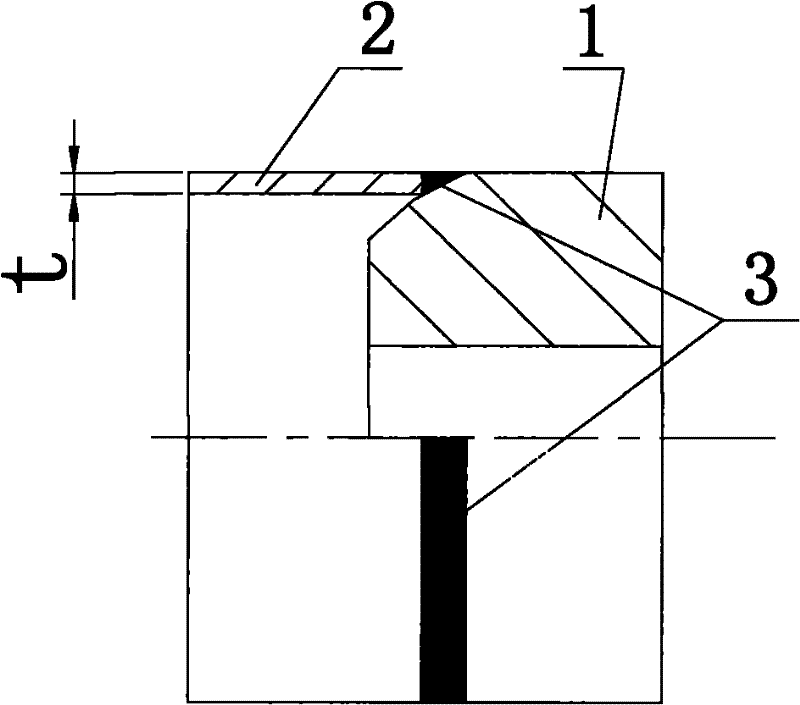

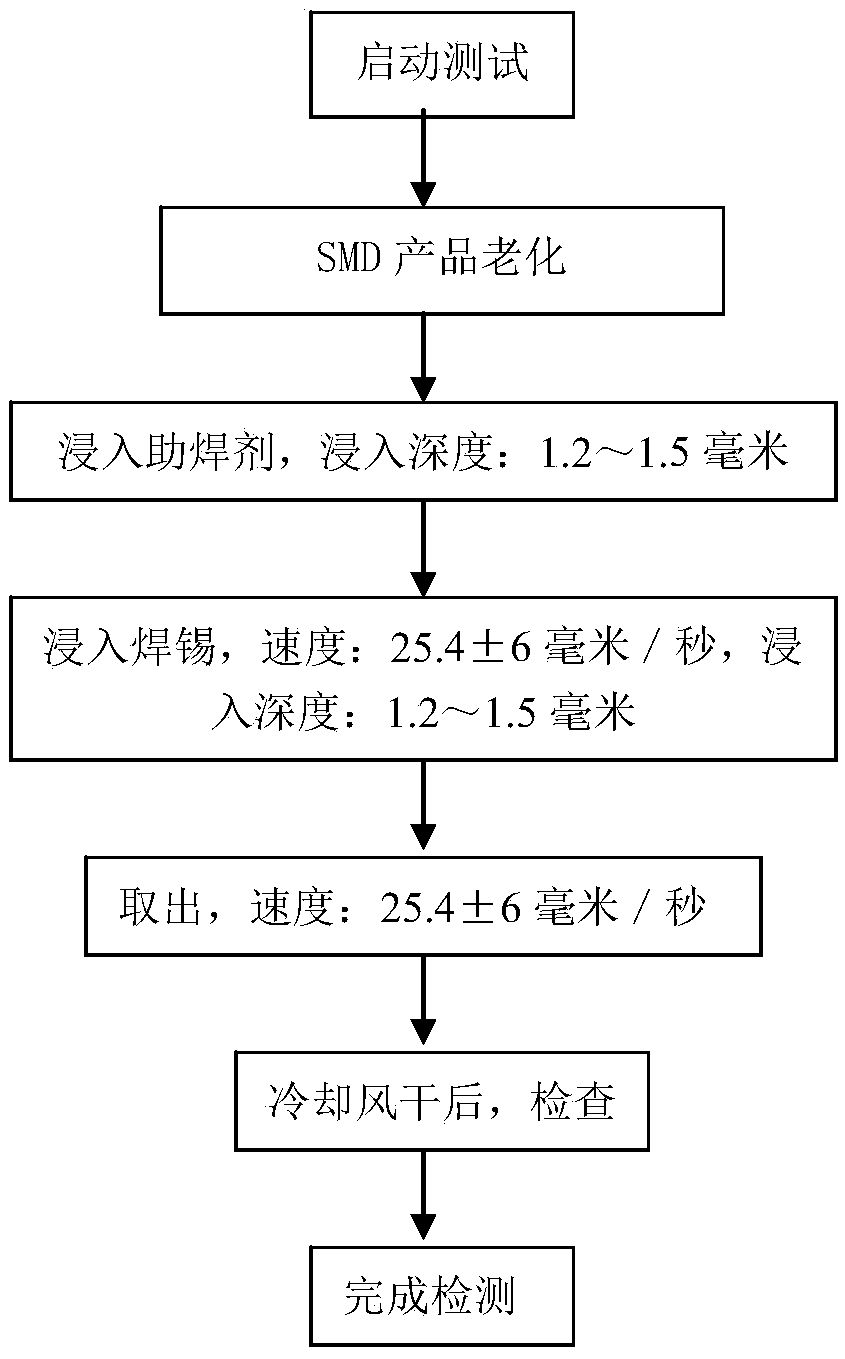

Method for testing weldability of SMD (Surface Mounted Device) product

InactiveCN105499822AGuaranteed SolderabilityReduce testing costsWelding/soldering/cutting articlesMetal working apparatusSurface mountingSolderability

The invention discloses a method for testing the weldability of an SMD (Surface Mounted Device) product. After the SMD product is subjected to steps of ageing, immersing in flux, immersing in soldering tin and drying with air, the weldability of the product is judged by observing a covering degree of a tin layer on the surface of the product. The method is simple and direct, expensive detection equipment does not need to be purchased, and thus the weldability of the SMD product is guaranteed while the detection cost is greatly reduced.

Owner:GUILIN STRONG MICROELECTRONICS

Chemical silver plating solution for surface treatment of printed circuit board (PCB)

InactiveCN109423635AUniform thicknessGuaranteed SolderabilityLiquid/solution decomposition chemical coatingSilver plateCopper wire

The invention discloses a chemical silver plating solution for the surface treatment of a printed circuit board (PCB). The chemical silver plating solution (1L) comprises following raw materials by weight: 10 to 100 grams of complexing agent, 0.1 to 3.0 grams of Cu<2+>, 0.5 to 15 grams of surfactant, 0.1 to 5.0 grams of copper antioxidant, 0.4 to 1.0 gram of silver ion, enough nitric acid, which can adjust the pH of the silver plating solution to 0.08-0.3, and the balance being distilled water. The chemical silver plating solution can form a silver layer on the copper circuits on a printed circuit board; the thickness of the silver layer is uniform and is in a range of 0.15 to 0.3 millimeter; after the surface treatment, other elements can still be welded on the PCB; the color is not changed after five times of reflow soldering; less than 10% of the thickness of copper layers of copper wires is corroded; and the processed PCB will not be corroded and the color will not change after thePCB is placed in neutral salt fog for 24 hours.

Owner:深圳市虹喜科技发展有限公司

Lead frame for semiconductor packaging and preparation method thereof

PendingCN112530896AGood weldabilityImprove product qualification rateSemiconductor/solid-state device detailsSolid-state devicesEtchingEngineering

The invention belongs to the technical field of semiconductor devices, and particularly relates to a lead frame for semiconductor packaging and a preparation method thereof. The lead frame comprises aframe body and an electroplating layer, the upper surface of the frame body is provided with a plurality of micro-etching grooves, each micro-etching groove is filled with the electroplating layer, and the thickness of the electroplating layer is the same as that of each micro-etching groove. According to the lead frame disclosed by the invention, the concave micro-etching grooves are formed in the frame body in a mode of first micro-etching and then electroplating, so that the electroplating layer is formed in the micro-etching grooves, and through reasonable control of micro-etching and electroplating processes, the thickness of the lead frame can be reduced, the thinning production of semiconductor packaging is facilitated, the effect of protecting the electroplating layer can also beachieved, and therefore, the weldability and the product percent of pass can be better ensured.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Dual-concave high-voltage ceramic capacitor and manufacturing process thereof

InactiveCN106910626AReduced risk of tip dischargeHigh charge densityFixed capacitor electrodesFixed capacitor dielectricDielectric substrateCopper

The invention relates to a dual-concave high-voltage ceramic capacitor and a manufacturing process thereof. A ceramic dielectric substrate of the capacitor is shaped like a cylinder, two truncated cone-shaped gaps are formed in the cylinder, and then two concave portions are formed, that is to say, the thickness of the edge of the ceramic substrate is greater than that of the center. A transition surface with an arc line being the cross section is arranged between a round surface in the center of the ceramic substrate and a concave inclined surface of a truncated cone-shaped side surface. The ceramic substrate is provided with an electrode. The electrode is divided into three layers, wherein the top layer is tin alloy. The electrode is welded to a lead wire. Epoxy resin wraps the substrate, the electrode and part of the lead wire. The manufacturing process of the capacitor includes ceramic substrate manufacturing, electric polarization, lead wire welding, coating, printing, and testing. The electrode of the capacitor is manufactured through magnetron sputtering, and can be freely controlled in size. Through the design of the transition surface in the substrate concave parts, point discharge risks of the electrode are reduced, the over-voltage resistance of the capacitor is further improved, and the capacitor can become miniature. Through the design of a copper-tin alloy layer, the electrode can still be welded if part of the electrode is oxidized.

Owner:KUSN WANFENG ELECTRONICS

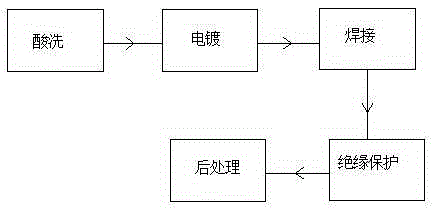

Production process for diodes

InactiveCN105428233ASave resourcesAvoid electrical degradationSemiconductor/solid-state device manufacturingSemiconductor devicesEnvironmental geologyElectroplating

The invention relates to a production process for diodes. The production process comprises five steps of acid washing, electroplating, welding, insulation protection and post-treatment. The production process for the diodes has the advantages that the steps of acid washing, welding and welding are performed in sequence; a chip is subjected to acid corrosion before welding, so that solders and metal impurities in lead wires are prevented from reacting with an acid liquid to influence a corrosive rate of the chip in the acid washing process; metal ions generated by reaction of metal and acid are prevented from being adhered to the surface of the chip, so that large amounts of washing processes are removed and resources are saved; the faults such as electric degradation and high-temperature thermal breakdown of a product are avoided, so that the electric yield of the product is increased; and meanwhile, the metal content of a discharged washing liquid is reduced and the soil pollution is alleviated, so that the environmental protection is facilitated.

