High-strength weldable aluminum alloy for vehicle bodies and preparation method thereof

A technology for aluminum alloys and car bodies, which is applied in the field of high-strength weldable aluminum alloys for vehicle bodies and its preparation, can solve problems such as easy recrystallization, application limitations, and blanks, and achieve the effect of improving strength and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

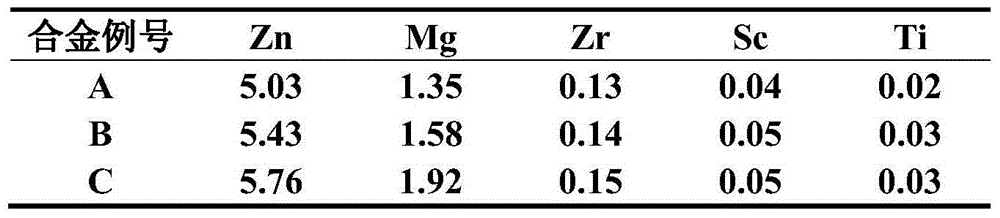

[0024] Embodiment: a high-strength weldable aluminum alloy for a vehicle body, Zn in the alloy: 4.8-6.6wt.%, Mg: 1.0-2.0wt.%, Zr: 0.08-0.16wt.%, Sc: 0.03- 0.06wt.%, Ti: 0.01~0.03wt.%, Fe: <0.15wt.%. The content of Zr, Sc and Ti is preferably: Zr: 0.10-0.12wt.%, Sc: 0.05-0.06wt.%, Ti: 0.01-0.02wt.%. In the solid solution aging state, the alloy has a tensile strength of 480MPa-550MPa, an elongation of 11%-14%, and a welding coefficient of more than 0.65.

[0025] The smelting process of the high-strength weldable aluminum alloy for the vehicle body of the present invention: add pure metal aluminum to the furnace for melting, add pure metal zinc, Al-Zr master alloy, Al-Sc master alloy, Al-Ti master alloy after melting and heat up to 730-740°C, add pure metal magnesium, after these metals are melted and stirred evenly, heat up to 740-750°C, then use degassing agent hexachloroethane or argon-chlorine mixed gas to treat for 10-15min, after the treatment is completed, stir the alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com