Method for testing weldability of SMD (Surface Mounted Device) product

A solderability and product technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high inspection cost and complicated operation, and achieve the effect of ensuring solderability and reducing inspection cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

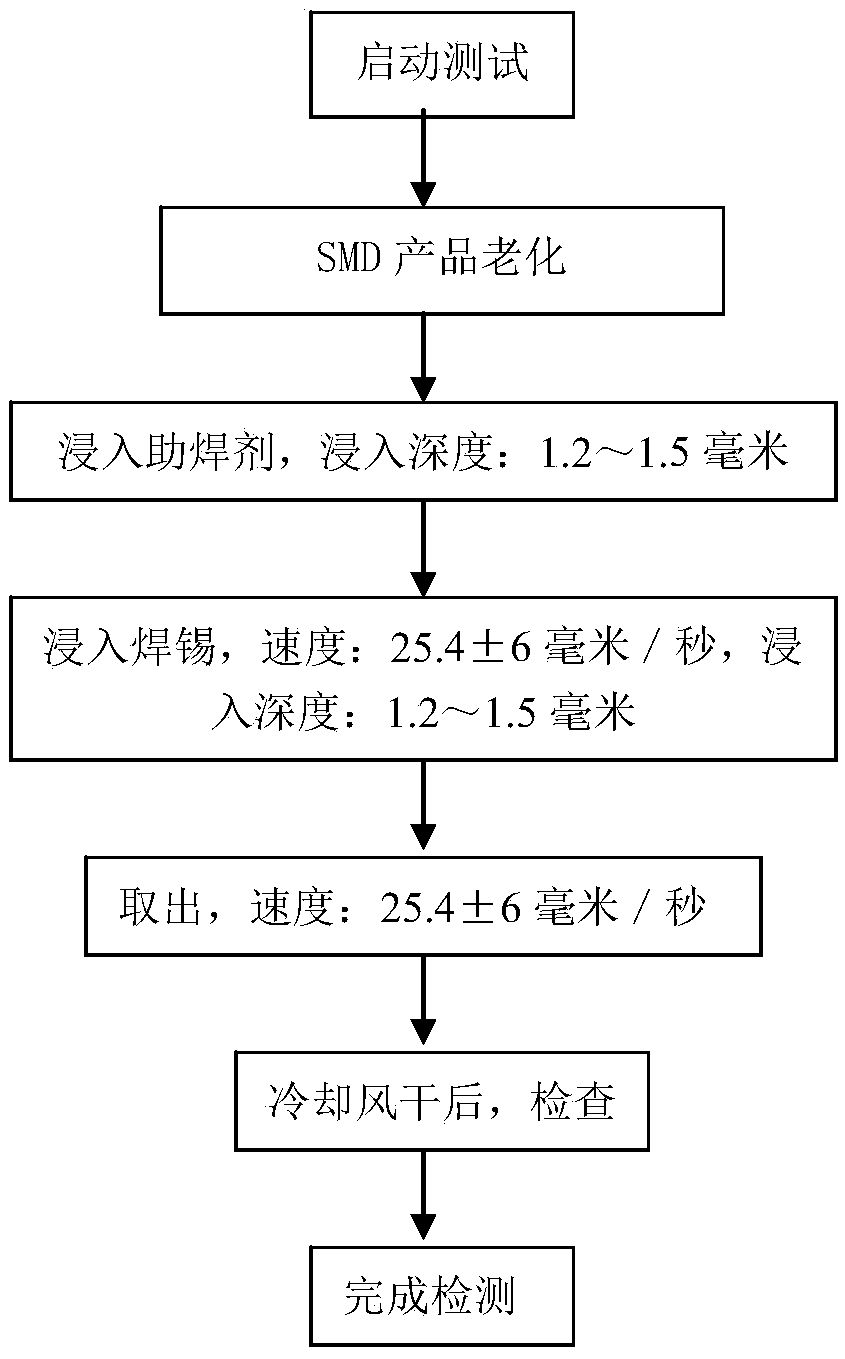

[0017] 1) Freeze the tested SMD product at -8°C for 40 minutes, then take it out and put it in an oven at 150°C for 60 minutes, do this alternately for 3 times, and finally take it out and cool it to room temperature;

[0018] 2) Immerse the surface of all solder ends of the aged SMD product under test into the flux at room temperature. The dipping depth of the pins is 1.5 mm. After keeping for 5 seconds, take it out, and then vertically erect the SMD product under test Clean the filter paper for 3 seconds to remove excess flux and allow to dry for 10 seconds before immersing in solder.

[0019] 3) Turn on the power switch of the tin furnace, set the constant temperature to 230°C; after the temperature of the tin furnace rises to the set temperature, scrape off the scum on the surface of the tin furnace, and put the tested SMD product soaked in flux (plastic package) The front is vertically downward) vertically dipped into the static tin layer at a speed of 25.4 mm / s, the dipp...

Embodiment 2

[0022] 1) Freeze the tested SMD product at -10°C for 40 minutes, then take it out and put it in an oven at 140°C for 80 minutes, do this twice alternately, and finally take it out and cool it to room temperature;

[0023] 2) Immerse the surface of all solder ends of the aged SMD product under test into the flux at room temperature. The dipping depth of the pins is 1.3 mm. After keeping for 5 seconds, take it out, and then vertically stand the SMD product under test on Clean filter paper for 3 seconds to remove excess flux and allow to dry for 10 seconds before immersing in solder, but do not preheat on a solder container.

[0024] 3) Turn on the power switch of the tin furnace, set the constant temperature to 235°C; after the temperature of the tin furnace rises to the set temperature, scrape off the scum on the surface of the tin furnace, and put the tested SMD product soaked in flux (plastic package) The front is vertically downward) vertically dipped into the static tin lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com