Owner:RUGAO DACHANG ELECTRONICS

Low-melting-point and high-hardness lead-free solder and preparation method thereof

InactiveCN106514032AGuaranteed touch resistanceGuaranteed SolderabilityWelding/cutting media/materialsSoldering mediaHardnessImpurity

The invention relates to a low-melting-point and high-hardness lead-free solder and a preparation method thereof. The low-melting-point and high-hardness lead-free solder is prepared from the following raw materials in percentage by weight: 5 to 8 percent of Zn, 30 to 40 percent of Bi, 0.2 to 0.5 percent of Mg, 0.1 to 0.2 percent of In, 0.01 to 0.015 percent of grapheme, and the balance being Sn and inevitable impurities. According to the low-melting-point and high-hardness lead-free solder disclosed by the invention, by optimizing components of the raw materials and adding the Mg and the grapheme, the hardness of the solder is effectively improved, a melting point is reduced, and the solder is enabled to have good welding performance.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

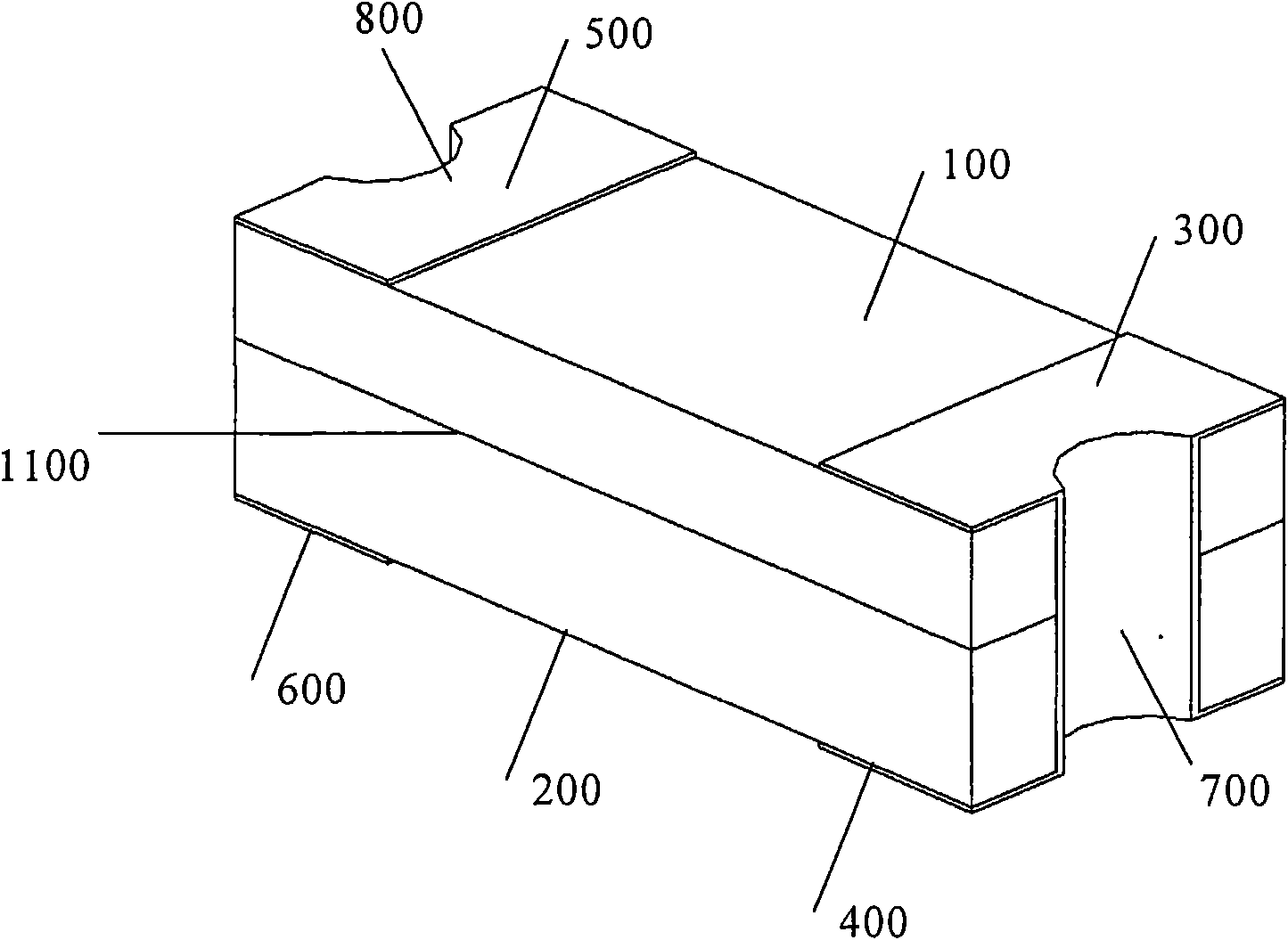

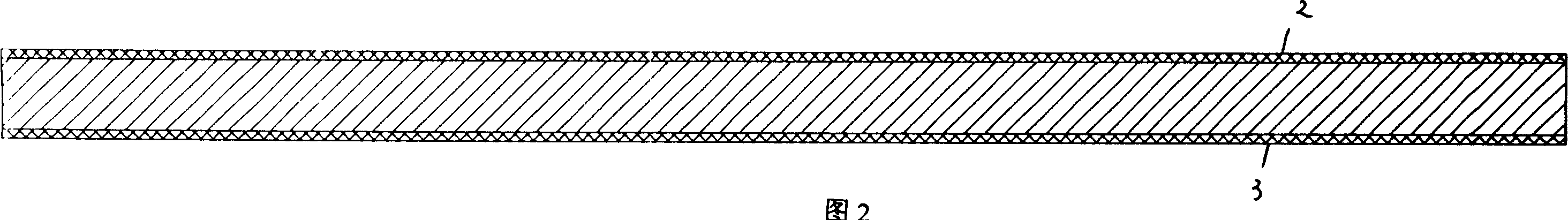

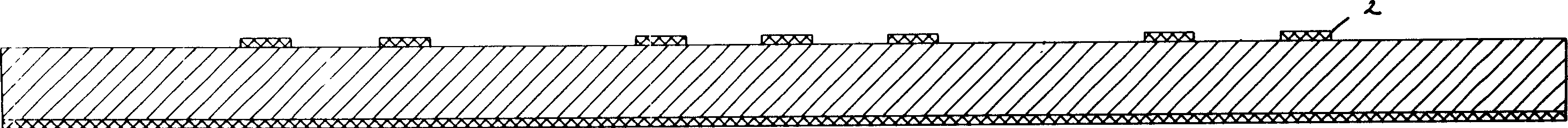

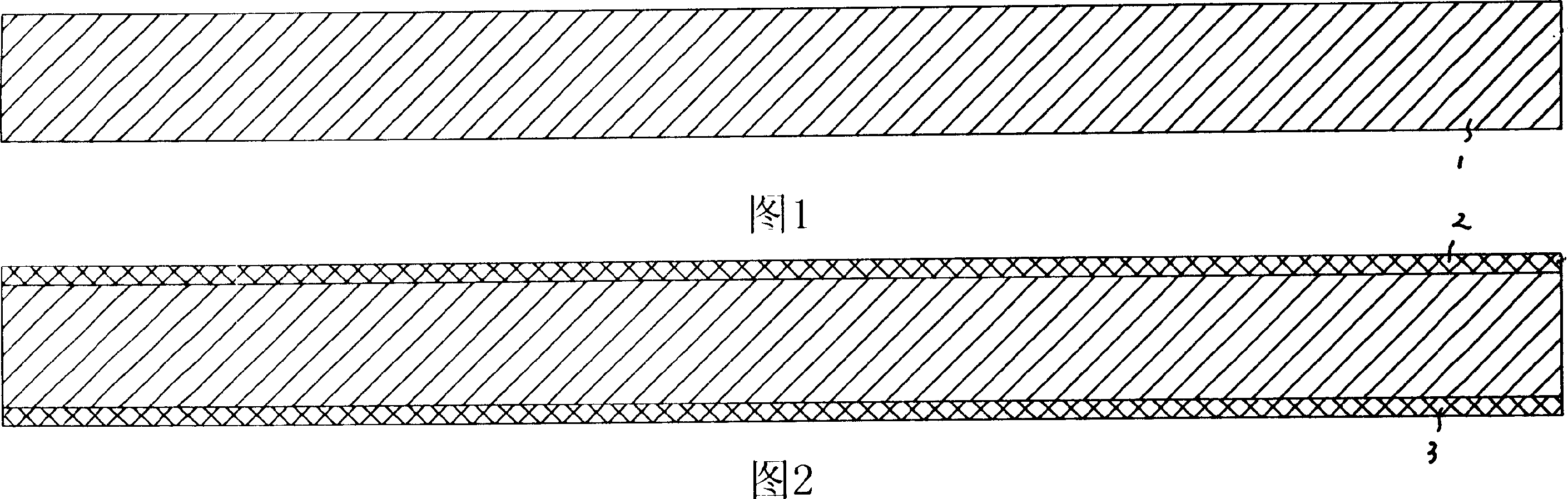

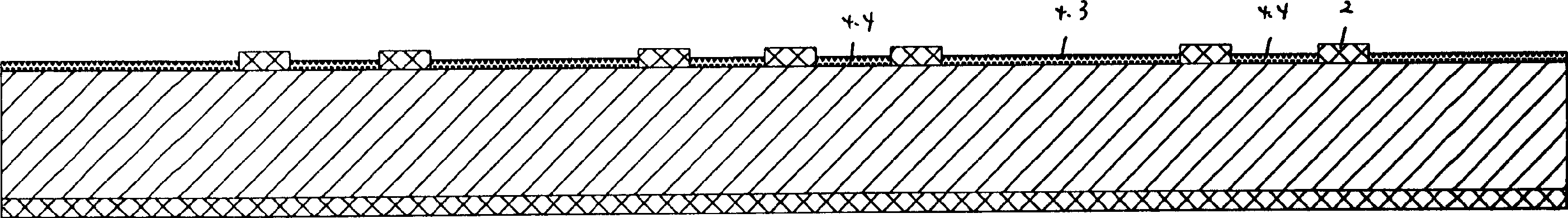

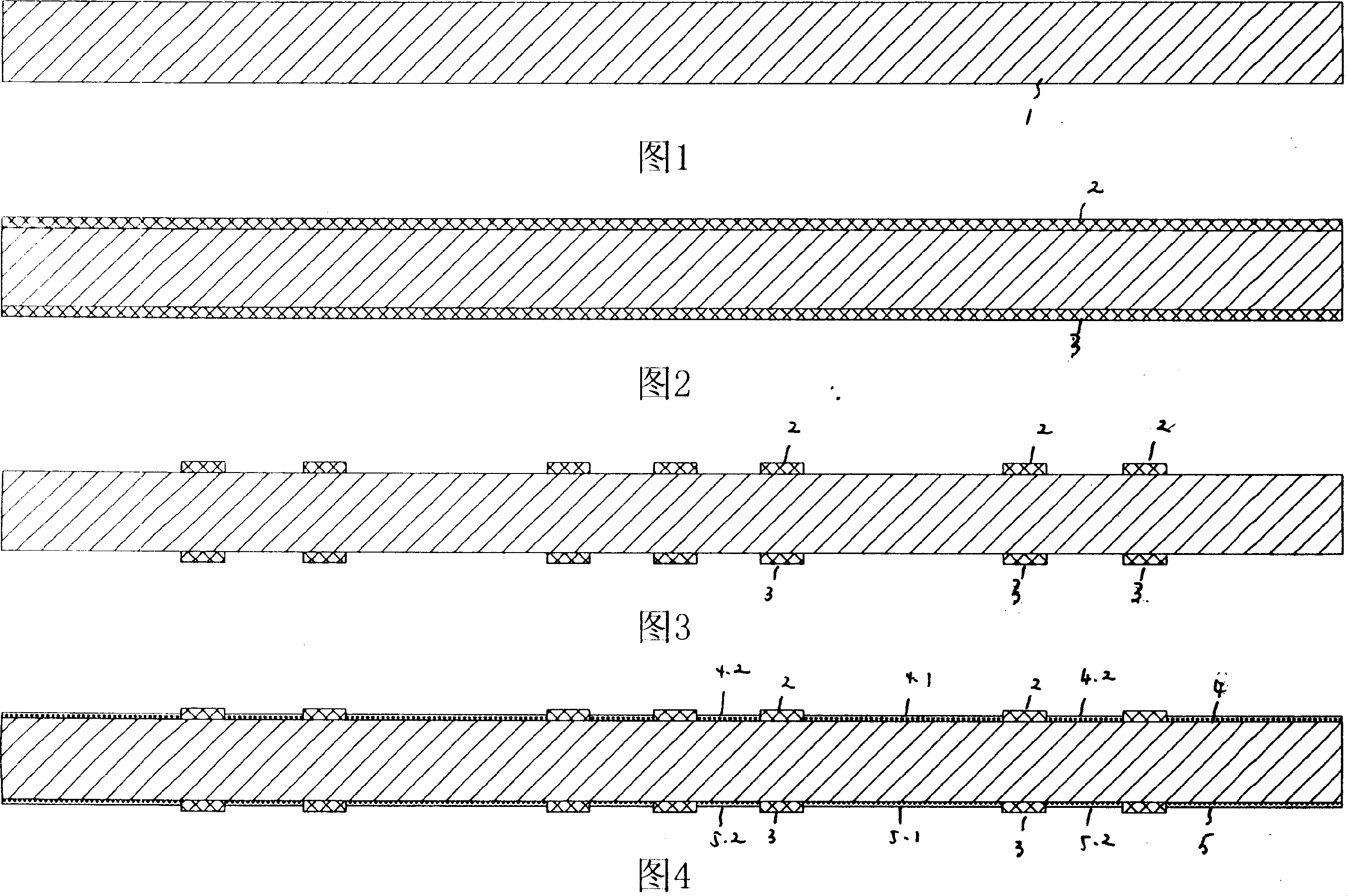

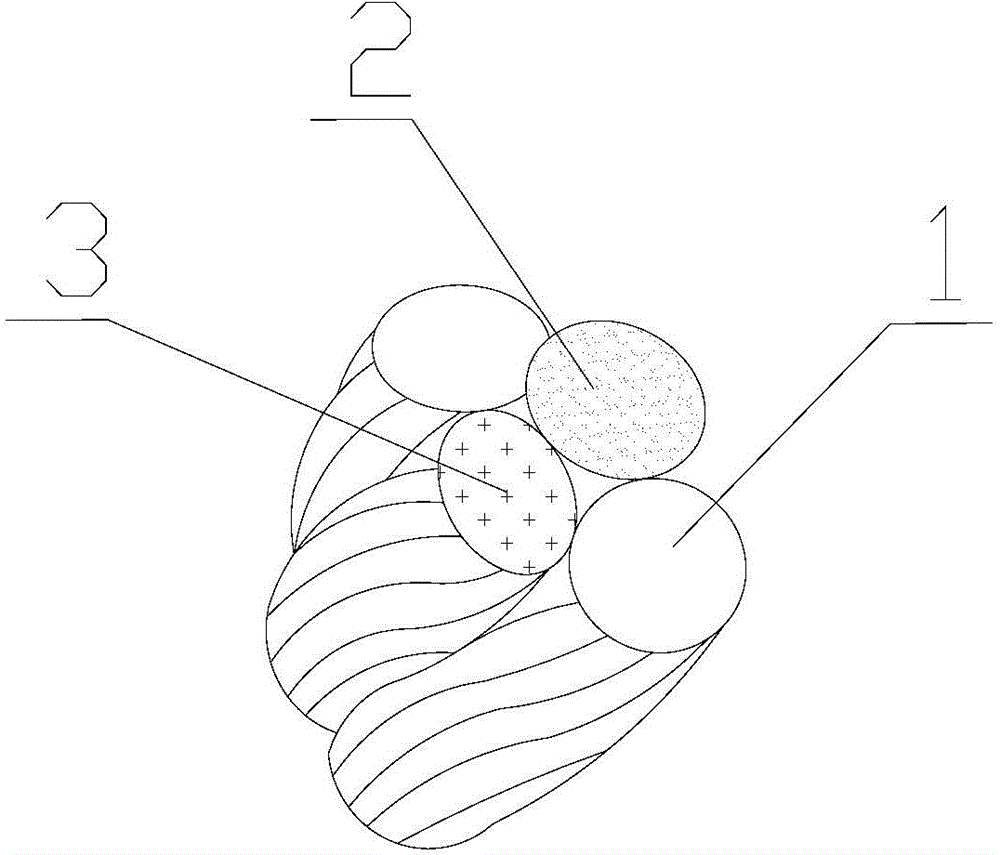

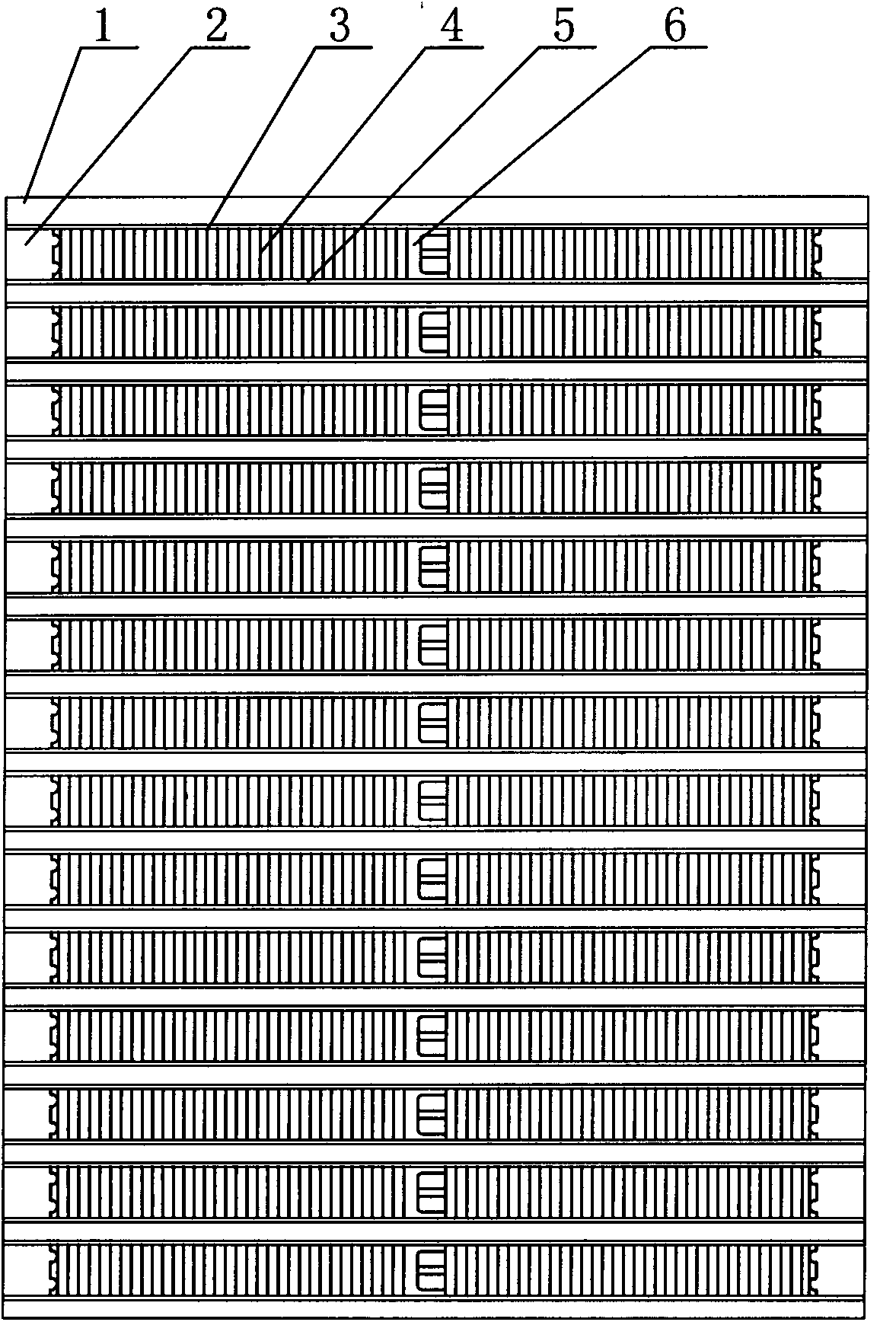

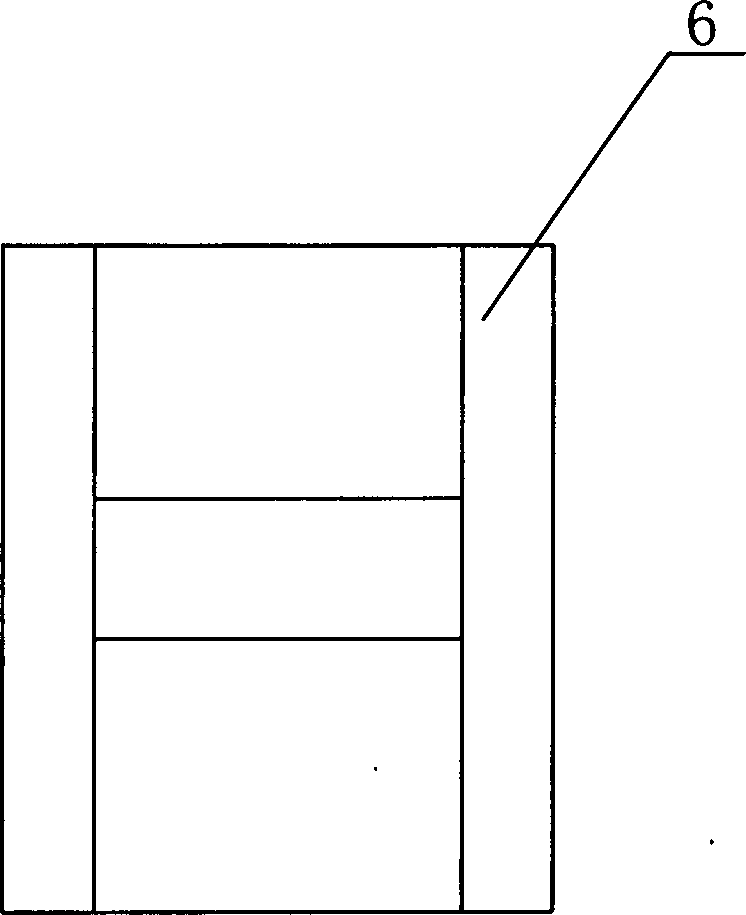

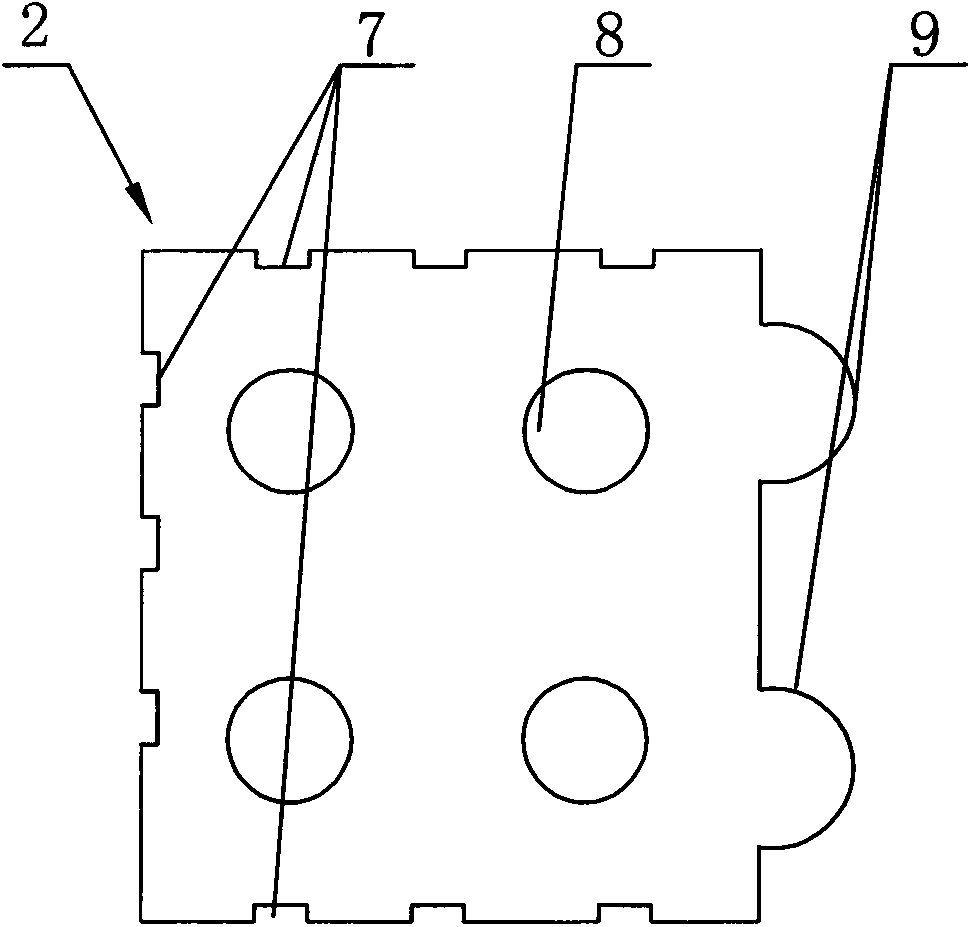

Novel integrated circuit or discrete component flat bump package technics and its package structure

