Butt mag welding method of low-alloy ultra-high-strength steel and high-quality carbon structural steel after quenching

A carbon structural steel, ultra-high-strength steel technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc. The weld is well formed, the generation of welding defects is reduced, and the effect of reducing welding arcing and arcing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

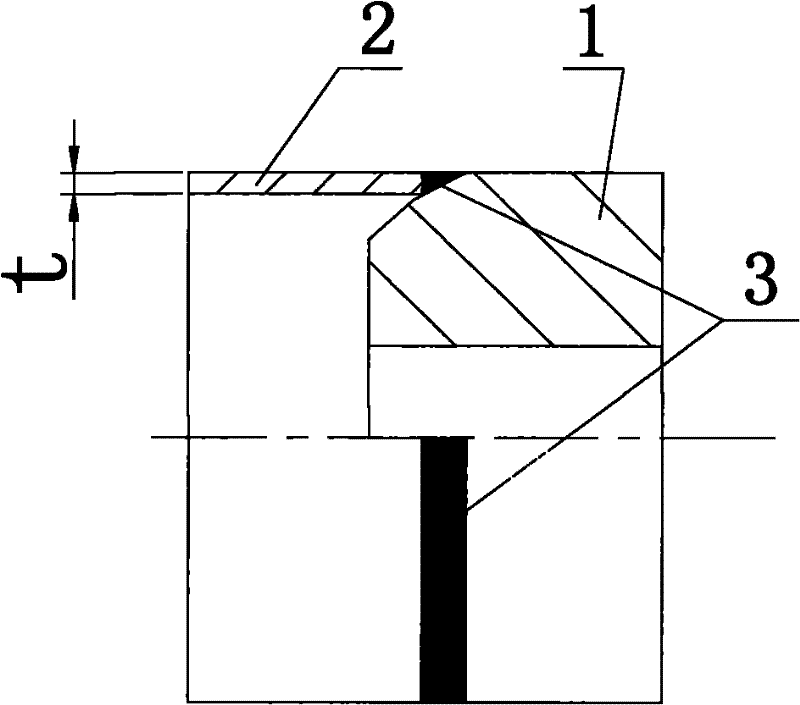

[0016] Specific implementation mode one: as figure 1 and 2 As shown, the welding method described in this embodiment is based on the MAG welding of circular butt joint circular seams of cylindrical parts of dissimilar steel materials, such as 35CrMnSiA low-alloy ultra-high-strength steel and 08Al high-quality carbon structural steel. The specific process of the welding method is as follows:

[0017] Step 1, processing the welding port of the 35CrMnSiA cylinder part 1 to be welded and the welding port of the 08Al cylinder part 2 to be welded: the welding end of the thicker 35CrMnSiA cylinder part 1 to be welded is processed into a seam (sealing is also a lock Bottom) bevel form, the lock edge bevel form means that the welding end of the 35CrMnSiA cylinder 1 is tapered in the shape of a truncated cone (the axial cross-sectional profile of the curved surface of the truncated cone is an oblique line or an arc), and the thinner The welding end face of the cylinder part 2 to be wel...

specific Embodiment approach 2

[0027] Specific implementation mode two: as figure 1 As shown, in step 1 of this embodiment, the wall thickness t of the 08Al tube 2 is 1.5 mm, and the wall thickness of the 35CrMnSiA tube 1 is 5 to 8 times the wall thickness of the 08Al tube 2 . Other steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: In this embodiment, in steps 3 (1) and 3 (2), the preheating temperature before and after tack welding should be lower than the tempering temperature by 50°C; otherwise, the ultra-high strength steel (low alloy ultra-high strength steel is 35CrMnSiA) will have softening problems and affect welding quality. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com