Thick steel plate for welded structure having excellent strength and toughness in central region of thickness and small variation of properties through thickness and method of producing the same

A central area, thick steel plate technology, applied in the field of thick steel plates, can solve the problems of damage to the toughness of welded parts, increase production costs, etc., and achieve the effect of excellent strength and toughness, and small performance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

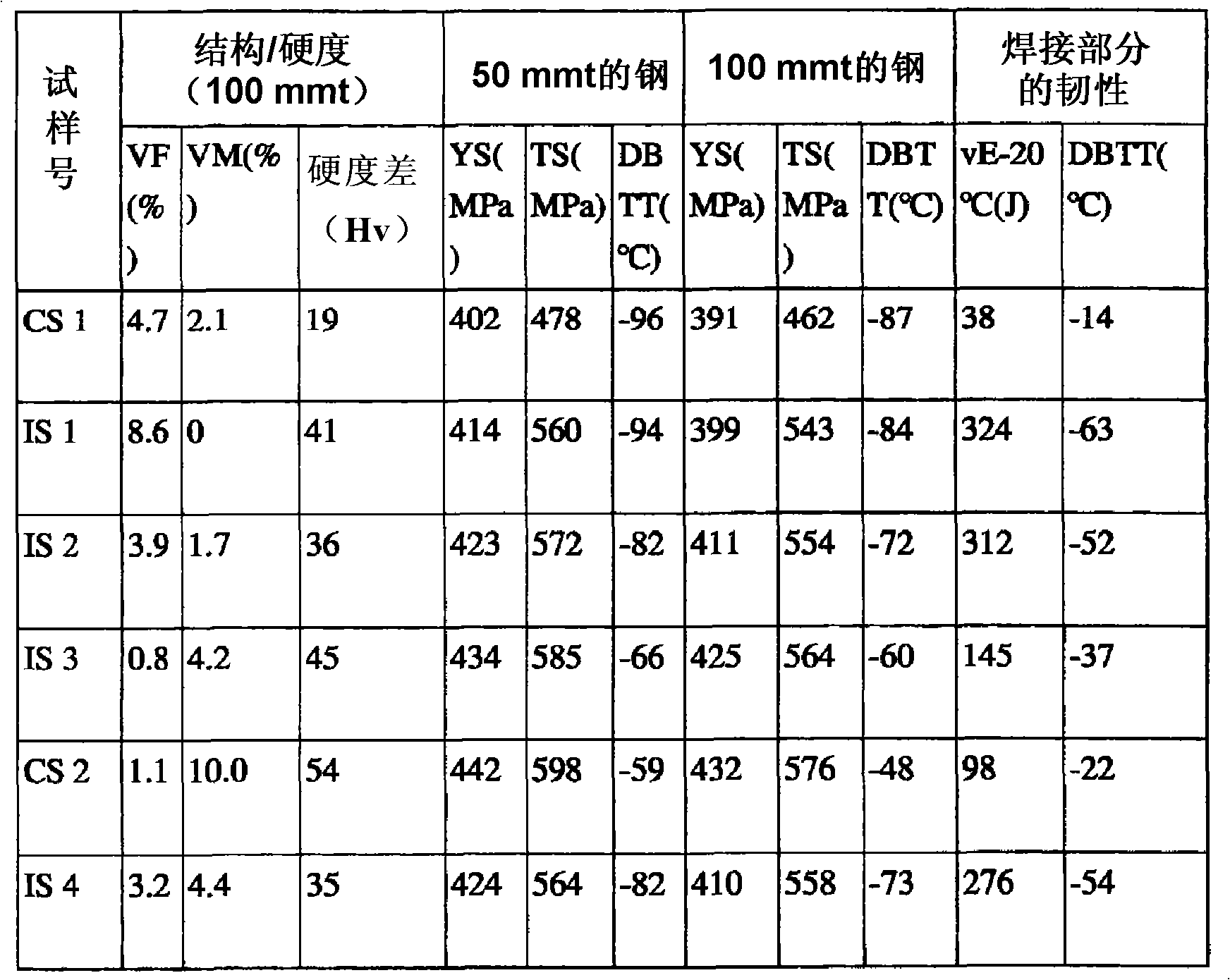

[0103] In order to confirm the properties of the steel sheets produced according to the present invention, after tempering and cold rolling each flat steel ingot having the composition listed in Table 1 below, at a temperature between the non-recrystallization temperature and Ar3 associated with the respective compositions Hot rolling is performed at a cumulative reduction ratio of 40% or more, where the steel plate has a thickness of 50 mm or 100 mm. After rolling, in Ar 3 The cooling of the steel sheets was started at a temperature of +10°C or higher while controlling the cooling rate of the central region of each steel sheet to be 3°C / sec.

[0104] Table 1

[0105] Sample No.

C

Si

m

no

P

S

B

Ti

Nb

Cu

Ni

Cr

m

o

N

Ti /

N

CP

CS1

0.024

0.

34

1.5

3

0.00

7

0.0

03

0.00

11 ...

Embodiment 2

[0129] After tempering and cold-rolling flat steel ingots having the compositions of Invention Steels 1 to 11 listed in Table 1, they were rolled and cooled under the conditions listed in Table 3 below to form thick steel plates each having a thickness of 100 mm.

[0130] table 3

[0131] base

body

try

Sample

No

Tnr

(℃

)

Ar 3 (

℃)

reheat

temperature

(℃)

T4(

℃)

T5(

℃)

Finished

example

(%)

start

cool down

temperature

(℃)

finally

cool down

temperature

(℃)

cool down

speed

(℃ / sec)

IM1

IS2

876

785

1100

875

822

50

808

443

3.1

IM2

IS2

876

785

1000

842

816

45

803

452

3.2

IM3

IS2

8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com