ActiveCN1738015APrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a plane point-protruded type packaging process and its structure of new integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films of upper layer; preparing base island and pin; plating active compound (4.3, 4.4) and metallic layer (4.1, 4.2) on the face; removing the left dry film on the front of base plate; half etching, removing the dry film layer (3) left on the back of base plate; planting chip (6), tying metallic thread (7), packaging plastic packaging body (8), pasting dry film layer (10) again on the back of metal base plate (1); etching again on the metal of left part (1.4) and the dry film on the back of half etched region (1.3) to make the back surfaces of base island (1.1) and pin (1.2) protrude from plastic packaging body (8); removing left dry film and plating active compound (11.3, 11.4) and metallic thread (11.1, 11.2); pasting film (12) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

Flat bump package technics for integrated circuit or discrete component

ActiveCN100376021CPrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a plane point-protruded type packaging process and its structure of integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films relatively; plating active compound and metallic layer on the area of base plate for forming base island and pins; removing the left dry film on the front of base plate; half etching to form a depressed half etched region (1, 3), base island 1.1 and pin 1.2; removing the dry film left on the back of base plate; planting chip (9) into the front metal layer of base island, tie metallic thread (10), packaging plastic packaging body (11), front printing (12), and etching again on the left metal 1.4 of half etched region (1.3); pasting film (13) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

