Production process for diodes

A production process and diode technology, applied in the field of diode production process, can solve the problems of copper ions not being able to be thoroughly cleaned, affecting chip corrosion rate, product electrical degradation, etc., to protect the environment and avoid electrical degradation. , Improve the effect of electrical yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

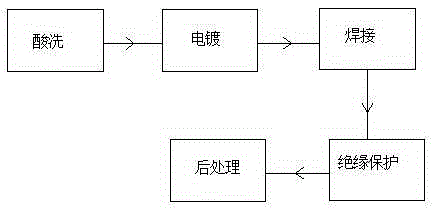

[0021] Such as figure 1 As shown, the production process of the diode in this embodiment includes five processes of pickling, electroplating, welding, insulation protection and post-treatment, and the specific steps are as follows:

[0022] (1) Pickling: Place the diode chip in a mixed solution of nitric acid and sulfuric acid with a volume ratio of 10:5 for acid corrosion. The corrosion time is 8 minutes, and the acid temperature is controlled between 5°C;

[0023] (2) Electroplating: The diode chip after pickling is electroplated to form a metal protective layer on the surface of the diode chip, and the thickness of the coating is 5 μm;

[0024] (3) Welding: Put the two metal lead electrodes, the soldering piece and the diode chip after electroplating into the fixture, send it to the welding furnace to heat up, the temperature is controlled at 300 ° C, and the welding time is 15 minutes, so that the diode chip is connected to the metal lead ;

[0025] (4) Insulation protec...

Embodiment 2

[0028] Such as figure 1 As shown, the production process of the diode in this embodiment includes five processes of pickling, electroplating, welding, insulation protection and post-treatment, and the specific steps are as follows:

[0029] (1) Pickling: Place the diode chip in a mixed solution of nitric acid and sulfuric acid with a volume ratio of 10:5 for acid corrosion. The corrosion time is 12 minutes, and the acid temperature is controlled between 0°C;

[0030] (2) Electroplating: The pickled diode chip is electroplated to form a metal protective layer on the surface of the diode chip, and the thickness of the coating is 3 μm;

[0031] (3) Welding: Put the two metal lead electrodes, the soldering piece and the diode chip after electroplating into the fixture, and send it to the welding furnace to heat up. The temperature is controlled at 290 ° C, and the welding time is 12 minutes, so that the diode chip is connected to the metal lead. ;

[0032] (4) Insulation protect...

Embodiment 3

[0035] Such as figure 1 As shown, the production process of the diode in this embodiment includes five processes of pickling, electroplating, welding, insulation protection and post-treatment, and the specific steps are as follows:

[0036] (1) Pickling: Place the diode chip in a mixed solution of nitric acid and sulfuric acid with a volume ratio of 10:5 for acid corrosion. The corrosion time is 10 minutes, and the acid temperature is controlled between 3°C;

[0037] (2) Electroplating: The pickled diode chip is electroplated to form a metal protective layer on the surface of the diode chip, and the thickness of the coating is 4 μm;

[0038] (3) Welding: Put the two metal lead electrodes, the soldering piece and the diode chip after electroplating into the fixture, and send it to the welding furnace to heat up. The temperature is controlled at 295 ° C, and the welding time is 13 minutes, so that the diode chip is connected to the metal lead. ;

[0039] (4) Insulation protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com