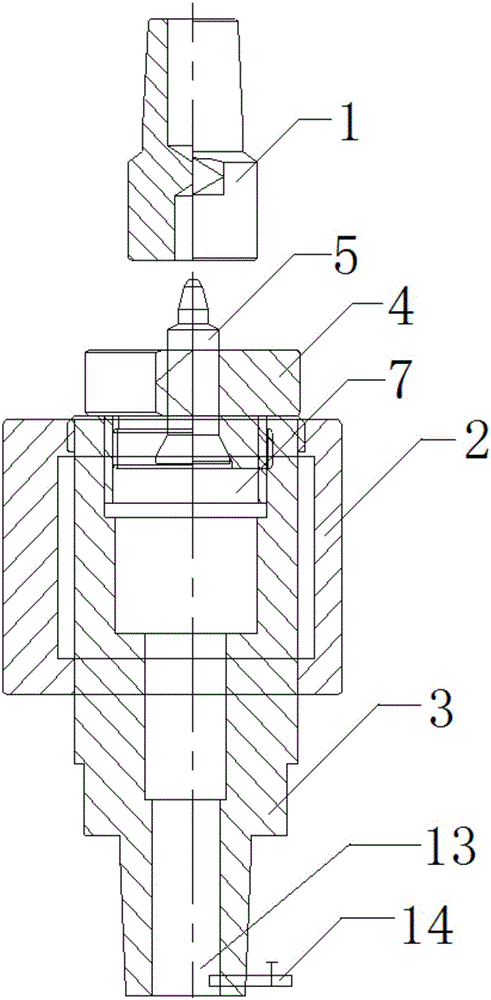

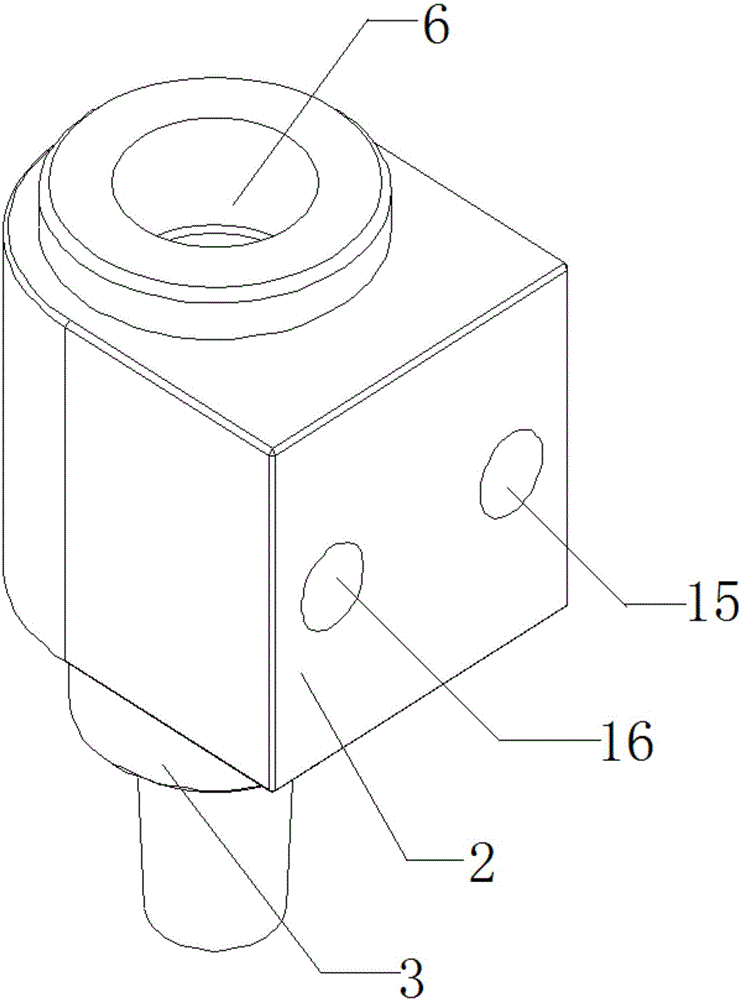

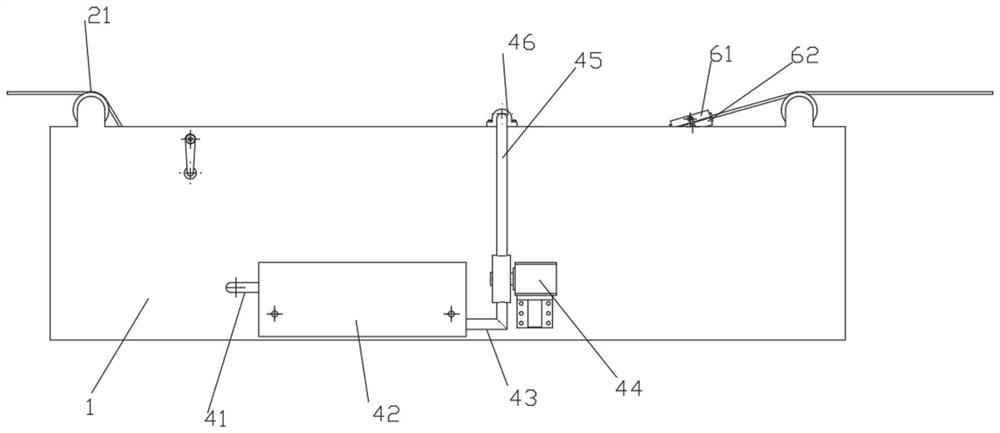

Electrode for projection welding of resistor

ActiveCN105057870AImprove cooling effectAvoid problems with poor coolingElectrode featuresCooling effectEngineering

The invention relates to an electrode for projection welding of a resistor. The electrode comprises an upper electrode assembly and a lower electrode assembly. The upper electrode assembly comprises an upper electrode body. The lower electrode assembly comprises a circulation water cooling block, an electrode holder, an electrode cover and a positioning pin. The circulation water cooling block is provided with a cooling hole, a connecting block is embedded in the cooling hole, and the top end of the electrode holder is embedded in one end of the cooling hole. The electrode cover comprises a cover body and a base, the base of the electrode cover is embedded in the other end of the cooling hole, and the top end of the electrode holder is connected with the base of the electrode cover through the connecting block. The positioning pin comprises a positioning body and a positioning head, the positioning body is embedded in the electrode cover, and the positioning head corresponds to the upper electrode body. By means of the electrode for projection welding of the resistor, the cooling effect of the electrode cover is improved, damage to the electrode holder is avoided, the use cost of the electrode assemblies can be saved, and management burden is relieved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

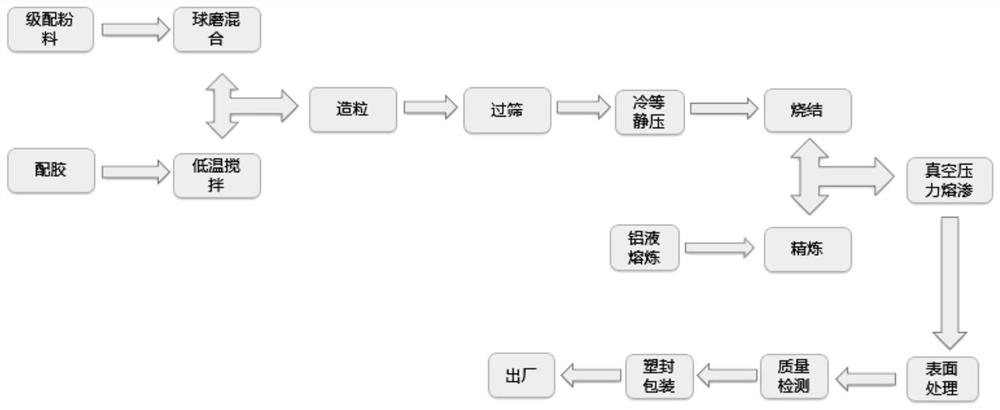

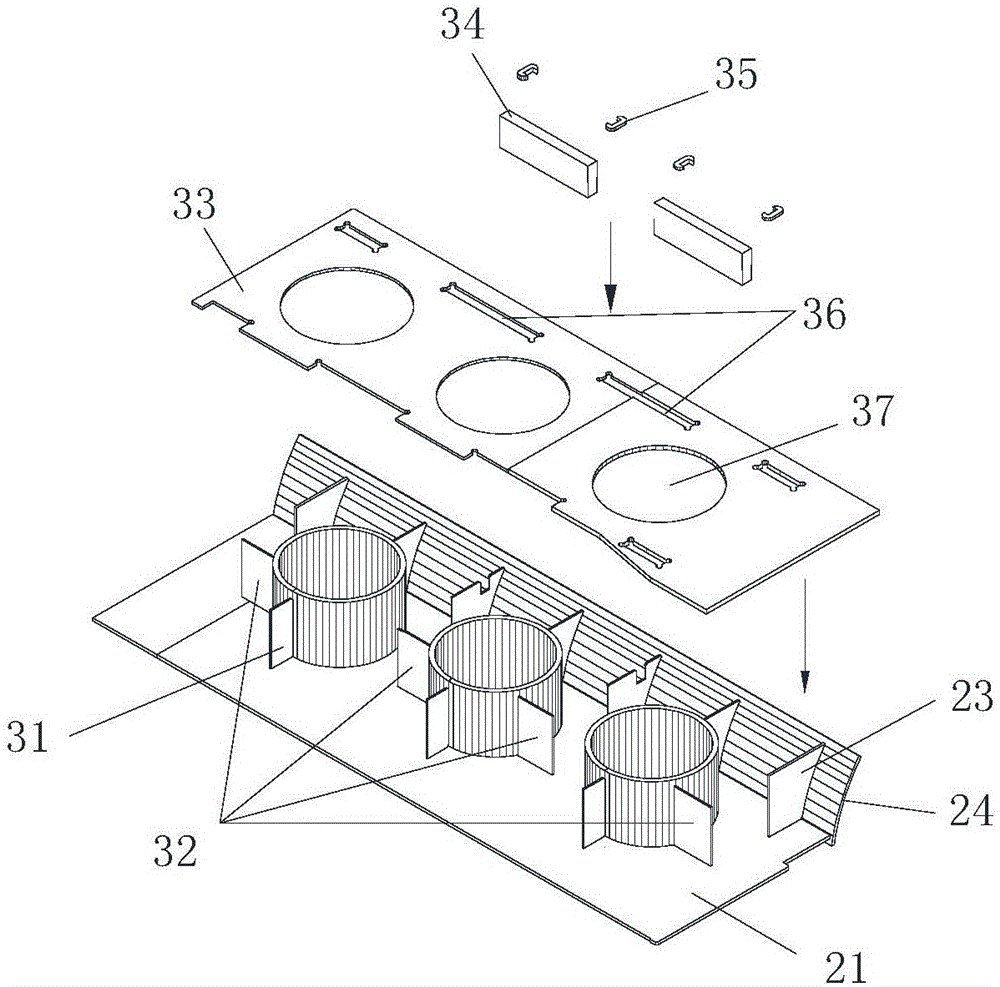

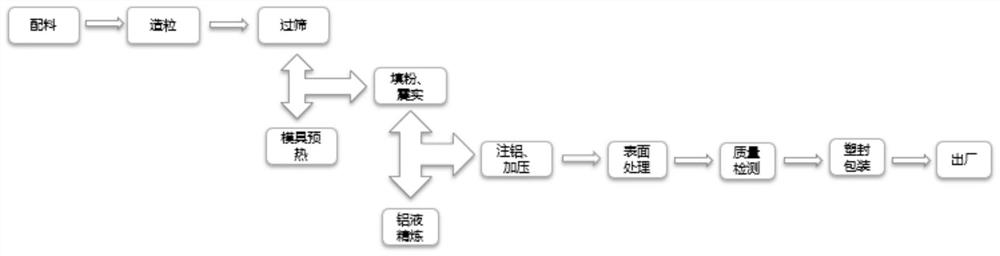

Aluminum silicon carbide high-power LED radiator and preparation method thereof

PendingCN113560541ASimple structureReduce consumptionFoundry mouldsFoundry coresCarbide siliconCeramic

The invention provides an aluminum silicon carbide high-power LED radiator and a preparation method thereof. The preparation method comprises the following steps: proportioning, ball-milling and mixing, granulating, and pretreating raw materials to obtain granulated powder; forming the granulated powder into a silicon carbide ceramic prefabricated part through a cold isostatic pressing technology; sintering the formed silicon carbide prefabricated part; smelting a ZL101A aluminum alloy to obtain an aluminum alloy melt; putting the silicon carbide ceramic prefabricated part into a steel mold through a vacuum pressure infiltration method, pressing molten aluminum alloy into pores of the silicon carbide ceramic prefabricated part by adopting high-pressure inert gas at a certain temperature in a vacuum environment, and carrying out heat treatment to prepare an aluminum silicon carbide casting; and carrying out surface metallization plating process treatment on an aluminum silicon carbide finished product to form the aluminum silicon carbide high-power LED radiator. The method overcomes the defects of complex process, expensive equipment, long production period and high energy consumption, has the advantages of compact products, excellent performance, simple operation and low cost, and is wide in application range.

Owner:珠海亿特立新材料有限公司

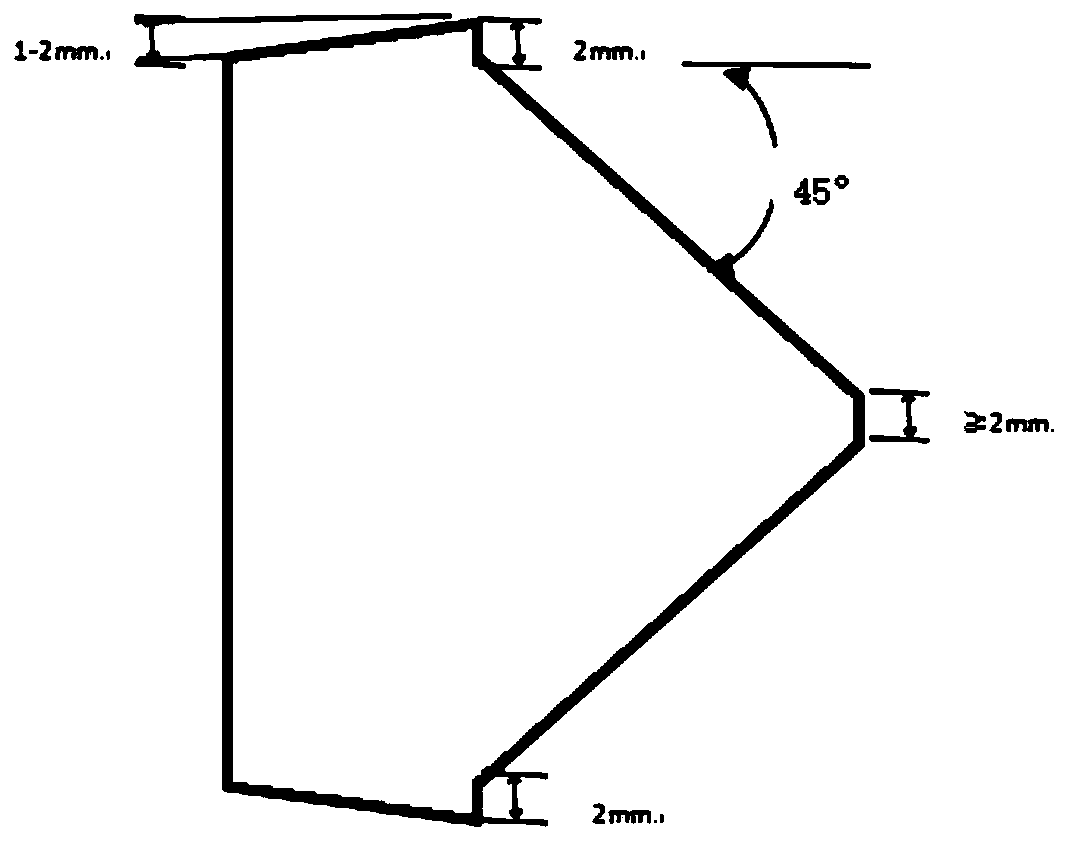

Symmetrical-hot-rolled composite plate blank and seal welding method thereof

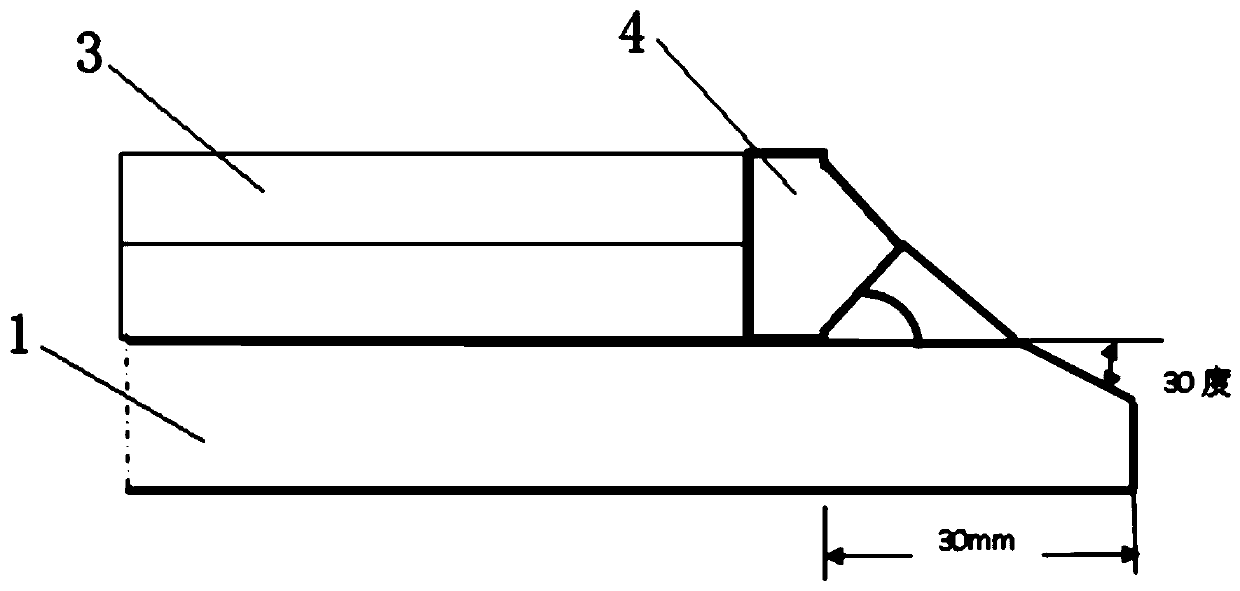

ActiveCN111299974ALower manufacturing requirementsReduce manufacturing difficultyLayered productsArc welding apparatusIsosceles trapezoidStructural engineering

The invention relates to a symmetrical-hot-rolled composite plate blank and a seal welding method thereof. An enclosure frame comprises two parts, the first part forms the inner side of the enclosureframe, and the cross section of the first part is an isosceles trapezoid; the second part forms the outer side of the enclosure frame, the cross section of the second part is trapezoidal, and the length of the lower bottom edge of the second part is smaller than the length of the lower bottom edge of the first part; a groove is formed in the side, close to the enclosure frame, of the end of an upper base material; a special groove structure is formed through the innovative enclosure frame structure design, and the seal welding process is innovatively divided into two welding process flows; automatic welding equipment such as an arc welding robot or a special machine is adopted, and laser weld joint tracking and self-adaptive welding equipment is configured; a horizontal position welding mode is adopted, a high-penetration welding process is adopted for a root welding bead, and a high-deposition-rate welding process is adopted for a filling welding bead; and compared with the prior art,high-quality, high-efficiency and low-cost seal welding is realized through unique methods such as enclosure frame structure design, groove structure design, two-step welding process flow, welding process optimization and automatic welding equipment.

Owner:科斯焊接技术(无锡)有限公司

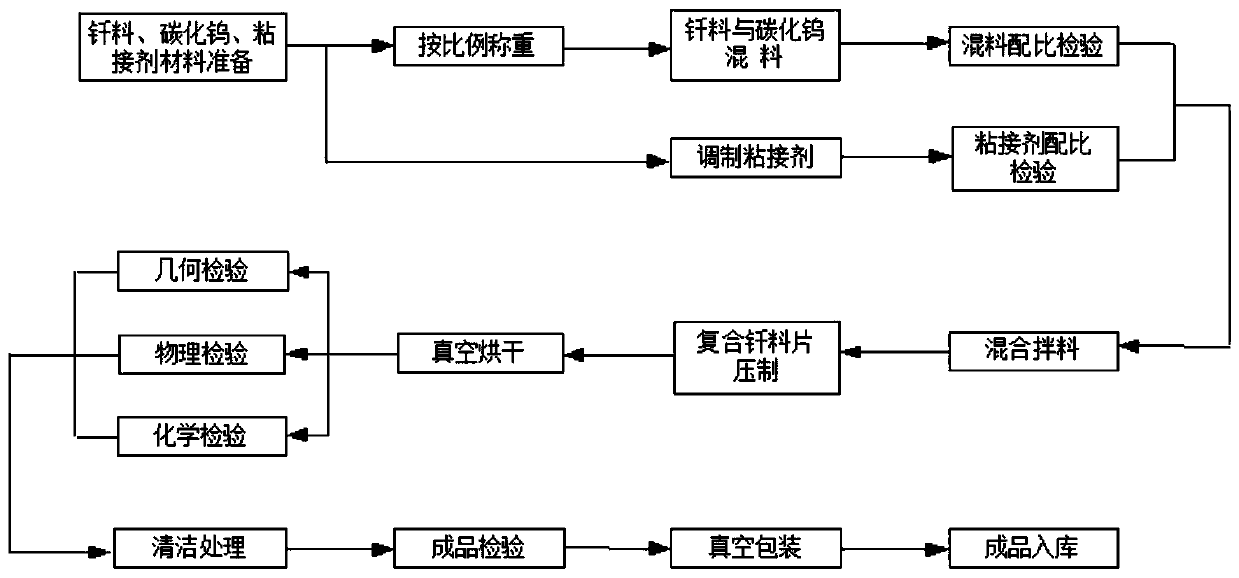

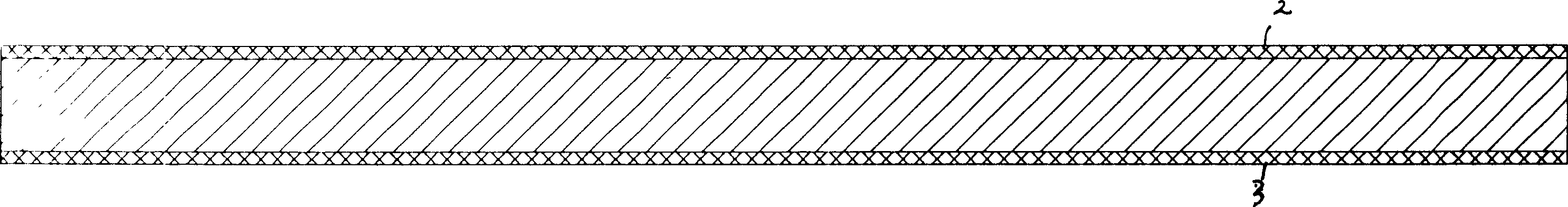

Flaky composite brazing filler metal, preparation method and application thereof and method for welding blades by adopting flaky composite brazing filler metal

ActiveCN110293331AGuaranteed SolderabilityPrevent oxidationWelding/cutting media/materialsSoldering mediaAdhesiveProduct processing

The invention discloses a flaky composite brazing filler metal, a preparation method and application thereof and a method for welding blades by adopting the flaky composite brazing filler metal. The flaky composite brazing filler metal with certain strength is prepared by stirring tungsten carbide, a brazing filler metal and an adhesive into mixed powder according to a specified proportion, pressing into sheets, and then stably solidifying; the flaky composite brazing filler metal is consistent in specification and size, the cladding amount on each blade can be guaranteed to be consistent, sothat the stability and quality of product processing are greatly improved; and as a solid flaky body, flaky composite brazing filler metal sheets are available on demand, with no need of deploying a pasty composite brazing filler metal on site, the working efficiency of preparation before welding the blades can be greatly improved. The flaky composite brazing filler metal sheets are melted throughthe cooperation of automatic equipment, so that the welding cladding quality is influenced by pollution caused by manual operation on cladding materials is avoided, and the high-efficiency automationof welding is realized.

Owner:AECC AVIATION POWER CO LTD

Construction method for gear case of self-elevating platform lifting system

ActiveCN106001955AOvercome spaceOvercome closed construction challengesWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringConstructability

The invention discloses a construction method for a gear case of a self-elevating platform lifting system. According to the method, the gear case is segmented into two assemblies to be constructed, and the two assemblies include a gear case body assembly and a gear case side cover assembly. The method specifically comprises the following steps that firstly, the gear case body assembly and the gear case side cover assembly are constructed; and secondly, the constructed gear case body assembly and the constructed gear case side cover assembly are combined. The method is utilized for constructing the gear case of a self-elevating platform lifting mechanism, and the construction problems that a gear case of a self-elevating platform lifting mechanism is high in welding requirement, and space is narrow and closed are solved; and through reasonable breaking joints of components, the reasonable component division and installing sequence and groove arrangement refining, the segmented constructability of the gear case of a platform is achieved, and weldability of components in the gear case is guaranteed.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Aluminum silicon carbide composite material, method and heat dissipation lining plate

InactiveCN113549792AHigh mechanical strengthSmall mechanical propertiesLiquid/solution decomposition chemical coatingAluminium alloyMelting furnace

The invention provides an aluminum silicon carbide composite material, a method and a heat dissipation lining plate. The method comprises the following steps that burdening, ball-milling and mixing, granulating are conducted, and raw materials are pretreated; meanwhile, a mold is preheated; pretreated silicon carbide particles are evenly mixed, and then a mold is filled with the silicon carbide particles; the mold is put into a heating furnace, and the mold is uniformly heated according to a corresponding heating rate; an aluminum alloy is put into an aluminum melting furnace for melting and casting; the heated mold is moved to a hot press platform, and an aluminum alloy solution in the aluminum melting furnace is injected into the mold; hot pressing is conducted on a hot press; a demolded casting is forged; and the aluminum silicon carbide composite material of the forged casting is machined by combining an ultrasonic vibration cutting technology with a diamond grinding head, and then surface metallization plating process treatment is conducted to obtain the aluminum silicon carbide composite material. The method has the advantages that the product is compact, the performance is good, operation is simple, the cost is low, and the application range is wide.

Owner:珠海亿特立新材料有限公司

Tin-plated copper alloy conductor production process and tin-plated structure

PendingCN114178782AEasy to press downEasy to installHot-dipping/immersion processesTinningElectrical conductor

The invention discloses a tinned copper alloy conductor production process and a tinned structure, and relates to the technical field of conductors, the tinned copper alloy conductor production process specifically comprises the following steps: step 1, removing surface oxides of a copper-aluminum-rare earth alloy blank by a polisher to obtain a copper-aluminum-rare earth alloy ingot; secondly, the aluminum alloy cast ingot is stretched through a water tank type drawing machine, drawing oil is sprayed synchronously during stretching, the drawing speed is 400 m / min, a bus is obtained, and the diameter of the bus is 2.05 mm; 3, a wire drawing machine carries out wire drawing treatment on the bus to obtain a wire rod, and the wire diameter of the wire rod is 0.8 mm; through the mode, the copper-aluminum rare earth alloy is replaced by the copper alloy wire, under the corrosion resistance of the copper element in the copper-aluminum rare earth alloy and the synergistic effect of the copper element and the aluminum element, the conductivity is not reduced while the surface oxidation resistance is improved, the weldability and the signal transmission of the wire are ensured, and meanwhile, the copper alloy wire has the advantages of being simple in structure and low in cost. And the soft wire can be conveniently mounted in the tinning structure during tinning.

Owner:常熟市普华电工材料有限公司

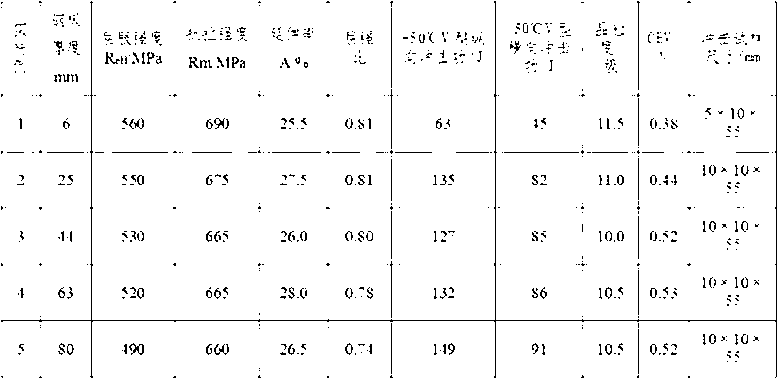

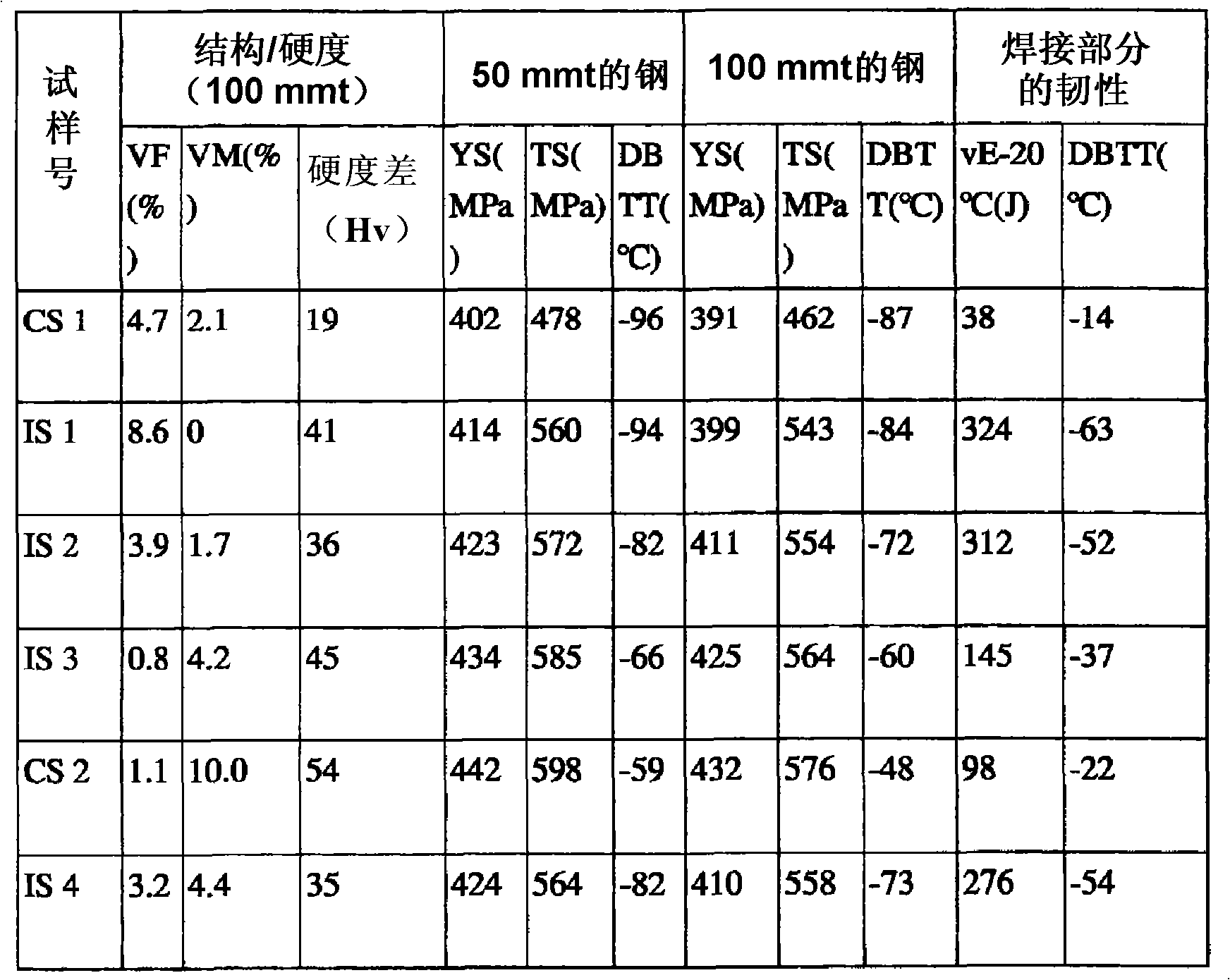

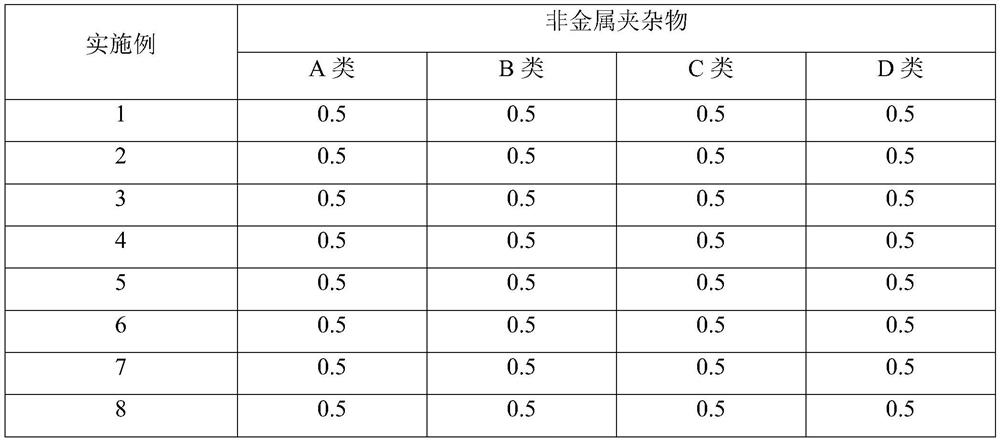

Thick steel plate for welded structure having excellent strength and toughness in central region of thickness and small variation of properties through thickness and method of producing the same

Disclosed herein is a thick steel plate for welded structure having excellent strength and toughness in a central region and exhibiting small variation in properties through thickness. The steel plate comprises 0.05 - 0.10 % of C, 0.10 - 0.5 % of Si, 1.3 - 1.7 % of Mn, 0.0005 - 0.0025 % of B; 0.005 - 0.03 % of Ti, 0.010 % or less of N, 0.005 - 0.03 % of Nb, 0.005 - 0.055 % of Sol. Al, and the balance of Fe and other unavoidable impurities, in terms of weight%, wherein a content ratio of Ti / N is 2.0 or more, and a CP represented by Expression 1 is 40 - 50. CP = 165 x %C + 6.8 x %Si + 10.2 x %Mn + 80.6 x %Nb + 9.5 x %Cu + 3.5 x %Ni + 12.5 x %Cr + 14.4 x %Mo ... (l).

Owner:POHANG IRON & STEEL CO LTD

Ultrahigh-strength steel with fatigue limit larger than 600 MPa for ocean engineering and preparation method thereof

ActiveCN113073263AHigh strengthGuaranteed SolderabilityFurnace typesHeat treatment furnacesTemperingUltimate tensile strength

The invention belongs to the field of preparation of steel and iron materials, and discloses ultrahigh-strength steel with the fatigue limit larger than 600 MPa for ocean engineering and a preparation method thereof. The ultrahigh-strength steel comprises the chemical components in percentage by weight: 0.08-0.11% of C, 0.20-0.50% of Si, 0.70-1.00% of Mn, 6.00-8.00% of Ni, 0.50-0.70% of Cr, 0.80-0.90% of Mo, 0.05-0.08% of V, less than or equal to 0.003% of P, less than or equal to 0.001% of S and the balance Fe and inevitable impurities. According to the steel plate manufacturing method of the ultrahigh-strength steel, a controlled rolling process is adopted, then a steel plate is subjected to a quenching and tempering heat treatment process, the yield strength of the steel plate is larger than or equal to 1000 MPa, the fatigue limit is larger than or equal to 600 MPa, and the impact energy at the temperature of -80 DEG C is larger than or equal to 100 J; and the microstructure of the steel plate is tempered martensite and VC precipitated phase.

Owner:NORTHEASTERN UNIV

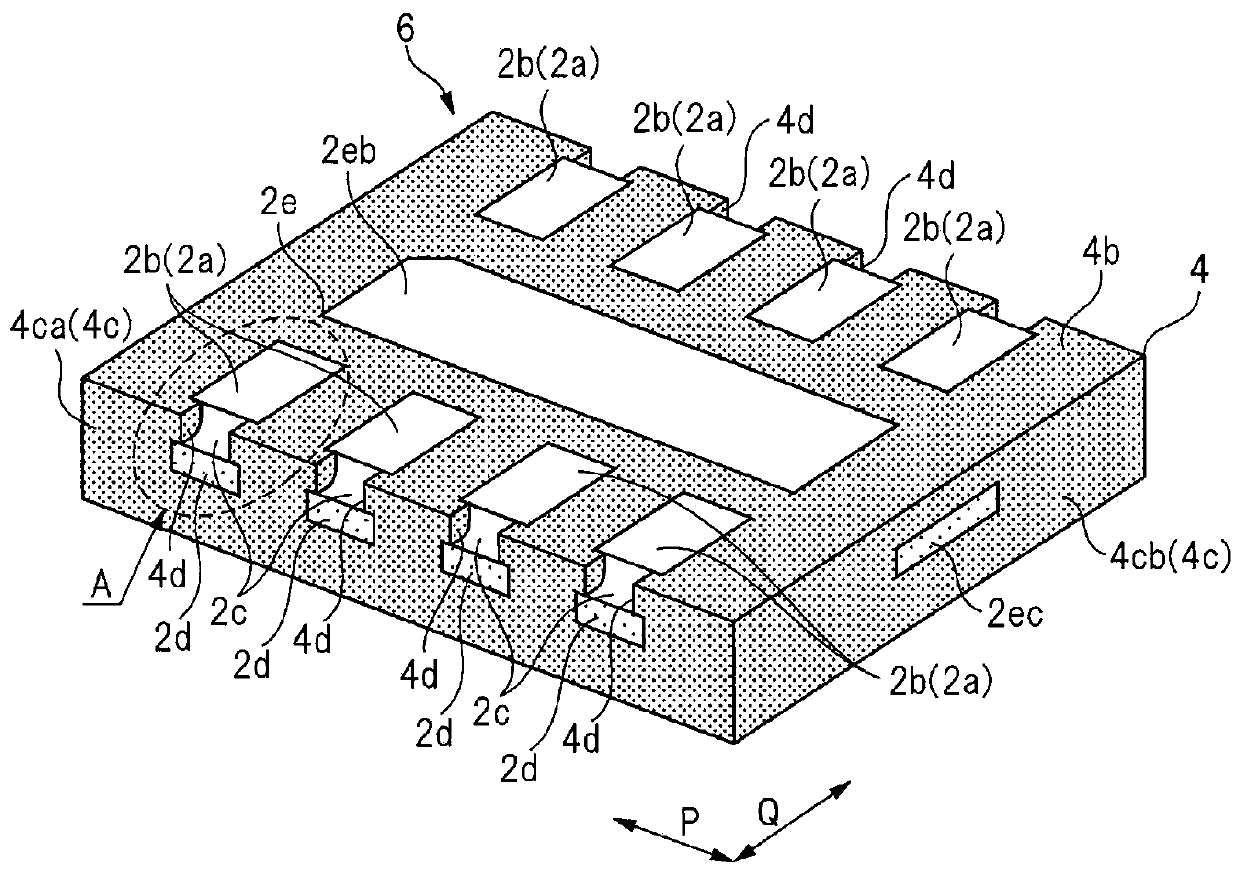

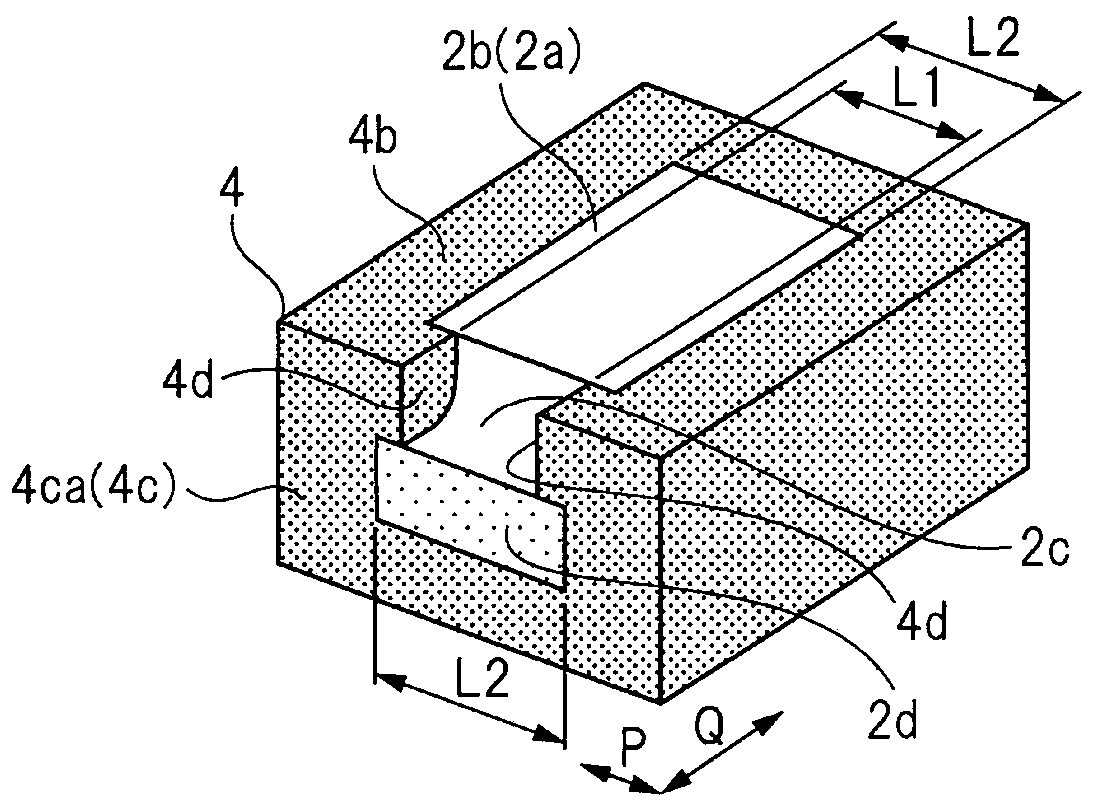

Semiconductor device and method for manufacturing same

ActiveCN110010580AGuaranteed SolderabilityImprove qualitySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSolderability

The invention provides a semiconductor device and a method for manufacturing the same, wherein the solderability of a pin part of the semiconductor device without a pin is ensured. A DFN (6) is provided with a semiconductor chip; a die pad; a plurality of pin parts (2a) arranged around the die pad and having notches (2c) formed at the tips of the pin parts; and a plurality of leads which electrically connect the surface electrode of the semiconductor chip and one of the plurality of pin parts (2a), and a resin sealing body (4) which covers the semiconductor chip and a part of each of the plurality of pin parts (2a). Furthermore, each of the plurality of pin parts (2a) has a terminal part (2b) exposed on the back surface (4b) of the sealing body (4), and the width of the cutout part (2c) inthe direction along the arrangement direction (P) of the plurality of pin parts (2a) is smaller than the width of the terminal part (2b) in the direction along the arrangement direction (P).

Owner:AOI ELECTRONICS CO LTD

Antibacterial antistatic composite Fe-Cr-Al fiber

The invention relates to the technical field of metal wires, and especially relates to an antibacterial antistatic composite Fe-Cr-Al fiber, comprising a fiber body. The fiber body is formed by winding two Fe-Cr-Al fibers, a brass fiber, and a nano-silver fiber. The surfaces of the Fe-Cr-Al fibers, the brass fiber, and the nano-silver fiber are coated with an active agent kind antistatic agent. The antibacterial antistatic composite Fe-Cr-Al fiber effectively improves strength and hardness of the Fe-Cr-Al fiber, and the surfaces are coated with the active agent kind antistatic agent, so antistatic property of the Fe-Cr-Al fiber is greatly improved, and toughness, electrical conductivity, weldability, and temperature resistance and rotproofness of metal are maintained, and the fiber has flexibility and spinnability of common fibers. The fiber has effects of effective sterilization and deodorization, and the fiber is used to manufacture a plurality of kinds of metal fiber products.

Owner:夏鹤鸣

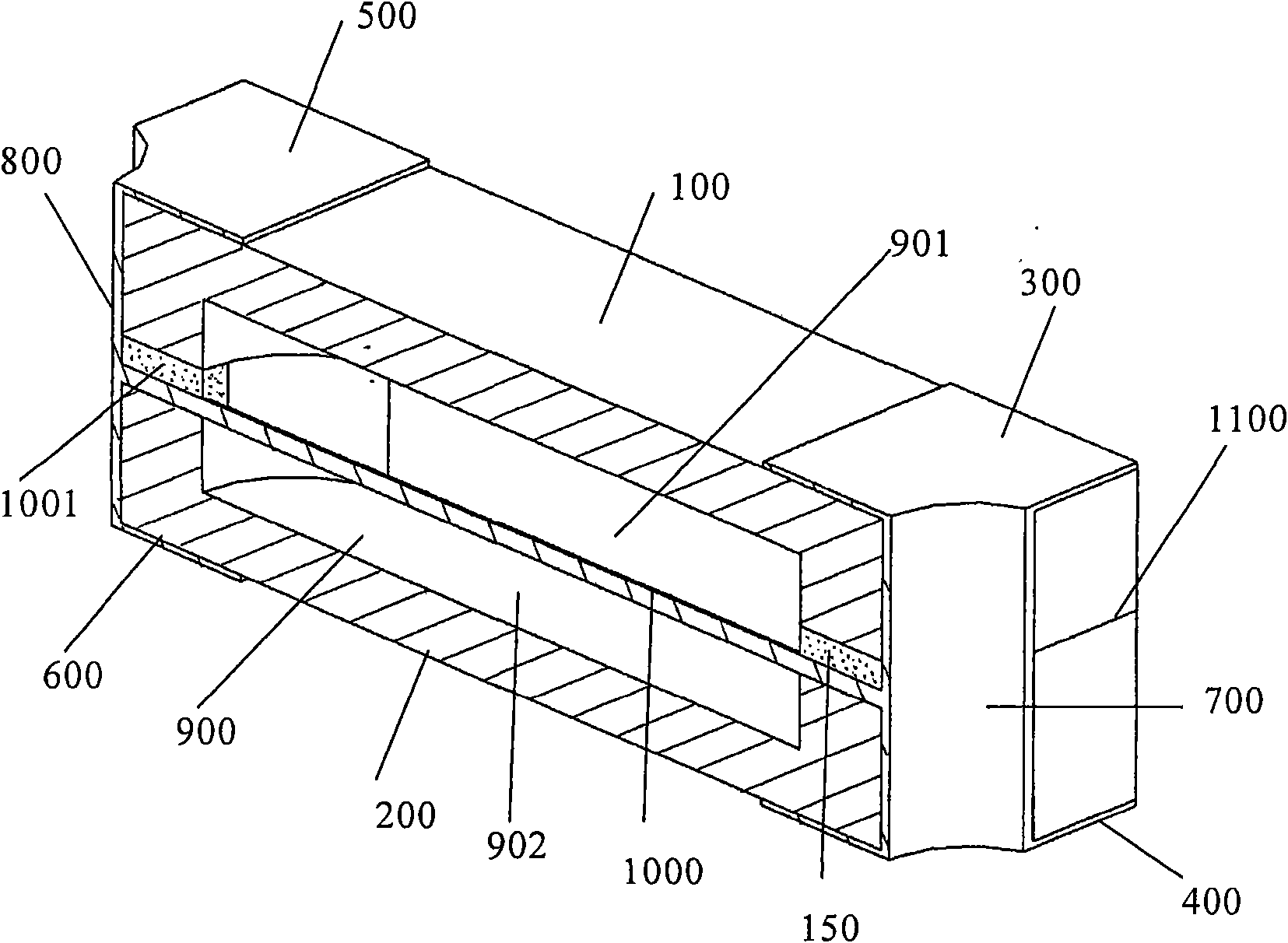

Integrated circuit or discrete component flat bump package technics and its package structure

ActiveCN1738014APrevent spillageNo pollution problemSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a plane point-protruded type packaging process and its structure of integrated circuit or discrete component, comprising following steps: pasting dry films (2, 3) on the two surfaces of a metallic base plate (1) while removing some dry films relatively; plating active compound and metallic layer on the area of base plate for forming base island and pins; removing the left dry film on the front of base plate; half etching to form a depressed half etched region (1, 3), base island 1.1 and pin 1.2; removing the dry film left on the back of base plate; planting chip (9) into the front metal layer of base island, tie metallic thread (10), packaging plastic packaging body (11), front printing (12), and etching again on the left metal 1.4 of half etched region (1.3); pasting film (13) on the face of plastic packaging body, and slicing. Said invention has strong welding property, better quantity, low cost, good adaptability, reflex able arrangement of chips, while avoiding the problem of infiltration of plastic packaging material.

Owner:长电科技管理有限公司

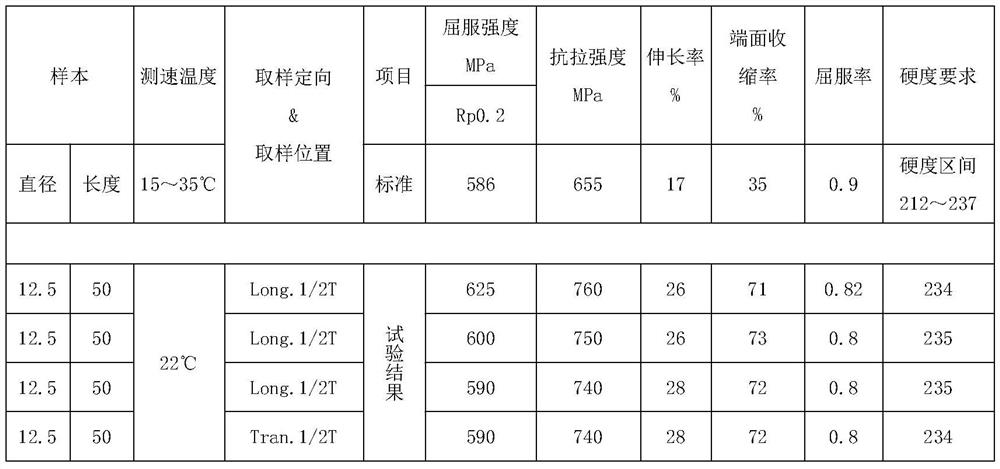

Production process of 8630MOD3-85K forge piece for deep sea wellhead casing hanger

InactiveCN113088820AIncrease yield pointHigh tensile strengthMetal-working apparatusFurnace typesEngineeringBiology

The invention discloses a production process of a 8630MOD3-85K forge piece for a deep sea wellhead casing hanger. A steel blank of the 8630MOD3-85K forge piece comprises the following chemical components in percentage by weight: 0.25 to 0.33 percent of C; 0.15 to 0.35 percent of Si; 0.7 to 1.1 percent of Mn; less than or equal to 0.015 percent of P; less than or equal to 0.01 percent of S; 0.85 to 1 percent of Cr; 0.75 to 0.99 percent of Ni; 0.35 to 0.45 percent of Mo; less than or equal to 0.25 percent of Cu; less than or equal to 0.025 percent of Ti; less than or equal to 0.01 percent of Bi; less than or equal to 0.012 percent of N; less than or equal to 0.01 percent of Nb; 0.02 to 0.035 percent of Al; less than or equal to 0.015 percent of Sn; 0.002 to 0.03 percent of V; less than or equal to 0.0005 percent of B; less than or equal to 0.01 percent of Pb; less than or equal to 0.02 percent of As; less than or equal to 0.02 percent of Sb; less than or equal to 1.6 ppm of H; less than or equal to 25 ppm of O; less than 0.833 percent of CE, and the balance Fe; and the DI value is larger than 8.0.

Owner:苏州雷格姆海洋石油设备科技有限公司

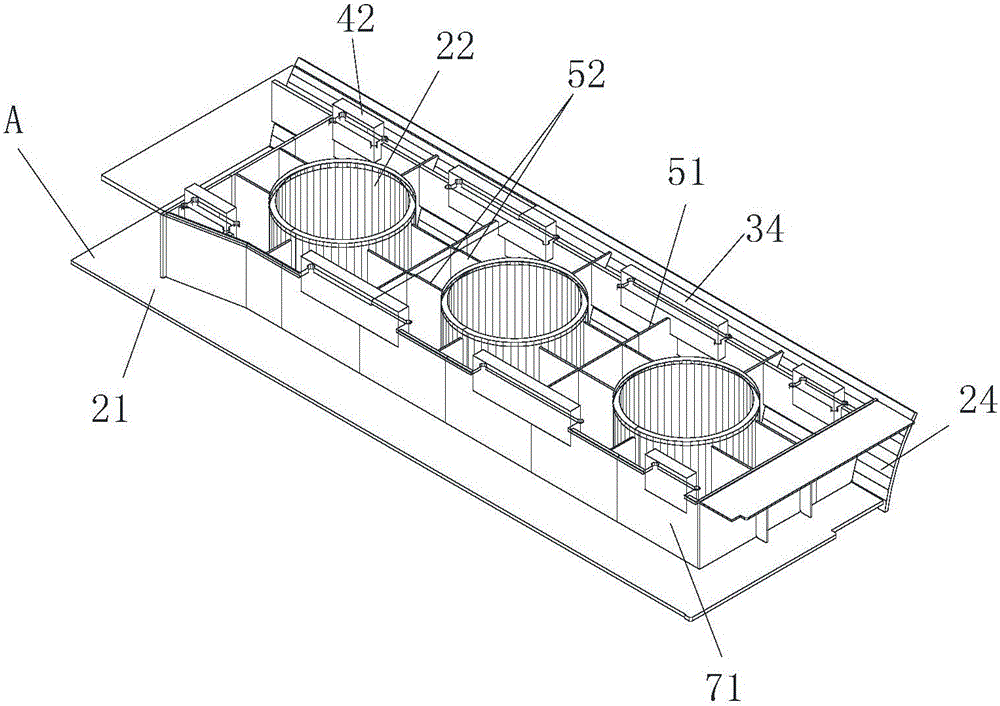

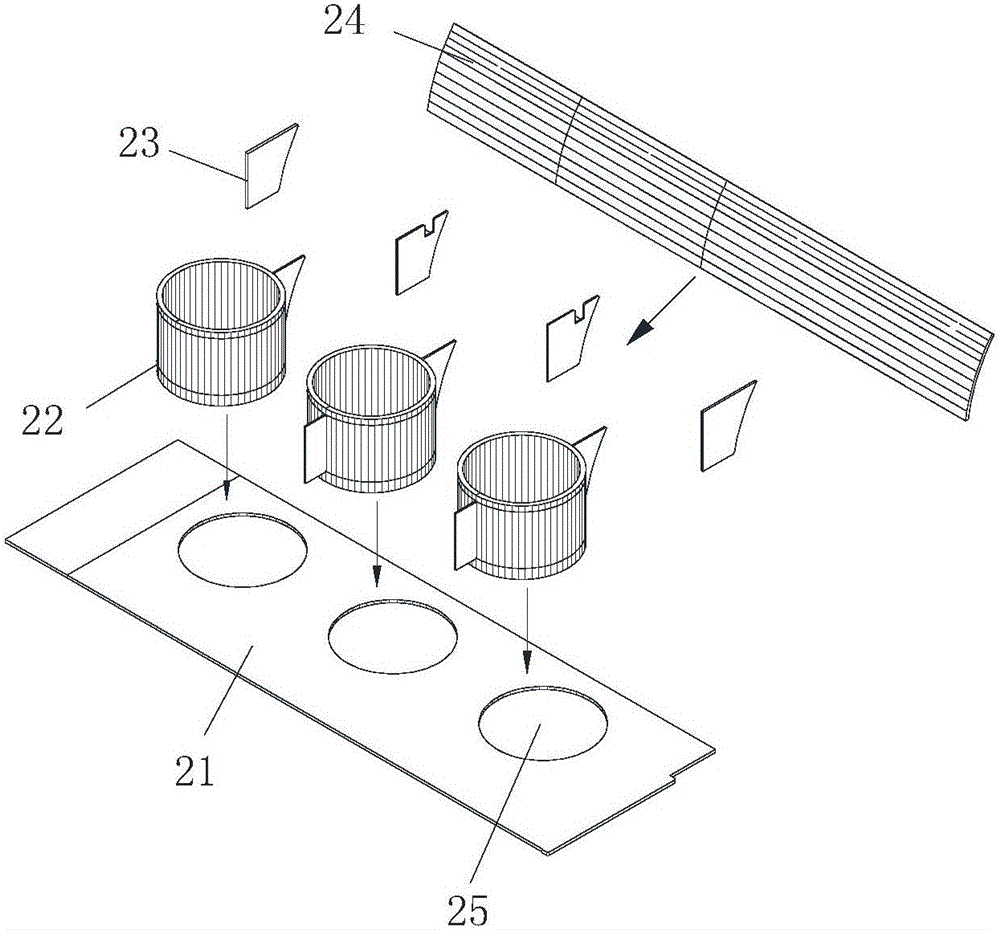

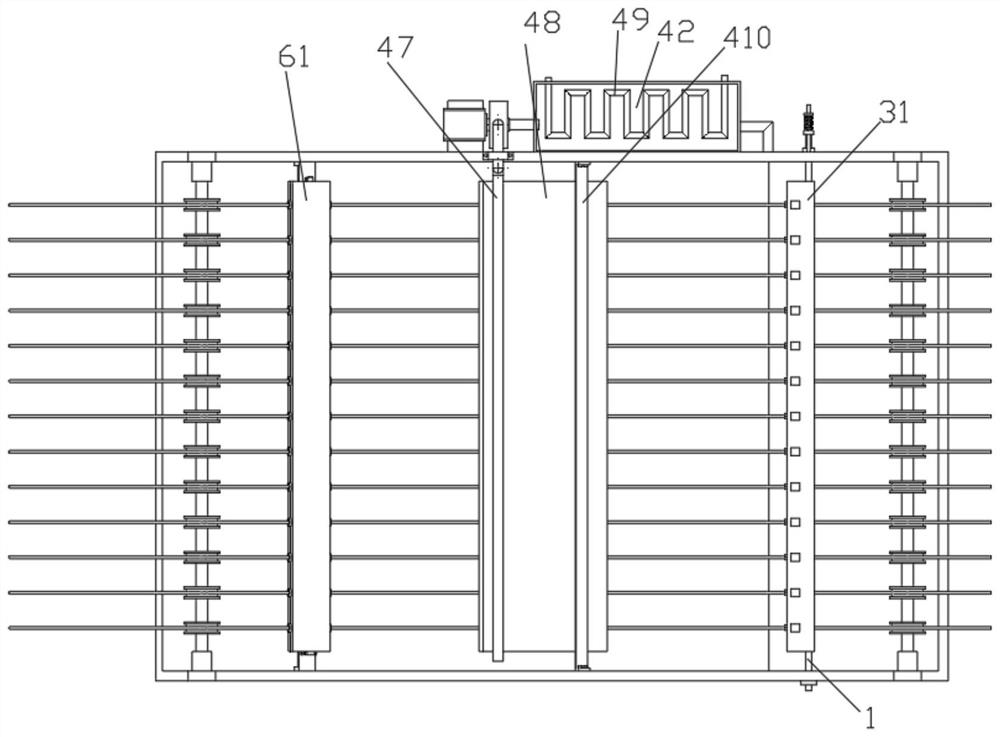

High-strength heat exchanger

InactiveCN103383205AIncrease contact areaHigh strengthHeat exchanger casingsLaminated elementsEngineeringHigh intensity

The invention relates to a high-strength heat exchanger which comprises cover plates arranged vertically and symmetrically, and a plurality of heat exchanging channels are arranged between the cover plates. The heat exchanging channels structurally comprise first partition plates and second partition plates which are arranged vertically at intervals. Fins distributed evenly are arranged between the first partition plates and the second partition plates, sealing strips are arranged at two ends of the fins, and reinforcing ribs are arranged in the middles of the fins. The reinforcing ribs structurally comprise vertical rods, one end of each vertical rod extends to form a branch rod perpendicular to the vertical rod, the branch rods are parallel, the other ends of the vertical rods and the end faces of the branch rods butt against the fins, and the outer ends of the upper branch rods and the lower branch rods butt against the first partition plates and the second partition plates respectively. The high-strength heat exchanger is reasonable in structure and convenient to manufacture, increases contact area between the fins and the partition plates by arranging the reinforcing ribs in the middles of the fins in the heat exchanging channels, improves the strength accordingly and is large in load bearing performance and long in service life.

Owner:WUXI FANGSHENG HEAT EXCHANGER MFG

High-strength heat exchanger

InactiveCN103383204AIncrease contact areaHigh strengthHeat exchanger casingsLaminated elementsEngineeringHigh intensity

The invention relates to a high-strength heat exchanger. The high-strength heat exchanger comprises cover plates installed symmetrically up and down, and a plurality of heat exchange channels are installed between the cover plates. The heat exchange channels structurally comprise first partition plates and second partition plates arranged at intervals up and down, evenly arranged fins are installed between the first partition plates and the second partition plates, sealing strips are installed at two ends of the fins, H-shaped reinforcing ribs are installed in the middle of the fins and are of an integrated structure, two sides of the H-shaped reinforcing ribs respectively abut against the fins, the upper end faces and the lower end faces of the H-shaped reinforcing ribs respectively abut against the first partition plates and the second partition plates, and the H-shaped reinforcing ribs are installed right in the middle of the heat exchange channels. The high-strength heat exchanger is reasonable in structure and convenient to manufacture; by installing the reinforcing ribs in the middle of the fins in the heat exchange channels, the contact area of the fins and the partition plates is increased, the strength of the heat exchanger is enhanced, and the high-strength heat exchanger is high in bearing capability and long in service life.

Owner:WUXI FANGSHENG HEAT EXCHANGER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com